Best Of

Re: Question about lining 90 year old cast iron sewer pipe

I work for a commercial plumbing company. Our service department has been involved in these kinds of repairs, I do side sewers from time to time with invaded, collapsed or otherwise compromised pipe.

As much as you don't want to cut the concrete, that is where I would go with the inside portion. If the entire sawing operation is done wet you will not have dust anywhere. It requires a crew with wet vacs all the time, some dams to control the water. Done right it is an easy cleanup.

I'd start with the saw operation and remove the concrete and old pipe. Very carefully, expose where it leaves the house and have a lining or bursting contractor send in a sleeve straight down the pipe to the plastic side sewer, taking care of that clay section and far more easily than doing it in a deep pit. Been there done that.

Now you don't have all that weird work around those wyes under the concrete that you would have to cut up anyway. You can put in proper modern plumbing.

skyking1

skyking1

Re: Literature on Geothermal

The loop will add or subtract heat energy from the earth around it. When winter is over the ground may be much colder, the sun recharges it.

I remember a couple of those small copper tube direct refrigerant systems, 6' deep warming the ground in the summer AC mode so much , that it killed the grass in the entire yard.

The Weller School near Fairbanks had a solar thermal system that dumped heat into the earth loops all summer to bring up the earth temperature.

hot_rod

hot_rod

Re: Near boiler piping/replacement boiler

FYI: If you originally had a WGO boiler of the same series, the OEM control would have been the L8148 aquastat. You would not have the option to set a low limit with that control because there is no low limit. Weil McLain does not see that maintaining a minimum 135° on a cold start boiler has any advantage. Their 66 and 68 series boilers also came with the L8148 aquastats and there are many of those 35 to 50 year old cold start boilers still operating across the country. The only advantage to maintaining 135°F in your boiler is to your fuel oil supplier. They make more $$$ the more oil you burn.

As far as repiping the boiler so the circulator pumps are located on the supply side of the boiler would be: if you are experiencing air problems. If you constantly need to purge air from your system (more that once a year) because you have no heat in a zone or a radiator resulting from air in the system, then you will gain an advantage in that repipe job, if designed correctly. Otherwise, if it ain't broke don't fix it. Lacking any air issues, there is no fuel savings or thermal efficiency to be gained my redesigning the pipes. The only advantage is to eliminate air problems.

Re: Near boiler piping/replacement boiler

@katman, The Aquastat that you have, may be the Original Equipment Manufacturer (OEM) specifically designed for WM. That control may not have the ability to operate as a WGO cold start boiler. If your system was originally installed with a WGO boiler and an indirect for DHW, then the control would automatically be set for cold start operation. All that said, since you are no longer using the Coil for DHW, there is no need to maintain any minimum temperature in the boiler when there is no call for heat of call for DHW. Set the control to the lowest temperature for LOW LIMIT as possible. If you can go as low as OFF that is the best setting for your situation. that will result in the lowest fuel usage. In the future, if you ever need to replace the Aquastat Control… Use the universal model that can be set to OFF in order to convert this WTGO to cold start operation like the WGO. Except for the tankless DHW coil, the WGO and WTGO are the same boiler in every other specification.

As far as setting up the burner to fire at 1 GPH with a .85 nozzle, that is where I would start and see if you get the minimum stack temperature of 350° within 5 minutes of cold start operation. If you do, then leave it there and look for signs of flue gas condensation on the vent connector, after several weeks of operating at this lower input. You may be in good shape.

Re: Near boiler piping/replacement boiler

If you don't have the tankless there is no reason to have it warm start, can set the low limit as low as it can go. 135 is a little low to keep it from condensing though oil can go lower than gas.

Re: Myers C48D53B86 jet pump- Help

I['ll bet it is an 1/8 npt if you take the brass out? A basic 1/8 radiator bleeder, ball valve, etc.

hot_rod

hot_rod

Re: Myers C48D53B86 jet pump- Help

@GW # you posted is the AO smith motor # not the pump. I found some myers pumps but could not find the bleeder and it was not listed as a separate part but I may have not had the right pump Probably could take that fitting out and silver solder something to it like a piece of copper and a valve.

Re: Myers C48D53B86 jet pump- Help

I don't see why you couldn't drill and tap it 1/8" IPS.

I don't know if you do oil burners, but the bypass plug that goes in a Suntec oil pump is 1/16" national pipe thread. You could try one for size to see if that fits or get one from an old oil pump or from Webb

Re: Near boiler piping/replacement boiler

The WM WGO-5 has a rated input of 1.45 GPH. That same boiler can be fired at 1.20GPH when it has a model number of WGO-5RD. That is a 5 section boiler that comes from the factory with a oil burner nozzle of 1.00 GPH and a pump pressure setting at 145 PSI.

Weil McLain allows you to reduce the fire rate by 15% and as much as 20% on most of their boilers by adjusting the gas pressure on Gas Fired units and reduced nozzle size on Oil Fired units. I might attempt to use a .85 GPH nozzle at 45 PSI. After checking the stack temperature and other combustion test numbers, you may find that you can get good numbers with the boiler firing at 1.02 GPH which would end up with a AHRI NET output of 107K BTUh. That will bring you from 3 times too big down to twice as big as needed. That will then reduce your short cycling by 30ish%.

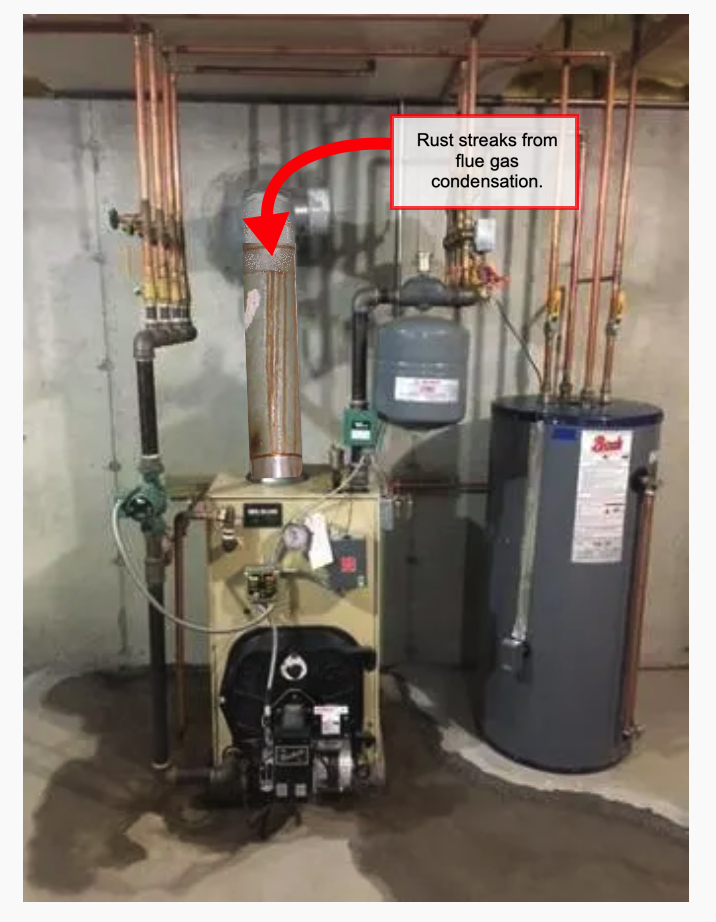

Now you may end up with flue gas condensation as a result of this change, but you may not. If you get the stack temperature to 350° within the first 3 minutes of operation, you will probably be alright. If you can't Then check the return water temperature. Since you are using Baseboard with copper tube/alum fin, you should have no problem getting return water to 140° within the first 5 minutes and the stack temperature should be 350° or more, without a problem. If you end up with Flue Gas Condensation you will notice water droplets that leak out the vent connector pipe and leave rust trails on the vent pipe in a few weeks. If you don't get that, you can leave the boiler operate at the reduced firing rate and save a little on fuel. If you do get the rust trails, then increase the fire rate to 1.1GPH by using a .90 GPH nozzle at 150 PSI.

Don't forget to paint the rust marks away with high heat aluminum or replace the vent connector pipe with new, so you can monitor for new rust streaks. You should be able to get the firing rate down enough so you can keep that oil boiler in operation for another 20 years. That will give you time to sack away enough for a new boiler later on.