Help with Peerless PF-140, Ignition issues, Control Board swap

Comments

-

If you can't get an adjustment out of the gas valve then the gas valve has failed. The blackened heat exchanger is a serious out of adjustment valve.

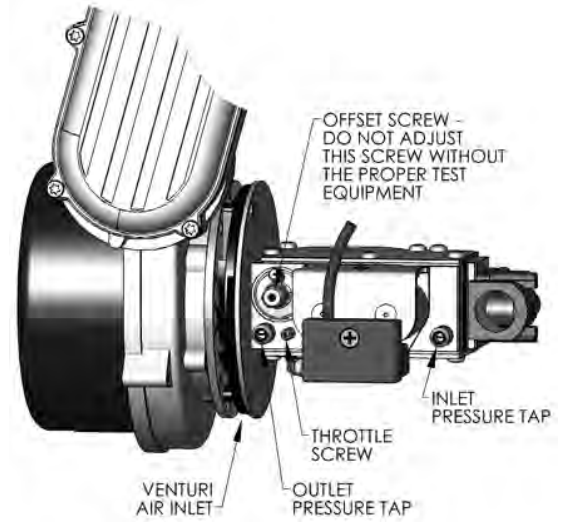

You can have your tech try and set up the old valve as if it's a new replacement valve. Turn the throttle adjustment screw, not the offset screw, counter clockwise which will completely close the gas valve. the throttle adjustment screw will have a plus and minus sign with an arrow stamped around it. After the throttle screw bottoms out, turn it back clockwise 6 full turns, paying very close attention to the number of turns. If the valve is good this will give you a starting point to get ignition and maintain a flame. From that point all have to do is tweak the throttle adjustment screw to get your combustion numbers where you want them. If you don't get flame or no change on the manometer at the test nipple on the gas valve then you gas valve is no good.

0 -

IMO the dysfunction in the HVAC industry is sad. The swirl plate should be aluminum. And the basic lack of information.

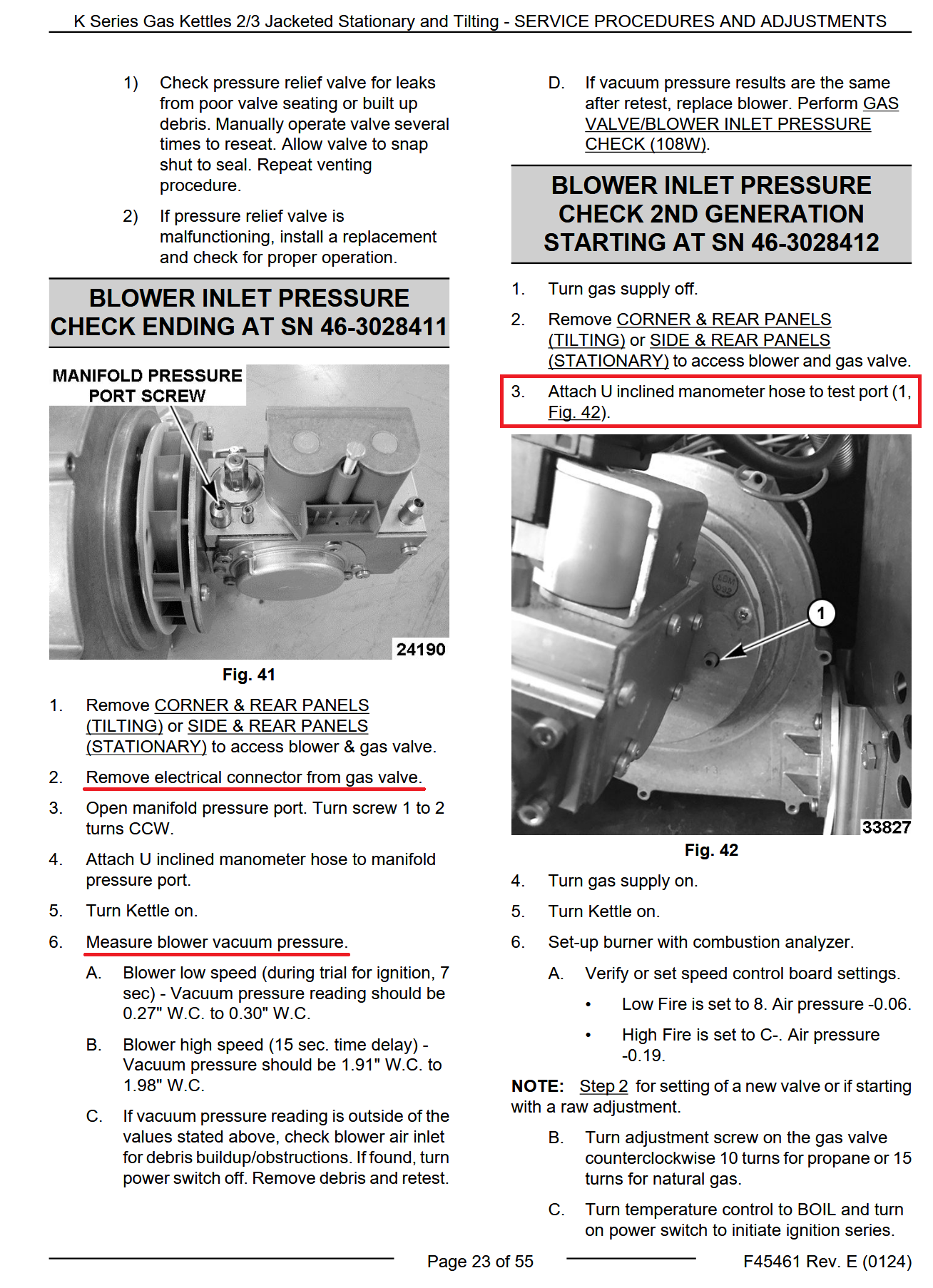

Also I found some more test information (different industry) on the blower / inducer / gas valve pressures. See page 23 and beyond of this document, and even this info. seems incomplete to me.

A U inclined manometer could probably be made with clear tubing.

https://www.vulcanequipment.com/sites/default/files/webdam_asset/83530244.pdf

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

All,

First, agree, it looks like the gas valve is next to try. It makes sense not only ffrom testing and your comments, but from history**

Great info that I have read over several times, each time a bit more sinks in. I finally understand the target value of 0 valve output pressure, or at least how flow is directly proportional to pressure, and if the system is designed for flow @ zero pressure, the mix will be much richer is pressure is increasing the flow.

The one thing that I don't quite grasp completely. The vacuum produced by the fan is opening the actuator in the valve, but once opened a proportional amount, at zero pressure there is zero pressure drop. Theoretically, there should be no flow. So, the gas is being drawn through the valve by the fan? So, the fan speed controls the amount of gas/air mix being delivered? If all that is true, then 3-5 psi of unrequested pressure "push" would definitely mess things up.

I mentioned history. I find it always helps to remember what did and didn't happen in the past, so if you start to chase something that logically doesn't make sense based on the history, you can remind yourself of that.

The history - This unit was never cleaned. The unit has recurring ignition faults and a few flame failures that cleaning the flame sensor helped, over years (not with me). Then the sensor clean no longer helped. The heat exchanger was cleaned. It ran a month just great, and died, terminal. Controller did not help, flame sensor and igniter didn't either. Swirl plate was bad, and the new one proved that, but changed a ignition error to a flame failure.

I try to look at the history and piece together what caused what, but it's hard to, logically. But once it died, it had to be something catastrophic (like control or gas delivery) because it just died, it didn't limp for a while first. It wasn't a build up thing. Sure, there were things like the swirl plate and thorough cleaning that addressed the limping, but something just died. Based on that and all of the above, the gas valve seems logical

We are looking for a gas valve locally, in the mean time, I'll try the few experiments mentioned previously

Cheers

Jim

1 -

I'm thinking the order of things being repaired / restored to normal may not be the reverse order of the dilapidation.

The greater the inducer draft the greater the fuel flow. So only the inducer fan speed has to be modulated for the burner to be modulated. Starting at ambient atmospheric pressure as the reference point, even though there is a changing flow rate that reference pressure at that point is maintained.

Personally I'd like to see better test procedures to determine a bad gas valve, bad inducer, restricted venting or other blockage causing venting back pressure. I don't like the change everything and hope for the best method.

I just wonder if the combustion analyze test port being so far away from where it should be makes the tuning process very difficult.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

This boiler has caused 132 responses here and it is still not resolved. Has anyone stopped to think about the KISS principle? We are engineering ourselves into insanity. We are building systems too complex to operate and troubleshoot within any modicum of reasonable time. We are becoming slaves to these machines.

Very soon, you will not be able to get replacement boards for these machines, even if you are willing to pay the fortune they charge. The large home appliance industry has been outed for engineering obsolescence. Your fancy refrigerator takes a dump and the board plus labor approaches 1/3rd the cost of a whole new machine so you buy another one—-for a 3 y/o appliance. Kids are not going into trade schools. We don't have the geeks who can test a board the solder in a replacement diode, resistor, or capacitor for a few bucks so you buy a board for $4-500.00. A guitar amp technician observed the reason she repairs tube amps only and no solid state is because they're still making good tubes so she'll have parts for the rest of her lifetime.

Homeowners cannot bear the burden of the diagnostic time it takes to track down and fix these machines any more than we can for our cars. It's insane and unsustainable. We are winning the race to the bottom in the name of efficiency, emissions, and convenience. We need a sane return to simplicity. People are paying big premiums for cars they can tune with a timing light, dwell meter, vacuum gauge and feeler gauges while sitting inside the engine compartment because there isn't all that junk blocking access.

80% CAT I appliances have received their death sentences. Soon, there will be only these complex monsters, so you had better prepare. You can learn electronics and how to replace board components but that does not address complex interactions, such as on this thread, that defy a simple logical troubleshooting and repair. If you old farts are good diagnosticians, you might want to consider opening training for the puppies coming up because most of my young technicians don't have the patience to follow a systematic sequence and understand all the interactions. We have modcons we're back out to weekly and the mfr. is out of suggestions. Back when I worked for a fireplace mfr., I was the factory rep. who was sent out to kill it or grill it. You don't see this in the HVAC business because the mfrs. don't want to incur the cost and liability so they much prefer forcing you to waste your time, without fair compensation, to battle with these critters. This industry has a very frustrating future ahead of it.

4 -

For the venting take a look at the termination. Like is there a wall or a bush that may cause re circ in low fire. The IOM has pretty good diagrams to go off of. Also with the gas valve you should zero it. Turn the throttle screw ( the one with the +/-) clockwise until it bottoms out. Then back it out 4.5 turns for LP. See if that gets it to run. Also if its going off on A-02. go into the installers menu and read the flame measure 1,2,3,4. If its losing flame signal their could be a problem with rectification. You could also try to get it running then go into the installer menu read the live flame signal and watch to see if the fire goes out first or if the controller loses the signal then the fire goes out. That way you can narrow it down to a gas issue or a rectification problem. Also 13"wc is kinda of high. In the manual they say 13.5" can damage the valve.

2 -

" You can have your tech try and set up the old valve as if it's a new replacement valve. Turn the throttle adjustment screw, not the offset screw, counter clockwise which will completely close the gas valve. the throttle adjustment screw will have a plus and minus sign with an arrow stamped around it. After the throttle screw bottoms out, turn it back clockwise 6 full turns, paying very close attention to the number of turns. "

" Also with the gas valve you should zero it. Turn the throttle screw ( the one with the +/-) clockwise until it bottoms out. Then back it out 4.5 turns for LP. "

Even this above does not seem consistent.

In the cutaway view, it looks like the valve should be closed with no draft. The throttle adjustment screw just changes the preload on the spring on that valve, so the valve opens proportionally to the draft flow for proper burner operation.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

@EODagon - Hi, I forgot to add the venting pic. Previously 6 turns were mentioned, but to confirm, 4 1/2 for LP? Previously, before swirl plate replace, it never made it past the 4 seconds before 1.2.3.4 are measured, so they were zero. With new swirl plate, it makes it 20 seconds, and I get good 1,2,3,4. But, I'll double check, and I'll also try to see if fire or signal drops first. I'll test and report.

But, we followed the flame failure test where you disconnect the flame sensor and run it, and it stops running as well. The manual inferred it should keep running although I don't know what. I have never understood or had exposure to the control algorithm.

@109A_5 - I know that when the tech returns he plans on drilling in the right spot.

Right now it looks like finding a gas valve will be a challenge which will lead me to replacing this boiler. In addition to what @Bob Harper mentioned, the cost of the parts (in addition to availability) along with @109A_5 comment regarding poor debug process leading you to uncertainty that the expensive non returnable parts will work, the mounting cha-ching, and the mounting hate for the brand, just drives you to moving on, and if that becomes widespread, damages any value they have in their "brand".

If I find a gas valve, the parts that I will have bought for this are about 1/2 (HE) to 2/3 (CI) of the price of a new equivalent boiler

I digress, off to testing…

1 -

so, is it 4 1/2 turns or 6? Is it referenced in the manual anywhere? I could not find anything, "throttle" only appeared on page 33

0 -

todays first test - I opened the inlet pipe where it is pressed fit, and blocked the inlet to the boiler case, made sure the HRV was running, tried to fire it up, no difference.

Flame signals 1,2,3,4 were 3.4, 4.4, 4.5, 4.6 uA

One thing that I noticed, at the end of the 20 seconds of running, you can see the flame lessen, and it seems like the inducer fan is speeding up to try to save it. It looks like it "almost" saves it before it extinguishes. I'll video and edit this post

EDit, here's the link. I included the "real time" (with a latency) flame signal in the view. Note how it fires up, and seems to be going, then starts to fade, the fan kicks up a notch, the flame revives a bit (redder) and then extinguishes.

I am doing this without my tech, so no manometer or combustion readings yet today. I think I'll go work on something else for my sanity.

1 -

Its from another one of their boilers manuals that use similar valves. 6 to 7 turns is for Nat gas. If there is a rectification problem you can try to clean the mating surface of the burner tube. Theres a little recess that the burner sits in. If they gets fouled up it can screw with rectification.

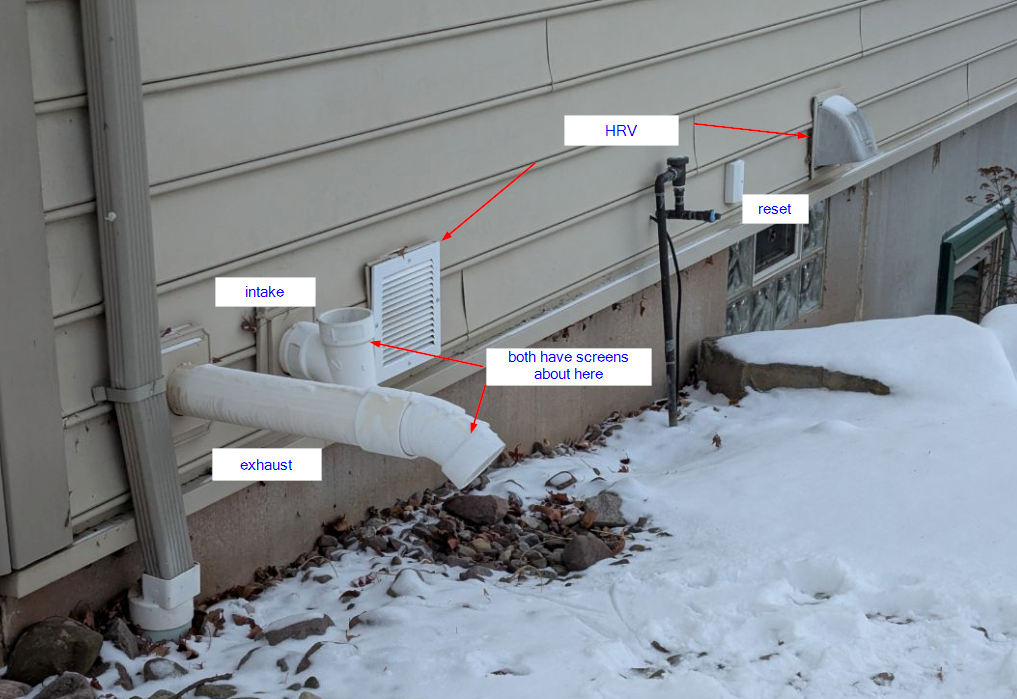

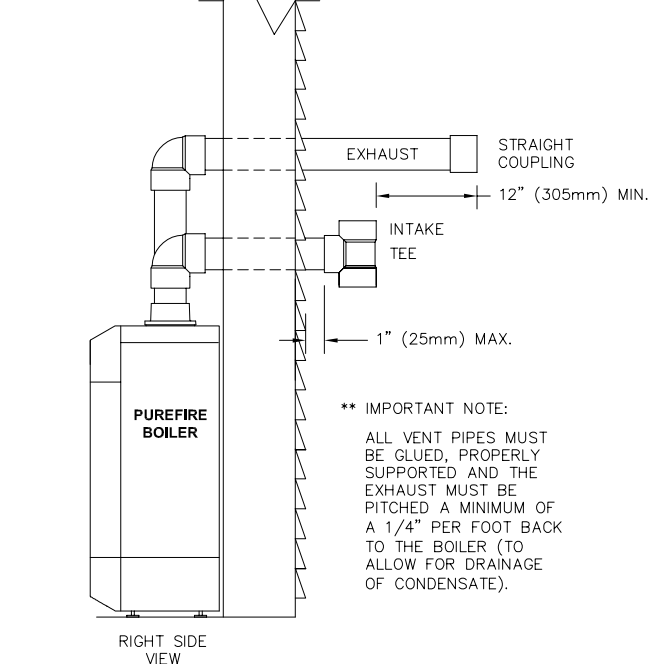

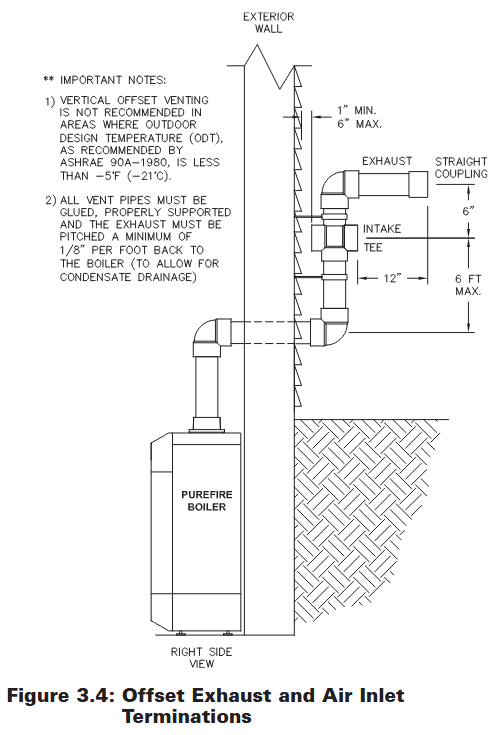

whats the distance from the intake and exhaust? Here is the diagram from their IOM

0 -

I have not measured it, but it looks like the start of the tee is about 1", and the end of the exhaust has to be the 12" or more. Besides, I disconnected and plugged the input, and tried to start it with inside air, and no go.

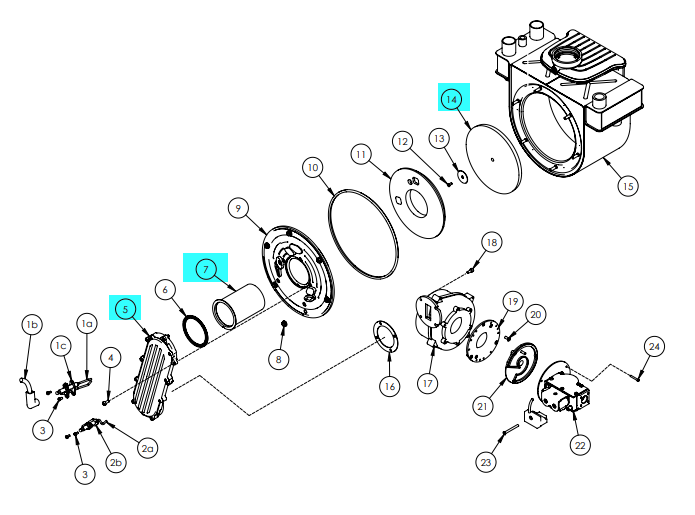

Burner tube - mating surface to 5 or 14?

The good news (for all of our sanity) is that if we can't find a gas valve (and I am betting we can't), this is it. I give up. Plus I will save the 9 hundred for a valve, and put it toward a new system.

0 -

Sorry i didnt see the video link. Have you tried to hold your hand over the swirl plate as its running. That will "choke it out" a little and see if your running to lean. Also on the left side of the gas valve toward the top is a little brass nipple with a very small hole. Make sure that is good and clear. You can also cover that hole with your finger if it stays running that mean the diaphragm in the valve is bad and the valve would need to be replaced. I feel that could be caused by excess inlet pressure. These valves are super temperamental.

0 -

I can remember starting up some Trane neg. pressure gas burners in their roof top units. I always checked the gas pressure and whatever they wanted (forgot the spec) I had. I always used a U tube manometer.

Then Trane came out and said "Under no circumstances ever adjust the gas pressure in the gas valve. There units had stickers and paperwork saying that.

Of course, I then had a couple of units that didn't work right.

Checked the GP and it was off. I think I had to break a seal to adjust it (forgot) but I did and it worked fine.

0 -

Hi @EODagon - Let's make sure I am clear, from the manual:

and my valve:

Do I have it ID'ed correctly? Also, how to clean? I have a cleaner tool for small carburetors (small engine repair) something like that? How far will I penetrate when it's clean?

will do on the tests involving the swirl and finger over the hole

I think I mentioned before, a trial combustion smells funky enough to notice

0 -

Yea that's it. Iv used a piece of brass i took from a brush and just run it up and down. just the length of the nipple.

0 -

A funny thing happened on the way to the scrap yard…

It works. I brought it up to temperature, circulated a bit, filled the indirect with hot water, and I'll be shutting it down for the night, as tech 3 will come over and do the CA and any other adjustments.

So, what happened? I did two things, and I wished I had tested in between

- I probed that little nipple on the valve above the offset adjust (thanks @EODagon ) with a brass wire brush. I did not try to thread the needle on something that small and that low, rather, I just pushed the brush on it a few times.

- I turned the gas valve CW down until closed, then backed it out 4 1/2 turns. It fired up and just ran

Recreating in my mind what happened if it's #2. After a cleaning and running for a month, something happened to cripple it. Probably the swirl plate. Possibly the swirl plate was compromised for a while, or things weren't adjusted properly by the previous owner, who knows. It stumped tech #1 and he said control board which I tried. I had tech #2 over and he was struggling with trying to get the outlet pressure right. Adjusting the throttle. Note the swirl pate was bad but it was not known. Before Tech #3 came out, with your help I found the cracked swirl plate and replaced it. Tech #3 (we believe) made all throttle adjustments from where the screw was initially (counting turns). I don't think he knew, or I remembered, what tech #2 did. Nor do I know it tech #2 put it back where it was before he started adjustment

I cannot begin to thank you all for your time, and especially for sharing knowledge and experience. I am on a couple electronics forums where I am you, and I find it rewarding, but you need to here it from people like me who really appreciate the time spent and patience. You all play nice together too 😉 I look at that boiler that I spent 2 weeks with and I feel I really know and understand it. Not the minutia like you all, but enough.

My path forward - first, pray that it starts up tomorrow, and then just get through the heating season and replace the boiler, my old indirect, and much of the plumbing that really wasn't done optimally. Sitting here today, I can tell you I definitely am going cast iron, Buderus preferred (my previous boiler). I find the condensing technology fascinating, but in the north east, in winter, nobody to service, no parts, I'd rather go skiing for excitement and come back to a warm house and hot shower.

We will see you around, especially if it running is an aberration, or this is just a dream

Jim

4 -

Well it is great to hear it is running. Perseverance for the Win.

Instead of just scrapping it, maybe when the change out happens I'd parts it out on eBay, may help someone else out and recover some money for you.

I wonder if the smell is the exhaust gas being recirculated back in to the boiler. I really don't like that exhaust vent configuration. Having the exhaust at the same height as the intake and then pointing down may contribute to exhaust gas being recirculated. You want the vertical isolation, shown in the previous drawing but the dimension was not specified. And 6 inches is probably a minimum.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I don't like the venting picture at all. Not enough separation between the the intake and exhaust to prevent recirculation. You typically want the exhaust at least 12-18" higher than the intake so the exhaust can't get pulled into the intake. And the intake should have an elbow pointing down, not up. Screens can do harm than good at times, ice can buildup on the screens. I don't think that any of this is the entire problem, but it could be contributing factors to why the boiler got so dirty and ran so poorly. I wouldn't vent a replacement boiler like that.

@Bob Harper is so right about how ridiculous it can be to repair this stuff. And a modcon can be a piece of cake compared to a multi zone VRF inverter heat pump or even a mini split.

0 -

As to your comments -

I'm not inclined to change the venting for the remaining few months of this boiler's life. First, on the intake, it's not an elbow, it's a tee. Second, to get a change in elevation I would have to angle/straight/angle the PVC for the elevation change as the two pipes are horizontally through the rim joist. Finally, I am 99% sure that I am going to replace with a cast iron, so there will be a different direct vent that will take it's place.

The screens are not screens they are big critter and debis barriers, wire mesh with maybe a 1/2" opening. I imagine mice could get past them, as you need 1/4" in our area to prevent field mice. Maybe it's the height, with nothing to scale, that prevents the mice

My heart wants to embrace another mod con, and tech #3 tells me the Viessmann's are real nice, but my head tells me no. Not with something so critical. The helpless feeling is similar to when my truck throws a code that I have never seen before.

As for the smell, it's gone, and I am almost certain it was an awful mixture that when I reset the gas valve (CW to stop 4 1/2 out) and it fired right up, no smell. Also, remember prior, when I opened it it was black in the chamber.

The fact that the number of turns to reset the throttle isn't published is dumb. How many small engine carburetors have we worked on where we get lost, with the mixture screw, dial it in, and back it out. What happened here is tech #2 (and possibly tech #1) adjusted the throttle, and never returned it to it's original spot. Who knows if it was ever in it's correct spot to begin with. Tech #3 came in, made some adjustments, but returned it to where it was before he started.

In the manual there is zero mention of resetting the throttle, even on the page that is tech only (adjusting pressures and combustion). They appear to give all the info to the qualified, yet, they hold some back.

One last thought, one observation that I had that didn't garner many/any comments - the flame modulation and poof, poof, poof during ignition. I told you that before all these issues (when I first met this boiler) each ignite would poof 5-6 times, and the flame would slightly flicker (modulate). When the tech#1 cleaned it, it reduced, I noticed it, 3-4 times. Now, with the new swirl plate and the valve adjustment, it's "poof", then light. I think the poof,poof,poof was a symptom, perhaps of the bad swirl affecting the venturi's control of the gas delivery or the mixture of gas and o2 (if I have that right)?

I really wonder about parting a boiler out on ebay in terms of risk, danger, liability. When it comes time, if it's still running, I'll probably ask my tech if there is an organization that I can donate it to.

Thanks again, sincerely

Jim

0 -

" As for the smell, it's gone, and I am almost certain it was an awful mixture that when I reset the gas valve (CW to stop 4 1/2 out) and it fired right up, no smell. Also, remember prior, when I opened it it was black in the chamber. "

The actual smell may be gone because the combustion is probably much better than it was. What I as getting at, is if the exhaust gases were not being recirculated you probably would not have smelled it at all, unless you were outside. For the short term I'd just extend the exhaust vent pipe out a bit.

As far as eBay New, Used, Previously owned, New Old Stock, HVAC parts are sold there all the time. Take a look.

With the Poof thing, with so many issues, flame detection rod / igniter, contaminated heat exchanger, swirl plate dilapidation, gas valve tuning, combustion analyzer port in the wrong place, exhaust gas recirculating… The poof thing is probably just a side effect of the issues.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

Mine looks like your first one, same height, except your first one it looks like there is a joist bay in between (32") where mine is adjacent (16"). I think mine extends quite far, it's just the camera angle. I'll measure and post just for completeness, and yea, I can extend it.

I am thinking the smell was not recirculation because I smelled it when I separated and blocked the intake piping, having it draw from room air.

Tech came, CA values in range low and high fire, we has to tweek the throttle the tiniest bit CW

I put the cover back on for the first time in a while 😊

Jim

0 -

-

I’m glad to hear that you got it going!

What you found off was what I was referring to in my last post where I mentioned that if there wasn’t a blockage in the flue gas path, then the regulator in the gas valve was off.

I know this has been a nightmare for you, but it all started with well-intentioned, but less than knowledgeable tech sending you down the wrong path by condemning the control board. In reality, all that was needed was a good cleaning, a swirl plate, and the combustion adjustments being done properly.

The lack of knowledge in this field is really a shame and inexcusable considering what’s available with training classes available and sites like this one on the internet.

Personably, I’d keep the boiler until it gets near its life expectancy which is 15 years or until something major goes.

Going back to cast iron may seem more reliable, but the new ones have just as much electronics as a mod/con and you’d be dealing with the same level of competency available to repair it.

You’re a smart guy: use the internet to educate yourself about your boiler and how it operates and you won’t get caught depending on someone less knowledgeable to repair and maintain your boiler.

And by the way: Buderus isn’t offering gas fired cast iron boilers any longer thanks to its parent company Bosch discontinuing them.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Hi Bob;

Thanks for your comments~

"I know this has been a nightmare for you, but it all started with well-intentioned, but less than knowledgeable tech sending you down the wrong path by condemning the control board. In reality, all that was needed was a good cleaning, a swirl plate, and the combustion adjustments being done properly."

A great assessment/summary. But along the way the one thing that was exposed is the answer to the question "what's the best system?" Its the one where you have knowledgeable techs, and parts are available. Fail.

All of you wonderful people that supported me said many times "There is nothing unique about peerless, you just need a good modcon tech" But I could not find one or worse (Tech #1) I find one that is masquerading as one. How am I to know? Peerless does not have a customer support number, my 3 techs did not know the peerless tech number, and I really didn't find the distributor until late (when I had the pleasure of buying an igniter, sensor, and piece of plastic (swirl) for the prices I did). Even though my career was electronics, our products came in molded plastic and I understand the various materials, molding processes, and costs, as I doubled in fixing molding machines as well. I won't say what that part cost the manufacturer.

But in the end, I do understand how the mod cons work, and I am better for it, similar to understanding hydronics having lived with them all my life. But I also feel with my 2 week experience, that the extra, say 7% efficiency comes with a price. That price is worse as the end user isn't told, or doesn't listen to "you have to maintain these things with a qualified tech, no exceptions". People are coming from cast iron boilers (like me) and thinking "yea, I'll clan the burners from time to time" Yes, you should, but with CI it isn't as risky if you don't as it is for these.

My tech #3 and I are going to kick the new system down the road until what he calls "new system weather" - summer. My brain tells me cast iron, and I have found nothing in terms of discussion that tell me I am making a huge mistake. But at the same time, I will let my tech persuade me that Viessmann are different, with reliability, support and parts. There are other parts of the hydronics that while working well, could be better, so we may redo the copper and pump wall, but that scares me more than a new boiler. I can't imagine the cost of all that copper, pumps, fittings, etc.

Yea, I was starting to realize that Buderus Logano isn't really around anymore. Shame. Tech #3 sells dunkirk. Not sure what is up there with Buderus, as Weil McClain seems to be turning to the HE as well.

Jim

0 -

While you are waiting for "new system weather" do some research into the present cast iron choices (read the manuals). It seems the cast iron choices are disappearing.

If you don't like what you find you can always buy a Combustion Analyzer and a Digital Manometer and do your own maintenance and be your own good modcon tech. Many folks on this site have come to the self maintained conclusion.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

-

I think for some folks it does become like a hobby, with others it is the cost of service calls that don't get issues resolved, so their labor time is free to themselves. Sometimes it is just simpler to deal with yourself.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Hi Bob;

I'll grab a previously posted picture for the description:

All of the way to the right, there is one secondary loop that supplied two zones of fin tube baseboard, the great room, and the master floor. The heat mixes because the master floor has an open loft.

Next, to the left a bit is a secondary loop that feeds 4 zone valves. Two of them are in floor radiant that each heat the two half of essentially a half height basement level (we are on a slope). One is living space, the other essentially basement.

One of the other valves provides in floor heat to the master bath, the other supplies a panel radiator to the first floor bath. Not sure if the panel was planned or an afterthought.**

There is also a panel radiator in the laundry room, but I have not figured out what feeds it yet. There might be a thermostatic valve on it, I just haven't spent the time to look. The laundry area is warm, so no hurry.

So, you can see the temp gague on each of the two secondary loops, the one to the fin tube reads about 160, and the other in floor loop about 120, so they must be using one of the two pumps in the middle to mix.

Tech #3 on a new install would like to redo this wall to eliminate all zone valves, use ecm pumps in their place, use mixing valves, and get some of the supply/return spacing further part.

Everything he wants to do sound great, but I look at that wall of copper, and when every pump, valve, etc costs $ add it all up (in my head) and it scares me considerably. Actually, what I think about more is the value changing it returns in terms of comfort, economy, etc.

** in thinking about the panel rad in the first floor bath, the other two baths are in floor, so perhaps they used the panel on purpose because of how baseboard can deteriorate in a wet environment, get it up off the floor and a panel is enameled finish

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements