Church Indirect Heating System

The building consists of a small partial basement housing the boiler, a ground-level entry foyer and meeting hall, and the 2nd floor sanctuary where service is held. There is inaccessible crawl space under most of the building.

There were (are) 4 plenums (for lack of a better term, -what do we call these enclosures?) housing 4 banks of 20 each H.B. Smith Gold Pin radiators. Two plenums are in the boiler room, and the other two are at the opposite end of the building higher up on the first floor. These heat the 2nd floor sanctuary through 5 (one plenum has two grates for some reason...) floor grates.

The entry foyer is heated by standing Crane radiators, and the meeting hall is heated alone by the steam pipes running along the walls. The pantry, library, and nursery are heated by Serpentine (my term) "radiators":

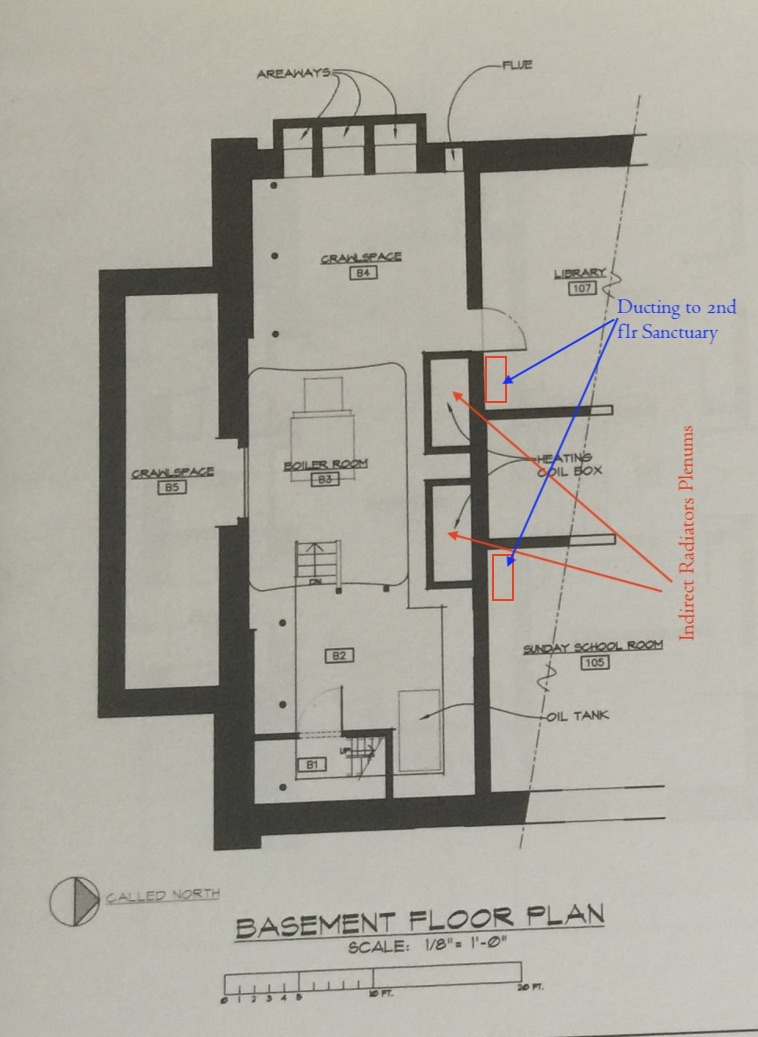

Here's the blue prints:

Basement/Boiler Room with two plenums:

1st Floor Meeting Hall & Stage:

2nd Floor Sanctuary:

To be Continued...

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com

Comments

-

When you say efficiently -- is it more a matter of not particularly evenly (I don't see how it could be even!) or that it burns more fuel than it ought to? Really two different questions.

There really isn't any particularly good reason why that sort of indirect setup (and no, I don't know what the "plenums" should be called, either!) should be particularly inefficient -- but it certainly could be pretty uneven!Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

The issues I think are two-fold: We may have found the first under-radiated building, and the plenums.

All the plenums I have seen had brick enclosures and cast iron doors. These four plenums have metal studs and drywall.

Obviously not original. But that's a mystery in itself. Who would go to the trouble to dismantle such a structure? And the basement has difficult access to boot.

At any rate, the original ducting that brought outside air in to the boiler room plenums is still up in the ceiling, but no longer connected. More interesting: The drywall plenums have sealed openings that line up perfectly with the original ducts. So when they rebuilt the plenums they either reconnected the outside air, or figured they might have to. What they did instead was run ducting from underneath these two plenums up to the first floor lobby and installed grates. Directly in front of the radiators:

They also installed fans to pull in the air on these two plenums. We found the fans in the off position, but operable. Did they pull all the heat out of the lobby and so were turned off? I don't imagine we're getting much convection pulling air from right in front of a radiator to the plenum though, without fan assist.

The rear plenums were also rebuilt with metal studs and drywall. We think either 1987 or 2001. (Did they use metal studs in 1987?). These pull air from behind the stage. A much cooler area than in the front (where they are pulling from in front of radiators). No fans here, natural draft. The only thing that really heats the first floor hall are the steam pipes along both walls:

So I am guessing the first floor is a little chilly...

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

The church has been in a trust since around 1875, and it has a board of trustees. And what is a board of trustees to do with difficult decisions? Hire an engineering/consulting firm of course.

And of course you know what they recommended:

Convert to hot water and use wall hung condensing boilers. Why ever not? I am sure those plenums will heat far better if we decrease their temperature by some 40%. I kid you not, they call for 130 supply temperature...

The other idea is to install 6 million mini-splits, completely destroying the aesthetics of the building.

And then there is yours truly. Poking around in all the dark corners, trying to figure out how it once was, and how best to get it purring again. And that's where you come in. I need all the eyes on this one I can get.

So start commenting already Wallies!

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

Single pipe or two pipe steam?

What's changed?

Follow the air back through the supply grills, across the radiators, & then stop and look around. If they originally drew outside air, the ΔT that drives the indirect would be monumental. If they're drawing more-or-less 'conditioned' air from inside the envelope now, the ΔT will be smaller & performance will subsequently suffer. I think.

2 -

If the indirect radiators themselves aren't heating, the usual vent-the-heck-out-of-it procedure should cure that.

And, what @ratio said about air movement.

These old indirect radiators can work well as long as the knuckleheads are kept away. Here's one location where they're still in regular use:

https://forum.heatinghelp.com/discussion/151036/lovely-lane-methodist-church-a-steam-heating-museum

That engineer is not worthy of the name if he can't figure this out.All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

I think so too. But I need to better understand the math. Certainly we are going to be moving a lot more air using the cold outside air. But then we'd also be heating very cold air, instead of warm air.ratio said:Single pipe or two pipe steam?

What's changed?

Follow the air back through the supply grills, across the radiators, & then stop and look around. If they originally drew outside air, the ΔT that drives the indirect would be monumental. If they're drawing more-or-less 'conditioned' air from inside the envelope now, the ΔT will be smaller & performance will subsequently suffer. I think.

It's a two-pipe, with everything dead ending into a wet return.

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com1 -

Speaking of outside air , what do they do for their required outside air now ?

( edit : oh by the way metal studs were common in 1987 I carried plenty that year with my friends dad who owned a drywall company ).hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

0 -

You want to give vacuum lines a try?

It will decrease the pickup losses, give you the control to heat whatever radiator you want, as fast as you want, makes the system self balancing in the off cycle, eliminates all other air vents as a point of failure.

It would be 100 X cheaper then converting to hot water.

As for the indirect heaters,

Your right about them needing air flow. If you can't take the outside air, you should be taking air from the space the radiator is serving (easier said then done).0 -

1. You can see in the basement blueprint there are 3 airways. One was used for the two plenums, the other two for combustion air, which are still in operation.

2. Keep in mind that total EDR is around 1500 and 900 of that is the Gold Pins/Plenums. Only 234 is radiators (5). The remainder is bare pipe. So the plenums are the whole deal really.

I think this is about moving air. But I am not an air-moving expert.New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

It also struck me that the opening from the plenums to the ducting is small (and very inaccessible). The opening might be 6" or 8" x 12". Maybe exactly what was needed originally to give the cold air time to heat? But now? Does it make sense to be the same size when we no longer have cold outside air?New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

I agree completely -- it's about moving air. Those big Gold Stars can almost certainly do the job, if they have enough circulation and the losses are cut.

I'm not really happy about the drywall and stud plenums and ducting. On the other hand, getting in there to insulate them and smooth the interiors -- which would help a lot -- might be a real bear. Worth thinking about. Also, take a second look and make sure that there is at least as much intake/return air area as there is duct and supply grille area. As a sort of if this doesn't work fall back, there are low noise high volume blowers which can be had which would solve the problem of not enough circulation.

I have a sort of suspicion that somewhere back in the '80s someone may have gotten fired up about saving energy, and that may be when the outside air connections were eliminated and the odd return grilles in front of the radiators installed. You might take a look see and see if there are alternative locations for those return openings -- I agree that it seems a somewhat odd location for them -- and the location doesn't favour gravity convection anyway, which is what the system was depending on.

On the steam piping -- two pipe but dead ending into wet returns? I presume that there are some dry returns also? Knowing you, I imagine you're way ahead of me on this, but... they are adequately vented, no? Assuming this is a more or less otherwise normal two pipe system, I'm not sure I see how @AMservices 's idea of vacuum lines would fit into it. And knowing churches (I work with some) I'd be dead set against anything even remotely complicated.

The engineer you mention should be put out to build pedestrian bridges over superhighways, perhaps. As usual...

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

That's a tough equation. Do you know what the CFM ratings are for the fans?0

-

I don’t know the rating of the fans, but it wasn’t much by observation, they were turned off (as in not used), and only 2 of 4 plenum have fans.New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

That sounds small to me. Look more closely- are there sliding dampers there?New England SteamWorks said:It also struck me that the opening from the plenums to the ducting is small (and very inaccessible). The opening might be 6" or 8" x 12". Maybe exactly what was needed originally to give the cold air time to heat? But now? Does it make sense to be the same size when we no longer have cold outside air?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

I'm not sure how they are connected but to promote airflow you would want a larger opening than the duct being served. I'm wondering how well this system ever worked after looking at that drawing. I'll bet someone came in on Saturday to stoke that thing to the hilt to be ready for Sunday.New England SteamWorks said:It also struck me that the opening from the plenums to the ducting is small (and very inaccessible). The opening might be 6" or 8" x 12". Maybe exactly what was needed originally to give the cold air time to heat? But now? Does it make sense to be the same size when we no longer have cold outside air?

hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

0 -

Here's a rough drawing of one of the boiler room plenums:

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

An artist! That's very clear, thank you! But if that little curved duct is the return air supply -- it's not big enough unless there is a fan on it, and I'm a little surprised that the opening into the vertical ducting is that small. I'd be interested if there were any signs of modifications to the brick work, as well as the new sheetrock ducting.

It can be made to work, though -- but may take a blower.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

The return duct does have a fan. But they don’t use it. Haven’t found out why yet, but I will hear soon.

No modifications to the brick still existing. But what was there before the drywall enclosure is unknown.New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

Thinking (sort of) about it -- I don't think you could go wrong figuring and airflow requirement and fans and duct sizes in the same way as you might forced air with the same BTU input as those gold pins... which isn't my thing, so I'm going to stop right there.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Not a heating guy and have no heating experience with air natural convection heating, but it amazes me that cross sectional area of return ducts are so small compared to hot vertical supply ducts. Just an engineer's observation.

Gut feel is that will throttle the flow. Unless there's some quirk that large area hot ducts help promote chimney effect draft, but that's not obvious.

0 -

I guess I'd start with some basic calculations:

1. What is the required heat input to heat the building adequately at the design day, do a heat loss calculation on the building and the separate smaller spaces? (different probably for churches than for homes I'd guess).

2. How does the existing boiler size and existing radiation size compare to the required heat needed? (if air circulation issues are fixed does the boiler and existing radiation even have a chance to do a proper job).

3. Then figure out required air flow at reasonable supply and heated air temperatures for the plenum air flow to deliver the heat the 40 gold pin radiators can supply. And, figure out where that air comes from (how much outside air is needed) and how it must be returned to the plenums/radiators to deliver the heat--pretty much a conventional forced air calculation using steam heated radiators as the heat source.

4. If the smaller spaces that are heated by radiators, wall pipes, etc are a problem, then perhaps they could be looked at separately once you get the main space set up.,

As Jamie indicated/implied, it's really a forced air heating system calculation with the heat delivered by steam heated radiators to the air stream, a little unusual, but not really complicated, other than trying to figure out how the air flow was supposed to work and then how it SHOULD work, and first if it ever can work with the existing boilers and radiation without boiler and/or radiator replacement or upsizing.

0 -

Thanks guys. Unfortunately, forced air isn't really my thing either, so I am little lost.

BTW, the job is to replace the boiler. It's leaking. I'm just not sure I want to get involved unless I can make an improvement. Making a big improvement is what I am all about.

But if I can't figure the air-thing out, I'll just be swapping boilers. Although I am sure I am the only one who took the time to calculate the EDR in the building, and it would be installed correctly, I am hesitating because of the air-thing....New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

On the other hand, if I could figure it out, -I'd be all in.New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

Rough rule of thumb for gas furnaces is 100-150 cfm per 10k btu depending on furnace type. You can go lower than that because of being indirect so I would roll the dice at 75 to 100. Also vfd's are cheap now ( all things considered ) .hvacfreak

Mechanical Enthusiast

Burnham MST 396 , 60 oz gauge , Tigerloop , Firomatic Check Valve , Mcdonnell Miller 67 lwco , Danfoss RA2k TRV'sEasyio FG20 Controller

0 -

Try Heat pumps on the outside walls for heat & AC0

-

They looked at this. Aesthetically a non-starter. Building is historic.RayH said:Try Heat pumps on the outside walls for heat & AC

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

You don't need heat pumps. You have a perfectly good steam system in there and I am quite sure with some thought and ingenuity -- which I happen to know you are good at -- you can get it to work just fine.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

Cant really bring in outside air unless the inside air can escape somehow. Can't get two pounds of coffee in a one pound can. Is there a radiator flue like schools use somewhere?gwgillplumbingandheating.com

Serving Cleveland's eastern suburbs from Cleveland Heights down to Cuyahoga Falls.0 -

Could they have used the crawl space for the outside air?

There should be evidence of outside inlet grills probably closed up. Hopefully no plumbing lines in it.

They may have relied upon loose windows to relieve the air pressure.

BTY, I work on a 1961 building that has steel studs.0 -

The air density of the cold outside air versus the density of the heated air would cause a decent air flow. Now with the OA cut off the difference in density of the air is only supply air to return air which may not cause enough air flow...hence the fans.

getting the ratings of the old indirect's would be ideal. If you can't find anything I would go by the size of the steam supply feeding the indirect's (not the indirect connection size) it would give you a rough guess.

Lets just say that your return air temp is 65 and you want a supply temp of 110 (anything less than 110 will fell cool when it is moving)

Then

lbs of steam (from pipe size or indirect rating) x 1000btu/lb of steam=btus

BTUs= cubic ft of air to move x 1,08 (a constant) x temp rise of air

So for an example 100,000 btus (100 lbs of steam)/(1.08 x45 deg air temp rise)=cfm

100,000/48.6=2,106 cfm

Then the fan ductwork and registers would be figured off that2 -

Well, today is the day we've been dreading for 4 months: Removal of the old boiler and delivery of the new sections. What's the reason for the dread? Access. There's only a very narrow steel ladder down to the boiler room:

Coupled with a low ceiling above the ladder:

...meant no way to get an A-Frame in, or any type of winch. That left us with only caveman tactics: Sledge hammers and axes to smash the sections up into "manageable" pieces:

Brutal.

Then the new sections had to be lowered down by hand. Heavy, dangerous work.

But, done:

And I am very relieved.

Tomorrow we start building.

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

Some progress. Nice to have Ilka!

New England SteamWorks

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

Beautiful as always Ryan @New England SteamWorksDL Mechanical LLC Heating, Cooling and Plumbing 732-266-5386

NJ Master HVACR Lic# 4630

Specializing in Steam Heating, Serving the residents of New Jersey

https://heatinghelp.com/find-a-contractor/detail/dl-mechanical-llc

https://m.facebook.com/DL-Mechanical-LLC-315309995326627/?ref=content_filter

I cannot force people to spend money, I can only suggest how to spend it wisely.......-1 -

Brick by brick...

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

AWESOME !gwgillplumbingandheating.com

Serving Cleveland's eastern suburbs from Cleveland Heights down to Cuyahoga Falls.0 -

Making progress!

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com1 -

that is one classy looking job to be proud of!gwgillplumbingandheating.com

Serving Cleveland's eastern suburbs from Cleveland Heights down to Cuyahoga Falls.-1 -

Beautiful install as always Ryan @New England SteamWorks-1

-

Finally finished this one. 6 months from conception to completion. The last phase was a hot water loop. So far, everything seems to be running just fine...

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements