Best Of

Re: Myers C48D53B86 jet pump- Help

you are all very smart

I should’ve slowed down and put a real wrench on it yesterday. But you know how it goes when things are moving quickly.

GW

GW

Re: BMI capacitors?

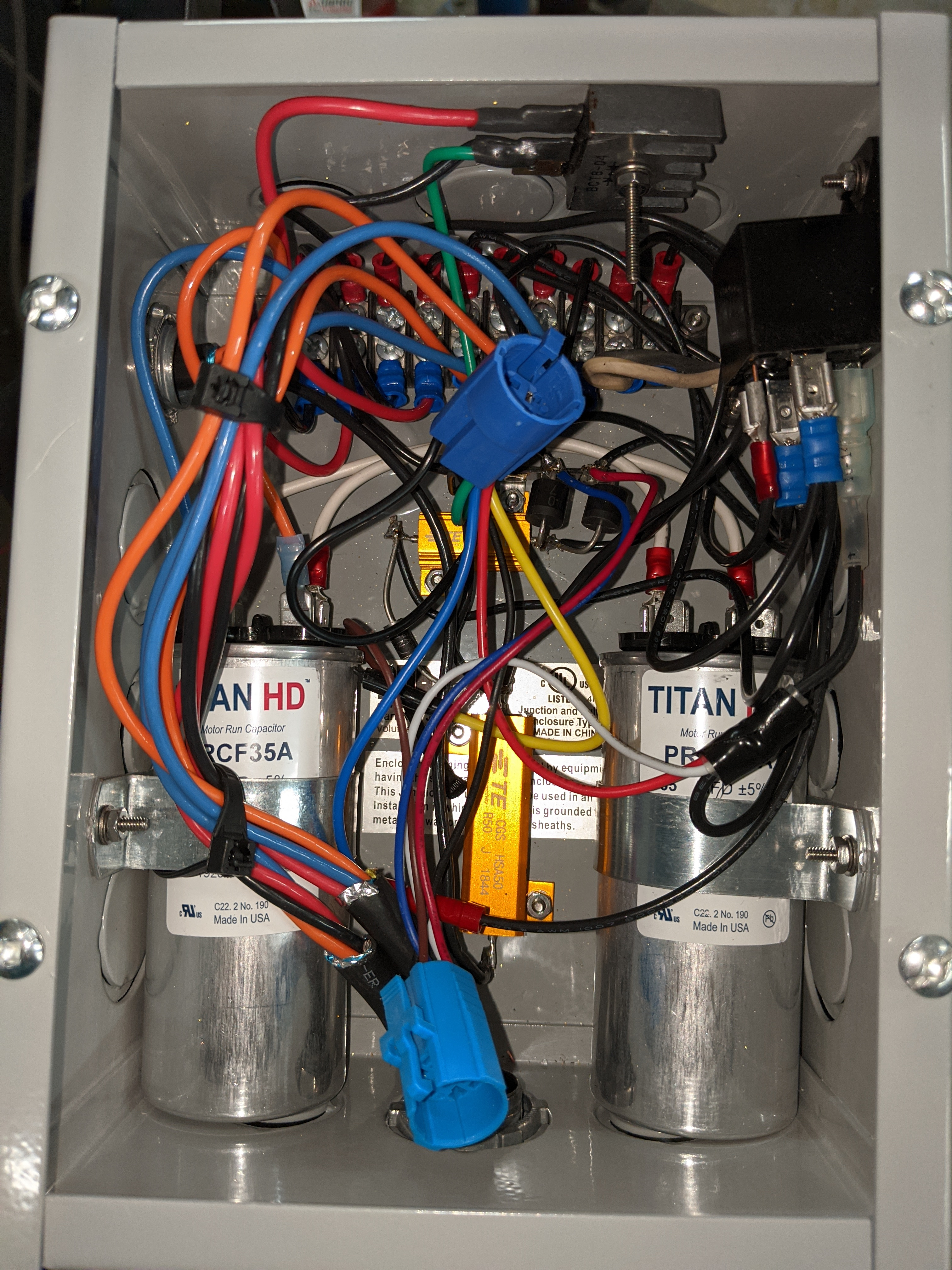

The Titan HD caps say right on the label "MADE IN USA".

I would think it would be kind of a big issue if they were actually made in Mexico, no?

Best picture I have of two of mine…. They definitely say Made In USA.

ChrisJ

ChrisJ

Its hot in here 84deg but I am a lot hotter

😓😓😓

At the condo we have slide out wall mounted ACs in a sleeve. 1 Upstairs 8000 btu and 1 downstairs 12000 btu.

All the appliances in this place were originally GE. In fact, I replaced the original GE dishwasher last year 1990 model, still worked fine but the plastic soap dispenser broke and even if the part was available, I wouldn't have bothered with it. The AC wall sleeves I think are GE as well.

During Covid the upstairs AC quit. I have no idea how old it was, but it wasn't original. I searched online and not much available during Covid, but I found a GE and ordered it and put it in. It worked for about 4 years great until the compressor quit. Some kind of foreign rotary compressor R-410. Put a line tap valve on it and the compressor ran but wouldn't pump. No warranty left. Tossed it and bought another one and installed it last year. Started it today and it runs ok……so far.

Now to the downstairs. This one had an Emerson quiet Cool. At least 20 years ago it quit. Took it out and it had no charge. R-22. Leaked tested with an electronic and couldn't find the leak but it had one. Cut the tubing and pulled out the evaporator coil. Found the tubing on the bottom chafed. Brazed it up put the coil back and recharged and it ran the last 20 years.

Last year it still worked but the fan was getting noisy. Time to replace the unit as it was at least 30 years old.

Bought a Friedrich 12000 btu (R-32) and installed it last year. Worked fine all year. Today I fired it up fan runs no cooling at all. No TD on evap with my Fluke 52 and no condenser heat.. At my age I ain't pulling it out of the sleeve myself the bottom of the AC is about 6' off the floor.

Finally, I put it on "fan only" with the fan on high speed. I went downstairs and pulled the CB panel cover and put an amprobe on the dedicated circuit and the fan draws 1 1/2 amps.

Went up and put it on cooling. The amps went up to 6 amps so now I know the fan and compressor are on. Still no cooling. Compressor amps is low so no gas most likely

I bought this online some place. Called Friedrich tech support and luckily there was only one call in front of me. Talked with a really nice guy. Told him how I checked it and he agreed it was toast. They don't repair anything under 1 ton.

He gave me the name of a local appliance dealer whom I know (we bought a refrigerator and dishwasher from them). I have to have them come and do a "diagnostic report" $139 which he sends to Friedrich to confirm the diag and they will ship me a new one😊😊😊😊

After that, I was out in my 2007 F-150 and the AC isn't doing much, cools a little. I had a bone yard engine dropped in last Feb and ran the AC after that to make sure it was ok and it was fine.

I leaked tested it quickly with my electronic and found nothing……..until I pulled the plastic Schrader caps and found both of them leaking a little.

Maybe when they recharged it after the engine change the old Schrader valves didn't like being disturbed

🤔🤔🤔🤔 It's been quite a day

Oh, the other spare bedroom upstairs has a 6000 btu Frigidaire window AC that is 39 years old and was my mothers and still rrruns fine.

All China Junk!!

Re: Near boiler piping/replacement boiler

tighten the packing on the gate valve so it stops leaking or add a little if tightening doesn't do it.

Re: Question about lining 90 year old cast iron sewer pipe

I work for a commercial plumbing company. Our service department has been involved in these kinds of repairs, I do side sewers from time to time with invaded, collapsed or otherwise compromised pipe.

As much as you don't want to cut the concrete, that is where I would go with the inside portion. If the entire sawing operation is done wet you will not have dust anywhere. It requires a crew with wet vacs all the time, some dams to control the water. Done right it is an easy cleanup.

I'd start with the saw operation and remove the concrete and old pipe. Very carefully, expose where it leaves the house and have a lining or bursting contractor send in a sleeve straight down the pipe to the plastic side sewer, taking care of that clay section and far more easily than doing it in a deep pit. Been there done that.

Now you don't have all that weird work around those wyes under the concrete that you would have to cut up anyway. You can put in proper modern plumbing.

skyking1

skyking1

Re: Literature on Geothermal

The loop will add or subtract heat energy from the earth around it. When winter is over the ground may be much colder, the sun recharges it.

I remember a couple of those small copper tube direct refrigerant systems, 6' deep warming the ground in the summer AC mode so much , that it killed the grass in the entire yard.

The Weller School near Fairbanks had a solar thermal system that dumped heat into the earth loops all summer to bring up the earth temperature.

hot_rod

hot_rod

Re: Near boiler piping/replacement boiler

FYI: If you originally had a WGO boiler of the same series, the OEM control would have been the L8148 aquastat. You would not have the option to set a low limit with that control because there is no low limit. Weil McLain does not see that maintaining a minimum 135° on a cold start boiler has any advantage. Their 66 and 68 series boilers also came with the L8148 aquastats and there are many of those 35 to 50 year old cold start boilers still operating across the country. The only advantage to maintaining 135°F in your boiler is to your fuel oil supplier. They make more $$$ the more oil you burn.

As far as repiping the boiler so the circulator pumps are located on the supply side of the boiler would be: if you are experiencing air problems. If you constantly need to purge air from your system (more that once a year) because you have no heat in a zone or a radiator resulting from air in the system, then you will gain an advantage in that repipe job, if designed correctly. Otherwise, if it ain't broke don't fix it. Lacking any air issues, there is no fuel savings or thermal efficiency to be gained my redesigning the pipes. The only advantage is to eliminate air problems.

Re: Near boiler piping/replacement boiler

@katman, The Aquastat that you have, may be the Original Equipment Manufacturer (OEM) specifically designed for WM. That control may not have the ability to operate as a WGO cold start boiler. If your system was originally installed with a WGO boiler and an indirect for DHW, then the control would automatically be set for cold start operation. All that said, since you are no longer using the Coil for DHW, there is no need to maintain any minimum temperature in the boiler when there is no call for heat of call for DHW. Set the control to the lowest temperature for LOW LIMIT as possible. If you can go as low as OFF that is the best setting for your situation. that will result in the lowest fuel usage. In the future, if you ever need to replace the Aquastat Control… Use the universal model that can be set to OFF in order to convert this WTGO to cold start operation like the WGO. Except for the tankless DHW coil, the WGO and WTGO are the same boiler in every other specification.

As far as setting up the burner to fire at 1 GPH with a .85 nozzle, that is where I would start and see if you get the minimum stack temperature of 350° within 5 minutes of cold start operation. If you do, then leave it there and look for signs of flue gas condensation on the vent connector, after several weeks of operating at this lower input. You may be in good shape.

Re: Near boiler piping/replacement boiler

If you don't have the tankless there is no reason to have it warm start, can set the low limit as low as it can go. 135 is a little low to keep it from condensing though oil can go lower than gas.