Best Of

Re: Mixing valves in oil fired radiant floor heating system

The forced air runs off the boiler as a high temperature loop? Or is all the hydronics low temperature. If so a mod con lp boiler would be my choice, running ODR.

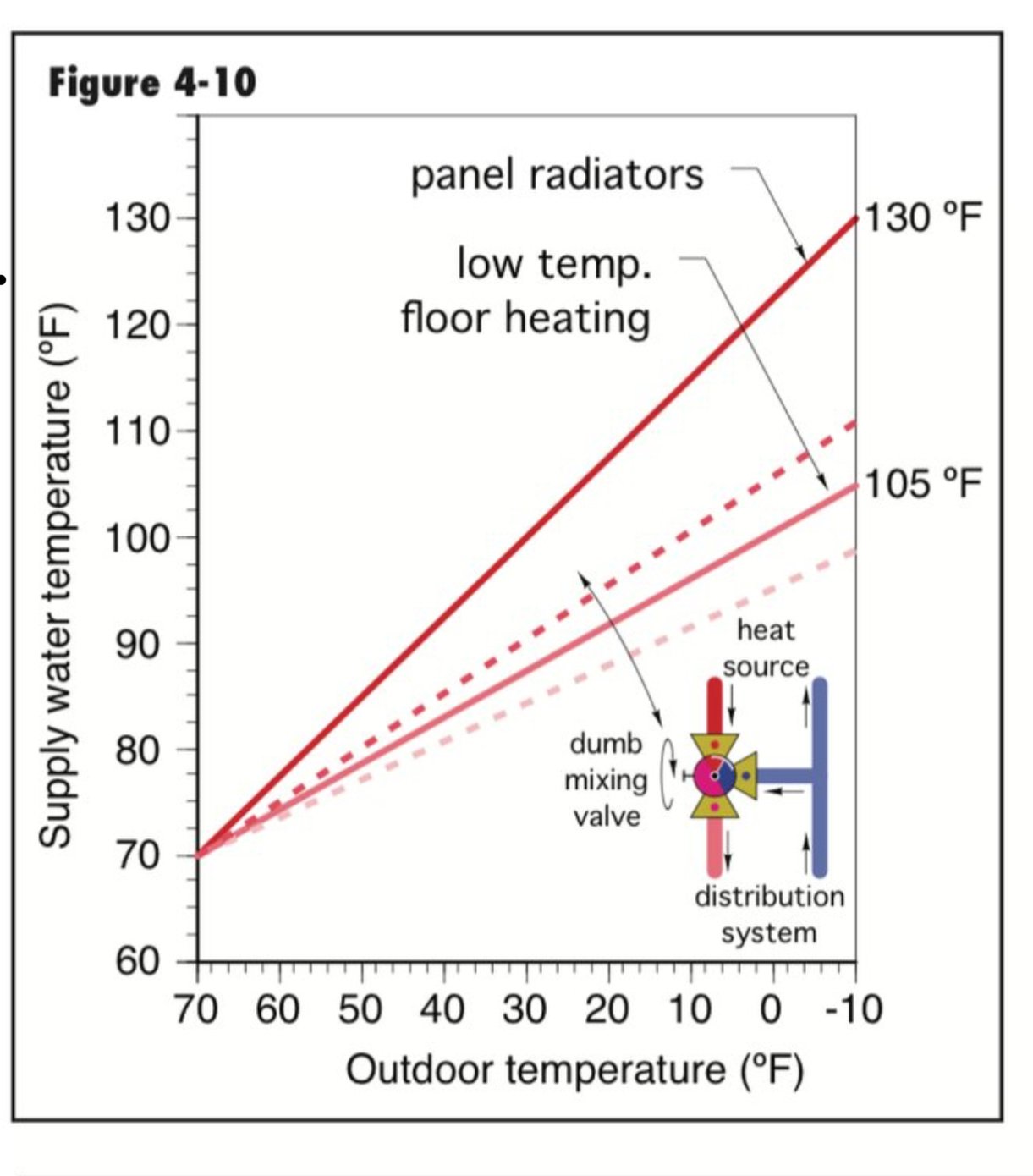

the manual mix valve will in fact track with the boilers changing temperature. As the boiler drops so will the mix from the manual valve. The manual valve does not have a sensor, it is a fixed blend.

On the mix down manual valve you can also adjust the offset, dotted red lines, how it tracks with the higher temperature.

This shows the relationship with a 130 panel rad system, but it could be a 160, 180 or higher zone also.

There is no reason to have ODR on the boiler and also on the low temperature zone.

Of course with a cast boiler you will have a minimum return to be aware of.

hot_rod

hot_rod

Re: Warm Start Boiler Summer Leak

Agree. If the boiler is a factory assembled block, then it should be covered.

Re: Warm Start Boiler Summer Leak

Still the upper port gasket leak qualifies as a leaking boiler and Weil McLain will usually honor that when it is brought to their attention via a warranty claim. The worst that can happen is the warranty folks at WM say no. Then you appeal and they say no again. But I remember when I did WM warranty claims, I could talk them into covering that exact situation. The warranty coverage uses the term "heat exchanger" not "boiler section" on the WGO, WTGO and SGO warranty form. See copy of warranty form here Weil McLain WTGO 20 Year Warranty

Re: leaking return line

If you don't know your connected EDR than the boiler nameplate may be informative.

1" copper is a happy medium. But you want to add isolation valves at each end hose bibs for flushing the return. Those valves, tees and fittings could be threaded pipe which would avoid soldering for those items.

Re: New Refrigerants

So glad to be retired.

My son does side work, and also is not interested in air conditioning any more. Oil heat is all he needs to make a few extra bucks after work and weekends.

Re: Mixing valves in oil fired radiant floor heating system

The supply water temperature to the floor will not change with the weather for the most part.

Lets say the fixed temperature mix for the floor needs to be 125° for the design days. (the coldest days) and the boiler will create 160° for that using the ODR when there is no call for DHW and the minimum temperature for the boiler return of 135°. The fixed temp mixing valve will take 160° supply water and add the proper amount of return water from the radiant in order to make 125° to the floor

When the boiler temperature drops lower temperatures based on the boiler or Tekmar ODR control sensing a warmer outside temperature (say 145°), the fixed temp mix valve will take the 145° reset temperature and mix less return water from the radiant return to make the supply 125° to the floor. So when the floor needs the lower temp on the warmer day, it will still be getting 125 °. That will over heat the room enough to satisfy (turn off) the thermostat until the room temperature drops below the thermostat set point and it calls for heat again. Room temperature thermostats and radiant floor heat are not the best combination to avoid large temperature swings in the rooms because of the slower reaction time of radiant floor systems.

Eventually the Tekmer or boiler ODR control will drop the supply temperature to 120° when the outside temperature is above 50°. That is when the 125 mix valve will not allow any return water from the radiant loop to mix with the 120° supply water. the 120° supply water will go straight through the mix valve. You will then get the lower floor temperature. Now this 120° boiler supply temperature will only happen when the boiler's burner is off. If the boiler's burner is firing then the minimum return temperature of 135° will need to happen by some function of the control system to protect the boiler from flue gas condensation.

I'm not saying that it won't work, I'm just pointing out the reason you might want to consider the Taco iSeries ODR valve. They were not available when I installed my radiant floor system so I installed fixed temp mix valves and used room thermostats. It worked fine for me. I just wanted you to know that without the ODR valve, you may be wasting your $$$ on using a Tekmer or other boiler ODR system.

What you think you are achieving with a Tekmar or other boiler temperature ODR may not happen after you spend all that $$$ on the control system. Save on the system ODR and use the ODR mix valve where it will do the most good. Or forget about ODR completely and save $$$ in installation costs.

Re: tiny droplet leak from the oil tank firomatic shut off valve.

A few drips of oil are not dangerous. Its something that should be fixed and not be ignored but I wouldn't panic about it. I would run the tank low and have it fixed. If the tank is old it may be time to change it.

Re: HTP Boiler humidity dislike + Error Code 11

Yeah I still don't see how we went from clogged condensate and an ignition error to descaling the pipes. Sounds like a fire side problem. All of the advice prior to calling a plumber was to service the fire side, you should never aim to descale the closed system boiler piping unless there is a massive problem with that water. The condensate that is coming out of the boiler is NOT from the closed system (unless there is a hole in the heat exchanger) again what you have is a fire side problem, you need burner service, and to clean the FIRE SIDE, not to descale the inside of the boiler piping, that will not fix your problem and very likely will cause new ones.

Re: I said "what???"

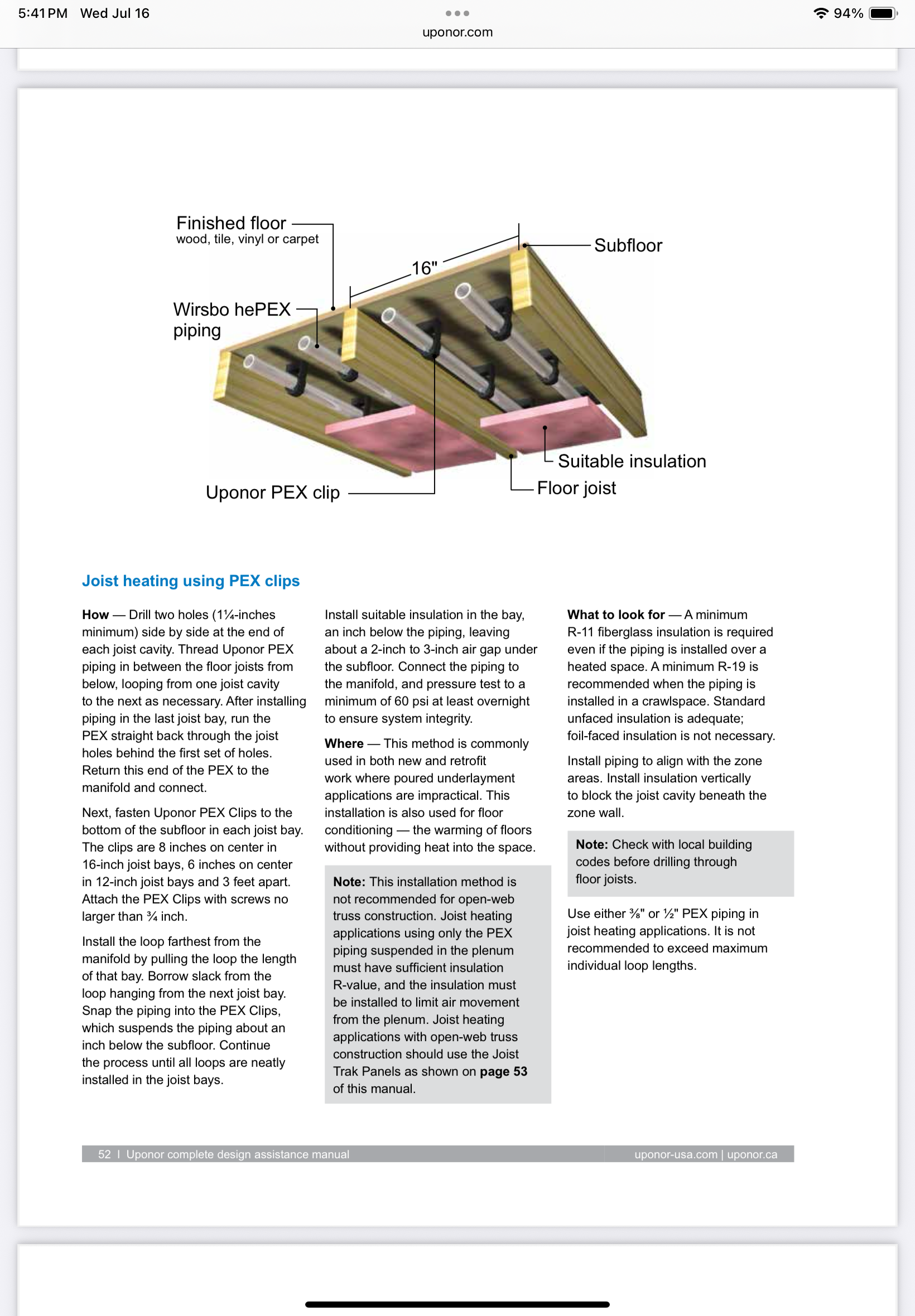

It is called joist bay heating. Uponor still has a method in their design guide using bare Pex tube in the joist bay. Suspend the tube an inch below the floor.

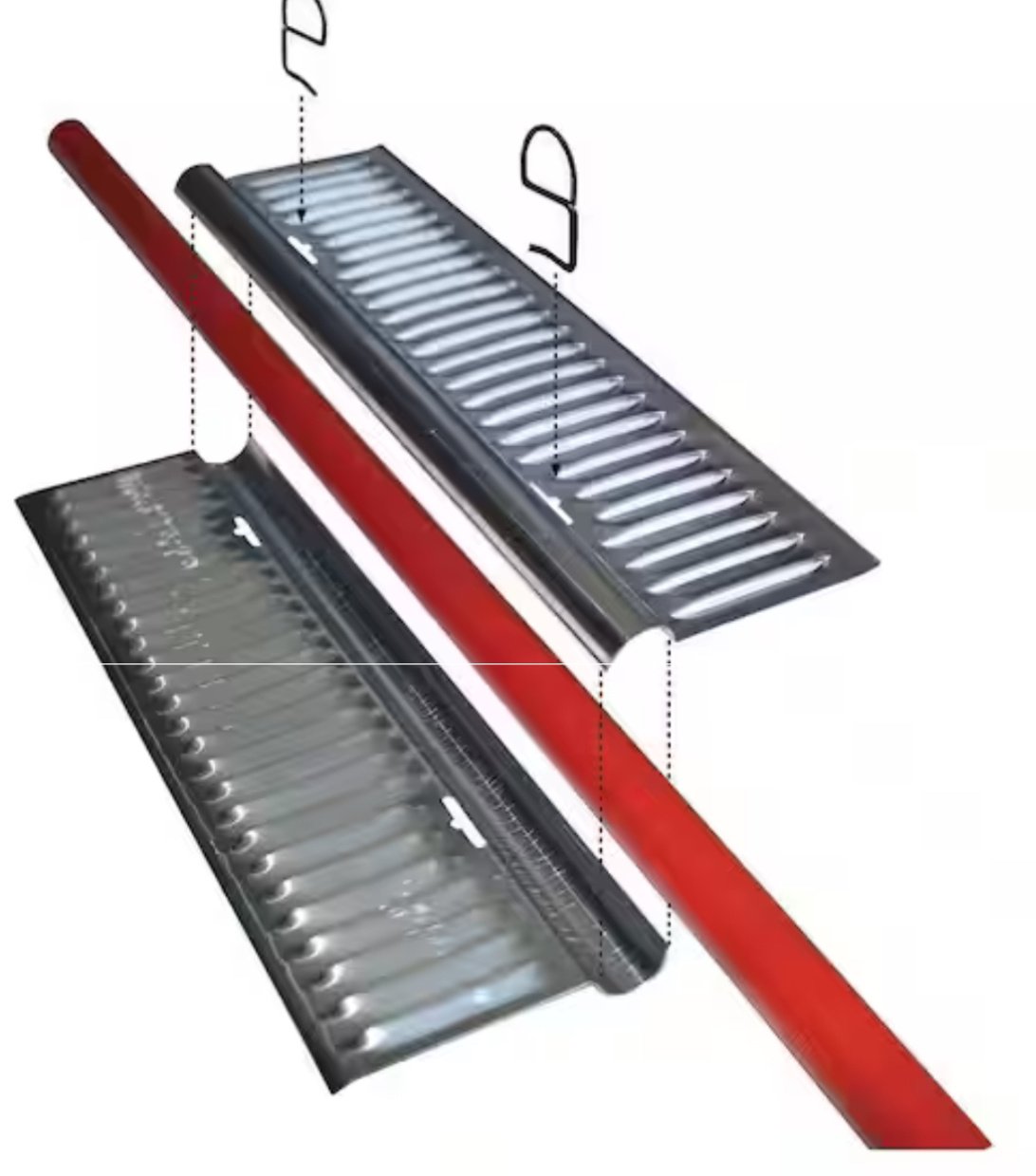

UltraFin is an aluminum convectors that snaps on Pex tube to increase convection. Either these or the fin tube can work fine

the fin tube is probable even better than these two options for getting the energy from the tube to the joist bay. Generally 140f and higher SWT required

hot_rod

hot_rod

Re: Prevent mold in mini-split heads

I've never heard anywhere except here that an inverter mini split NEEDS to run at 100% capacity. Everything I have ever learned about them says they are more efficient at lower loads, and they tend to run better if they coast along at low loads, rather than full load (this is manufacturer training, and engineers telling me this). Obviously if your low turndown capacity is larger than the internal load you will end up short cycling which isn't good. But can you explain why an inverter mini split needs to run at full load?