Best Of

Re: Near boiler piping/replacement boiler

If you don't have the tankless there is no reason to have it warm start, can set the low limit as low as it can go. 135 is a little low to keep it from condensing though oil can go lower than gas.

Re: Myers C48D53B86 jet pump- Help

I['ll bet it is an 1/8 npt if you take the brass out? A basic 1/8 radiator bleeder, ball valve, etc.

hot_rod

hot_rod

Re: Myers C48D53B86 jet pump- Help

@GW # you posted is the AO smith motor # not the pump. I found some myers pumps but could not find the bleeder and it was not listed as a separate part but I may have not had the right pump Probably could take that fitting out and silver solder something to it like a piece of copper and a valve.

Re: Myers C48D53B86 jet pump- Help

I don't see why you couldn't drill and tap it 1/8" IPS.

I don't know if you do oil burners, but the bypass plug that goes in a Suntec oil pump is 1/16" national pipe thread. You could try one for size to see if that fits or get one from an old oil pump or from Webb

Re: Near boiler piping/replacement boiler

The WM WGO-5 has a rated input of 1.45 GPH. That same boiler can be fired at 1.20GPH when it has a model number of WGO-5RD. That is a 5 section boiler that comes from the factory with a oil burner nozzle of 1.00 GPH and a pump pressure setting at 145 PSI.

Weil McLain allows you to reduce the fire rate by 15% and as much as 20% on most of their boilers by adjusting the gas pressure on Gas Fired units and reduced nozzle size on Oil Fired units. I might attempt to use a .85 GPH nozzle at 45 PSI. After checking the stack temperature and other combustion test numbers, you may find that you can get good numbers with the boiler firing at 1.02 GPH which would end up with a AHRI NET output of 107K BTUh. That will bring you from 3 times too big down to twice as big as needed. That will then reduce your short cycling by 30ish%.

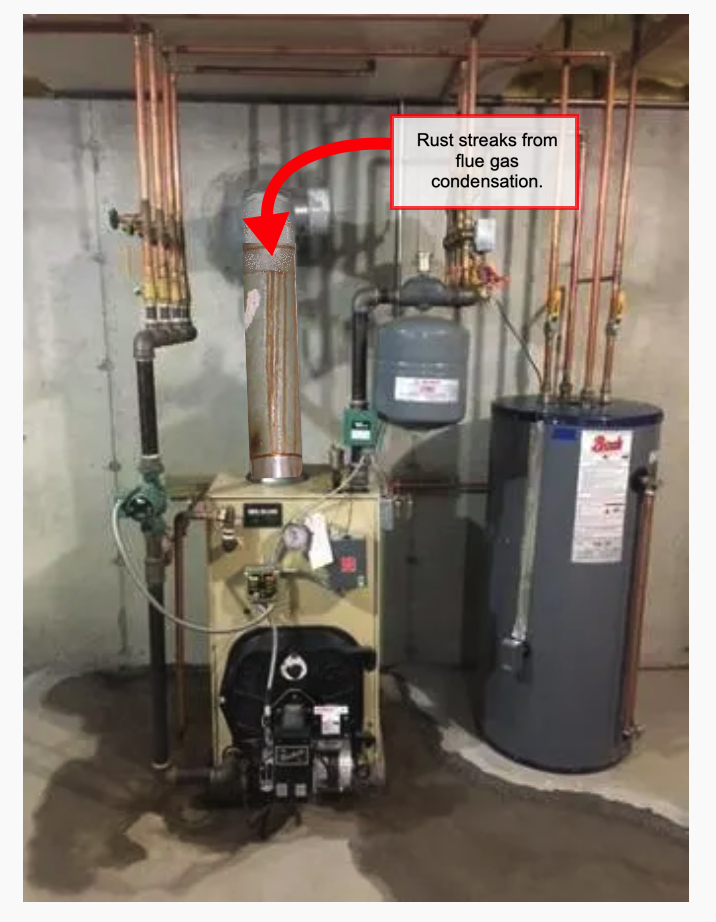

Now you may end up with flue gas condensation as a result of this change, but you may not. If you get the stack temperature to 350° within the first 3 minutes of operation, you will probably be alright. If you can't Then check the return water temperature. Since you are using Baseboard with copper tube/alum fin, you should have no problem getting return water to 140° within the first 5 minutes and the stack temperature should be 350° or more, without a problem. If you end up with Flue Gas Condensation you will notice water droplets that leak out the vent connector pipe and leave rust trails on the vent pipe in a few weeks. If you don't get that, you can leave the boiler operate at the reduced firing rate and save a little on fuel. If you do get the rust trails, then increase the fire rate to 1.1GPH by using a .90 GPH nozzle at 150 PSI.

Don't forget to paint the rust marks away with high heat aluminum or replace the vent connector pipe with new, so you can monitor for new rust streaks. You should be able to get the firing rate down enough so you can keep that oil boiler in operation for another 20 years. That will give you time to sack away enough for a new boiler later on.

Re: Radiators make my apartment unbearable during winter

The heavy blanket will fix the overheating. Perhaps discreetly contacting an attorney can solve the bullying.

Re: NJ Boiler replacement decision points...

Jupiter Heating carries most Munchkin parts. I’ve found that Munchkins heating radiators last longer; less acidic condensation in the HX. IBC has an “SL” model with side tappings like the Munchkins which makes the replacement easier.

Re: Old copper pipe smaller than todays 1/2"

Possibly 3/8 OD that expanded when it froze. That is common with hard drawn 1/2" in homes when they freeze.

I've used a flaring bar to size it back down to put a fitting on.

hot_rod

hot_rod