Best Of

Re: Refurbished radiator making bird noises. Not vent?

Use extra layers of teflon tape with the vent. - try 6 wraps and use more if you think it may still be bottoming out. It's possible the vent it bottoming out allowing a very tiny amount of steam to escape

BobC

BobC

Re: Refurbished radiator making bird noises. Not vent?

My thought was that if there’s a hole I may hear air escaping

Re: Refurbished radiator making bird noises. Not vent?

If it does heat, there's a hole making a hawk screech noise.

HVACNUT

HVACNUT

Re: Sun Room- Add Sixth Baseboard Hotwater Zone or a Mini Split

Please don’t listen to that plumber.

keep the HW for when single digits and that NW wind blows.

pecmsg

pecmsg

Re: Sun Room- Add Sixth Baseboard Hotwater Zone or a Mini Split

I'd run the baseboard into the sun room — but on its own zone, as sun room heat demands are so different from other rooms.

As to freezing — unless that room is isolated from the rest of the house (doesn't sound like it) it's not much more likely to freeze than the rest of the house!

Re: Sun Room- Add Sixth Baseboard Hotwater Zone or a Mini Split

Im confused

You're eliminating the HW forced air but keeping the baseboard?

In not a fan of 100% mini heat pumps, too man y things to go wrong and parts are NOT readely available.

Keep the HW heating as a backup.

pecmsg

pecmsg

Re: Need some advice for a vintage Peerless radiator valve hookup

Saw the nut off the spud by cutting in two places to split the nut. Then put something metal a piece of round stock use threaded rod, a cold chisel handle or whatever you have inside the spud so it doesn't crush with a pipe wrench on it

Re: Need help with new install of radiant with Buderus cast iron boiler

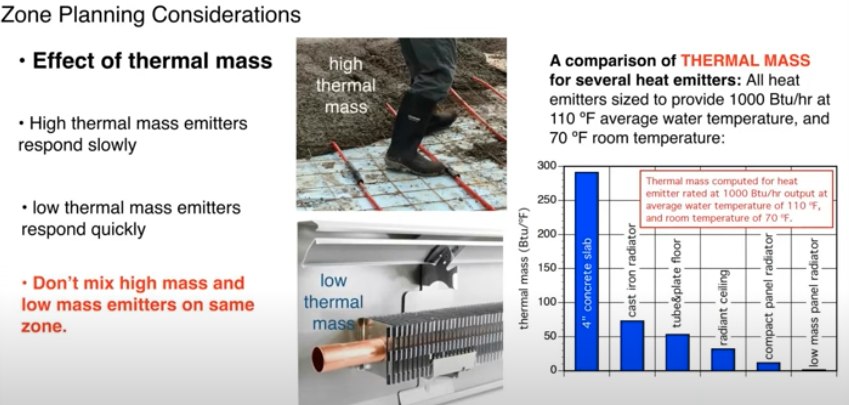

Some heat emitter comparison from the recent Coffee with Caleffi.

Notice a panel radiator is about 1% the mass of a 4" slab!

hot_rod

hot_rod

Re: Oversized overtall chimney?

Strongly disagree that a chimney can't be oversized. draft is caused by the temp difference of heated air versus combustion air.

You go to a cabin on a cold wet damp day. You have the door open, and you try and light the fireplace and its back drafting.

Nothing to do with MU air you have the door open.

You get the newspaper and kindling going and it starts to draft because the chimney is warming up. the bigger the chimney the more heat it takes to get going.

How many gas fired atmospherics have been ripped out and the existing gas fired water heater is left in the chimney with the boiler replaced by a MOD CON. Then the chimney may be to large for the water heater and you have to comply with the 7X rule.

So of course chimneys can be too big.

Re: Oversized overtall chimney?

Guys,,, I really don't think the problem is a lack of combustion air… He's got a whacking great chimney there and is trying to find ways to reduce the amount of air going up it. I have seen a chimney that size develop enough draught to break a four foot a square piece of quarter inch plywood and try to such it up the chimney on a cold day with normal room temperature indoors.

If he really wants to reduce that draught he's going to have to drop a liner in there, sized to the appliance, and seal the space around the liner in the existing flue. That's going to cost, and other than the feel good of not having so much draught up the chimney it won't save enough on heating costs to make it worth the effort.

But folks, from the sound of it — don't worry about not having enough combustion air. That's not the problem.