Best Of

Re: tiny droplet leak from the oil tank firomatic shut off valve.

I don't see any oil stain on the concrete floor just below the valve or the oil filter. This looks pretty normal to me. that coating of shiny fuel glaze on the pipes, fittings, and oil filter seem to be normal from my experience. If there were dripping fuel, that would be a different story. I would expect to see a darker stain on the concrete floor all around that tank leg like this:

But if you have a constant drip… drip… drip and the only place on the concrete that is showing the oil stain is that small spot, then the black rim must be a sump pump pit that is cemented into the basement floor. If all the dripping oil is ending up in the pit and pumped away to the pump's discharge termination, wherever that is, then you have a real problem.

If that is the case, you need to solve this sooner than later.

Good practice for replacing oil tanks

- Do not put any oil from the old tank into the new tank.

- If you are going to use a contractor that is including putting your old iol back in the new tank, then get another contractor.

- With 1/2 tank of oil, you will need three 55 gallon drums to remove all the old oil in order to remove the old tank

- If you can install the replacement tank in a different location, then you can avoid pumping old oil from the old tank. leave the old tank in place with that drip pan for collecting the dripping oil while you burn off the oil.

- With all the old oil removed from the tank and the new tank in place (or the new tank in a different place) you can have new fuel delivered from a delivery truck while the tank installer is on location. It is always good practice to have two people for the first delivery in case there is a problem with the install, the person on the inside can alert the delivery driver to stop the delivery so the problem can be fixed before it becomes a bigger problem.

- Have the 55 gallon drums remain on site with a temporary fuel supply from the drums to the oil burner until you run out of old oil.

- If that is not an option and you can not install the new tank so the old tank can be the temporary storage, then donate your oil to a local church or pay to have it disposed of. While your fuel oil is on your property it is either a usable fuel or a hazardous waste, you get to decide.

- DO NO PUT ANY FUEL FROM THE OLD FUEL TANK INTO YOUR NEW TANK, no matter how good of a filter your contractor says he has.

Finally I have told this story before: read the EDIT: Case History here

Did you happen to read that I don't recommend old oil be placed into a new tank?

Re: HTP Boiler humidity dislike + Error Code 11

btw those "additions" are the aluminum from the fins in the stainless hx.

Re: HTP Boiler humidity dislike + Error Code 11

If you stuck your finger into where the condensate trap connects and found goo then you need a cleaning on the fire side of the heat exchanger, not the water side. Clean the fire side of the heat exchanger first, nothing here indicates an issue in the water side

Re: I'm getting solar panels. I'll let you know how it goes in this discussion thread.

So does mine — but they cant replace aging components, nor upgrade it. It's purely reactive, not proactive.

Re: leaking return line

For what it's worth, I have a customer with an approximate 150, 000 BTU input boiler with a 3/4 inch copper wet return. Everything works perfectly. Would certainly never suggest such a thing but....

Re: leaking return line

No way that you need 1.5". 1" copper would probably be enough for most homes. But of course we need the numbers. And keep in mind, the old charts were sized assuming steel, which tends to rust on the inside and clog. There was a bit of a tendency to oversize to compensate for that. If you are looking to save on labor, you could always get yourself a ProPress. Maybe find a place that will rent it to you

Re: Mixing valves in oil fired radiant floor heating system

The forced air runs off the boiler as a high temperature loop? Or is all the hydronics low temperature. If so a mod con lp boiler would be my choice, running ODR.

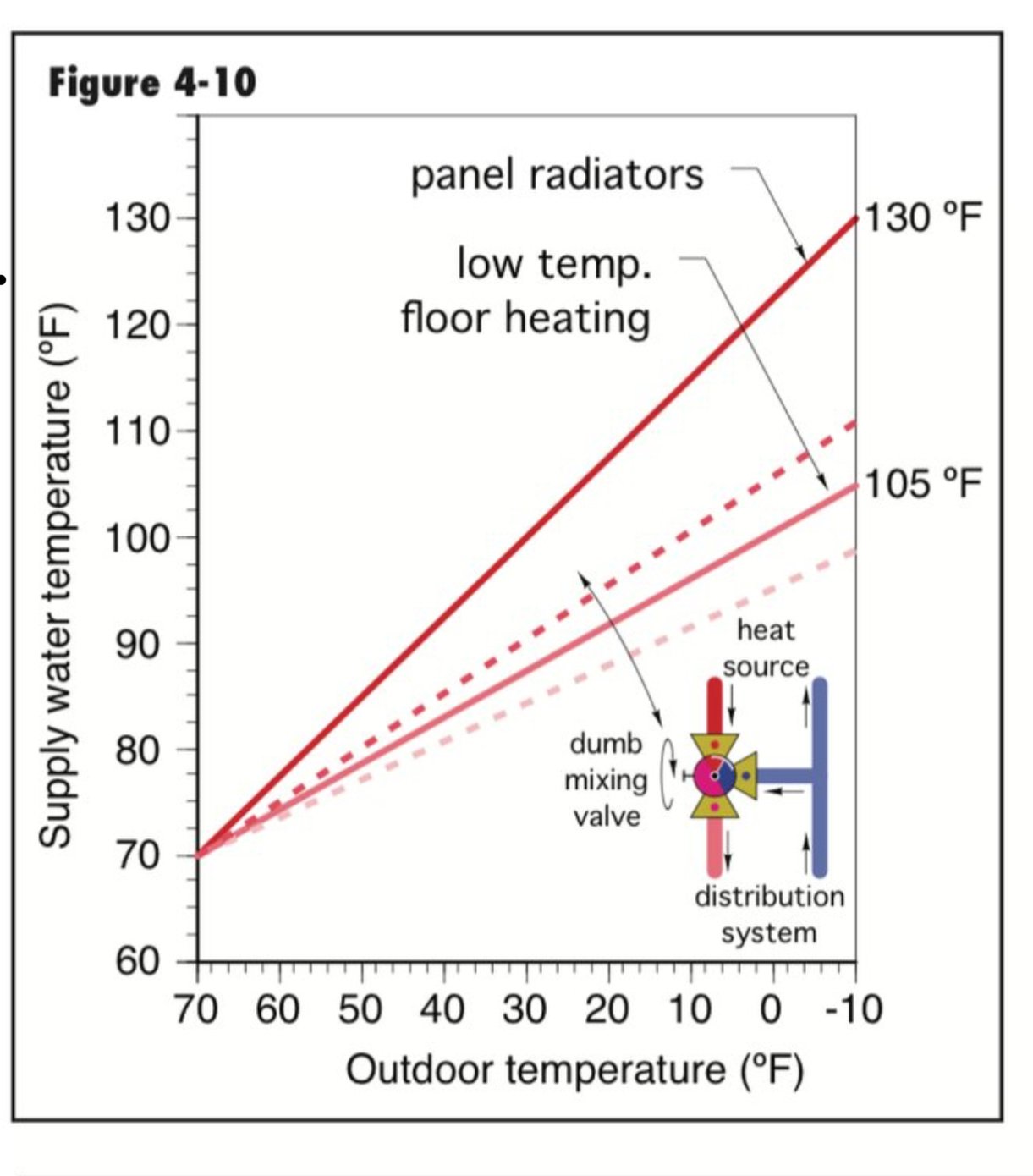

the manual mix valve will in fact track with the boilers changing temperature. As the boiler drops so will the mix from the manual valve. The manual valve does not have a sensor, it is a fixed blend.

On the mix down manual valve you can also adjust the offset, dotted red lines, how it tracks with the higher temperature.

This shows the relationship with a 130 panel rad system, but it could be a 160, 180 or higher zone also.

There is no reason to have ODR on the boiler and also on the low temperature zone.

Of course with a cast boiler you will have a minimum return to be aware of.

hot_rod

hot_rod

Re: Warm Start Boiler Summer Leak

Agree. If the boiler is a factory assembled block, then it should be covered.

Re: Warm Start Boiler Summer Leak

Still the upper port gasket leak qualifies as a leaking boiler and Weil McLain will usually honor that when it is brought to their attention via a warranty claim. The worst that can happen is the warranty folks at WM say no. Then you appeal and they say no again. But I remember when I did WM warranty claims, I could talk them into covering that exact situation. The warranty coverage uses the term "heat exchanger" not "boiler section" on the WGO, WTGO and SGO warranty form. See copy of warranty form here Weil McLain WTGO 20 Year Warranty

Re: leaking return line

If you don't know your connected EDR than the boiler nameplate may be informative.

1" copper is a happy medium. But you want to add isolation valves at each end hose bibs for flushing the return. Those valves, tees and fittings could be threaded pipe which would avoid soldering for those items.