Help with Peerless PF-140, Ignition issues, Control Board swap

Comments

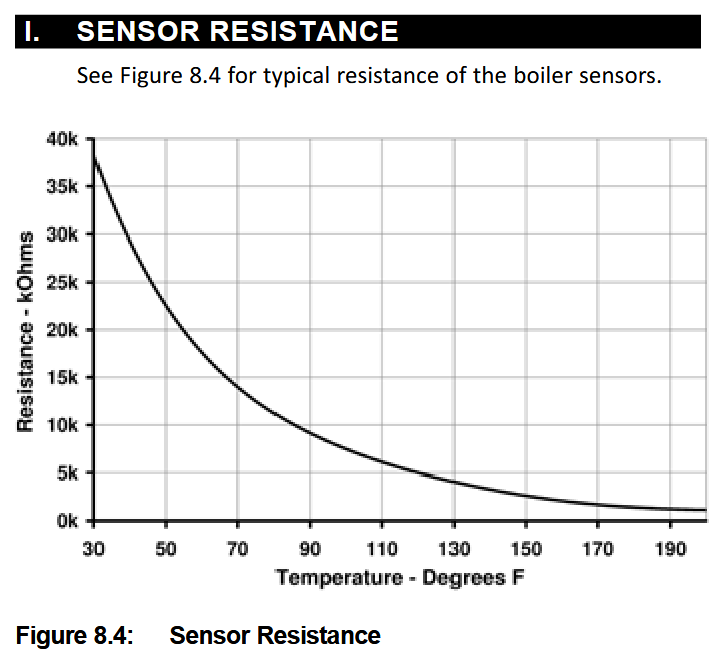

-

That boiler has the same heat exchanger as a lot of other water tube models/cons and the controls are similar on all of them.

What I’m saying is that there’s nothing unique or special about that boiler or the fact that it’s a Peerless. Any technician that’s competent with mod/cons can service that boiler. You don’t need a Peerless specialist.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.3 -

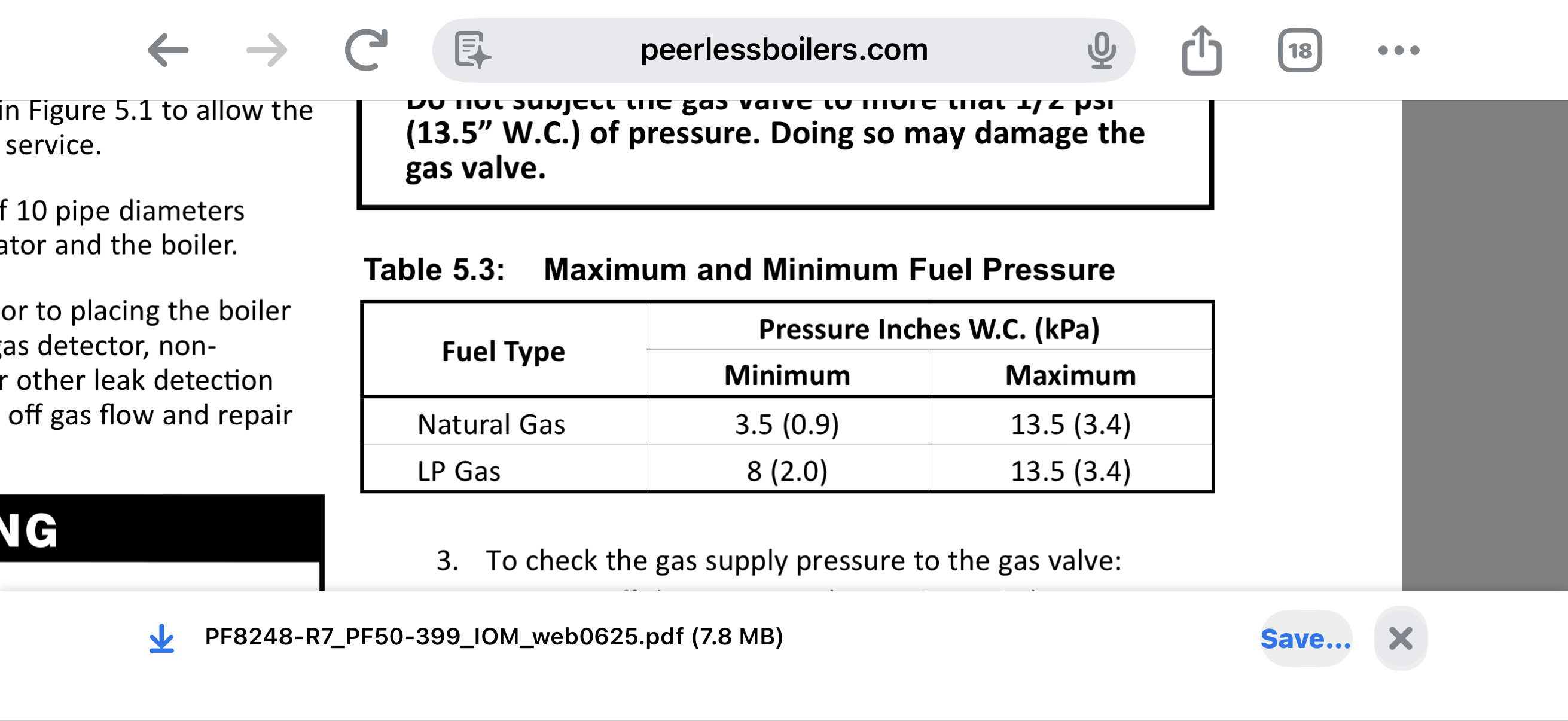

Make sure the new tech. has a manometer and combustion analyzer and that they know how to use them. Having gone through this thread, the first thing I would check is the gas pressure drop when the boiler fires. This is done on the inlet test port and you don't want to see a big drop.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab2 -

-

" Tech just left, measured incoming pressure (13) and pressure on the other side of the valve (4). "

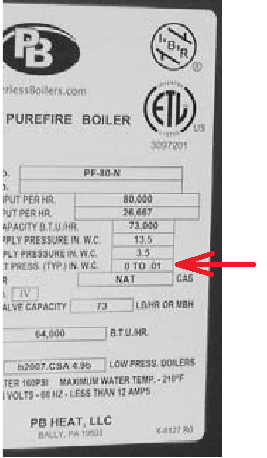

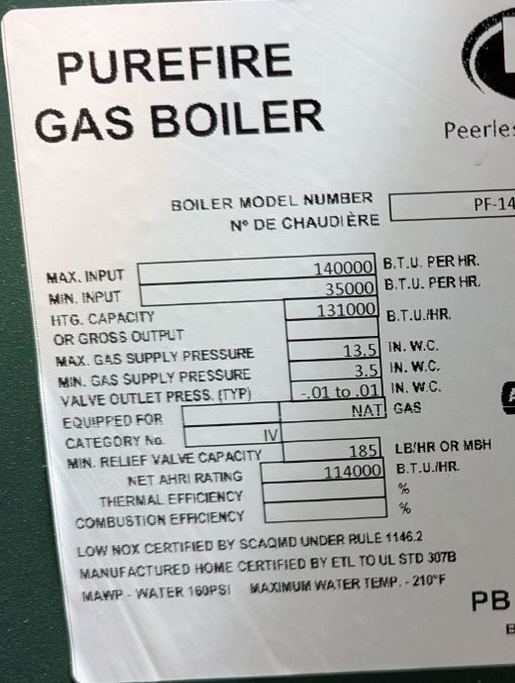

Only example I could find on the net. What is the outlet pressure rated at on the specifications sticker on the side of the boiler ?

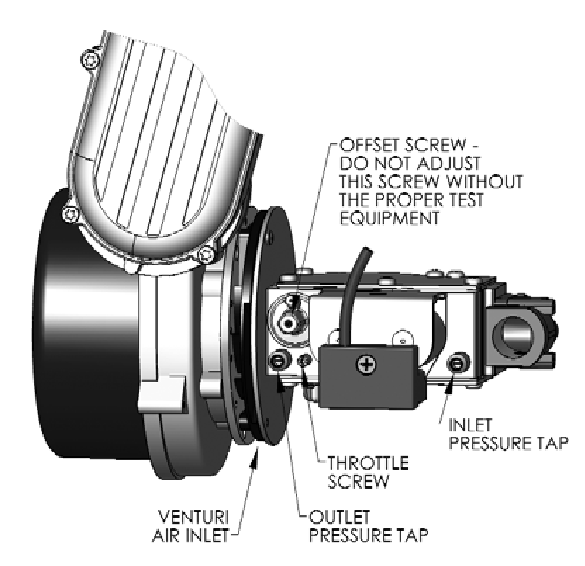

If the outlet pressure is actually 4 Inches of WC and it should be near zero, it would seem the gas valve outlet orifice going to the venturi air inlet swirl plate may be restricted.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Sadly it seems many business models today support failure, you only get so much time, then it is time to move on, whether it is working or not.

It's funny they talk about growth but they are not willing to take the time to learn what actually repairs the tougher problems.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Thank you for your comments and I will address a few of them in no particular order.

- As far as the devotion/knowledge of the techs, that, and trying to bill me for an hour spent trying to sell me a new boiler, and telling me about his life and family and how great he was, finally not reserving a part and it was gone when he got there (I offered to go pick it up), then blaming it on me (?) is why he is no longer involved. I have to be fair to the second one. He inherited this mess and didn't have the time yesterday, but came anyhow, spent maybe 2 hours with me as he had several "no heats" yet he made time, and didn't want to charge me. I insisted so we settled on an hour to be billed. I can probably get him back in on Monday. 3rd generation of a family business. I really liked him. Seems like most places sell Navian around here, but I have only contacted 4 out of maybe 30+ places.

- I am also thinking it's gas related. A few posts back 109 posted the suspicion that the gas was dropping/failing at the red line. I am betting it's more like the blue line. Reason, the two seconds between the blue and the red is when the flame sensor was read 4x and I get all zeros. Second, remember I said instead of poof,poof,poof (with flame modulating) before, I am now getting poof with a short steady flame. My thought (based on all of your comments, and eliminating all but the wiring harness), is the modulation I observed might not have been right, rather the start of being intermittent, which would also explain why I would get occasional flame failures (boiler had been running for minutes, flame estinguishes, chamber reverberates.

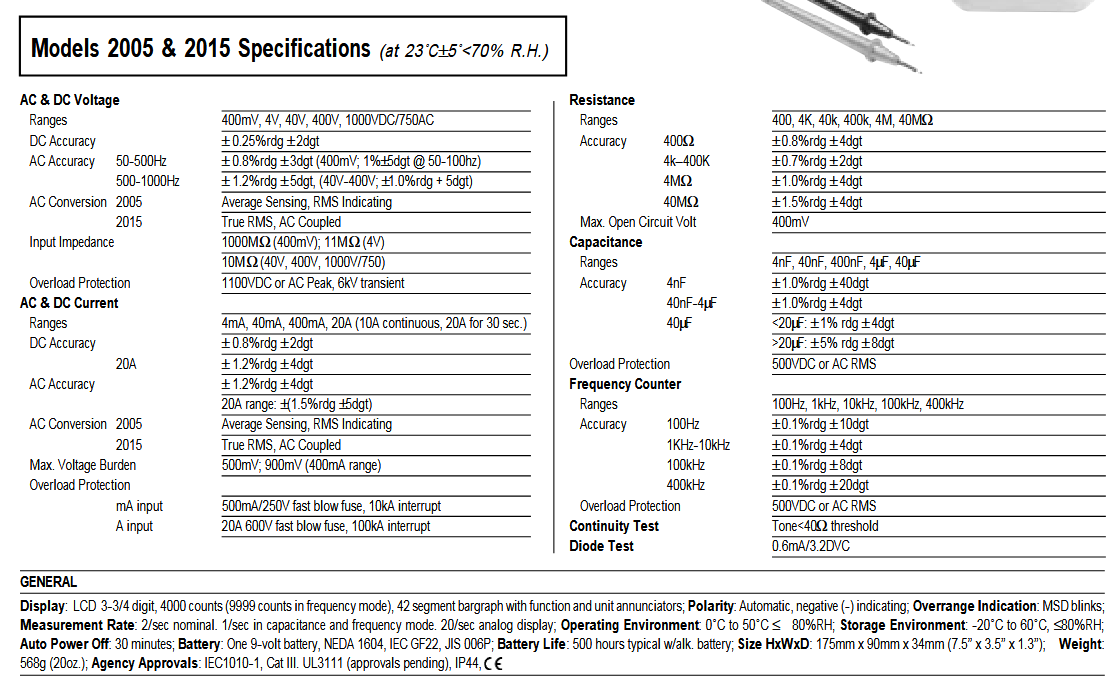

3. As for the gas measurement comments, I asked the tech for the measurements, and I believe that both the 13 (inlet) and the 3-4 (outlet) were inches of WC. He did test both through the boiler firing cycle. He said the inlet was pretty steady, and seemed happy with what he saw. He concluded it was not a propane tank to valve issue. AS for the outlet, he did mention that it dropped during the firing cycle, and I got the sense (only the sense, I am not the pro), that he didn't expect to see the drop. I could ask him again

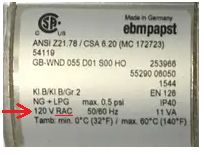

4. 109, here is my boiler tag:

yes, I see the -0.01 to 0.01, and yes he said 3-4, I am sure, I wrote it down. Is this something I could disassemble and clean? Or, would it be a defect/damage (not cleanable) and I would have to replace the part? Also, is the value on the tag a static (non flame) value? He was measuring the 3-4 through the flame sequence.

6. As for the combustion analyzer, he didn't test, said he could, but seemed hesitant that it would be specific to this boiler that he was not familiar with. Remember he was squeezing me in. Neither did tech 1.

7. Bob, understand. I am getting the impression with the 2-3 techs I have spoken to that standard cast iron boiler servicing is more common. I do have a guy that is very technically advanced who would have been my first shot, but he is dealing with a family health issue and taking some time away from the work. He is also a two man band, so his availability has always been tough.

That's all for now, I'll try to get clarity on the readings. Let me know if I should take the gas valve/venturi apart and clean (if possible).

/* Note - I remember finding a thread, here I think, where a member was having the same issue and it turned out to be a damaged swirl plate. Here's the thread

0 -

The slightly negative pressure on the outlet side of the gas valve is a dynamic value, i.e. with the gas valve on. A value of 3-4 tells me something is wrong.

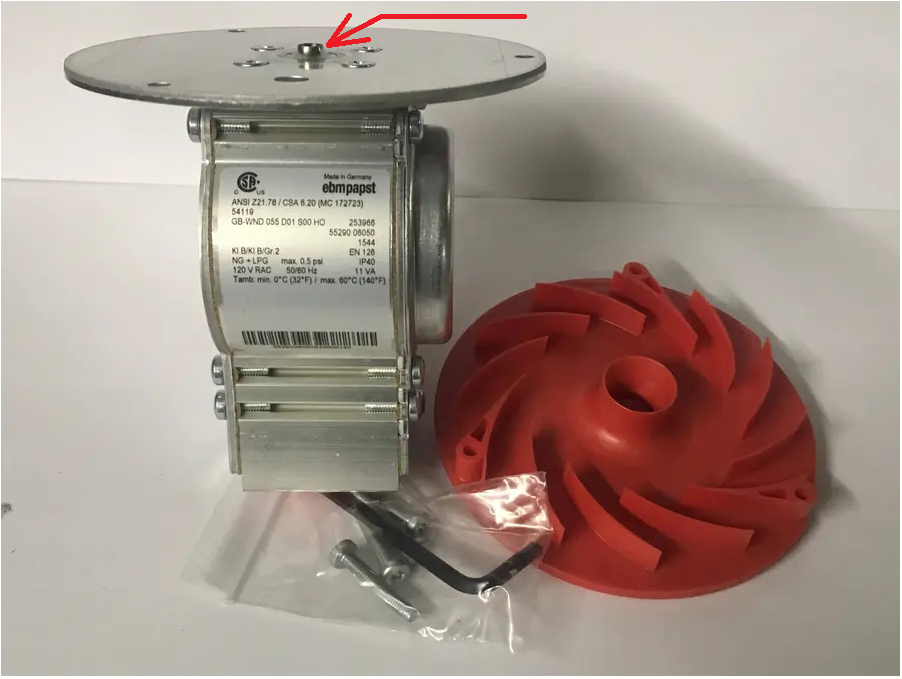

With my limited knowledge of negative pressure gas valves, somewhere between the valve and the burner, there is an aberration. If I were on the job, I’d take the whole gas valve, Venturi and burner apart to see what’s wrong.Before doing that, just for shi*s and giggles, I’d pull the inlet pipe (combustion air) off the Venturi on the inducer fan - there should be a rubber coupling there - and see if the boiler fires with just room air. I found a dead bird in there once.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

Alan, thanks, I'll check that. I know that tech #1 suspected the intake as he mentioned the windy weather with leaves we had had, but he checked it, I think by disconnecting the fernco fitting (see my pics of boiler). I had also gone outside and both air in and exhaust PVC's had screens inserted (they looked like HVAC screens, about 1/2" to 3/4" openings.

But I am suspicious of fuel (gas/o2) as well (plus, what else is there?), so I'll probably carefully disassemble the valve/swirl cage area and see if anything looks odd. Before that I will disconnect and try to fire the boiler.

0 -

I think on this boiler the venturi / air inlet swirl plate is the combustion air intake for the burner. I assume the boiler has the same symptoms with the front cover off.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Funny you should say that. I was trying to figure that out as well. Yes, I have had the front cover off the whole time.

I think I, as a handy homeowner, and defeated. I just don't have the instrumentation or experience. Problem is with each tech billing hours, and the price of the parts these days, it might be time to cut bait and get a new system, installed by a company that will support it, and can get parts. My problem with this is the Peerless came with the house, and the installer retired.

I looked through the thread I linked again, and within that there was another thread linked where the poor guy had the EXACT same symptoms as me (when mine was running) and he thrashed about quite a bit until a peerless tech came out, and adjusted the valve (even though the valve was within spec). What are the chances of that happening? and if it does, what is the final the bill to keep a 7 year old boiler and 24 year old indirect HW tank running vs. starting a new?

That second thread is frightening to read through, it makes it sound like these things are way to touchy. But I am sure they are not, properly installed. That is the key, "properly installed". How can a commoner tell?

Didn't hear from tech #2, tech #3 coming Monday and I gained enough knowledge to make sure they do the right tests. Tech #3 (referred to me by Peerless customer support) says they are not experienced with Peerless (of course he said that) but he would get the right tech on the line and promised me they would get it running. He may be sorry he said that.

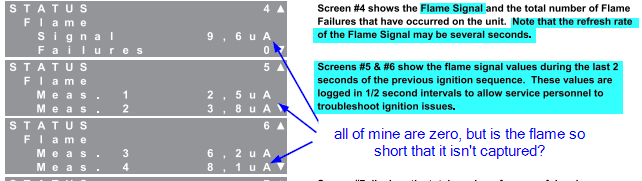

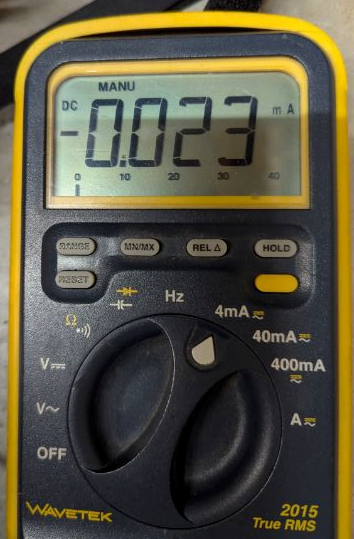

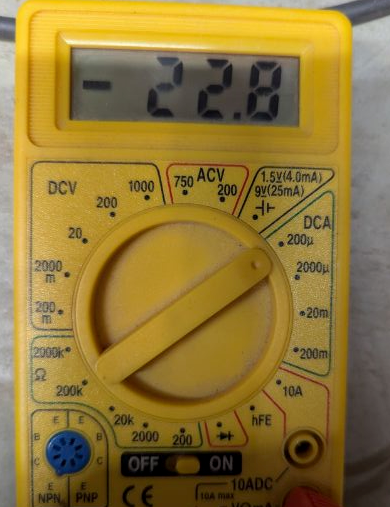

It's bound to be something really dumb. I keep getting stuck on the point that I see zero uA both on screens (used to see values) yet I can read uA of current with a meter in line:

Having replaced everything control, except for the wiring harness, and checked all grounds for continuity to the supply AC ground, and the copper pipe, I am thinking it's gas, but when to quit?

I appreciate all the advice and if nothing else, I learned a ton. Thank you all for the time you take out of your day to help us flailing commoners out 😉

Jim

1 -

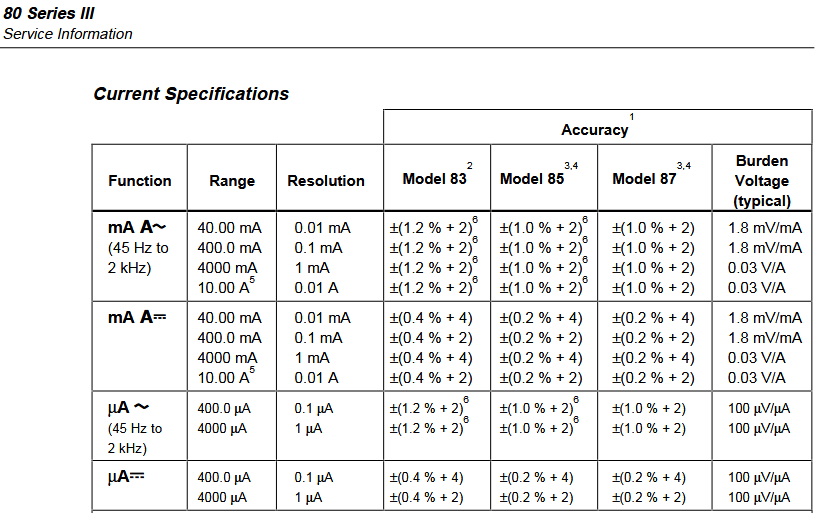

I'll try this again. What model is your Wavetek meter.

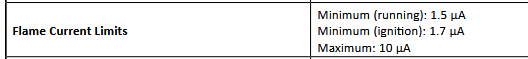

Without knowing the specifications of your meter I don't trust it. Do you only see 3 seconds of current since in the video that is all the flame time you had AND the meter reading you quoted were way beyond the boiler's specification I posted.

In my opinion, as a handy homeowner with an EE, there is a lot more things you could do without spending a fortune, may take some time. And the way I see it, the next boiler (if you go that route) is going to be the same or very similar technology and the Techs in your area potentially could have the same difficulty repairing a difficult issue.

For example, High tech electronics in the automotive industry has crippled many vehicles for way longer than anyone should tolerate and it is not getting any better IMO. One I found sadly amusing; The back up camera had a leak, corroded the electronics, brought down the onboard network communications, now the vehicle requires a tow truck and a Tech that could find that issue. I've been driving for decades, I rather have reliability and forget the camera.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

109 - It's a 2015, but as I mentioned, there is a 4 digit mA scale so 0.001 is one uA. I grabbed one of my harbor freight ones and it has a uA scale and it measured the exact same thing that the Wavetek did.

Note that the two reading were taken during different firing cycles

But the reading seems an order of magnitude high? Perhaps the meter is interpreting the current as straight DC, but the sensor has an AC component that the controller interprets correctly, or there is an offset current? Unsure.

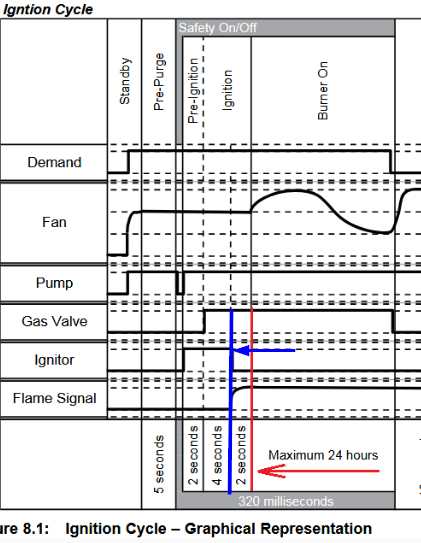

But to your point, I am going to revisit timing again. From the timing diagram the igniter turns on, then there is 2 seconds before the gas valve is turned on ("click") then 4 seconds, then 2 seconds where the flame sensor is measured 4x (assuming 1/2 sec per measurement). I'll try to time the click to the start and end of the observed flame. Maybe I can pick both up in a video and measure the timing in terms of frames.

I also have an analog meter which will give a better indication of timing

I am still thinking that I used to see extended flame time (with modulated flame and sound), and hence uA readings. Now I only see a flame, and a single poof. Maybe no uA readings because it never gets to that 2 second read interval.

0 -

There only should be DC current when the flame is burning. The flame is like a rectifier diode with a large series resistance when conducting. The higher than specification current value does bother me. And some meters don't do well discerning between AC and DC with very low current levels.

Basically I believe flame detection circuits use AC as the voltage source. And expects current flow on one alternation only for normal operation. If there is actually AC current flow (both alternations) there is a fault to ground detected (no rectification) and that may generate an error. If there is DC current flow when there should not be a flame present that would also cause an error (like the gas valve is not closing properly). All depends on the system what errors are captured and reported.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

See how Fluke publishes the resolution. I like that, it fits in my comfort zone well. Since you have two meters with the same basic reading that does help with a sanity test a bit. Your 2015 is AC coupled conversion in AC current mode, I think I would try that just to see what it reads.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

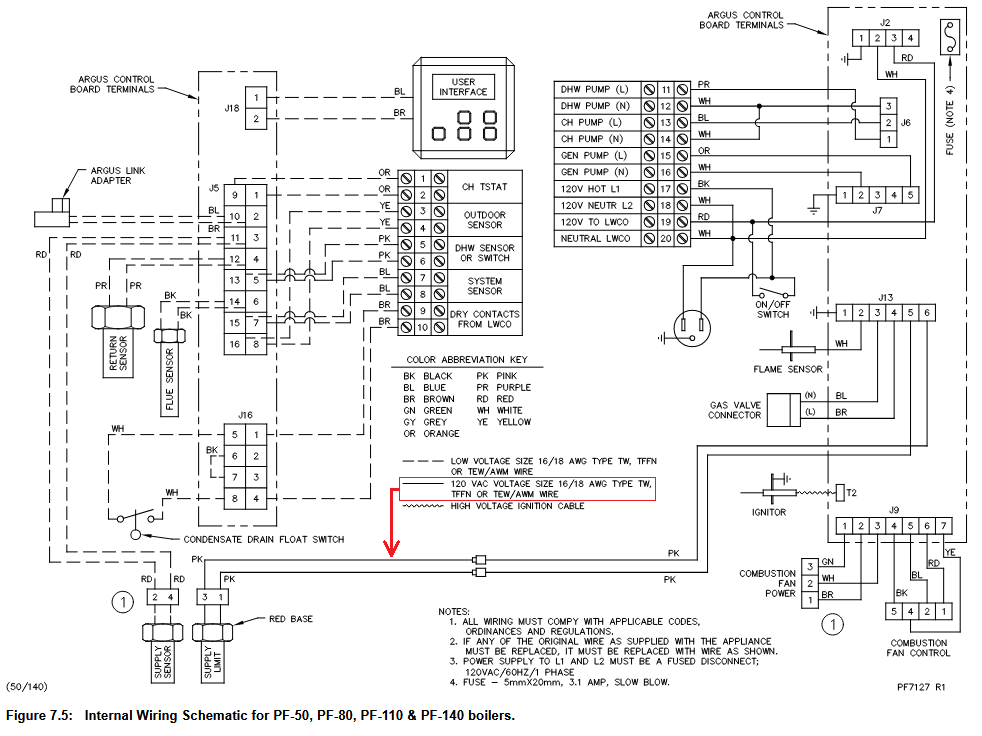

If this was my boiler, I'd build a wiring break-out device to put between the gas valve's connector and the wiring harness connector, to measure voltage and current to each solenoid individually. Connector parts are available from Digikey.com and Mouser.com and others, dimensions may need to be measured to determine the correct connectors. Also with the gas valve I would measure the resistance of the Gas valve solenoids for future reference.

I'd verify the Gas valve's voltage, the replacement one shows 120 RAC (Rectified AC), also I'd want to know if it is just AC coming from the control board or if there is Phase Angle control also (modulation). I'd devise a means to manually control the gas valve to better test system pressures.

Manometer, water manometer (clear tubing) or Dwyer Magnehelic Gage (inexpensive on eBay.com) to measure the pressure of the outlet side of the gas valve myself. And the differential pressure between the exhaust vent and the air intake. Future reference for failing inducer or other restriction.

Inspect the outlet side of the gas valve orifice port, maybe there is just a piece of Teflon tape that migrated along and is floating around in there. And inspect the venturi / air inlet swirl plate too.

I'd be doing a lot of my own testing to find out why the flame is going out in 3 seconds.

Variable DC power supply and a Resistor (100K or 1 Meg maybe) to verify the flame current monitor operation.

Needed hand tools, buy once use for a lifetime.

What they hide inside, an example;

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

109- Thank you for putting all the time into your posts and finding the video. It's funny when you see someone where you react "that's me"! "Worst decision I've ever made", "techs say, I've never seen anything like that, looks like a Lokinvar, but not really", "Techs coming out once a year for one reason or another"

Another solid reason to move on. I also noticed that the prices have doubled in the part 8 years since the video. I have a small New Holland Tractor where I have to make some of the simple parts because they are either unaffordable or unavailable. I had a driveshaft for PTO to snowblower that got damaged. $1500 from NH, but discontinued. Went to a truck repair place, they built me one for $200…I digress.

A couple things going on -

- I have the kids coming over Christmas today so my time is going to be limited today (Sunday)

- The Tech I wanted to use, very skilled and a self professed "hydronics nerd" is going to give me a call. He was my first choice, but, a family member has been going through some health issues, so he has been unavailable. He asked if the previous techs did all of the test you guys are suggesting including a combustion analysis.

- I will start to look at the gas valve at the control board connections, should be easier. I appreciate your advice on building specialized test tools, as I have built many, but by time a Moser delivery comes and I build them, this boiler will be at the scrap yard. All my life I have worked to keep stuff running longer than I should have (and taken pride in it), but have decided I'm to old for that now with stuff that is not enjoyable (to me).

- I'll check out the high limit sensor from the video

- I still want to make a video, perhaps with meters for flame current and gas valve voltage in view with the spy hole, and extract time stamps as to when things are happening or not. My main tech should be available in a bit (he would be my choice to replace my system) so it might help him.

- Tech #3 is coming Monday, we'll give him a shot, but he's probably going to be the last.

Happy Sunday…

Jim

1 -

Looks like we’ve got you going every which way. I feel your pain.

I hear you when you said that the make-up air pipe was inspected, but did anyone try to fire the boiler with it disconnected at the fan? If not, give it a try.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

was the gas valve changed?

guys, go back and reread the supply and manifold pressures on the rating plate, 13.5"

psimax, 3.5"psimin supply to valve, -0.1~0.1 manifold / burner side(fire side), and these are Nat Gas numbers,OP says he is converted to(not?), or, using LP, need LP #s if so, and a major retune,

known to beat dead horses0 -

@Alan (California Radiant) Forbes I don't think you can separate the fan like that, in this case the air and fuel goes through the fan.

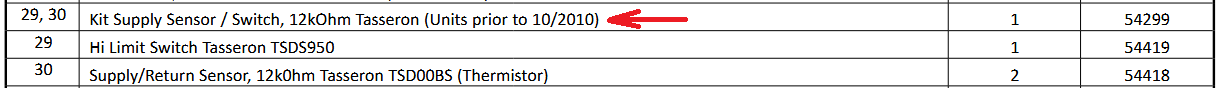

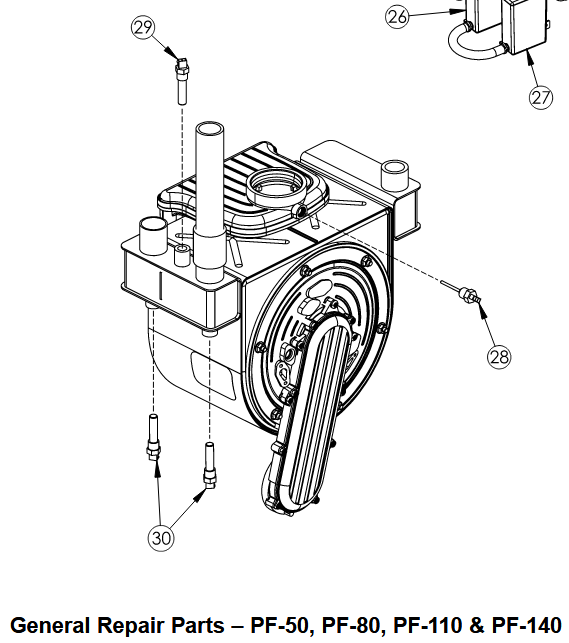

@Redrum Folks speak like that when they hit the frustration level. Parts Cannon type troubleshooting is another source of frustration. With these these 'High Tech' appliances and automotive stuff it is common to have problem that are hard to chase out. The unit in the video was only good for a year. And to me it seems there was some confusion if that is a thermistor or a temperature switch and there is a change in the parts list, so I'm thinking it may have been a factory screw up or update.

Sensors (thermistor or switch) go bad all the time and can be strangely intermittent, the connections to them have to be intact too, I find bad crimps all the time. If someone put a thermistor where a switch should be things are not going to work correctly. With your unit who knows what was done before you got there. Personally I like repairing the tough ones and enjoying the fruit of my labor, everyone is different.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

@neilc I looked over the conversion instructions document it was just tuning the gas valve different, they don't cite any pressure changes, it is not an atmospheric burner scenario.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

ok, right, but doesn't the op say the tech read 4"

psion the outlet?did I read that wrong?

known to beat dead horses0 -

I wrote psi, but meant inches, going back to edit

known to beat dead horses0 -

and rating plate does say 8.5" min LP, but I think that's covered, as long as it's not dropping more than 1,

from Alan

known to beat dead horses0 -

I read through your comments, thank you.

Here's what (I think) I know, not being in this particular business.

I took a video of my ammeter connected in series with the flame sensor, and the spy glass to observe flame. I can post it but…The gas valve clicks, flame is seen, the ammeter show current, the flame extinguishes, and the current disappears. All of this occurs in 3 seconds. What this means to me—-

If you look at the timing diagram, the gas valve is turned on, then there is a 4 second dwell prior, then a 2 second period where the 4 current measurements are made and stored in the installer→status menu. Well, the flame and current extinguishes in 3 seconds (recorded on video), 1 second before any readings were taken.

I mentioned in the past when this was an intermittent issue, the flame and combustion sound would modulate and I would see good readings in the installer→settings menu. Now I get zeros. Why? Because now that the failure is terminal, the flame extinguishes much earlier than it used to when the issue was just chronic. Now the flame does not modulate, nor does the sound, because it is very short.

The zeros led tech #1 to say it's the control module (because we read current on the meter, but the system didn't record it). He was wrong, the meter and the system were not reading current at the same time. Tech #2 didn't call when he said he would, tech #3, I was supposed to hear from about Monday but didn't. I don't blame them, they are busy servicing stuff they sell and know.

So, it is a gas or combustion thing despite dropping some serious $ into electronic parts and sensors. But what is it exactly? It's out of my comfort zone. Add to that I have techs that say that they will call but don't, and even if I get it fixed, what is the point? Why own a finicky device that no one local sells, installs, services, and only one place has parts, and let's not get started on the parts prices.

As for your comments and questions on the gas pressures, tech #1 didn't do any because he claimed the ports on the valve were siezed. Tech #2 and I got them loose and he said he measures 13 inch colums H20 on the input and 3-4 on the output. I know zero about this, so I just wrote them down. He seemed to be a cast iron boiler guy working on a mod con, not really comfortable/knowledgeable.

This whole thing comes down to the "find an installer" menu on the Peerless site does not reveal anyone that actually installs or services Peerless. No phone number for consumers, but, there is an online request, great, right? They got right back to me right away and suggested (drum roll) another tech that doesn't do Peerless. Is Peerless some garage shop company or something? Yes, I am trolling for someone from Peerless to reach out.

I am interested in getting it running short term, of course, but my real interest has shifted to what I am going to replace it with. If my roof was unreliable I would not keep climbing up on it with a bucket of tar, and I certainly would not say "there, that should fix it" when I get off the ladder. If I ever put the cover back on this boiler, I will not say that, and might tip toe past it…

Thanks for your comments, have a great week.

Jim

0 -

Why are you so focused on the fact that the boiler is a Peerless?

That same boiler is sold as at least a half dozen different brands. You don't need a "Peerless tech". You just need someone who has experience with any condensing boilers and has a combustion analyzer and the ability to read the installation instructions.

Any condensing boiler, especially when burning propane need to be combustion tested in minimum and maximum firing rate whenever service or repairs are done.

You would have experienced the same problems with any brand of boiler when everyone who has worked on it doesn't even have the tools required to work on it and ignores the installation instructions.

If you install a different boiler you are going to have the same problems because it's apparently impossible for you to find a tech who knows how to follow instructions and owns a combustion analyzer.

2 -

-

Hi Supertech ~

Spot on, agree 100%, but I did not know that that boiler is sold by a half dozen brands, nor do I know that a half dozen more are very similar (if that's true). This is not my business, although I admit a lifelong love for hydronic heat. But the techs I call do not say that (they service the same ones under different brands), instead they say "no, but we can give it a try", or "no, you would be better someone else. The ones that do come out struggle, then ghost me.

I will admit that I have a brand that the brand does not support the end user that has their product, no phone number available to the consumer, not even just to find a local "trained installer". I filled out and online contact form, and they respond with another firm that says they don't have experience, think they can help, but I never heard from them again.

What you are hearing is the frustration of working on this for 10 days without heat, showering at the Y. If there was someone diligently working on it I would feel better, but instead I get calls and texts not returned.

Sorry for the vent.

But today, Monday, is a new day. I start a new. I have a few ideas that I feel comfortable testing (like V to the gas valve through the ignition process, etc) and I am going to chase down my ghosts to see who wants to come back.

I feel that we (all of you and I) have narrowed it down to a specific symptom set. It's not anything control, ignite, and flame sensor, unless it's the harness. Grounds have been checked.

What is happening is the flame is igniting and extinguishing quicker than before. Quicker than the time the flame sensor reads for flame (unless the control is actually taking a reading earlier and it's not documented). If it's true that the flame sensor is not read until the 4th second, it is not the control shutting it down, its the flame estinguishing

I am also a firm believer in the prior symptoms being early evidence of a future issue. This boiler to my knowledge has had lockout →clean sensor→ fixed it problems for years. Then under me, that fix stopped working and a thorough cleaning fixed everything, for about a month. Problem returned one day with a vengeance, ignition errors, flame failures then dead (as it is today)

I posted a thread earlier that had a thread contained where the guy floundered and everything was to spec, until the Peerless Tech came out and adjusted the gas valve. I'll post it here again. The thread was frightening.

Finally, ST - your final point is solid. The only difference is with a new boiler it would be from a firm that installs that brand, parts are available, and I would hope they would have an interest in supporting their installs. With this situation I inherited it with the house.

Yellow dog, let me consider that and try to figure out what an inducer motor is :)

Jim

1 -

-

Hi Bob;

That would be great, I am in Cambria, which is Lockport mailing address 14094.

Can we do PM's on this forum? Never tried. Or you could just get their name and number

Update to follow

Jim

0 -

Update - I know many of you may say "I told you that" but…

No time to work on it today as, we had high winds with the power out most of the day. But, I was able to chat with my preferred guy, who has been available because of family issues.

He is going to come out on Wednesday to start to design a new system just in case, but will also take a look at the current dead soldier.

He felt pretty strongly that the cleaning that occurred may not have been good enough, in between the ribs, and that might explain what I am seeing, and why before cleaning it was bad, after cleaning good, then a month later bad. I know you guys emphasized that, I just hadn't watched tech #1 that closely.

So, I am going to open it up tomorrow and work on it myself, and yes be careful, and yes clean the condensate drain after. I'll use all non metallic tools, he also said nothing more that a shop vac, microfiber, and water (distilled preferred).

It will give me something to do.

Bob, I would still love to hear from Peerless if you would be so kind…

Jim

0 -

The only time I’ve seen the cleaning be an issue on Giannoni HX’s is when the coffee grounds build up so much that it stops proper drainage and the combustion chamber fills with water.

I really don’t think this is your issue. Just my 2 cents.8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

I understand your frustration. I really don't think you need to consider replacing it! All it needs is proper maintenance and combustion analysis. If someone can't do it on that boiler they shouldn't be working on boilers, that Peerless Purefire is as easy as it gets in my experience. If you find a decent tech you will be surprised by how easy it is to get that boiler dialed in once it's cleaned. Unless you have a boiler that's not properly installed. All these posts and we haven't seen any pictures of the way your boiler is installed, that would be really helpful.

The only condensing boiler that I know of that claims combustion analysis is not necessary is the Burnham Alta, but I don't have any experience with it personally. Whatever you end up doing please stay away from Navien boilers

0 -

-

ST - see previous posts where I posted the installation as requested. Please feel free to ask any questions.

As for the not needing to replace it, all I need is a decent tech, then, there is the challenge, eh? I have been through 2, 2 others were no show, and the one guy I trust is coming over wednesday (but to work on replacing). That's where my bi*ch is with Peerless., Should be able to contact them and either get their attention, or have them refer me to someone. Go to their "find an installer" call them, they say "nope, we do Navian but we can come out to take a look". If either were happening, I would be feeling different about things. I am adrift and a company is unwilling to let their consumer reach out to ask for help. Keeping your house heated is huge in the north east in the winter, and I am two thousand five hundred into this with no heat for 10 days counting. Time to cut bait.

That's my reasoning. If I had called a tech that cleaned, checked everything out, charged me a few hours of service and it didn't lead to 10 days without heat, I'd keep the system. If I didn't find a kit with flame sensors, some 220 grit and a dollar bill with "how to fix boiler" when we got the house, I might have more confidence.

Alan, cleaning - possibly/probably not, but at least it will make me fell I am doing something positive. I think your comment is what my trusted tech is thinking, that my previous tech "cleaned" the chamber, but not in the grooved and sediment might have combined with condensate over the moth it worked and bugger things up.

I'm pretty good at sarcasm, none of it is directed at you, I do appreciate your input. REALLY appreciate it. I have learned soooo much, including you can do wonders with a few small electric heaters, a gas fireplace with a fan, and showers at the Y.

The "tech I trust" is coming Wed to start to plan a new system. I'll clean it tomorrow and we'll go from there.

Cheer,

Jim

1 -

So did you test the sensors ? If the gas valve is not getting the correct power (Supply Limit switch closed), I would not expect it to work correctly. Cleaning the heat exchanger more may be a waste of time since the guy in the video said he cleaned his every year and yet his boiler still has the exact same issues as yours does.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

"Lochinvar WB80 not lighting, many new parts already. SOLVED"

Look familiar ? Different brand, different gas valve. Replacing the sensor fixed it.

" After getting the new Output Temp/Hi-Limit sensor a couple days ago I can finally say the unit is fixed. I opted to install myself; it was pretty basic, just drain off the pressure and let a little glycol out. I also replaced the Inlet Temp sensor, figured might as well, now just about everything is new. Crazy, all that money spent on parts because the Service Tech didn't make the correct diagnosis of the fault in the first place. "

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

you need to do 2 things.

First you need to check and make sure the swirl plate is not damaged. the swirl plate will start to warp out and it will effect you combustion at ignition. What you see in the sight glass as a good flame might not be the same where the flame rod sits due to bad air/gas mixture. I'm leaning this way for your problem because I used to see this quite a lot but commercial condensing boilers use venturi for the air gas mix. When you have a bad swirl plate it will start off with a slow rumbling at first and get gradually worse overtime and then you get ignition failure.

Next you need to get that gas pressure downstream into zero at start up. IT will decrease into a negative as the ecm blower speed increases. you shouldn't be in a positive and if your say the 3-4 positive or negative your way off. these gas valves are zero governor gas valves meaning that operate from zero into a negative but I yet to see them down into the -3,-4 area. lowest I've seem is -.17 at max RPM.

i work on condensing boilers almost everyday. there really is not difference between manufacturers. most heat exchangers are purchase from 3 major manufacturers. Whether they are water tube or fire tube. the only real difference is the software. Most will now come MOD-BUS ready so they can be integrated into the BMS. also if you are going to do another clean out of the heat exchanger remove the burner from the burner plate and blow out the mesh heat exchanger with compressed air. I had a very difficult one years ago it although it looked clean it was the whole issue with ignition. IT caused the pressure switch to trip after ignition and it would start all over again. There wasn't enough pressure differential in the chamber.

I perform PM's every year. sorry I cant help you. I live in downtown Boston. good luck

your jets really put on a good show Sunday LMAO

0 -

Hi Pedmec - Jets fan? WESTERN New York, Bills fan. We have a common team to ridicule, the Jets. :)

I have taken a look at the swirl casually, will take a closer look today. There is another thread on this board that I might have posted earlier that had the exact same symptoms and the swirl was damaged.

As for the gas pressure on the outlet, I only am reflecting what one tech told me, I don't have a gas pressure measurement thingie. The "tech I trust" will have one on Wednesday. No tech to date has done a combustion analysis which the "tech I trust" grumbled about. As a reminder (If you are thinking, why not use him?), he had health issues with his family so he had to step back for a few weeks to take care of things.

As for the burner, will do that to. I found a good video on doing both

As for the PM - I meant "private message" :). Bob had offered to find a Peerless rep and I thought I could "PM" him my contact info. So my question, is there a way for members to send messages to each other?

109 - I will check that today. I also have not checked the gas valve voltage at the control board (easier than at the valve) will do that. I got set back because we had some very major winds in the area and lost power for most of the day.

I am going to do the cleaning for a few reasons, one - "tech I trust" suggested it, even though it was done, second, a few of you strongly suggested making sure it was done right. Third, I get to see it and if it's a half **** job. When the dust settled, I will be going back to tech #1's boss to discuss charging me 5 hours of labor for the clean and diagnosing it's 100% the control board, having me buy one, then ghosting me. They treated me pretty poorly, not how I treated customers. I need to see it for myself. Plus, if I get another mod con, I'll be doing the cleaning. I'm quite anal, um, a perfectionist, and do almost everything myself. Dad raised me that way :). I just didn't do it out of the gate because I hadn't learned all this good info from your gracious input.

Funny story, Yesterday was the day we switched propane suppliers, and I helped the guy change out the 500 gal tank and regulator in the high 20's and high winds. Those guys are hearty. Anyhow, he had me go inside and turn on the gas stovetop to bleed out the air. The igniters didn't work (now what, something else broke?), and the smoke detectors started peeping (what? The gas??). I used a lighter on the stove top, turned it off and went out to tell the tech. When we both came back in, I switched on a light, nothing. Power was out. Doh! Making it worse, when power finally restored, for a while it was @ about 60vac (I measured) so we ran around disconnecting screaming CO detectors and yanking chords from electronics out of the wall. I have never had that happen before. It wasn't a leg lost, as I had power on both sides of the box

But a shout out to the power company, they had about 100,000 locations without power and we were back on line in about 6-8 hours.

I spent the little bit of time yesterday pulling the controller and display module out and putting mine back in. I am going to try to return them, but if they won't take them I'll put them on the bay.

So, as far as moving on, this peerless is 7 years old, was never maintained (best of my knowledge, previous homeowner said they had a guy out for routine once), on a 12 year lifespan. Service for it here is non existent. Seems to be an ok thing to do. I just have to decide about staying with a mod con, or going back to CI. I had a Buderus in my last house that I installed in 2007 that I loved. I understand the pros and cons and impact on in floor radiant. We'll see what "tech I trust" says.

1 -

I guess my troubleshooting strategy is different than others. Especially when things are behaving strangely.

Power; No electrical / electronic device works well or properly if the power is insufficient.

Easy resistance checks. Although not as thorough as power on loaded measurement it still may catch something obvious.

Multimeter measurements can usually be done relatively quickly. So not much time is wasted doing them and it gives you a better baseline at to what is most likely good and not causing the issue.

Troubleshooting strategy is largely about eliminating what is good and moving on. Eliminate the things that are quick to test and then move on to the more time consuming items.

I have a saying or a Troubleshooting rule, "Check the power supply first, if you don't you wish you did hours later".

BTW when the power goes out and a utility re-closer device does not restore it quickly I just shut off all the breakers and/or the main, it is one central point and it is quick. Once the neighborhood shows some sign of normal stable power then I will turn my stuff back on.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements