Help with Peerless PF-140, Ignition issues, Control Board swap

Comments

-

The high temp sensor is ok, I checked continuity out of circuit (almost 0 ohms) and also jumped the control board connection as in the video, no change.

I tried to wring out the gas valve connector from the J13 connector on the control board (blu, brn, grn/yel) to the 6 pin connector on the gas valve, but only had luck with the ground. Once I found I could split the connector I found out why. There is a little PCB in there. This is not in the schematic

But I was able to cycle the ignite sequence and see 120vac (across the brn and blu) when the valve was on. But I can't be sure what the valve itself is seeing, nor do I know the function of the PCB, maybe because it is a modulating valve…

On to the next tests and inspections.

0 -

It looks (to me) like tech #1 did a thorough cleaning down into the "grooves" This picture is of the bottom of the chamber (phone in the chamber facing down)

and here is a zoom in:

I ran a piece of sheet styrene I had in some of the grooves and I didn't seem to hit or dislodge anything. I'll vac and wipe down the chamber and vac the burner anyhow. Tech I trust said just a damp (water) microfiber

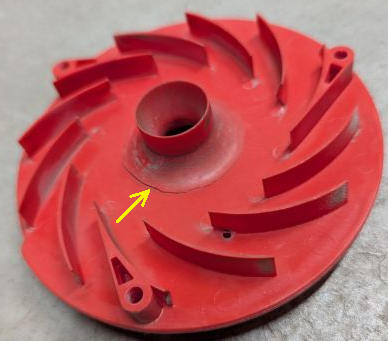

The swirl plate looks ok to me. I'll take a closer look. I guess I am looking for a deformation or, say tear, or something?

So, here is where I am at (to the best of my ability) - controls and igniter/flame sensor are ok, high temp sensor ok, chamber seems ok, 120vac seen at the gas valve, swirl plate looks ok (but I'll look closer).

That leaves the gas valve and that funky pressure on the boiler side of the valve.

Tomorrow the "tech I trust" will be coming by to start to design the next system and I am sure he will take a look. I'll ask him to retest the pressure and I think he will want to do a combustion analysis.

and we go from there. That first shower in our own shower is going to be glorious once up and running 😍🤞

0 -

Swirl plate looks ok.

0 -

@yellowdog mentioned the inducer motor? It's only a thou, I'll take 2…

https://www.partstoyourdoor.com/blower-pf-140-54191

For about 5-8 major parts you can get a new boiler. Maybe the business to be in is buying boilers and parting them out?

1 -

-

I agree the swirl plate looks cracked, what I wonder it that is enough to upset it. kind of makes me wonder if a thin layer of epoxy on both sides for a test would work. I wonder if the crack gets wider with the inducer blower running.

Earlier in this thread I posted a similar picture of a gas valve connector with the bridge rectifier on the board, I guess it went unnoticed. That green PCB may just slide out if it is not glued in. Inspect the solder Joints.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

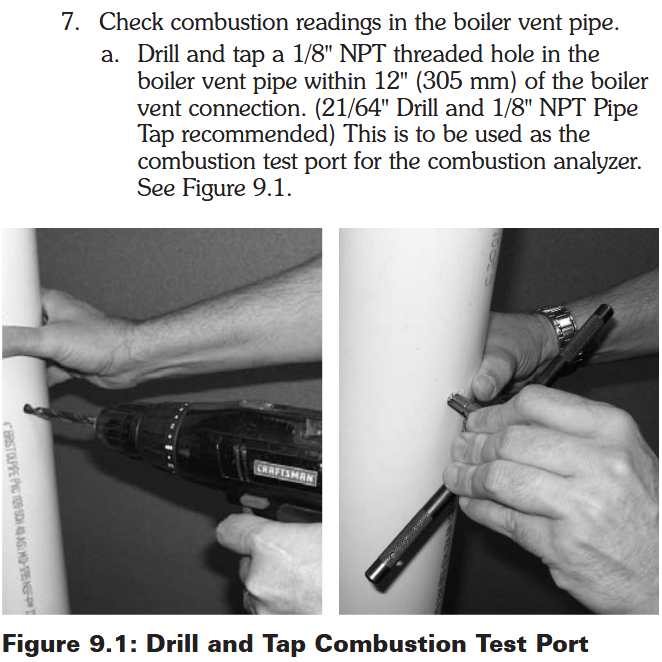

In the picture with the vent pipe, I don't see any port drilled and plugged like the manual shows. Although there is some stuff in the way. Kind of wonder if it was ever done.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

supertech, I heard ya, not ignoring ya, as I mentioned previously the first 2 techs did not do a CA, and the "tech I trust" is coming tomorrow. He asked if one was done, but I am not sure he will do one, we will see. He's coming to start the design of the new system. He's not doing repairs because of his family situation, but he might, we will see. Let's not forget I have called other techs only to get blown off. I can call more, I just love tossing around benji's for no good reason, explaining everything to a new person right from the beginning, only to have them not show, or not come back (sorry, I am pretty beaten down, my faith in capitalism is shaken).

109 - I did not skip past that post, I saw it, and I commented that I would probably take this to the curb before a shipment from moser came :). I tried sliding the board out and the connector seemed secured into that black case somehow, I decided not to break it. Besides, the valve clicks and I see a real good strong blue flame (but only for 2-3 seconds). I could check the DC at the 5 pin connector, but there is no scheme, etc that tells me what I should look for. I even tried finding the gas valve on the net. I suppose I could just probe it to find out what it is, but what is it supposed to be?

Bob, good spot, I can take it out tomorrow, it was an easy removal. But, how critical is it? It's not a jet turbine, right? Asking because I don't know. Should I just look for instability, like if I flex it if the crack opens or not?

what did you guys thing of the Combustion chamber?

I do want to get this running, the dream of a hot shower in my own home is a glorious one, but I have to be a realist. It's a 7 year old boiler that hasn't been maintained, and has, what 5 years left? it isn't supported in my area, the parts are a fortune, and hard to get. My indirect tank is 25 years old as well. I think throwing a thou a part at it is nuts. Try a gas valve? Maybe? Only nine hundred something….I'm not much of a gambler.

I want to go back to cast iron, you guys think I'm nuts? My only concern is I have in floor radiant and baseboard.

Jim

0 -

-

OK if you understood there was a possibly of bridge rectifier hiding in the gas valve connector housing this statement confuses me.

" I tried to wring out the gas valve connector from the J13 connector on the control board (blu, brn, grn/yel) to the 6 pin connector on the gas valve, but only had luck with the ground. Once I found I could split the connector I found out why. There is a little PCB in there. This is not in the schematic "

Is there a diode symbol anywhere on the connector housing ?

Kind of wondering if the if the crack gets wider with the inducer blower running. Thus causing the draft through the venturi to diminish resulting in the wrong pressure at the outlet side of the gas valve.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Mod Cons are just like a new car. When they work, they can't be beat. When they go down in a lot of cases they are a big pile of expensive junk.

And just like the newer cars parts are $$$$$.if they are even available after a certain time. It seems like we are forced into a 10 year? life cycle.

Where do you draw the line between mod con fuel savings and parts cost? $800 blower assemblies etc You have to save a lot of fuel to make up that cost. Its just like a car when it start eating $$$ and your shooting the parts cannon at it you get sick of it fast.

Add to that fact just like cars in many areas you can find someone who can fix it. The cars and the mod cons require skilled technicians who can fix it.

I watch a guy on U tube "South Main Auto" he gets all kinds of cars sent to him from other shops, cars sent to him from dealers who can't fix the brand they sell.

By the time he gets a car some have been to 2-3 shop/dealers who have blasted the thing with a parts cannon.

And don't even talk about the lack of quality in aftermarket car parts that don't work right out of the box.

Its our own fault for giving all the jobs to China. Now we pay for it.

If the new tech can't fix it go Cast iron or steel a normal boiler.

60 years ago my old man used to say "buy a Chevy or a Ford, anyone at the local gas station can fix it" with the shortage of technicians around its not bad advice.

My last 2025 rant.

0 -

The manual wants to be within 12 inches of the boiler.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

You need a new swirl plates as that crack will open when running. I'm certain that is your issue. The control chase is a red herring. This needs replacing anyway because you don't throw that back in an expect it to work. Peerless has a parts supplier online that you can get ship right away.

Your boiler, when properly maintained, will give you another 15-20 years of good service provided the installation is good (questionable from the pics, but reconnecting a new boiler into the same set-up will give you the same results). The installer is more important than the boiler. Like they say, you pay for ****, you eat ****.

0 -

I believe EBM PAPST is German engineering, the stuff in these boilers is tiny compared to some of their product line.

@EBEBRATT-Ed If you like SMA try Pine Hollow Auto Diagnostics.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

May not be a crack in the swirler.

@109A_5 Yes I have seen Pine Hollow. They have worked together on occasion

0 -

Looks like a crack to me, it looks like it is on both sides, anyway it should be verified. I'd try epoxy as a test before I spent any more money on parts, etc.

https://www.partstoyourdoor.com/peerless-5517-swirl-plate-red-9-mm

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Apparently that cracking is a known issue, however the cause is maybe unknown, at least in 2015. @Redrum you may find the post interesting.

Some folks feel it is worse with LP.

https://forum.heatinghelp.com/discussion/comment/1384524

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

More carnage:

From back in 2011:

Did some checking with HTP about "swirl plate" problems here is their comment:

I believe pre mature failure is due to two reasons:

The back draft of flue gases from venting system through heat exchanger and back out through swirl plate. The spent flue gases contain a great deal of corrosive condensate. The fix we used was to increase post purge on fan to clear all spent flue gases from venting system.

Another cause can be recirculation of flue gasses entering the cabinet and being drawn into swirl plate. Same material just from another direction.

About two years ago the manufacturer of the swirl plates changed what they are made of. They switched to Poly Propylene a more durable product that can also take higher temperatures. Swirl plates made of this newer material can be identified by the letters PP under the triangle on the back side of swirl plate.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

@Redrum I know you don't want to waste money on calling techs, you shouldn't trust anyone who doesn't have a digital combustion analyzer! It's simple, call around and anyone who doesn't have a combustion analyzer can be disregarded. All you need to do is find a tech who is familiar with condensing boilers and combustion analysis. You can do this over the phone without spending any money. I'd help you out myself but I'm in the Hudson valley and you guys have disrespected my Jets in this thread. (Lol, they deserve it).

The pictures of the inside of the boiler look good, it's nice and clean. If I was working on it I would replace the swirl plate and check the venting before doing the combustion analysis. I've seen boilers with similar problems where the venting was the root of the problem. Exhaust recirculation due to the intake and exhaust pipes not having the required horizontal and vertical separation.

It's great to see that someone at some point did a combustion analysis but it really needs to be done every time the boiler is serviced and repaired. I always leave a printout of the combustion analysis results in minimum and maximum firing rate at the boiler after I work on it.

That is a great boiler in my opinion. Once you get it tuned properly it you should get at least 20 years out of it with proper maintenance.

0 -

Hi Everyone, thanks for your comments, a lot to digest, I'll address everything, easy stuff first

@EBEBRATT-Ed - your "rant" is exactly where my head is at. My dad built the family house in '61, and installed a first oil boiler, and then converted to NG. I remember my mom replacing the original boiler with a Weil McClain in the late 90's. When I bought my home in '91, it had a Weil McLain, and I replaced it with a Buderus in 2016. We moved in 2024. With the WM I think I replaced couplings, then a pump when I found why the couplings were failing, air bleeds, a motor of the honeywell zone valves, pressure regultors, got everything local, and was never down for more than a day.

But I am still going to try to save this, and I will let the tech I trust help steer me properly for the new system

@SuperTech - Yea, but you don't know what the tech is going to be like when you meet him, and if you let him in the door, it's going to cost you and hour. One thing is stuck in my head, if this only stays lit for 2-3 seconds, is that enough combustion to analyze?

@109A_5 - I can't control where the test port was drilled, it came with the house 😉. Noted.

Also, 109, and the rest of you. I'll delve into the swirl plate more today, @pedmec , I hope that you are right, I'll pay a hundred easy for heat and hot water, in fact I'll pay…..

I zoomed in on the photo:

As I mentioned the "tech I trust" I have known for quite a while and he is big time into hydronics, AC, etc, and being an engineer, I appreciate when he talks the science of what and why. I may not understand exactly what he is saying in terms of the specifics as it relates to this, but I know it's not BS because I understand enough of the science to recognize BS. I'll see him today. I asked if he could perform gas valve measurements and a combustion analysis, but the main reason he is coming is for the new design.

I will mention the swirl plate to him, and we may take it out. If he doesn't, I will and get back to you, but I am betting he'll perk up when I show him. Edit - just spoke with him via text, he said "that'll do it". We are checking to see if we can get one locally (ERB supply in Buffalo). I don't mind this part, even if it's not the fix, it's broke and needs replacing.

I had it in my hands and it didn't feel like PP (I spent some time in plastic molding industry). It had more of a nylon look. PP is recycle number 5 ans the triangle is empty (see pic)

I'll look through those links now, thanks. The ones that go multiple pages (like this one) scare me. Maybe some day this thread will help/scare someone else!

Jim

0 -

One more thought. I imagine that this could explain an occasional but chronic ignite of flame failure that progressively gets worse, and is worsened by a dirty chamber. Thinking the crack slowly gets worse over time. The cleaning temporarily revives it because part of the issue is fixed, but then, as the crack worsens, the issue returns and one day it becomes terminal (in a day), perhaps because the crack worsens faster as it get bigger

Does this sound like a "maybe"? It would explain the symptom set that I experienced.

0 -

EDir - Disregard, they found one, going out to get it

so, my local supplier is out of stock, Supply house backordered until Feb/March, and parts to your door not shipping until 1/5. They said call for a heat emergency, I will after my tech comes.

I am wondering about @109A_5 's idea of epoxy (as temp fix). I have all kinds of epoxy, one being penetrating (its very thin, for stabilizing rotted wood). I am wondering about masking one side, use the penetrating to fill the crack void.

But, what kind of heat and other stressors would it be exposed to? Also, is there a flammability concern in this area?

Jim

0 -

"I can't control where the test port was drilled, it came with the house 😉. Noted."

I understand you can't control when someone does it incorrectly and before your time there. This is correctable just drill another hole where the manufacture states.

As far as heating of the plate, I would not think it should get too hot with a properly installed boiler. Since the combustion air should not get preheated much especially with the boiler's cover on and cold winter air being drawn in.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

So, here is an update, good news, almost, well, not really.

My tech (I trust) found a swirl plate locally, and the supplier tagged it for us just before it was going to get shipped out of state. They gave preference to an account holder (my tech). Turns out that Peerless told the sales rep they won't have any new ones until Feb, March. That jives with supply house. To me that is a head shaker that a manufacturer can't make sure parts that are prone to fail are available.

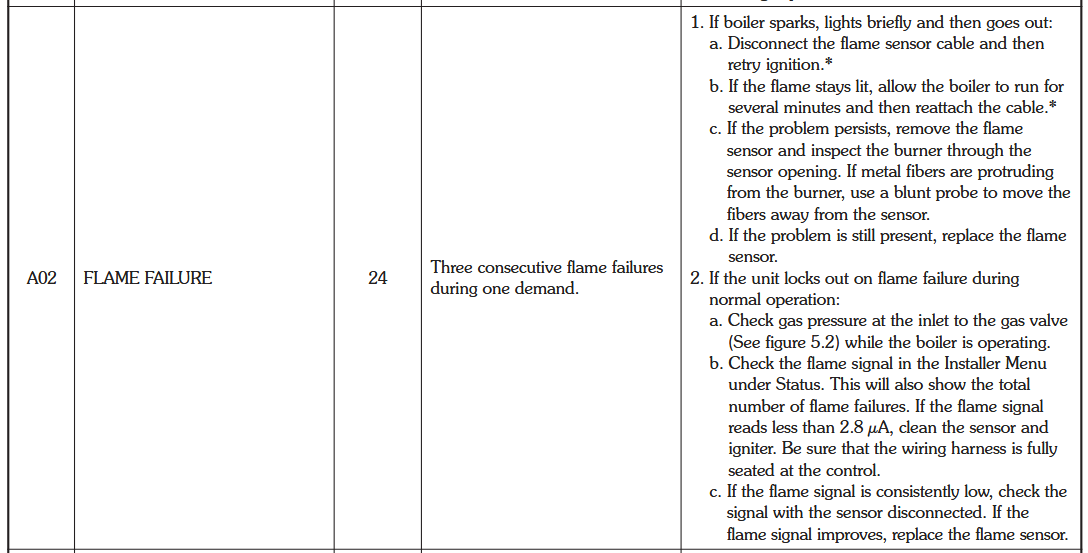

We installed it, and it fixed the A01 Ignition failure error (so it was definitely a factor). But, the flame extinguishes after, say, 20-30 seconds (instead of 2-3), causing an A02 Flame Failure. So, the benji for a plastic molded part got me a step further. I can read real good readings on the flame sensor in the installer menu where there were zeros before.

We got good LP pressure on the input, through the ignite, flame, extinguish cycle.

We could not get the outlet pressure to zero, it would climb to 3,4,5 during the flame period. He tried adjusting the valve, but it didn't seem to make a difference. So, we took apart the swirl, valve, and inspected the Orifice. Looked ok, except that there were a couple of what looked like hair we pulled out, might have been teflon from upstream piping.

He hooked up his combustion analyzer and struggled with that as well. First, the boiler only ran for 20-30 seconds at a time, and second, no adjustments could get the CO2 down. He was not pleased that he could not solve it.

He said that all recirculation was supposed to be off, so we did that, and "tea kettled" (new phrase for me), the boiler PR. At least we got to see the water color 😒. So, the rest of the test had to be done with the circulator on feeding the indirect.

All his adjustments were with the throttle screw.

So, we decided to quit, it's NYE, his wife was his next appointment, and we are doing just fine with our alternate electric heat and showers at the Y.

He will call his supplier (who I got the swirl from) to see if he can get tied into Peerless on Friday and come back.

I told him about how much you guys were helping me and I read back many of the relevant posts and he was genuinely interested, not just a "I know everything guy". We double checked a lot of things based on your input.

We are looking at replacing the whole mess with Viessmann (if Modcon), or he does Dunkirk if cast iron. I prefer the Buderus that I had, but he doesn't install them

So, the dilemma continues. Ideally get this thing running and take our time to design the new system (maybe install in summer). But, if it's a gas valve ($900 assuming you can find one), is it worth it instead of limping along for a couple more weeks, then week to install, so say a month, for a new system. I think I'd have to say the $900 is worth it, but it's on top of a lot more for sensors, controller, swirl plate, etc. I think it's about $2,500 of parts I am just tossing (or maybe part out)

So, the good news, the swirl plate was definitely a problem, just not the only one

All my best for 2026 to you all!

Jim

2 -

@EODagon - thanks, I can check vs the manual, but there is bound to be some variance. Can you tell me what specifically to look for? Or, can I take a few more pictures to help you all see what I have? Inside and outside?

That is something I can do before my tech comes back on friday

0 -

Failure to obtain negative pressure after adjusting the throttle sounds like there’s an obstruction somewhere, from the burner, through the heat exchanger, and then through the vent pipe.

It’s either that or the regulator in the gas valve is off.

Try temporarily firing the boiler with the vent pipe disconnected after you’ve visually confirmed that there’s no blockage in the pipe.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

-

-

First a little info, then answers to your questions/comments. My tech sent me a text with his notes to himself. Note that 1-4 are for the current system, 5-6 are for the next system

Tech wrote:

Notes for myself.

1. Supply LP pressure around 13w/c static. 9.2 w/c firing

2. Combustion access not 12 inches from the boiler, but does not run long enough to stabilize a good combustion reading. When it does, throttle adjustment swings all over . Even in high fire test. Had manometer on also to watch throttle adjustment. Swings from 7wc to 11, flames out when lowering throttle below 5 and won't lite at that inlet pressure. ( This should be zero to a negative reading)

3. One time was able to get the CO down to 14, won't run long enough to see particulate measurements. Once seen it at 2000 while CO was at 22. (12 is target)

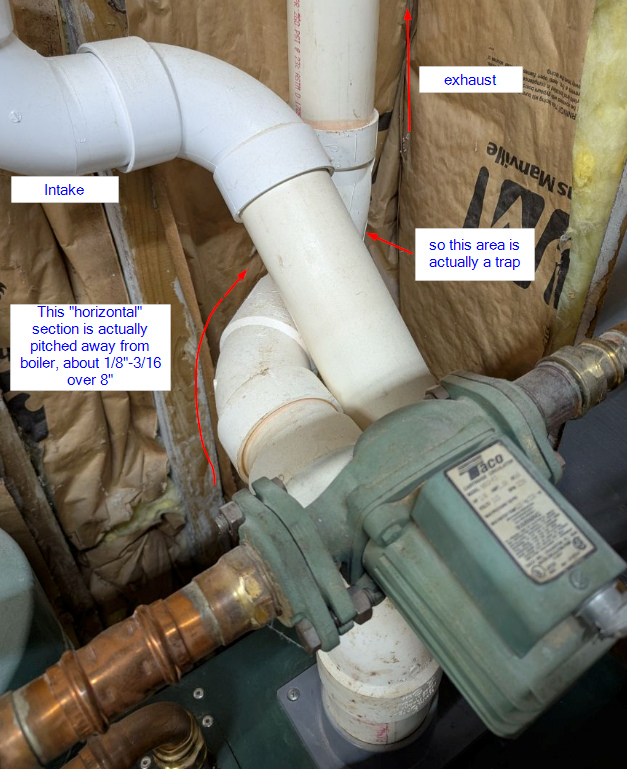

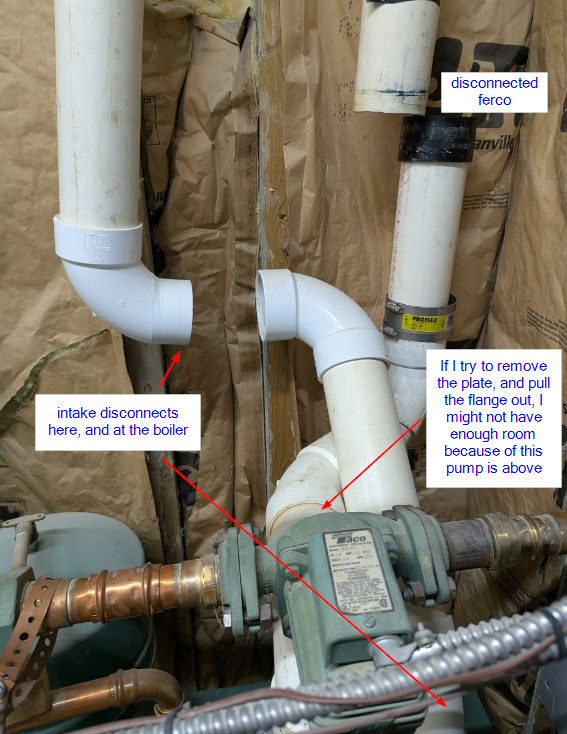

4. Condensate seems to be draining, although I don't like the venting materials used, not do I like the horizontal pipe (Missing pitch)

5. Non boiler issues, the system is not plumbed correctly with many issues. Pumps to close, oversized pumps, no tempering valves in radiant zones. Expansion tank is not piped to a purging area/ air eliminator.

6. no isolation, flow checks, bleeders. Boiler water is black (Probably from boiler before/ no flush)7. Simplify zone circuits to a pump relay, add adjustable flow balance manifolds to radiant) 8. Radiant. Doubt any drawings/layouts / insulation factors were performed. Do not know loop sizes, circuits has 2 with a mystery to bathroom at the moment.

My comments:

a) I'll put a level on the horizontal section, the manual allows for horizontal with a certain pitch. The manual also says that schedule 40 is ok.

b) Where the boiler lit for 2 seconds before (not ran), it now runs for 20 seconds. The control ramps up to 100% (because water is at room temp) and the fire in the spyglass goes from blue to a white. It's obvious that the swirl plate was broken, and it's obvious that replacing it fixed a portion of the issue

c) @109A_5 - Yes, we went through section 1 of the AO2 flame failure. Disconnecting did not allow it to stay lit, so - 1c) I had just had the burner out, and measured the gap between the igniter and flame sensors to the burner and both were in spec. Also, it was clean, no metal fibers, and, the flame sensor is brand new.

The burner mesh was cleaned (shop vac'ed) by me, and it looked clean, but what do I know? There was no visable build up and the holes looked open. Plus, Tech #1 must have cleaned it when he cleaned the chamber.

d) @EBEBRATT-Ed - as my kids would say "true that". I emailed with the previous homeowner (2018-2024) to ask who he used the service the boiler and he said it was only once and they did one of those "checkups" from a random tech service. The guy was rude to his wife, she gave it to him, and they were never asked back. My point being the boiler was replaced to sell the house to them, and it looks like it was never serviced in that 8 years. The water was quite dark/black, so I am wondering what type of boiler was in there before, and if the lines were properly flushed. There is a lot of copper, and some pex (including in floor)

So, to your point, something not run and maintained properly can start to fail in one way, which can trigger a fail in something else, and so on, until something catastrophic happens

Remember, I think this was giving flame failure lockouts for years before me. They had a fix kit. The owner said "it was a fault in their design". Knowing what I know now, something was wrong, perhaps as early as the install.

e) @Ironman - I'll take a look at the vent path you describe. I'll need to figure out the exhaust travel past combustion, as I don't know it, I am sure I can find it on the web.

Enjoy your holiday. My wife asked if I had any resolutions, I said "fix or replace the boiler"

Jim

0 -

The exhaust piping which appears to have a horizontal section, should be pitched toward boiler. It's not, it's pitched away as described.

0 -

Another thing I would try (if it has not been), if the house / boiler room is rather air tight, the majority of the combustion intake air will still come through the boiler's air intake even with the cover off. As a test I would intentionally block off the boiler's air intake and open the closest window or door from outdoors to the boiler (complete air path) and see if it changes anything when the boiler tries to ramp up to 100%.

Picture(s) of the intake and vent pipes outdoors ? Any bushes or other obstructions in the area ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Peerless does have Tech Support. The tech should call while on site.

0 -

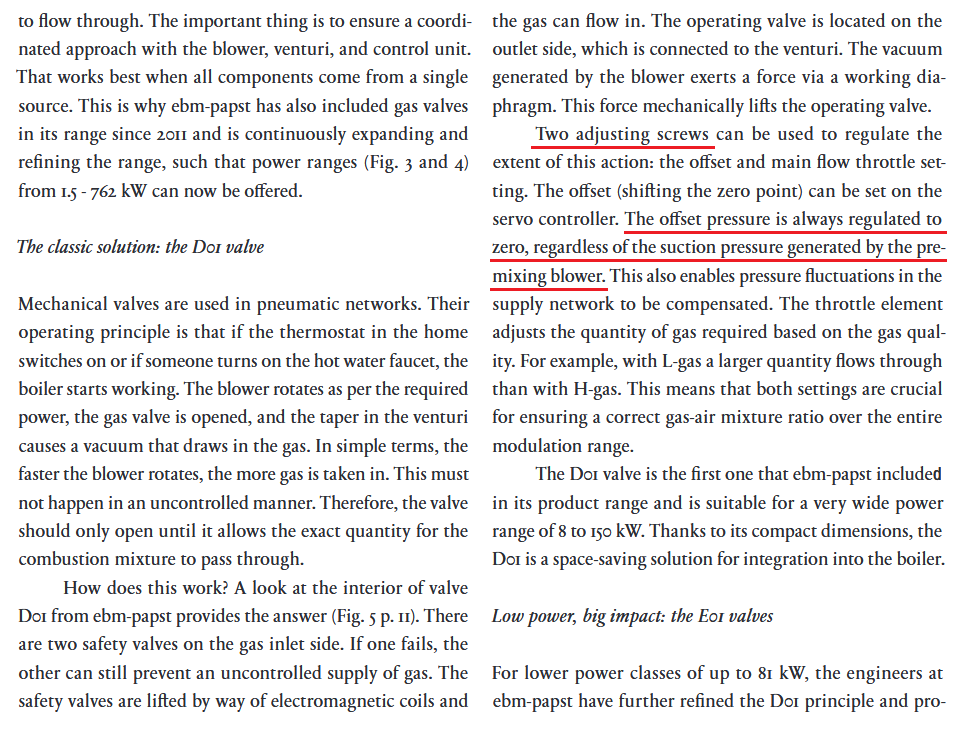

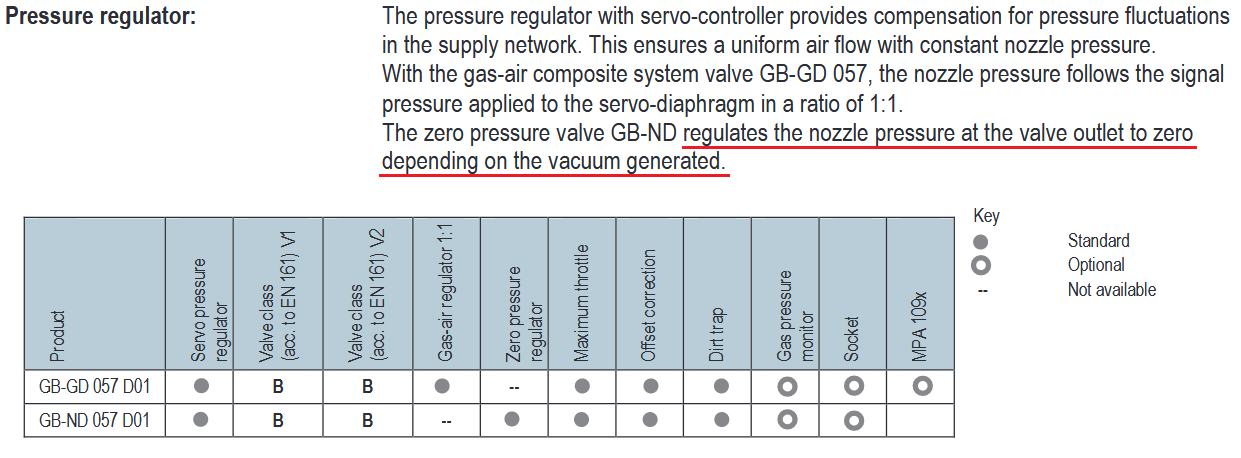

You may find this interesting.

https://www.ebmpapst.com/content/dam/ebm-papst/loc/europe/gb/tech-mag/techmag%2001-22.pdf

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Todays fun, which also may address, your comments, questions

I opened the combustion chamber again, and poured water between the exchangers, and saw the same/similar amount of water drain to the condensate tank. I could not figure out how to these the other condensate pipe but I guess I could just pour water in the exhaust vent.

But I noticed the previously cleaned chamber was quite blackened, perhaps because the tech was adjusting the gas valve. However, tech 1 cleaned it and it was shiny. I ran it for a month, it failed, but when I opened it, still shiny. After yesterdays work with tech it looks like this

Second, I wanted to check the vents as best as I could. I disconnected the exhaust at the fernco, and ran a plumbers snake from the outside to the fernco - it was clean. I found that the intake piping was just press fit in one spot, as it pulled apart. So I attempted to remove the fitting plate for both on the top of the boiler, but quit because it seemed like the exhaust side was in some type of gasket. I looked at the parts diagram and it looked like it had a tail, and I wondered if I could pull it out before hitting the motor above. So I chickened out. I checked the inlet venting all the way through, it's clean.

Outside, I'll get a pic when I go outside. But basically it's wide open (trees and bushes no closer than say 8'). The in vent is a PVC Tee with screens in top and bottom, the exhaust is a PVC horizontal pipe, maybe 4-6' long with a 45 turning down, also screened. Both seem to be above a reasonable snow level.

@HVACNUT - I am sure peerless does, the question is what the number is? My tech is going to call his local distributor who is a peerless dealer to try to get the number.

@109A_5 - thanks for the link from the gas valve manufacturer. I'll send it on to my tech. I know that the offset had a "do not adjust without the proper equipment!" flag in the manual.

As for your comment about blocking the input, will do. The house is very tight, it is a timber frame with SIP panels, and I have a HRV (which I have running 20on/40off). It was built with efficiency in mind (for 2001).

Which reminds me, I should be able to just run the HRV and close the intake vent, right? The HRV will provide the outside air. What will I learn from this?

One last thing - Ever since we installed the swirl plate and tried to adjust the valve, this thing, when running, has a bit of a smell, like combustion, burning, overdone toast, etc. Very faint. I am wondering and thinking that perhaps the swirl plate is getting heated and "broken in" or, something significant changed in combustion. I had not smelled anything like that before. Note though, it's very faint.

Happy new year!

Jim

0 -

I'm thinking presently it is running too rich. Which is too much fuel or not enough air (oxygen), or both. As a test forcing the boiler to use a different air source may help determine if the boiler is breathing its own exhaust.

Looking at the gas valve cut away view it looks like there should be no gas flow without inducer blower draft (vacuum) at the gas valve outlet.

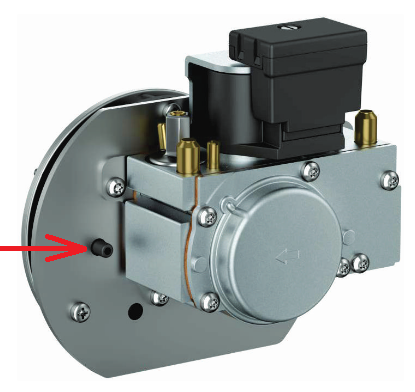

Gas valve cut away view.

https://www.techritecontrols.com.au/cms/uploads/Techrite-Controls-Ebm-Papst-Ebm-Papst-Gb-055-Wnd-D01-Whirlwind-Valve-1199.pdf

" We could not get the outlet pressure to zero, it would climb to 3,4,5 during the flame period. He tried adjusting the valve, but it didn't seem to make a difference. So, we took apart the swirl, valve, and inspected the Orifice. Looked ok, except that there were a couple of what looked like hair we pulled out, might have been teflon from upstream piping. "

Looking at some of the data sheets the offset correction (Servo pressure regulator) seems very small, but that may be dynamic. So I wonder if that adjustment is capable of adjusting out a static 3 to 5 Inches of Water Column offset.

If in fact it only just puts a slight bias on the metering of the main operating valve and can't adjust out 3 to 5 Inches of Water Column, i'm starting to think the gas valve has an issue. Like the main operating valve leaking or not seating properly due to contamination causing it to leak or not regulate properly. Causing the boiler to run rich.

They don't really state at what vacuum levels the zero pressures happen at. And how would the vacuum be measured any how ? Some inducers have a sampling port.

A test I would do is energize the gas valve with no inducer vacuum and see if it leaks, I suspect the control board logic may try to prevent this.

Another thing as a test is as the boiler ramps up to 100% partially close the gas manual shut off valve (restricting fuel) to see if it runs longer and the flame color changes less.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

Kind of wondering if this is a test port (inducer / venting performance), or maybe it is Top Secret.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements