Help with Peerless PF-140, Ignition issues, Control Board swap

Hi;

I'll try to be thorough with the details, I'd be happy to elaborate on anything with more sorted detail.

I am a homeowner, end user experience with Weil-McClain, and Buderus "standard" hydronic boilers for, say 30 years. We recently moved into a house (18 months ago) that has a Peerless PF-140 Rev 2 with a more sophisticated loop (both baseboard and in floor, primary and secondary loops), and uses a Tekmar 363 for much of the control (as far as I can tell). It's mystery box to me. The system also has indirect HW. The boiler was installed 2018.

The first winter we had ignition/lockout issues. The previous homeowner had a "kit" with extra sensors, sandpaper, and a $bill. Cleanup fixed, then it reoccurred a couple months later. Spring came.

This winter the fault occurred more frequently, until finally I had a hard time keeping it running one day. I also experienced flame failures (which would cause a resonant sound) I called in a contractor who was NOT experienced with Peerless (but said he was), he determined it needed cleaning, he came back and cleaned the cylindrical combustion chamber which was dirty (I have pictures, before and after). That resolved things for about a month.

The issue is back, and it's worse. The boiler started it's old ignition failure lockout, I'd reset, run, failure, lockout…, etc until now it just will not start. In fact, in previous failures you could watch through the watch glass and see it go "puff, puff, puff (ignition sounds) as it tried to light, but now it's one puff and nothing. To me it seems like the control is triggering the ignighter, sees nothing, and flags the failure.

The contractor came back and checked many things and was obviously struggling, he even had the control board out of the module and said there was "corrosion". There wasn't. I'm an EE that designs and debugs PCB's.

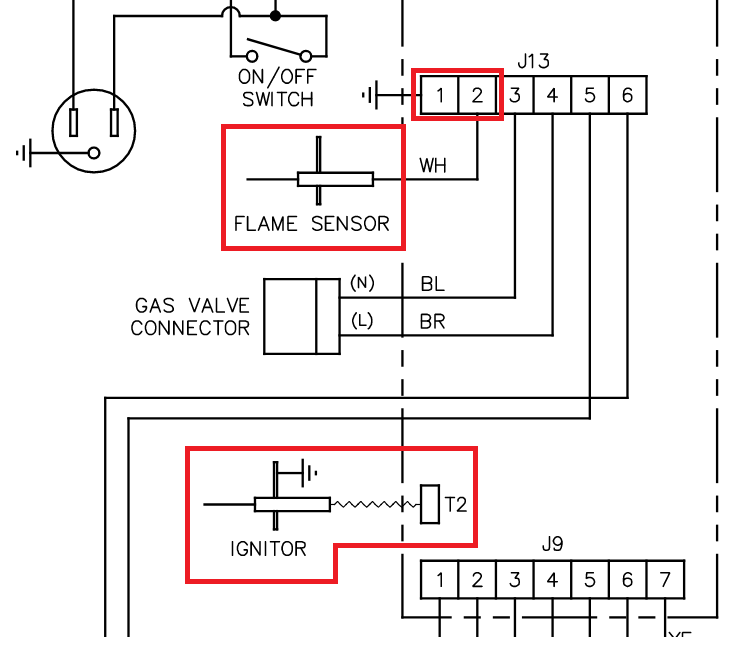

He might be right. we see current coming from the flame sensor to the PCB (ammeter inline) but in the installer menu (which I showed him) there are only zeros. I had seen good values before. I also checked to make sure ground is good (e.g. board ground to boiler to copper piping), and also made sure the ignition wire is NOT continuous to ground.

I agreed to have them install a control board with about a 100% markup, but they never told the supplier to hold it, and someone else got it. That somehow became my fault. My contractor says "no one in western new york" uses peerless, and said he can't get another board for a week to 10 days.

So I identified and bought the module and display board (kit) from supply house and had it overnighted. I have it now. But my contractor says they won't install it (possibly liability, lack of markup, or the fact that I told them I prefer solutions to excuses).

We have been without heat and hot water for 5 days (using space heaters and out fireplace). The holidays are here, things shut down. We are doing ok, but have to go to the Y for a shower :).

I told my contractor that I am about $1000 in labor into them and all I have to show is a cleaned broken boiler. They are claiming this is a "new problem" Possibly, but the same symptoms.

So, my questions (finally):

- Anything else to try. test?

- I feel I am capable of installing the new control board and display, but I am not sure what settings I have to record on what menus to transfer over to the new controls. Then there is the old "what if that's not it" and returning the $900 kit to supply house (if they take it)

- I have not found anyone in my area that is experienced with Peerless, and my patience has run out on working with the current contract that doesn't. I asked him if he could contact peerless. He said "they don't answer". Should there be a local manufacturers rep that can steer me to someone with experience?

As usual, I am grateful to you all for any insight you can supply

Jim

Comments

-

-

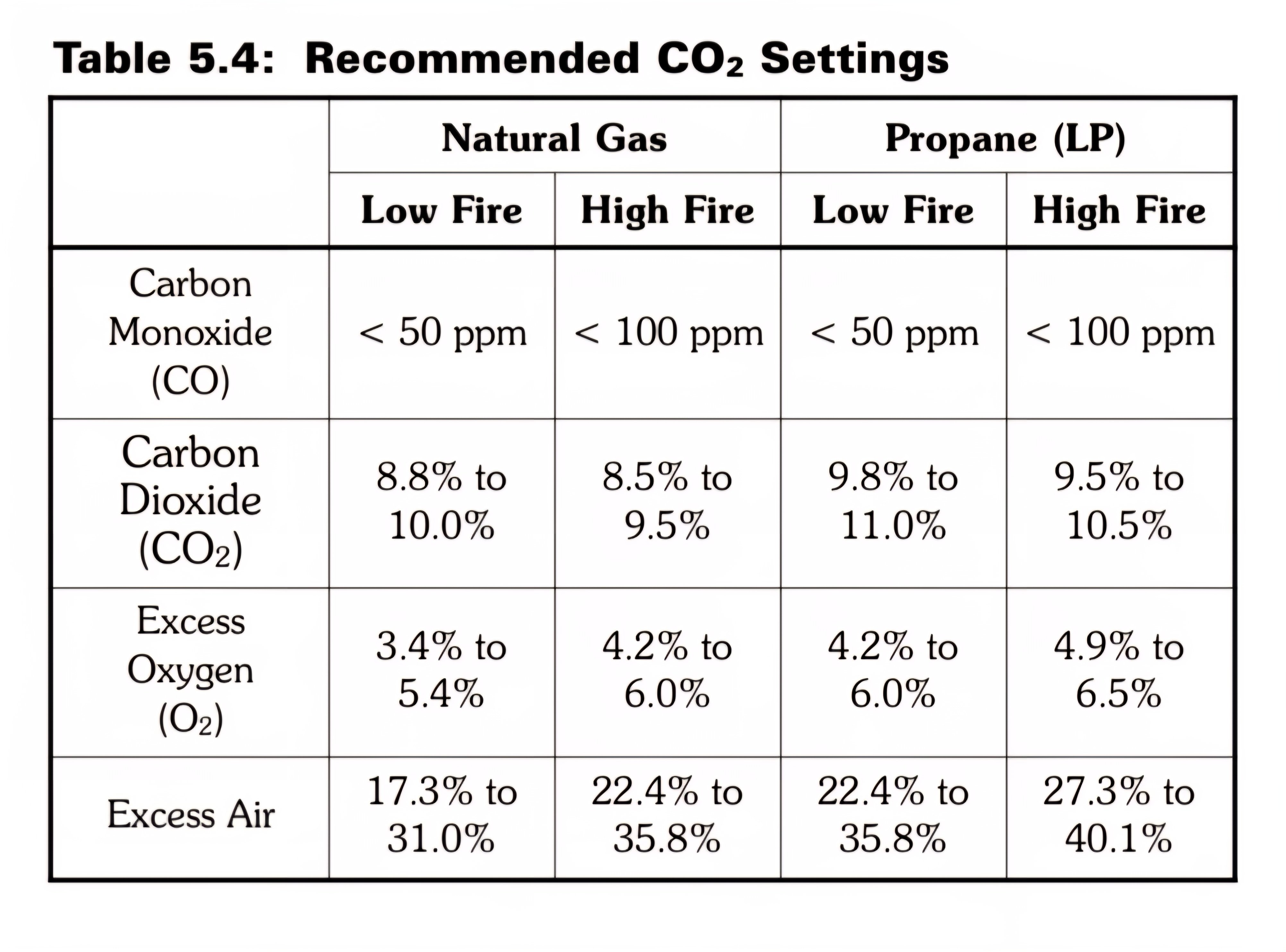

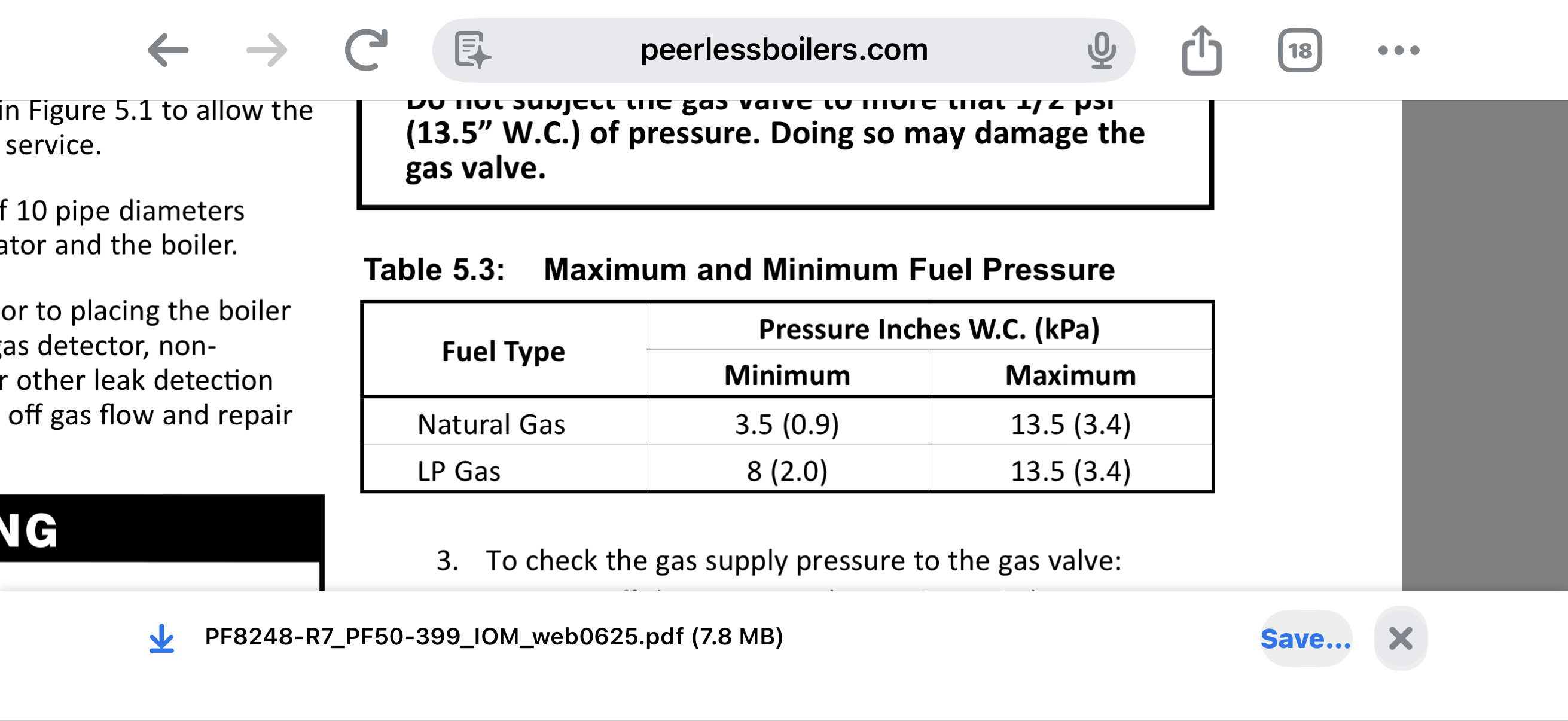

Thanks, I realized I left a couple things out. I am so used to Nat Gas I forget to mention we are on Propane. Also, we are switching supplier, and the new supplier coming Monday wanted our tank (500 Gal) below 30%, we are at 23% right now. I immediately suspected that (

The tech did test gas pressure (as we had to consider the low tank) but it was good. Combustion test not to my knowledge. He complained that something was "siezed" on the gas valve. I know he had to disconnect the supply hose to test the gas.

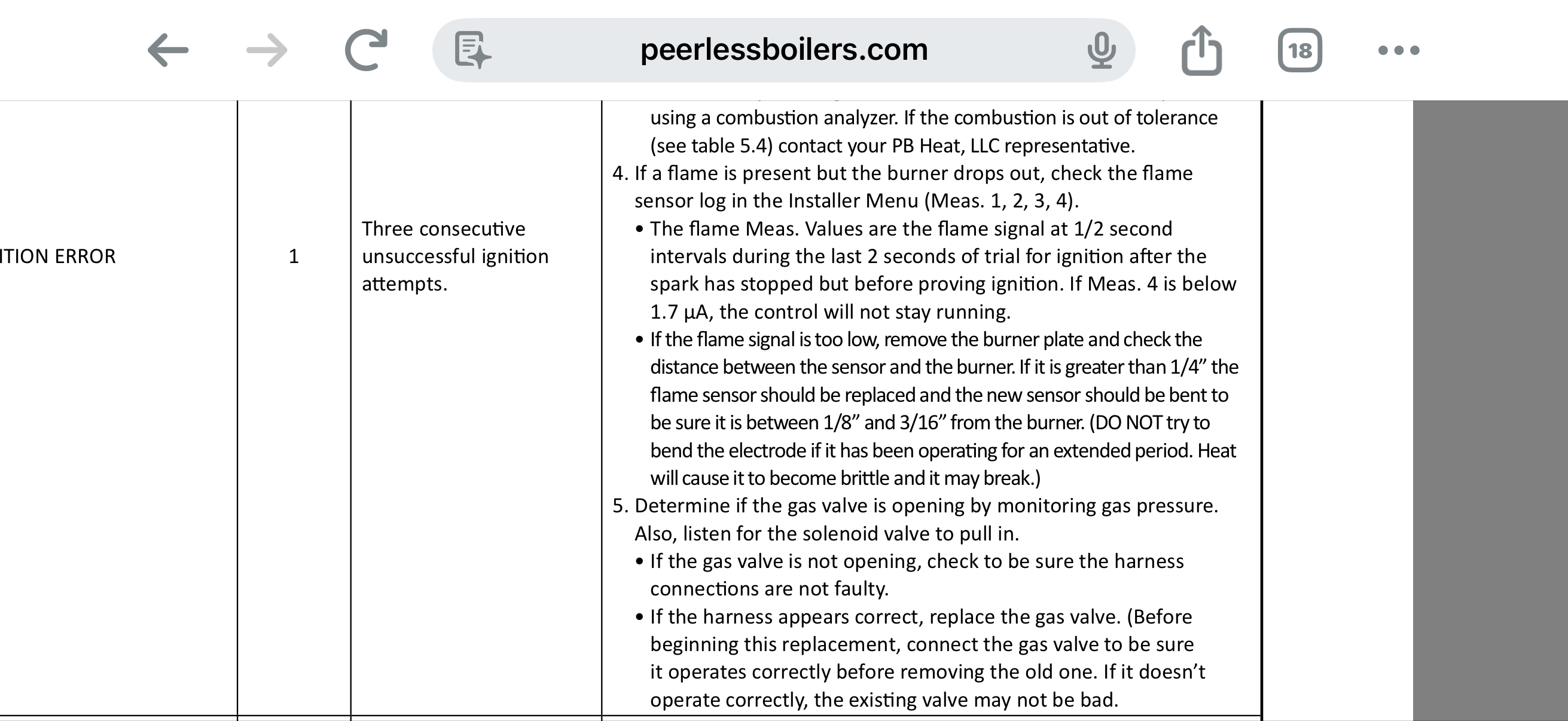

I also found this in the manual which makes me less sure it's electronic, and maybe is gas:

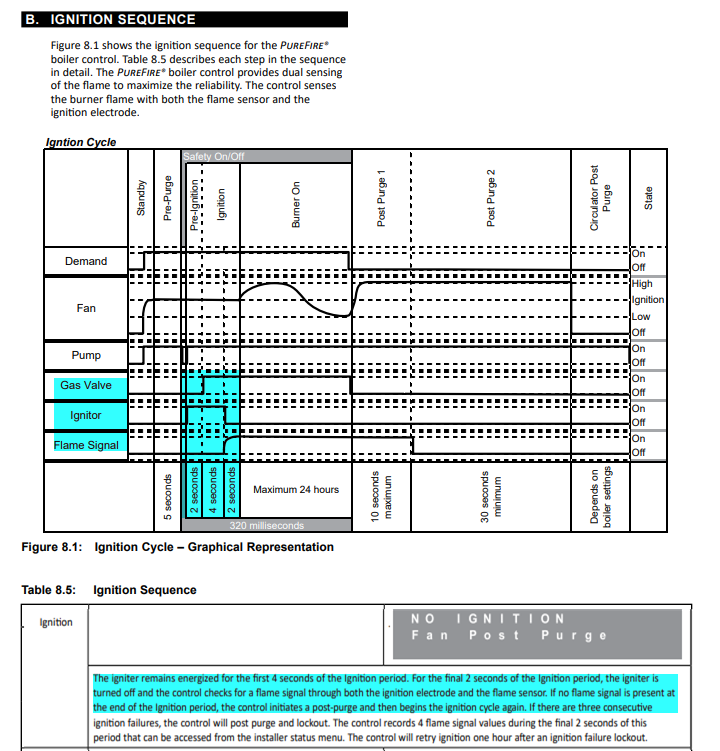

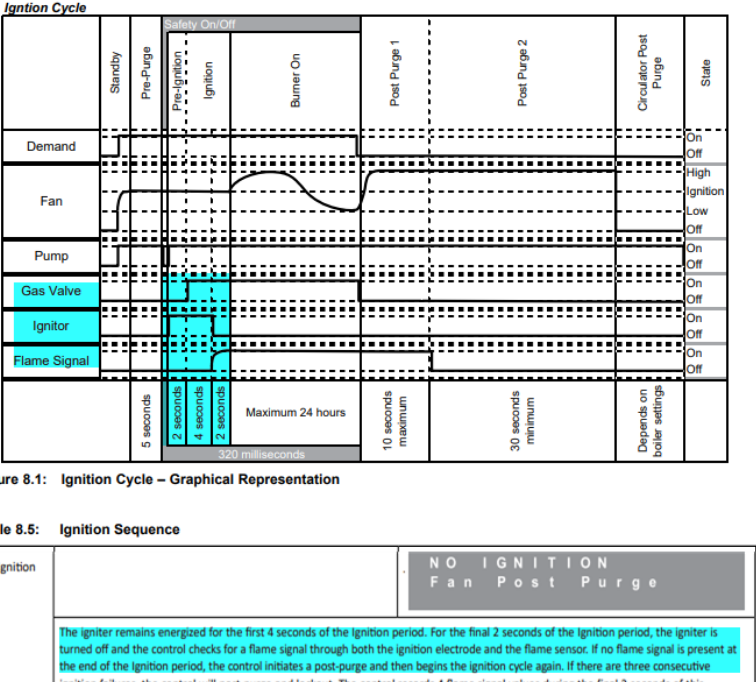

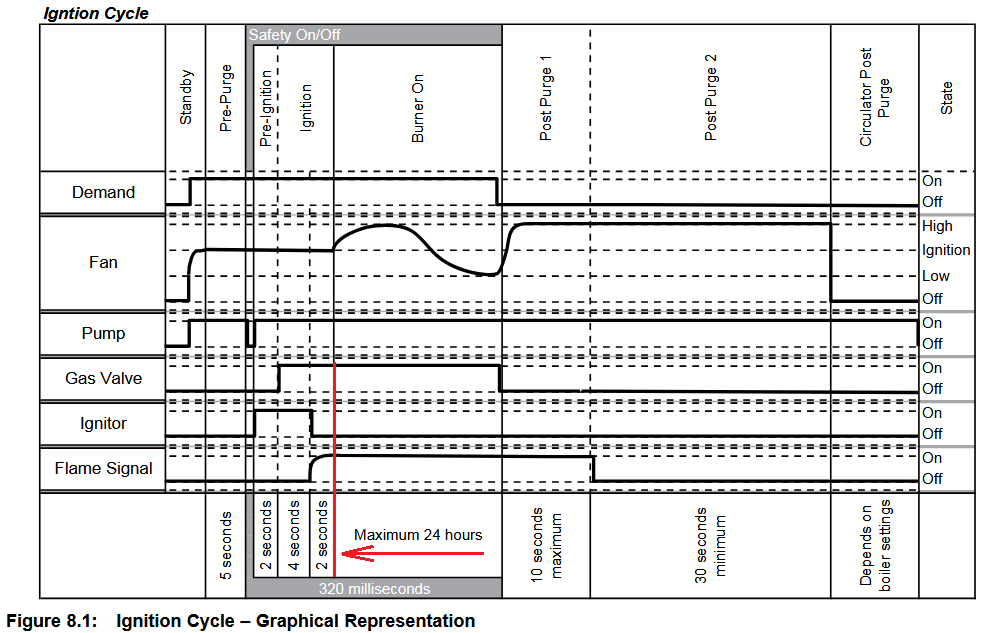

So, when the boiler does a "trial for ignition" I look through the glass, see a "glow" like a flame, then it goes out, and moves on to fan post purge. I had thought (wrongly) that the timing was - ignite on, test for flame, no flame, turn off gas valve. It appears that the timing is ignite on, ignite off, test for flame, gas valve remains on unless no flame detected. Then you can go into settings and check the 4 flame sensor currents (which are all zero). My point is zero is possible if no flame because of when it was checked. Zero values do not indicate a bad board (I think)

So, I know that I can check the AC voltage to the control valve and see if it's getting good voltage at the right time, but I don't think I can test if mechanically it is passing the gas.

you mention the "flame sensor trick". I have an extra sensor, I was wondering if I could leave the one in, connect the spare, and hold a flame to it while going through ignition. I am wondering if a flame from a lighter would provide enough energy to record uA in the controls. I have a map gas torch as well. That would tell me sensor and board are probably ok.

Edit, also can you please elaborate on "flame rectification"?

Jim

0 -

"He might be right. we see current coming from the flame sensor to the PCB (ammeter inline) but in the installer menu (which I showed him) there are only zeros. I had seen good values before. "

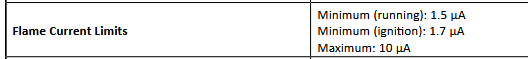

What current were you seeing uA or microamps DC ? The flame acts as a rectifier diode with a high forward series resistance. Many flame detection circuits can tell if the flame detection wire / electrode is somehow compromised to ground, since there will be AC current (which may be excessive) or when there should not be any current and there is and/or the flame rectification is not within specification.

It seems odd that you are measuring current (multimeter) but the board is not detecting it any more. The refresh rate of the boilers display may be slow, so if the flame goes out immediately it does not display anything.

What causes the flame to go out ? Incorrect combustion, lack of fuel or air, or the gas valve actually closes.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Thank you

I'll go down and rerun some tests to get you some good information, but from memory about 30-40 uA. Again, I'll retest. I can't get to it until this afternoon (EST)

As for the zero readings, when we initially had this issue before, we got readings where I checked them, and they were good. Now, they are zero. Plus, as I mentioned, the ignition sequence used to be longer (a few "puff" noises) and now they are much shorter (one puff, glow goes out).

I agree on the "odd" regarding the controller. My experience with electronics is it's unlikely that a chronic turned terminal is the control, it's more likely to be something else operating barely in spec, until it's not.

I'll be back later today with more info.

Jim

0 -

Western NY is like the WW west.

I would call Peerless. They must have a MFG rep who could help you find someone. Is the current technician the one that did the install? Probably not since 'no one uses Peerless". Do you know or can you find out who the original installer is?

You could also try to find the Plumbing supply that sells Peerless and they might be able to help. I would also check any propane regulators for ice or spiders etc in the vent connections. If the vent gets blocked or restricted and the reg can't breathe it can't control.

Also ask the propane supplier about moisture in the propane than to rule that out.

0 -

Thanks Ebe - Unfortunately Peerless does not have a consumer number anywhere, the only ones to call them are contractors and suppliers. Unfortunately, the contractors on the Peerless sight say "really? We are listed?" when I contact them about Peerless. Your point about a supplier and even a manufacturers rep is the probable next step.

I did find a new contractor (one of the "really?") who seems quite nice, his company, and he is going to come out Friday afternoon, but he admittedly isn't knowledgable with Peerless and doesn't do much with high efficiency boilers.

The original installer was on the paperwork I got with the house, and he is since retired.

I think a new system might be in the cards this summer as our indirect tank is a monster, and circa 2001 (when the house was built). But, I need to get through this winter and I'm not one to make rush decisions on a purchase like that.

Test results next post

0 -

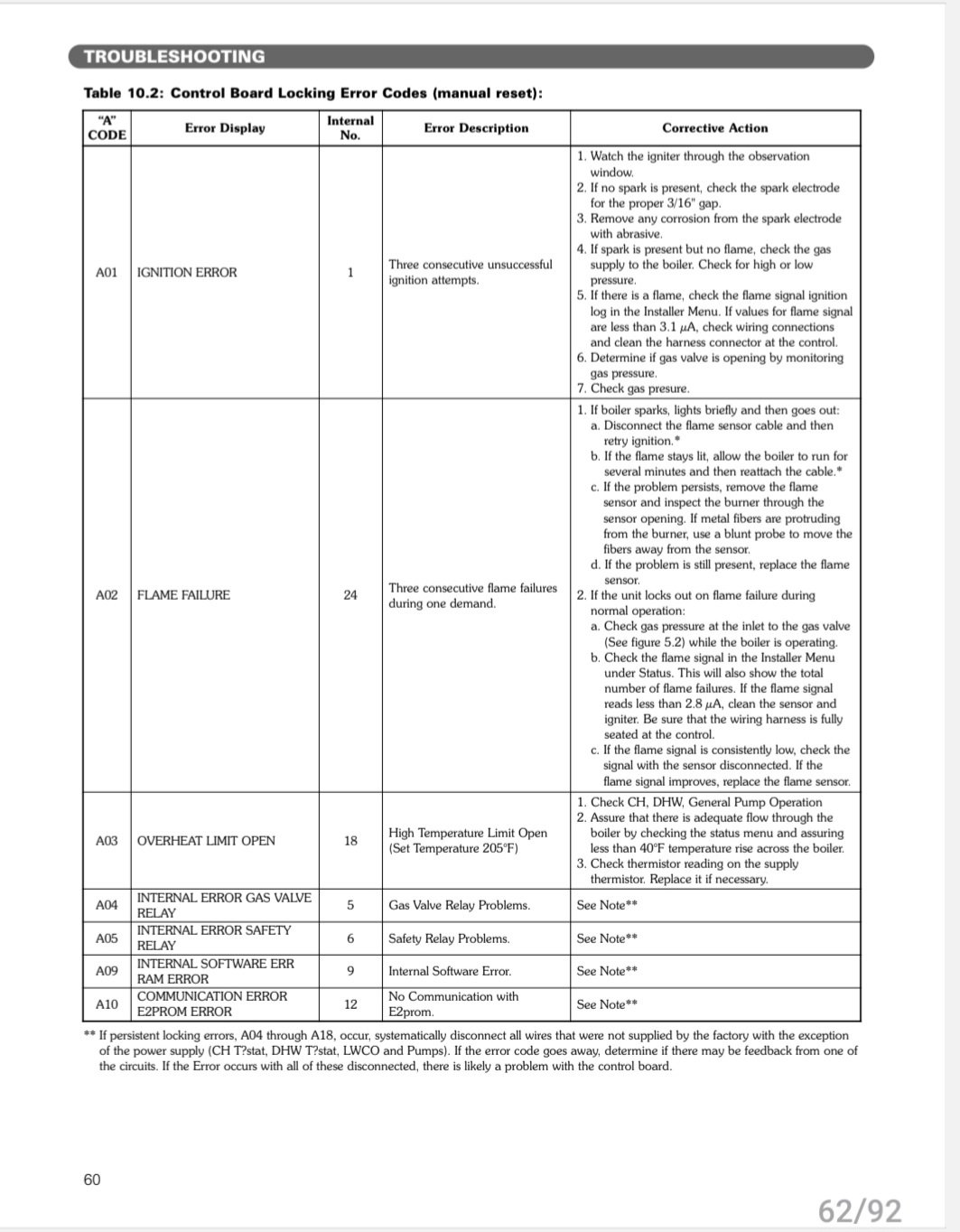

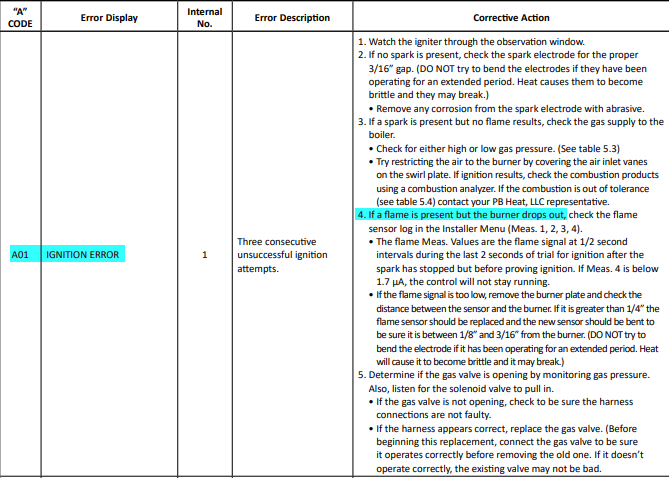

OK, Hvacnut, I pulled the same section from my exact product, a bit different:

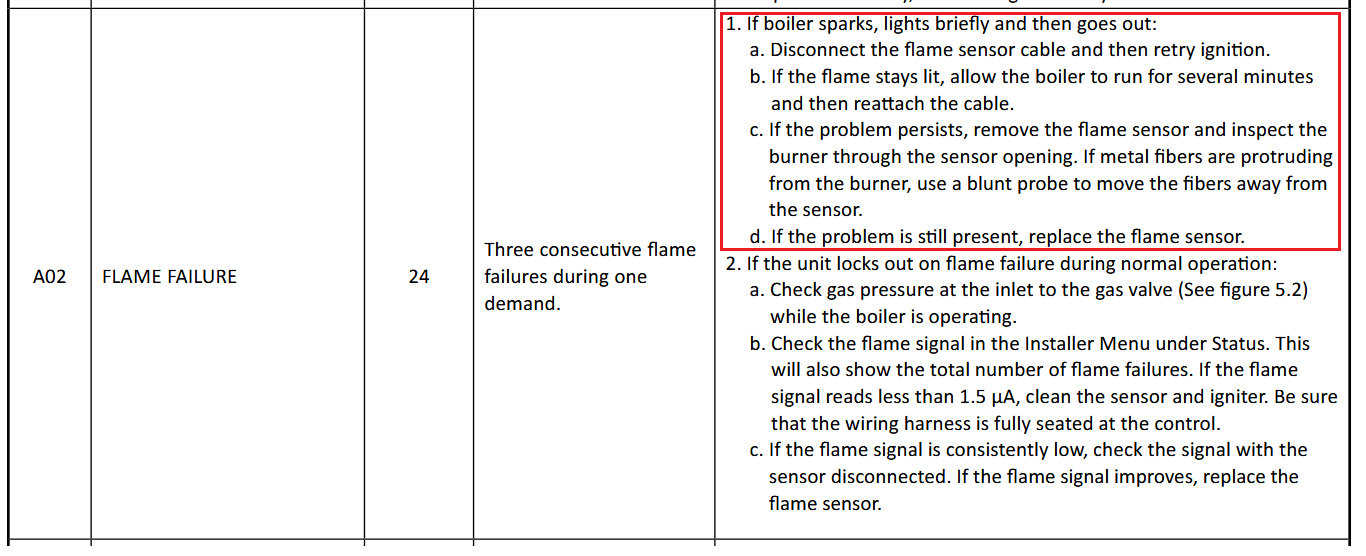

So, my issue has always been A01 Ignition, but I have also had A02 flame failure

I just ran a couple tests. During a cycle, I feel (and hear) the solenoid on the valve click, hear (poof) and see the flame, steady for a second, then out, then the solenoid clicks (off) a couple seconds later, then fan purge.

The values of Meas 1-4 are all zero (see 4). They used to have values until recently.

I have an old Fluke meter, it only measures mA. I put it in series with the flame sensor and control board, repeated the test, and measured 0.021-0.028, which according to my math is 21 to 28 uA which seems wrong. From distant memory I remember seeing about 3-4 uA in the readings (when there were readings).

The thought that the current is there and the board doesn't see it, therefore bad board may be wrong. It could be that when I see the current is different from when the 4 readings are being taken. I mentioned before that during previous flame failures the "ignition try" seemed longer, like a poof, poof, poof (up to 5) when now it's just one poof. "Poof" being the sound of ignition.

As for 5, I cannot measure it myself, but the new tech coming Friday can. What I find interesting is the "flame present but does not sustain leads to the possibility of no, or insufficient gas (#5). I would have thought see flame = gas there, but I guess not.

Jim

0 -

I ran a few more experiments, but first, a couple pictures of the spy hole into the combustion chamber:

normal:

During the ignition process:

My tests:

I turned off the gas supply and never saw (or heard) anything, it just looked like the first picture. I then turned on the gas and saw and heard the ignition as shown below.

I disconnected the igniter and as expected, saw nothing.

So, my thoughts - It is getting gas, enough to lite, but enough to sustain the combustion? Is it getting enough air as well? Or, is everything ok with the gas, but the control is not seeing the flame sensor signal and therefore shutting down the ignition and complaining about it.

As I mentioned, I have the control and display kit, about $900. I could try it, and be vary careful in hopes of returning it, but gladly paying it if it's the solution.

0 -

-

Curiosity, what model Fluke meter do you have ?

Was the resistance of the high voltage wire verified while flexing it ? Were both electrodes cleaned ?

Things that can degrade over time are the integrity of solder joints, especially at connectors and relays and other large items soldered to the board like transformers. Capacitor ESR can also be an issue.

High voltage ignition Sparks can jump a poor connection, current in the uA range with a low power supply voltage will have a much tougher time.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I think Har5bor Freight has some cheap meters around $25 or less that will read uA. Could be another issue but the symptoms point to not sensing flame. Or it might be a pressure switch issue. You get as far as ignition and when it lights the presence of the flame changes to pressure and the switch trips. But I guess your not getting an error code for that.

0 -

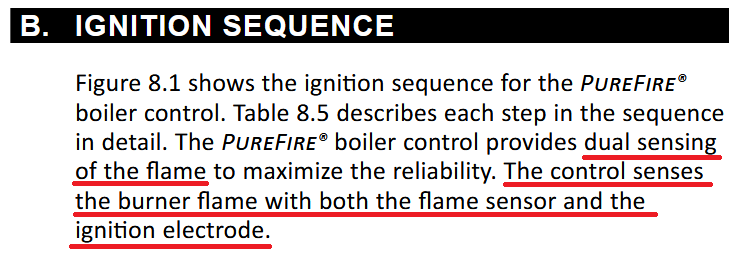

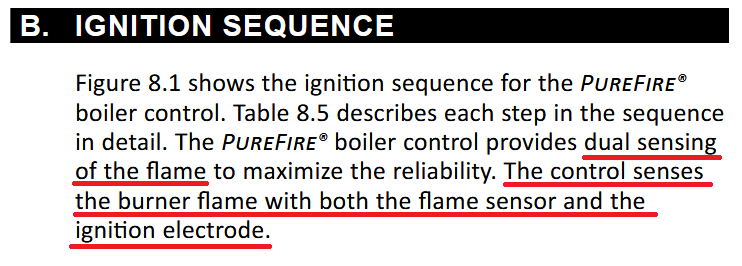

I find this interesting.

"dual sensing" So is it AND or OR logic or something else?

"maximize reliability" reliability of what ? The boiler actually working or locking out and being (ummm) safe ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I really feel like without a combustion analysis, any and all efforts to solve the problem are futile, especially with propane. Pictures of the boiler installation and the venting would be great. The fact that it was so dirty and malfunctioned again after it was cleaned are indicating the combustion settings are way off, maybe it wasn't converted to LP properly. I wouldn't have spent a dime on any replacement parts until combustion is set properly. Sorry but this isn't a DIY thing, you need to find a professional who knows how to use a combustion analyzer and read the installation instructions.

1 -

Maximizing reliability compared to the older Peerless Pinnacle/HTP Munchkin boilers that only used the sensor and has tons of issues, because they weren't setup properly with a combustion analyzer and had flame rectification issues as a result.

0 -

@SuperTech So your are saying it is OR logic ? If either flame sensor is satisfied the flame should continue ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The newest controller uses both parts to read the flame current. This helps when ignition isn't perfect and the flame pattern is poor, it prevents the boiler from locking out due to not sensing the flame when the flame is there, but combustion or ignition is poor and a single sensor may be unable to reliably prove the flame is remaining lit.

0 -

So it would seem the sensors are wired in parallel then.

I did this once with a commercial burner. It had a gas pilot and main flame was oil. 46 gallons/hour.

The factory mounting for the flame scanner would pick up the pilot flame fine and main flame on oil as well. But after a long run time the combustion chamber would be glowing hot. The boiler would shut down on pressure and then recycle to start. The flame scanner would pick up the glowing hot chamber on prepurge and the burner would lock out on a false flame.. Another scanner wired in parallel fixed the issue siting in a different spot.

The problem could have been fixed by changing to an ultraviolet scanner that wouldn't sense hot refractory by it wasn't allowed by MA. code. It was ok in 49 other states but not here.

0 -

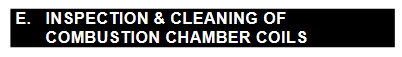

Was this procedure done ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Thank you for all the comments. I'll be checking back, but because of the holiday, no expectations of you guys having more input.

I'll try to address everyone's comments in no particular order:

- I did not do the test for the A02 Flame Failure error, as I am getting A01, but since I have A02 in the past (boiler lit but after a while a reverberating noise as the boiler fails → A02 reported. But it looks like it's a test that might work for A01 too.

- I have another pro coming Friday, but he says he is not more of a Navian tech (he installs them) and not much experience with the high efficiency boilers, But, he will have the ability to measure gas pressure and combustion. AS mentioned, I can't find anyone local (yet) with experience with this product, and as mentioned before Peerless doesn't have a contact number for us lowly consumers. But, I will try to find a supplier or manufacturers rep Friday as well.

- I was not aware of the flame sensor and the igniter both being used to detect ignition. Yes, AND or OR is not described, but it is a big question.

- My Fluke is my best meter, it's about 15 years old, but I have as many meters as tape measures and utility knives. I have a quite a few of the HF. I'll look around. I just grabbed my "best" but agree when measuring uA, the signal path is critical. I guess for now I look at it as "the meter measures current when the system says there is none". I'll clean the flame sensor and igniter leads and try a different meter.

- Super Tech - I agree with your comment on CA and not spending a dime, but I have been without heat for a week now, and while we are in the high 20's and low 30's weather can turn cold here fast. The previous tech that diagnosed "control board" then lost his source (failed to have it held), and said 5-10 days to get one, so I bought one from Supply house. Not as a DIY (unless I have to) but as a "have the part in hand in case it's needed. Actually, without heat in the winter is frightening, but we are doing pretty well with solar heat, space heaters, and the propane fireplace. But 30's is one thing and single digit another.

- HVACNUT, yes, flame signal should be above 3.1uA, and it was in the past (when the boiler was struggling, not non responsive like now). But I question if the flame is present when the readings are taken. The manual says the timing is gas valve on→Igniter on→igniter off, take 4 flame measurements over the following 2 seconds. So, it is possible the flame is there, but gone before the measurements are taken. SEE 7 FOR WHY i THINK THIS MIGHT BE TELLING

- When the boiler was struggling in the past (would fail, lockout, reset, then work) I could watch and listen to the ignition and the flame would surge (brighten) and the "poof" noise would repeat 3-5 times before a failure. When the chamber was cleaned by the tech, that sequence seemed to be 2-3 and it always fired. Now that it's in "broke mode" it only flames and "poofs" once. This is not imagined, I am sure of this. In fact, there are 3 ignition retries before lockout. When it was struggling, the second set might be 5-7 times. I am wondering/guessing that the ignite control of the valve/igniter might be more sophisticated than the manual reflects. So, my thinking is that MAYBE, the 4 reads that would occur over the 2-3 or 3-5, are occuring after the 1 poof. It could also be that the control sees no current and after the first poof just aborts, where otherwise, it sees something, just not enough, and repeats the poof.

- HVACNUT, you said there "is" a way to force fire it, did you mean "is"? Because I don't know how.

- I'll post a picture of the install and venting. Remember, I have had hot water heat all my life (even as a kid) but this is not my install (so install criticisms are not my fault :), we bought the place 18 months ago and were so happy to have hydronic heat…but this system has been more than finicky. I miss my Buderus.

My conclusion to date is it could be gas is there, but not enough, it could be o2 causing combustion issues, and it could be electronics. Again, I am not trying to DIY, but I am having a problem finding the right contractor/support. I asked my previous tech, when it was very apparent he was struggling, if he could call Peerless tech support (which I have read is available). He said "they won't answer". I contacted another tech and his answering service says "sure, we do Peerless" and 1 hour after the 2-4PM window he called me and said "I'm sorry, we don't do peerless" but he was nice enough to stay on the phone and discuss it with me.

But, back to one of the original questions. If I do have to replace the control board on my own, electrically and mechanically, I am fine with the job, but my previous tech mentioned that I had to copy down values from the menus to put into the new system. Just wondering if anyone has done this, and maybe what in particular I should focus on.

I am not going to do any control board swap until the Friday Tech comes, and he should be able do a gas and combustion check. But, again, I think the single "puff" and visual flame surge now, compared to multiple previously, is a clue

Jim

0 -

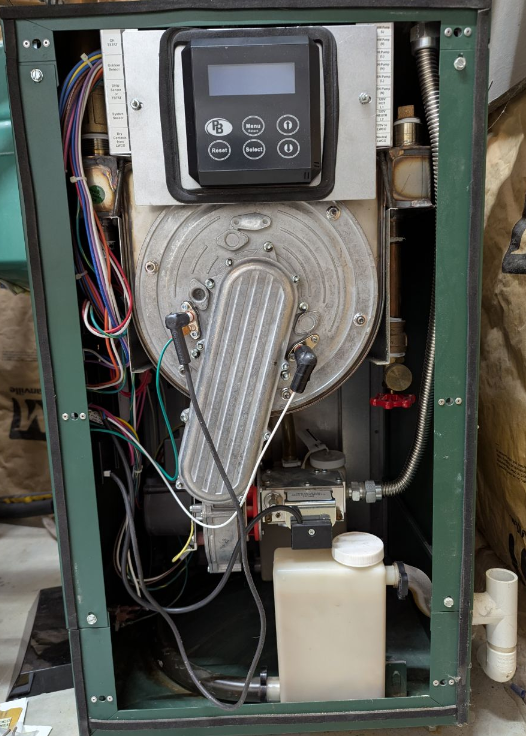

pictures of system

Tekmar 363 with outdoor reset controls the pumps and zone valves. One secondary loops feeds two pumps (far right) for main living and master level area (baseboard). The other secondary zone feeds a series of zone valves for two lower level (walk out basement) zones - in floor radiant heat, one zone for master bath (in floor radiant), and the last one for a panel radiator in the first floor bathroom.

I can get a pic of the outdoor venting if needed but it is all clean and each has screens (looks like about 1/2" or 3/4") to prevent debris.

0 -

Most electronic ignition failures are due to poor ground connection. Use fine emery, fine steel wool or a Dremel tool with wire wheel and scrub the ground connection to bare metal. If you have a grounding strap, cut off any solderless connector, strip to new wire and crimp on new then attach to shined up connection point.

If the resistance to ground is imbalanced on a dual sensor, it could confuse the board. Try to measure the impedance of both.

Gas pressures should always be part of first echelon troubleshooting. Measure static, ignition trial, burning (if possible) and if you get it to fire then try it with everything else firing so its under full load.

Check the vent to ensure its not blocked or disconnected.

Consider using De-Oxit on electrical connects that are suspect and you cannot replace them.

0 -

Thanks Bob, will do on the grounds, but I had tested continuity to system ground and real ground. The ground from the controller is attached to the front plate with one of the screws from the igniter. I test board to that ground, it was good. I also tested the ground I mentioned to the copper piping, and it was continuous. I have not opened the 120v connection to get at that ground or insure that it is attached to the box (it should be as it's metal). But I'll dig around a bit more and look for other grounds.

As far as measuring the impedance on the "dual sensor", first, there is only one flame sensor, but the manual says it uses the igniter, so, sure, I can measure that, but how to measure? Impedence = resistance in a DC circuit, but not AC. I "think" that AC is supplied to "excite" the sensor, thought I read that, could be wrong.

I did use deoxit when I unplugged all of the connector on the control board and plugged them back in with a wiggle. Great stuff. But I am sure there are other connections, like the display module.

I'l take a new look at all of that. The connections all look very "clean" (no corrosion or oxidation) but you never know.

Yes on the gas pressure it will be measured tomorrow by the new tech. It was measured by tech #1 and he said it was "good". I mentioned early on I don't believe in concidences. We are changing suppliers (Monday) and they wanted us to run the 500 gal tank to 25% then call, it's currently at 22%. We have never run it that low. I just wonder if this is related somehow. I have been burned a few times by assuming things are unrelated. But the new propane company said they will test all lines and pressures at each applience (boiler, fireplace, dryer)

Jim

0 -

How well was the heat exchanger cleaned? If the contractor only removed the surface debris and didn’t use a credit card and chemicals to get between the tubes, then it wasn’t properly cleaned and that may be the issue.

Unfortunately, when a homeowner or a tech who’s not properly trained starts giving their diagnosis of the problem, it can be like a red herring that sends the entire thread in the wrong direction.

I’m not implying that you aren’t intelligent, but you were sent in one direction by the tech you hired and then began pursuing that and sending this thread in that direction.

I doubt that there’s an issue with the control board, but it could be possible.

When we come to a service call, we can see the entire system and evaluate everything based on our experience and knowledge. But when a thread begins with “help with control board”, because that’s what a tech said, it’s already set sail on that path.

Any manufacturer will tell you that over 90% of control boards that are replaced were not defective. An incompetent tech will inevitably blame the board because he doesn’t understand it.

Again, it MAY be the board, but I doubt it.

A dirty heat exchanger and improper combustion settings will give the symptoms you described.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.2 -

Ironman, very astute observation, and yes one direction. But I have to say that by nature (I am an engineer) I am exploring and always looking for other possibilities. It's a bit of a disease. If you read through all of my blah blah, you would see that I remain unconvinced of the issue.

The one thing I am convinced of, the ignition sequence is different (see my previous post). Why? Unknown, but I really think it's a symptom of the illness.

Yes, the thread starter was "how to replace the control board" because at that time, the tech had 5 billable hours on it and his conclusion led him there. I was and am skeptical. Electronics usually don't go intermittent before fail, it's usually something that is deteriorating that is more physical and mechanical in nature. I wanted them to fix it so if it was not the control board I didn't have to pay, but they assumed the one part would be at the supplier indefinitely, and it was not there when they went to pick it up. Then it became may fault somehow, I decided to move on. Especially since a $900 kit was going to cost $1,500 after their markup. But I was willing to pay, if their diagnosis + $1,600 + labor fixed it.

I bought the control board/display kit out of desperation and "just in case" (I get a new tech and he said "wish we had a control board). It's in an up opened box, can be returned. as I am not ready to go there yet. I'll meet with tomorrow's tech first.

As for how clean, I don't have answers, I saw that he used a drill with a nylon brush wheel (like the old wire wheels only nylon). He took some befores and afters:

He said it was really dirty, I am not a good judge of that, I have no clue. I spoke with the previous homeowner and I got the impression that from 2018 to 2025 it had not had anything but "superficial" service, and only once.

0 -

The flue gasses pass from inside of the heat exchanger to the outer side by going between the tubes. If that part isn’t properly cleaned, then just cleaning the inner surface area is of little value.

It’s time consuming and a pain, but it’s crucial for proper operation.

I can’t tell for sure, but it looks like just the surface was done.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

Hi Bob, By tubes do you mean what I would consider the grooves of the corrugated cylinder? In between the ridges that look clean? Using a drain pipe reference.

I have other pictures I can take a look at further.

He said his experience was with commercial units, I think Lockinvar? and cleaned them for places like hospitals, businesses, etc. Much bigger than mine. Anyhow, no way to tell without opening up. He said it was a complete cleaning, and it took him 2-3 hours. I left him along for much of that time.

Can I just remove that oval plate to inspect both that and the igniter and sensor positions with respect to the burner? Or do I have to take the whole front off?

Jim

Edit - Cleaning helped. Prior to cleaning it had chronic ignition issues, hard to keep the boiler going. After cleaning it has zero issues. But only for about 3-4 weeks, then chronic came back, and the next day it finally it went to terminal (which it is now, impossible to get to ignite)

Edit #2 - I now remember him using a spray bottle, looked like diluted simple green when he was cleaning

0 -

Here’s a link to a YouTube video on cleaning the type of heat exchanger that you have.

Unfortunately, they didn’t put as much emphasis on cleaning between the tubes as I would have liked, but it’s helpful.

You need to use an old credit card or something similar to get between the tubes as they’re about 1-1/2” deep.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

This one may show it better, skip to 3:41 if you want

Keep in mind all the debris generated by the cleaning must be removed.

Also I kind of wanted the Fluke model number to look up the spec. It kind of looks like an 87 series which should do uA.

Did you read this part of the manual ?

"(which it is now, impossible to get to ignite)"

I'm kind of confused about the blue flame in the picture. So now at this point there is no flame at all ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Bob, 109 - thanks for the videos, I'll hang on to them. As for the manual instructions, I did read them, but only after the tech did the cleaning. If I don't end up replacing the boiler, or the new one is similar, I'll probably do annual cleanings (bi-annual?) myself. I'm pretty meticulous.

I have to emphasize that before the cleaning the boiler igniting was hit and miss. In the three tries before lockout, it might light on the 2nd or third, or lockout. Cleaning made it ignite first try every time (for about 3-4 weeks, then hit or miss returned, then dead.

As for the blue flame in the picture confusion - IMO, the ignition occurs, it just doesn't stay lit. It's not just a spark. Again, one thing I think is key, but a mystery, is the ignition visual and sound is different. Before now, when I was getting uA readings in the installer→status menu, it would pulsate a bit, both the flame and the "poof" (like poof,poof,poof). Now it is one blue flame, about 2 seconds, one "poof" →failure. Also, no readings in the installer→settings.

The manual and timing diagram above show that it's gas valve on, igniter on, then off, then the 4 current measurements are taken in the next 2 seconds, if inadequite, gas valve off, failure. I can feel and here the gas valve solenoid click.

I checked and wrung out all of the grounds, even those behind the display

Turns out the meter is a wavetek (I have both, both yellow). It has mA but can read to 0.000, so it can read down to uA.

But I think a strong clue is that I can read current in series with the control and the sensor during ignition and the control doesn't see anything, or is looking at a time the meter is not reading, which would lead my tech suspicions to the control module.

The other clue is it used to pulsate poof,poof,poof, now it's one poof. Peerless doesn't supply this detail, but perhaps the control is modulating the gas valve (hence the poof,poof,poof before), but since it doesn't see any uA on the first step of the modulation, it aborts early.

I'll take a video, not sure if I can load them here, but I can provide a link to my dropbox.

The other (far fetched) thing that sticks in my head is that the disassembly process of cleaning dislodged a connection, ground, etc but not enough to make it inoperable, but over time the sketchy connection dislodged completely. The tech's boss disagreed with me (strongly) that is was the same issue (before and after cleaning), so if not it was a different issue with the same symptom. But neither of us could say for sure.

Jim

0 -

Video of an ignition try. Note the single poof, flame, then gone. In the past it was multiple poofs with flame modulation.

Please let me know if you can't view it, or if you need a vid or pic of something else.

Jim

0 -

The video is viewable. I believe I hear the gas valve open, but not sure if the gas valve is closing or the flame just goes out, seems like a lack of fuel for some reason.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

agree 109. I don't think the gas valve is closing as I hear it close 2-4 seconds after flame extinguishes. I truncated the video to keep it small. I'll go back to the original and maybe post a longer one.

That is really THE question, is the flame going out due to gas or 02, or because the control is turning it off.

Can you clarify how these gas valves work? I assume that there is on and off, but is it an analog thing where the amount of gas passed is variable? I would think, because the boiler seems to regulate the gas based on the amount of h2o heating that needs to occur.

Jim

0 -

I'm certainly no gas valve or combustion expert, but I believe that gas valve is designed so when the blower / inducer air volume is changed or modulated the amount of fuel is also changed or modulated. Kind of like a carburetor did years ago with gasoline.

The pressures on either side of the gas valve would have to be monitored to get a better understanding if that is an issue. And maybe a meter monitoring the Gas Valve voltage to know exactly the control board actually removes power from the gas valve.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I thought to check at the valve and then I saw this connector and decided not to. First, I'd have to figure out which lead and even then I would fear even the slightest damage to the sockets with makeshift probes

but I can tell you I hear and feel the gas valve solenoid per the timing diagram I previously posted and will post again here:

I definitely hear the gas valve turn off some time after the fan purge has started.

Sadly, it looks like my new tech this afternoon might be questionable, as I can't get in touch with him to confirm. We'll see.

0 -

You said that the flame goes out before the gas valve closes? Check your inlet gas pressures again. Static (gas valve off), dynamic (gas valve on) and running after flame established over time.

The gas pressure should not drop more than 1”.8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

To me it looks fuel starved (blue flame just fades away) basically before it gets to the red line below, since the flame does not seem to even last the first 4 seconds of the 6 seconds of the ignition period. Time index 2 seconds to 5 seconds of the video.

I believe there is a full wave bridge rectifier hidden in that molded connector. I think there was a recent post about a similar connector with a Weil McLain boiler having issues with a similar connector / wiring harness. I don't recall if they stated the boilers symptoms other than maybe intermittent operation of some sort.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Tech just left, measured incoming pressure (13) and pressure on the other side of the valve (4).

We decided to try the new control and display modules. It did not fix the issue. He made a couple calls with associates and I am going out for a new flame and ignition sensor. Note that the ignition device is also a flame sensor with a ground rod. One fork is shaped just like a flame sensor.

I'll install and report back

0 -

13 inches static. The gauge should stay on the inlet port for ignition and run to see the pressure drop when the gas valve opens. I don't know what (4) is, but the outlet side of the gas valve should read about zero to negative inches Hg while running.

Is the Venturi intact? No cracks? When the boiler was open, was the condensate drain tested? Is there water in the trap?

3 -

as for the gas, I can only report what he told me. He did run the ignition sequence (which fails) both with the gauge on the inlet and outlet port. I know that the previous tech did not make the same measurements, only on the gas line itself, because he told me that the ports on the valve were "seized". The new tech gave it a bit more persuasion, and got them lose.

I picked up the igniter and flame sensor, tried the igniter first, sensor second, No change.

I think what I need more than anything is a tech that either has Peerless experience or will call into peerless tech support.

Or just replace the boiler

0 -

condensate drain was cleaned and new neutralizer added. I'm not sure what the venturi is, but on this boiler maybe it's the squirrel cage?

Let me post a pic of the boiler, opened and you can let me know what to check

Here's where I am. Control and Display Module changed, Igniter and wire changed, flame sensor changed, nothing did anything. I am still getting 0.0uA on the installer settings→status, screen 4,5. Boiler ignites, flames, goes out,3x until lockout.

I contacted Peerless though their website form, and they recommended another tech firm, I called them, and while they said they were not very well versed in Peerless (sigh), they would be able to work with Peerless tech support to resolve it on Monday.

So, with first tech, control module, igniter and sensor, second tech, I am in over $2k on a 7 year old boiler. At some time it will be time to cut bait and install a new system. Frustration talking, but also being a realist. Why own something so important that no one can service? Hoping a Peerless employee is stalking this thread 😀

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements