Replacing thermostat circuit board in a Taco 006 with a 5 wire fan capacitor?

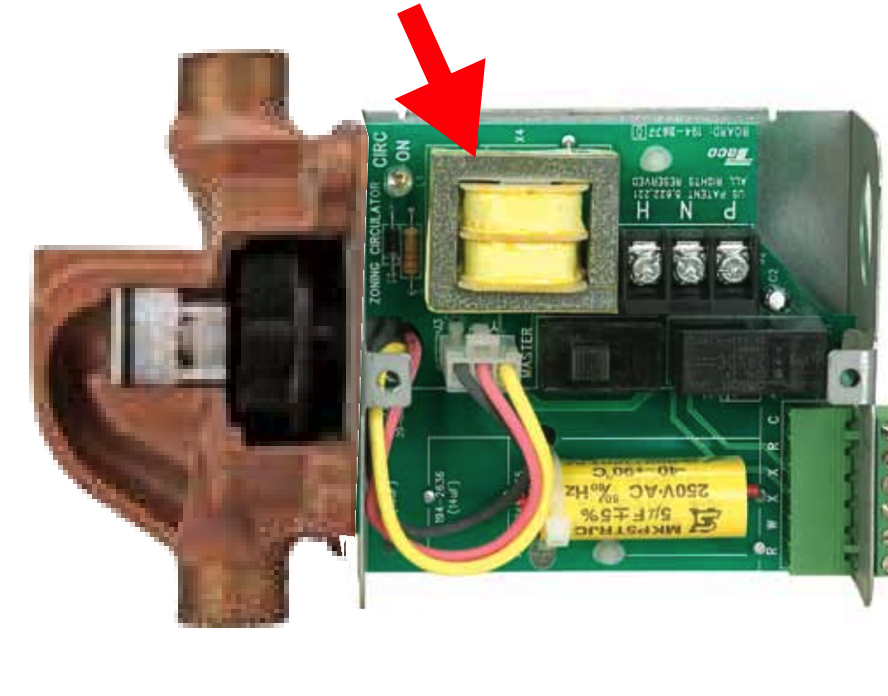

I'm adding a relay unit with C wire to enable a smart thermostat, and one way to do it is pull the board from the Taco and replace it with the relay, but I still need a starting cap. Will a fan cap like these work? I have one sitting around. My recollection of electronics says yes as long as the Mf rating matches and the voltage is high enough. But how do I wire it in? The Taco has a red, black and yellow from the motor. Obviously I ignore the red & brown wires, but then what? Or does it need to be a 2 wire electrolytic capacitor?

Comments

-

If you are talking about the Taco 006 ZB-4, I am not understanding why you need to remove the circuit board?!? If it has a printed circuit board on it, then that IS the relay you need to operate the smart thermostat.

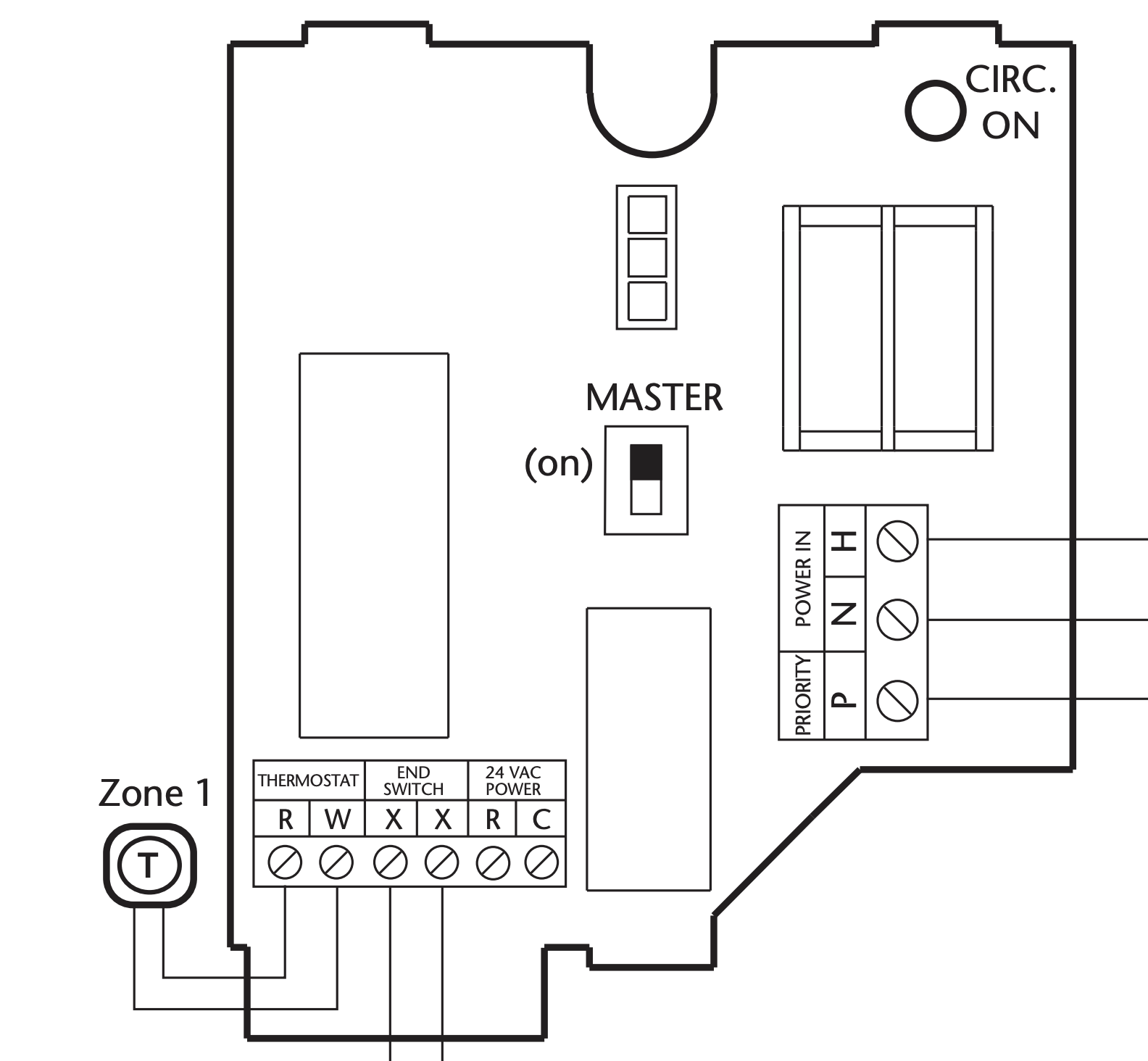

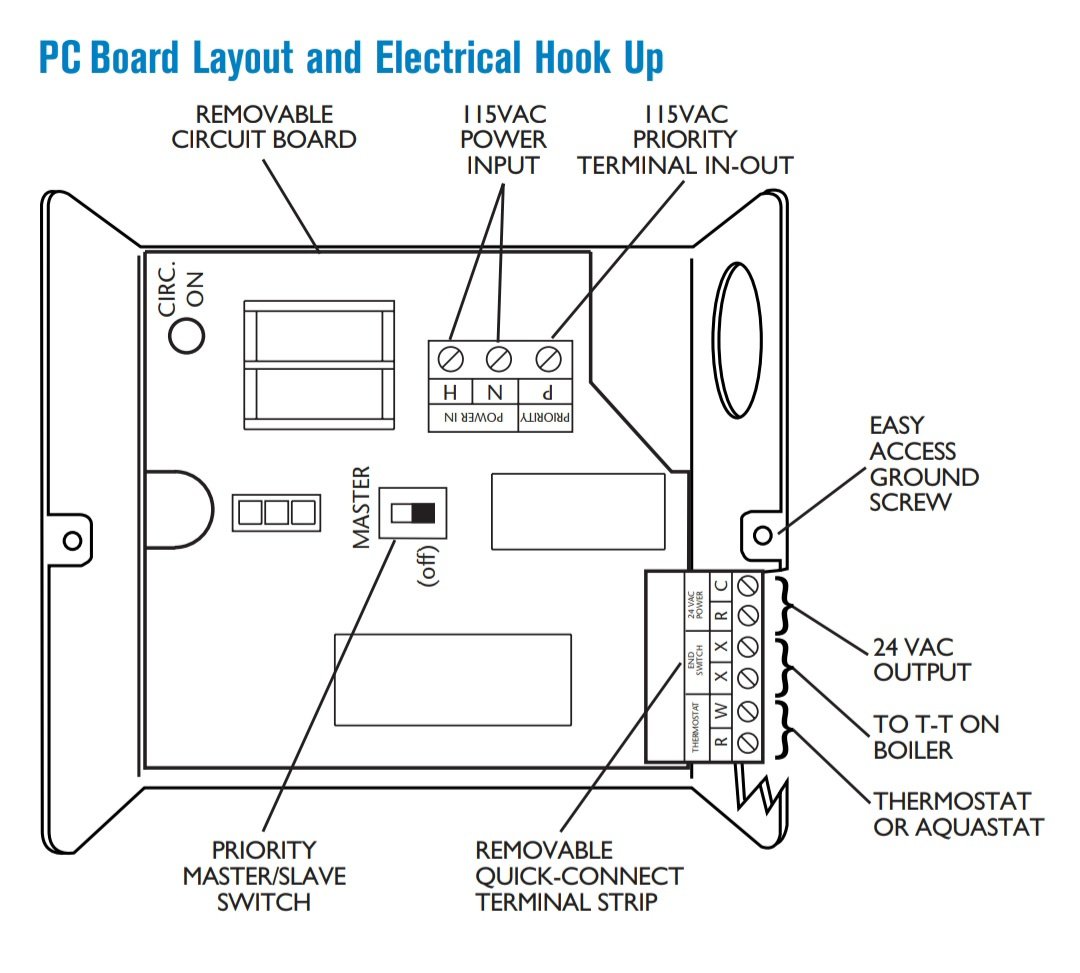

Across the bottom row of terminals are the place you connect the R from the thermostat, then the W from the thermostat. Then X X are connected to dry contacts to operate the burner when the zone relay in the 006 gets a call for heat. next is the the R for the transformer which is the same wire as the R to the thermostat behind the board. Then the C for the transformer that gets connected to the C on the thermostat.

If I understand your comment above, you want to remove a relay (PC board) with a C terminal to install a relay with a C terminal. Is that correct?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

What's the VA rating on the transformer on that board?

There's a Common available, but can the transformer handle it?

0 -

" and one way to do it is pull the board from the Taco and replace it with the relay, "

This sounds very odd, do you have proof this modification actually works ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

no idea what you're trying to do. a taco 006 is a line voltage circulator that is controlled by some sort of relay or other line voltage control.

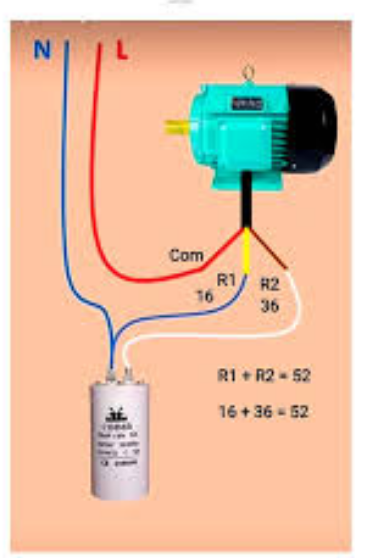

all capacitors are 2 wire, if there is more than 2 then there is ore than one capacitor in that package

0 -

I am getting an error using the onboard C wire even though it registers voltage. I've triple checked the connections on both sides, even pulled out the R from the Nest connector and touched it to the W, and the Taco started. Dunno.

@109A_5 Yes, I've used a packaged unit with relay and transformer to control a circulator, https://www.amazon.com/dp/B0C4LXXYHK. it's designed for resistive heating but works great for this. But that one was external, I didn't mess with the Taco's board that wasn't a relay board anyway.

@mattmia2 note the photo of the 5 wire cap. you choose which of the 3 capacitances you want, and seems like maybe the 2 gray are continuous, so it's really only 4 wire, and you only use 2. But my question stands, if I want to replace the board with a capacitor, how would the wiring go? Is it like the diagram below, but with the R2 from the motor being the black wire?

0 -

@Jellis said: "I am getting an error using the onboard C wire even though it registers voltage. I've triple checked the connections on both sides, even pulled out the R from the Nest connector and touched it to the W, and the Taco started. Dunno."

Then the transformer on the Taco on board does not have sufficient power to operate the NEST Thermostat. Use an separate transformer and isolation relay to power the Nest. The relay contacts can close the R and W on the Taco PCB. No need to reinvent the wheel, Isolation relays are used by Nest Pro installers all the time. I have several posts about using an isolation relay in this diascussion I started a few years ago:

Your system diagram to follow

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

-

You're spending an awful lot of work to do something shady, all just to avoid doing it the right way. Add a fan center somewhere, use that to feed the Nest & switch the circ.

Anyone who works on it will be able to figure it out, unlike your current plan; also it can meet any building code you have, which your current plan will not. That's a sticking point for me, as it opens you up for liability, as in if something should go wrong, the insurance company will certainly opt to not pay out on any claims.

Do it the right way. You'll be glad you did in the end.

0 -

My fundamental problem with this whole thread is… a relay, a PC board, and a capacitor are all fundamentally different things.

And I'm left wondering… what on earth are we trying to do here?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

Got it!

0 -

Basically, the OP has a circulator with the control relay (PC board) built into it. But the transformer in the circulator control relay is not sufficient to add the mirrored cereal bowl smart thermostat to its list if amp draw. The capacitor, which is part of the OEM control relay PC board, is not part of the OP's replacement control relay. So the OP needs to source a retrofit run capacitor for the circulator. Yes, this is what we've become. I want to know if the finished product at the very least fits in the original Taco electrical enclosure. Or will it be Dr. Frankenstein meets MacGyver?

0 -

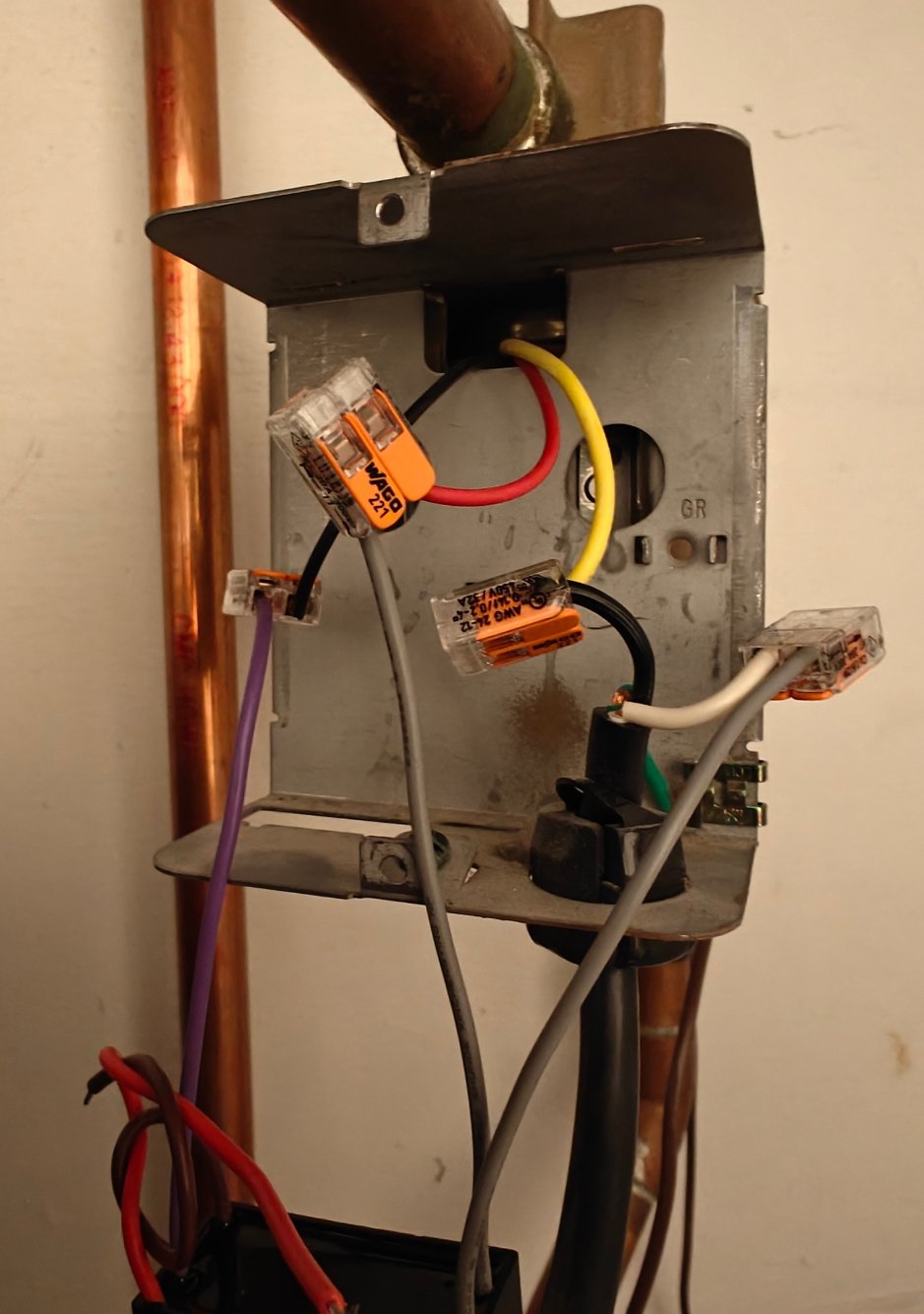

Thanks for seeing through the haze and summarizing! Yup, all fits fine. Only ugly is the 3 low voltage leads coming out of the enclosure to connect to the thermostat wire. I double and triple checked the damn Taco board, the Nest kept telling me my white was disconnected when shorting the red to it started the pump. ??? Whatever, it's done, it works, it was short money for the parts, like $35. It lets me look like a good landlord providing fancy thermostats, given out free by my utility!

0 -

-

I think there is a picture that showed a step in the rebuild that is missing. Half jokingly I would not be surprised if the NEST when up in flames.

How does that new to the situation Capacitor make the NEST happy ???!!!

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

So a bigger transformer and a different relay, different capacitor is stuffed in there ?

And this is in there too ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Why would the Nest care at all about the motor capacitor? It's getting its 24v circuitry from the transformer in the relay block, nothing to do with the 120v motor circuit controlled by the relay. Seriously, do you know much about electronics?

Yeah, I missed the broken insulation on the line in, but there's nothing conductive flying loose around the enclosure, there were exposed conductors on the circuit board I removed too!

0 -

Then just add the Caphttps://www.supplyhouse.com/Taco-007-002RP-Taco-Capacitor-for-Select-003-008-ModelsOr find a lower price equivalent.Nevermind… I see the original post with the three different uf value capacitors with the same enclosure. The purple and one of the grey wires = 5uf. Does that Cap have the same or higher voltage rating? Did you cap off the2 unused leads separately?@Jells, Can I ask you what relay you are replacing the Taco PCB with? Since you already own the relay, I have a feeling that you may have been able to add that relay/transformer unit to the Taco 006ZB-4 without removing the Taco PC Board that included the Taco capacitor.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

this reminds me of the low voltage screen control switch my coworker found burnt up because someone connected it to a line voltage screen instead of one with a built in or separate low voltage control.

0 -

I had linked it far above in the thread, but I can understand not wanting to rummage.

What I can't understand is all the people in this thread acting like old women, afraid of anything different that they don't understand, of skinning the cat a different way. Yes, I could have taken that unit and mounted it externally to the Taco, using the relay circuit to simply close the Taco's thermostat circuit. But it would have been clunkier than doing what I did, and not been all neatly contained in the original enclosure.

The original Taco board had a transformer, a relay, and a capacitor. I replaced it with... a transformer, a relay, and a capacitor!

Edit: yes, I clipped the leads for the other two capacitances and screwed on small wire nuts.

0 -

-

" Why would the Nest care at all about the motor capacitor? "

I don't know either but that is the way you started the thread.

" Replacing thermostat circuit board in a Taco 006 with a 5 wire fan capacitor? "So instant confusion !!!

No mention of a bigger transformer and a different relay. Which could have been added in another J-box (even at another location) for a nice neat installation without modifying the circulator, chafed wires and flying connections outside of the box. Just poor workmanship in my opinion.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

-

Or just chased to the box for the circulator connections. Also dont know if anything about the components on the board in the circulator are important for overload protection or other listing requirements.

0 -

@109A_5 I don't believe that the Nest problem had anything to do with the capacitor or anything on the line voltage side of the Taco PCB. The Nest had a problem with this transformer on the PCB.

The problem with removing the PCB to get rid of the transformer, you loose the Capacitor. The Nest likes this transformer relay combination, but the Capacitor is missing so the motor won't operate.

So adding a $10.00 Capacitor and a $30.00 relay/transformer thing gets the system to operate. I just think that a $25.00 relay would be a less expensive, less time consuming, and a less liability way to do the job. But that is just my opinion. The different relay/transformer combination would allow for low voltage to operate the Taco PCB. The Combination relay/transformer that @Jells purchased does not have the ability to do the low voltage contacts, only the line voltage circuit switch is available to turn on the circulator motor. And it all fits inside the electric box on the pump housing.

If the thing fails in the future, then @Jells has only himself to blame and will need to spend the $$$ for fix the failure. But if it lasts for 20 years, then we were all worried for nothing. I often tell my customers that just because it works does not mean it is safe. Like driving your car with no breaks is safe as long as you don't need to stop. But It's safe up to that point. just don't stop! Turn off the motor and coast to a gradual stop. It works for years if you are the only car, until there is another care on the road.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

I think you misunderstand. The reason why nobody understood what you were doing is because it was a dumb idea that no one here would have done. You were asking a trivial question, the answer to which was pretty obvious; indicating that you were in pretty far over your head.

There are right ways and wrong ways to do things. Just because it works doesn't make it safe or reliable. In this litigious society, doing something illegal in a rental property just doesn't make sense. It doesn't even have to fail, if your tenant notices that 'fix' & calls the building department, they're not going to say 'nah, it's fine".

0 -

Illegal? There's nothing at all illegal here. People replace parts all the time. That relay is wildly over rated for switching the pump on, and people replace motor capacitors all the time in household and industrial fans etc. The wires coming out are low voltage, no risks. And if the original question was so trivial, why did no one actually answer it?

0 -

Why didn't people answer the original question — including me? Because it made no sense at all as stated.

And it still doesn't.

On illegal. Whether what you have done is, or is not, illegal, depends not on what you have done — but where. If this is not an owner occupied house, it's illegal, unless you were working under the supervision of a licensed electrician. You can work on your own primary residence (although in many jurisdictions you need to have a permit for any work), but not on any other property.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I do not believe you are correct about the legality. This is a device that literally plugs into a wall socket. There is no licensing requirement to work on it an more than a vacuum cleaner. As for my OP, I asked a question about motor capacitors, something I thought people here would have experience with. I was wrong. I figured it out by tracing the leads on the board holding it up to the light, to see that the cap bridged the red and black.

0 -

Not UL listed = not up to building code. Not up to building code = illegal.

It might be illegal in one of those bureaucratic ways that seem to spring up like toadstools wherever government gets started, but illegal nonetheless. And a bad idea anyway.

0 -

The queestion you asked, and I quote, was "replacing thermostat circuit board in a Taco 006 with a 5 wire fan capacitor.

the termostat circuit board in a Taco has nothing to do with a fan capacitor. A fan capacitor — by which I naively assumed a motor starter capacitor — has nothing to do the the thermostat circuit board, and certainly doesn't have five wires.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

So you believe that had I simply spent $45 more for an identical relay unit with a UL listing like this one below which I've used previously, then there would be no problem at all, right?

https://a.co/d/3v2A2NH

0 -

-

No, I think if you had used one of these: https://www.supplyhouse.com/White-Rodgers-90-113-Fan-Control-Center-120-VAC-Primary-24-VAC-Secondary-SPDT-Relay would have an installation that is a) legal (UL listed), b) safe (made for this use), c) reliable (no parts of unknown origin or potentially misapplied), and most importantly d) any service tech will understand exactly what's going on.

If I came across this in the field, my repair would include replacing that circulator, along with the parts to do it right. You might be able to get Chuck in a truck to fiddle with it, but can he offer you the warranty that I do? Or the insurance, or bond, or licensing?

2 -

So a listed part argument was a red herring, it has to be EXACTY what you're familiar with, the same part that's been used for decades, and a simple more modern modular part like I used, which is listed for use in resistive heating, a far more demanding task, is just no good. Got it.

0 -

I have carefully read your original post, @Jells , as well as all your replies to the folks who have tried to understand what you wanted to do and what your actually did.

I dare say what you did worked… by accident. Things sometimes do. But I still have no idea what you were trying to accomplish, and I am fairly well convinced that you have no clue what you were doing or what the parts were that you were fiddling with or what they did…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

No, you dissassembled a non serviceable part & made unauthorized changes to it. The benefit of having something anyone can work on is just icing on the cake. (There are other ways of adding a transformer to power a stat, that's just the most convenient. A separate transformer & RIB would work identically & likely be cheaper by a few bucks, but twice as many parts.)

UL will come out & make a field determination if you want, but I'm pretty sure that it still wouldn't be kosher. Call the mfgr & ask them if they're ok with your changes. Call your building department & ask them how they feel about it. Call your lawyer & ask them. Call the fire department & ask them.

If it were in my basement, yeah sure I might do that in a pinch to get a circ back on on a Sunday in February. In a rental? No way.

0 -

@Jells I may have told this story before but this has real meaning in your case.

I have experience with field adjustments to a factory design. An architect specified a Lennox Pulse furnace to be installed in a closet. The builder installed the closet for the furnace according the the dimensions provided by the architect. When the furnace arrived for installation and connection to the ductwork, gas pipe and electrical wiring I found that the furnace fit perfectly with all the clearance to combustible with no room to spare. Architects do that sometimes. The problem is that the exhaust vent needs to exit the right side of the furnace then enter a tee fitting. There was to be a piece of 2” PVC to go down to a drain fitting to collect condensate and there was to be a 2” PVC vent to go up and exit to a side wall or thru the roof. There was no room for the venting system as it was specified in the I/O manual with a wordy description ans several illustrations. All the illustrations needed the ose the right side to have at least 6" of clearance for the exhaust system.

When the architect was contacted to tell me how to install this with no room for the venting system they replied that “the installing contractor may make adjustments in order to install the equipment in accordance with the manufacturer’s instructions” as stated on the blueprints. Basically he was saying that he screwed up but there is a clause in the blueprints that says that it is not his problem.

I came us with a great solution, there was just enough room to have all that happen inside the dimensions of the furnace, so I cut a hole in the vestibule floor of the burner compartment and fabricated a sleeve that went into the blower compartment. I sealed the sleeve with silicone because I didn’t want the extreme negative pressure of the blower suction in the blower compartment to draw exhaust gasses from the vent pipe in the event that the exhaust vent ever failed in the future. This worked out perfectly and the system operated as it was designed for the entire heating season. There was a problem with the cooling system as a result of exceeding the maximum refrigerant line lengths and also burying the refrigerant lines below grade. I installed oversized lines and added a hefty receiver as instructed by Lennox technical Support as a result of my not wanting to install their equipment with unusual piping design without their approval.

When the first summer heat wave arrived 7 months after the installation was completed, the factory modifications did not account for a reduction in capacity, so the system did not cool the home as designed with the architect specified equipment sizes. They specified 4 tons of cooling was needed but the reduction in performance would mean that I needed to install a 5 ton unit to get 4 ton of capacity after it was derated due to the excessive lineset length and other reason.

To get this diagnosis from the factory I needed to meet with the factory rep from Lennox Industries, the architect, the homeowners lawyer and the builder on the job site. As soon as the Lennox people saw the furnace modification for the vent pipe (which has nothing to do with the air conditioning performance issues) they indicated that the equipment was not installed in accordance with the installation manual and therefore the warranty was void. They accepted no liability for their problem with the air conditioning side of the system because they saw an easy way out to keep from having to pour warrant money into solving the problem.

Needless to say it ended up in court with everyone being sued. The architect, the builder, Lennox Industries. Everyone except me. The homeowner watched the entire process and knew that I knew how to fix the problem so he didn’t want to piss me off. You see, I was his HVAC guy on several properties and he knew that I knew what I was doing, and he saw how Lennox threw me under the bus. I got the system to operate adequately and never sold another Lennox Product again.

So your modification may have no consequences at all @Jells, but you never know!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

it is in a real way as well. we don't know what safety features are designed i to the control board that has been bypassed. you wouldn't need just an electrician, you would need a PE to evaluate the modification and sign off on it if it didn't bypass any required features.

0 -

My confusion and (thank you @EdTheHeaterMan for your explanation) I did figure it out as I stated above, but your explanation may help others that need the clarity.

I stand by this;

What does the Red underlined words have to do with the Orange underlined words ??? Especially since looking at the picture that @EdTheHeaterMan provided there are other components on the circuit board that may support other functionality, not just the apparent Run Capacitor.

I'm sure any UL listing or any other applicable electrical regulatory certifications have been voided (at least for the modified part). UL listing or any other applicable electrical regulatory certifications apply to plugged in devices also.

In my opinion there are good 'tricks' (if you want to call it that) to doing well meaning modifications, you violated most or all of them.

Again " No mention of a bigger transformer and a different relay. "

The NEST use did not come up until almost everyone freaked out.

Well that is easy, IMO, it is the piece of consumer electronics that does the best job of inviting this kind of nonsense.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

I give up. Many of you seem to think that there's some kind of magic to the OEM board. There is not, I have examined it closely. It is just a relay, transformer, and capacitor, plus a couple of diodes and resistors for LEDs. I have worked on many machine tool motors and fans and other devices, the stuff is not usually rocket science. My post was entirely just trying to decipher the color code of the motor wiring.

The comment about the thermostat on the 24 volt circuit blowing up was illustrative of how little this stuff is understood here. Machinists, a group I belong to, are way more savvy about just getting things to work and understanding why they do. Many of us have built dynamic 3 phase converters from scratch without blowing ourselves up. And then when VFDs came along we embraced those rather than shrinking from them as scary new technology. Oh well, different strokes.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements