Awful smell & health concerns from new Weil McLain install

The installers have flushed the system 3-4 times, including once when they ran the system for two days with vinegar in it. The smell is less, but still enough that we've shut the boiler off and are back to space heaters. We need some help!

What could this be? Why would it start all of a sudden when this new boiler was installed? Is it unusual for there to be smells, or smells this potent?

We're at a total loss for what to do next...

**What do we do to 1) stay safe and 2) get our heat back??**

Here's a more detailed narrative of what happened/what we've tried:

Nine days ago (10/27) a local company installed a new Weil McLain EG/PEG-40 Series 5 Natural Gas-powered steam boiler in our basement, replacing a 15 year old Burnham Oil-fired boiler. It's a 1-pipe steam system. I liked these guys at first and they seem reputable, but many things have gone wrong with this installation in the last week.The main one is: When the boiler is fired up, the radiators throughout the house vent an absolutely awful smell, like burning plastic. There was absolutely NO smell coming from our radiators before the installation. If I'm in it for more than 5-10 minutes my lungs hurt/burn a little bit, and I get a headache. Recently I've noticed a faint burning sensation in the back of my throat and on my nose. My wife has pulmonary fibrosis, a lung disease, and we are very wary of putting her in a context where her disease will be exacerbated or worsen (short or long term).

We reached out to the installers immediately (after shutting off the boiler and switching to space heaters), and they came back the next day to do a flushing/cleaning. On installation day the only cleaning they did is a VERY fast skim (10-15 seconds) while the boiler was hot/boiling and at 4-5psi pressure, shooting some steaming water into a bucket and then dumping it on our lawn. (I've since convinced them to lower the pressuretrol. Still not happy about the lawn.)

Fast forward to today. The problem did not go away after the first flush/cleaning. They've come back 4 days this last week to do more cleaning (we had to move out of our house for those days), including at one point adding a gallon of vinegar. They've been consistently running the system with the thermostat at 82-85 degrees. The smell is less, but still bothersome after a few minutes. And the thing is, we have no idea WHAT we're breathing in. The installers said, "no, there's never anything toxic in there." Between the pipe dope, flux, pipe oil, all the unidentified "oils" present in the boiler, and everything we DON'T know about... I'm not convinced.

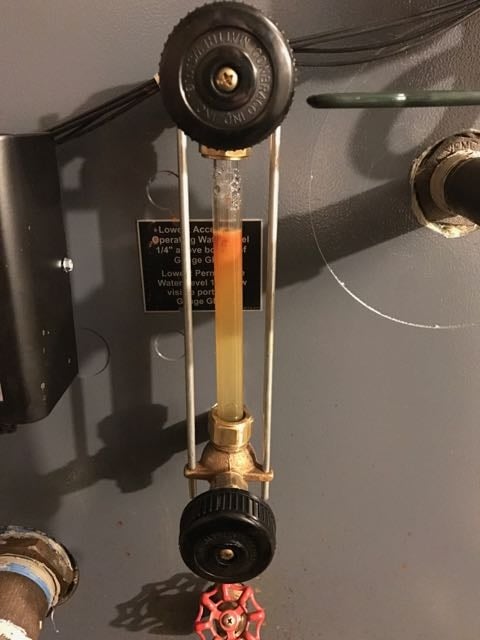

Most recently the water in the sight glass has taken on this eery yellowish tint with an orange/red substance that's floated to the top (see attached picture). We turned the boiler off again and are back to space heaters, in part because of how we've been feeling -- me with a headache, burning in throat and nose; my wife with higher than normal levels of pain. Even our cat has some congestion/is wheezing. We don't know what to do next. (Neither do the installers.)

Where could this smell be coming from? What is it? What health risks do we run by turning the boiler back on? What guarantees are there that these are NOT harmful chemicals that we're dealing with?

Could this all be from the new Weil McLain and the new piping they put in? Could any of this be from our existing piping/radiator system? Again, there was ZERO smell before they installed this new boiler.

Some pictures

The sight glass:

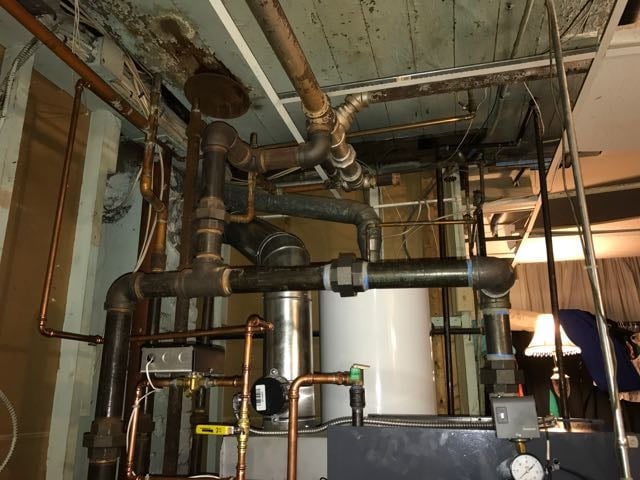

The boiler:

Comments

-

I would say they either put some kind of chemical cleaner in the boiler and they have failed to drain the boiler and actually washed the inside down with a wand OR they left a rag or some tool in the piping/boiler and it is dissolving/melting in the boiler.

There is no way to actually skim a boiler with it running/boiling and the pressure at 4 or 5 PSI. Turn the scale on the front of the Pressuretrol down to .5 PSI. Take the cover off of the Pressuretrol (screw on center bottom front). There is a white wheel inside. Set it to "1" facing the front of the Pressuretrol. That will give you a Cut-in of .5 PSI and a Cut-out of 1.5PSI. That's about as high as the pressure should go, actually the thermostat should be satisfied without the Pressuretrol intervening. The Pressuretrol is actually a safety device.

I would suggest letting the boiler cool down, draining it and at least filling it two or three times and draining it each time before filling it to the correct level on the sight glass and firing it up. It will still likely need to be skimmed slowly but at least, hopefully, you can get the smell out. I wouldn't use vinegar either. It's OK and won't do any harm but it does add to the odor and it does change the ph of the water.1 -

The only thing that I know of that is rubber that would get heat in that boiler are the push fittings connecting the sections together, but they should never get hot enough to burn. Maybe you should get one of the pros on here to come over and take a look.0

-

The piping actually looks good which is surprising, though I can't tell if there's a proper hartford loop or not from the pictures.

If it was mine, I would hit the emergency off switch on the boiler, wait for the boiler to cool some, open the skim port with a 5 gallon bucket under it and crack the manual feed valve and slowly start adding water. Water will slowly start running into the bucket through the skim port.

Fill the 5 gallon bucket as much as you feel comfortable carrying and as it gets near that point either switch it with another bucket or shut the manual feed off before it overfills.

Do this for 2 or 3 buckets worth and then drain the entire boiler. Once it's drained, refill and skim 1 more bucket worth. After that drain it to it's normal operating level and try it out. Oh, and open the drain on the bottom of the gauge glass using a wrench to flush it out as well. Make sure the skim port valve is shut and the cap is on before you turn the emergency shut off back on.

This is more time consuming than anything but I would expect very good results. I think you'll be very pleased when you're done.

Please remember you'll be working with extremely hot water early on, though it will get cooler and cooler as you go. DO NOT get the water on you, it'll be 200+F if the boiler was on recently. This is something anyone could do, but take your time.Single pipe quasi-vapor system. Typical operating pressure 0.14 - 0.43 oz. EcoSteam ES-20 Advanced Control for Residential Steam boilers. Rectorseal Steamaster water treatment2 -

Here's a video of one of the last times I skimmed my boiler. This is about as fast as you want to go in my opinion. This will also give you a good idea of what you're doing, and perhaps show you it's nothing difficult or scary. You're just skimming water off of the top of the boiler's water. https://youtu.be/nPKTSn-depc

https://youtu.be/nPKTSn-depc

Single pipe quasi-vapor system. Typical operating pressure 0.14 - 0.43 oz. EcoSteam ES-20 Advanced Control for Residential Steam boilers. Rectorseal Steamaster water treatment2 -

Technically speaking, the return connection to the Hartford loop is not connected properly.

This is how it should look:

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

I would drain and fill the boiler a few times while cool. Add 1 lb tsp & 1 lb of caustic soda/50 gallons of boiler water, raise the boiler water temp until the header is hot (but no steam) then skim. Drain then fill when you can hold your hand on the sections comfortably0

-

Thanks for the quick replies. Y'all are awesome.

@Fred - The installers said they have not put any kind of cleaner in the boiler, besides the vinegar they tried on 11/1. Since the install, they have drained and refilled the boiler 3+ times (according to them -- I have only been present for bits and pieces, but trust them on this). They did NOT do any cleaning on/in the boiler when first installing it.

They have NOT washed the inside with a wand. And my sense is the boiler has not been properly skimmed yet -- the "skimming" that is being done it seems is being done much too rapidly.

What would be the next step to see if it is indeed a rag/tool left inside one of the pipes?0 -

Rag or tool may be difficult to find without taking all the piping off the boiler. But what if they did drop a can of flux or pipe dope in the boiler?? I suppose it might account for the awful smell & funny looking sight glass. Or maybe they dropped their lunch in their!! Sorry it's not funny you shouldn't have to put up with this.

You may have to stand on your high horse with them to get results!!

The fact is you had NO SMELL until the boiler was installed. I think the least they owe you is a proper skim in accordance with the boiler MFG. requirements (read the manual)

Then see what happens after that2 -

@ChrisJ & @Ironman - thanks for looking over the piping. Here are two more shots that might make things clearer. Ironman, correct me if I'm wrong, but I think the piping actually DOES match that specification -- you just couldn't see it in the original pictures I posted. It's hard (but possible) to see even in this first picture below.

@ChrisJ & all - you've convinced me to give skimming a try! I read in a post by Dan "the man" Holohan (does anyone ever call him that?) that he recommends skimming cold. What's the rationale for doing it warm vs cold?

I read in a post by Dan "the man" Holohan (does anyone ever call him that?) that he recommends skimming cold. What's the rationale for doing it warm vs cold?

1 -

It looks like you have a union in the middle of the header that could be taken loose and you could probe in that piping with a camera and it also looks like there is a plug/drain valve on the bottom of the equalizer that could also be an access point to inspect the lower portion of the piping. Do you hear any tapping/clanging coming from inside the boiler? That might indicate a tool bouncing around when the boiler is steaming.

Before I did any of that though, I would personally do a very slow skim and then drain and refill the boiler a couple times. Just because they say they didn't put anything in it, doesn't mean they didn't. It just strikes me as a bit peculiar that the water in that sight glass has what looks like three layers, kind of milky on the bottom, a more translucent yellow in the middle and an orange on the top. It's as if one or two of those liquids isn't water soluble.

All the water droplets in the very top of that sight glass is also indicative of a boiler that is begging for skimming.0 -

Yes, that pic clarifies it. It looks right.Justin said:@ChrisJ & @Ironman - thanks for looking over the piping. Here are two more shots that might make things clearer. Ironman, correct me if I'm wrong, but I think the piping actually DOES match that specification -- you just couldn't see it in the original pictures I posted. It's hard (but possible) to see even in this first picture below.

@ChrisJ & all - you've convinced me to give skimming a try! I read in a post by Dan "the man" Holohan (does anyone ever call him that?) that he recommends skimming cold. What's the rationale for doing it warm vs cold?

I read in a post by Dan "the man" Holohan (does anyone ever call him that?) that he recommends skimming cold. What's the rationale for doing it warm vs cold?

Judging from the older looking dope on the pipes farther from the boiler, it looks like they may not have done them?

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Vinegar won't clean a steam boiler. In fact, it will add to the odor problem. Old timers used it to lower the ph if it was too high.

I'd recommend that you slowly drain an fill the boiler and wet return a few times then skim it properly. Then add some TSP (trisodium phosphate) to clean it. Let it cycle, then drain, fill, and skim again until your sight glass is clear.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

The hartford loop looks right.

The mains should have been modified, but it may work fine, at least the boiler has a proper header.

Skim it as I said and I'm betting things are going to improve.

Be warned, it may run fine for a bit, and then get dirty again. That's normal. It's going to take time for the oils and such to work their way out but you need to keep the boiler clean.Single pipe quasi-vapor system. Typical operating pressure 0.14 - 0.43 oz. EcoSteam ES-20 Advanced Control for Residential Steam boilers. Rectorseal Steamaster water treatment1 -

@Justin Looks like from the pics the installer bushed down the skim tap. Why?? And also that boiler is dirty. Also looks to be only a 2" riser and header judging from pics anyway, if thats the case your steam velocity is waaaay up to almost 31 FPS. The Weil McLain manual suggests a minimum of 2-1/2 which keeps velocity around 22 FPS, still too much for me. With that boiler I run two 2-1/2 risers which give me around 11 FPM

If this is the case, call the installers and demand they install the proper size piping listed in the boiler manual, because of course Weil McLain would void your warrentee if the instructions aren't followed.

DL Mechanical LLC Heating, Cooling and Plumbing 732-266-5386

NJ Master HVACR Lic# 4630

Specializing in Steam Heating, Serving the residents of New Jersey

https://heatinghelp.com/find-a-contractor/detail/dl-mechanical-llc

https://m.facebook.com/DL-Mechanical-LLC-315309995326627/?ref=content_filter

I cannot force people to spend money, I can only suggest how to spend it wisely.......1 -

This reminds me of another thread from earlier this year. Never heard if they had any resolution though.

http://forum.heatinghelp.com/discussion/157986/asthma-attacks-from-new-steam-boiler-please-help/p11 -

Reminds me of the Weil rep with the glass-piped demonstration boiler. He admonishes that no matter how late the install goes, never wait until the next day to skim. Once the boiler steams and everything gets up into the system it will be much more difficult to clean it all out. May or may not be applicable in this case, but a timely reminder.New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com2 -

Why is no one commenting on the bull-fed tee on the main?Contact John "JohnNY" Cataneo, NYC Master Plumber, Lic 1784

Consulting & Troubleshooting

Heating in NYC or NJ.

Classes1 -

I saw it too. Just didn't comment because it looks like it was done by a previous installer and it's certainly a secondary issue to the HO at this moment.JohnNY said:Why is no one commenting on the bull-fed tee on the main?

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

-

Or the reducing fittings on the horizontal...0

-

@RI_SteamWorks - This was my original thought. After watching a few youtube videos of people skimming and/or hosing out their boilers (especially Gerry Gill), I thought... "So, you mean all that crap is being boiled up into our system each time we turn on our boiler...?"RI_SteamWorks said:Reminds me of the Weil rep with the glass-piped demonstration boiler. He admonishes that no matter how late the install goes, never wait until the next day to skim. Once the boiler steams and everything gets up into the system it will be much more difficult to clean it all out. May or may not be applicable in this case, but a timely reminder.

0 -

@Justin Ask the installers to show you the spool of Teflon tape and the can of pipe dope they used on the pipe joints. See if the containers have rated temps on them. I'm wondering if they used something that is not rated for the temps of a steam installation. Clearly whatever that stuff is, it's heavier than water.

Also, do you know how much vinegar they put in the boiler? Vinegar, being acidic may well be the cause of the burning you feel in your throat when it boils and the vapor/fumes flow through your system and out through the vents until the vents close. In fact, if the radiators are not getting hot all the way across, the radiator vents will never close. The weather has been mild enough, in most places that the radiators are not getting hot all the way across and the vents will remain open.0 -

@KC_Jones - WHOA. That person (Casey / @asthma ) is describing very similar what we are going through. Does anyone know if there was a resolution?KC_Jones said:This reminds me of another thread from earlier this year. Never heard if they had any resolution though.

http://forum.heatinghelp.com/discussion/157986/asthma-attacks-from-new-steam-boiler-please-help/p10 -

You need a second opinion. You need to ask one of the pros on here to come in and look at it. Your gonna make yourself nuts trying to figure this out. It's an ugly deal, but if your current plumber did something wrong, he's not gonna admit it and your fight with him is gonna escalate when you demand rework or refund. You need one of the trusted pros figure it out.

If the come over and it's a easy fix, I would demand that the existing plumber reemburse you for the service cost.

Your dealing with a possible hazardous condition which is keeping you out of your house/on electric heating. Time to take a more aggressive approach or you will be in a freezing cold house with your electric bill sky rocketing while you try and stay warm.0 -

@Justin I'm not sticking up for the installer by say what I'm gonna say however I will say I did have a customer who freaked when I first fired the boiler scared his son would get brain damage from the "fumes" . Here's the deal and I don't know what your installers did but a new boiler is going to give off some oders, when we thread pipe we use oil on the pipe being threaded, when the boiler is manufactured it has a lot of oil on and in it, then add in the extra oil used for cutting the threads into the boiler. The boiler also has sealing compounds around the flue areas and fiberglass insulation wrapping the boiler under the covers. All of this stuff kinda has a bit of what I like call burn in time and will give oders until then. The smells coming from the radiators is most definitely the oils used in manufacture and thread cutting, these need to SKIMMED out and if skimming isn't working then the inside of the boiler should be washed out with a wash wand either through the skin port or through the lower return, what ever is accessible. I had said in an earlier post that your boiler is really dirty and I understand they came back to clean to no avail. It looks like they used a cleaner in the water and didn't get it all flushed out.

All that being said the smells coming from everything normally are not life threatening, some people do have more sensitivity and allergies and it may bother them more. Like I said I'm not at your house so I don't know what's going on, but I just wanted to give you an idea that a new boiler will have oders for a few days.DL Mechanical LLC Heating, Cooling and Plumbing 732-266-5386

NJ Master HVACR Lic# 4630

Specializing in Steam Heating, Serving the residents of New Jersey

https://heatinghelp.com/find-a-contractor/detail/dl-mechanical-llc

https://m.facebook.com/DL-Mechanical-LLC-315309995326627/?ref=content_filter

I cannot force people to spend money, I can only suggest how to spend it wisely.......0 -

I hear you, @Dave0176 . I think we're talking about something different entirely. I smelled the "new boiler smell" in the basement when they first fired it up. Unpleasant, but it went away after a day or two. The smell we're smelling is coming from the radiator vents, is noxious, and isn't going away on its own or with the current level of flushing & cleaning our installers are doing.Dave0176 said:All of this stuff kinda has a bit of what I like call burn in time and will give oders until then. The smells coming from the radiators is most definitely the oils used in manufacture and thread cutting, these need to SKIMMED out and if skimming isn't working then the inside of the boiler should be washed out with a wash wand either through the skin port or through the lower return, what ever is accessible. I had said in an earlier post that your boiler is really dirty and I understand they came back to clean to no avail. It looks like they used a cleaner in the water and didn't get it all flushed out.

All that being said the smells coming from everything normally are not life threatening, some people do have more sensitivity and allergies and it may bother them more. Like I said I'm not at your house so I don't know what's going on, but I just wanted to give you an idea that a new boiler will have oders for a few days.

It sounds like the collective wisdom here is: skim the boiler lots, and also flush it out and wash it inside with a wand. I'll talk to our installers about that.

I also think getting a second opinion would be useful.

@adambnyc do you work in Connecticut (New Haven area)? @Charlie from wmass are you active? PM me.

Others: Do any of you work in/travel to Connecticut? Or do you have someone you would recommend? Send me a PM or post here.0 -

I am booked for most of November. Skimming, as described above, is your best option to start with.Cost is what you spend , value is what you get.

cell # 413-841-6726

https://heatinghelp.com/find-a-contractor/detail/charles-garrity-plumbing-and-heating0 -

How to clean a boiler:

https://heatinghelp.com/systems-help-center/washing-out-a-steam-boiler/

Thanks again, Gerry!Retired and loving it.2 -

My new boiler install stank for ages until I had completely skimmed out the oil and cleaned with a wand. this took several goes at hot and cold skimming done both slowly and more quickly. The smell came with the install and was very intense, but only in the basement. Then again, I have a two pipe with no traps so nothing escaping from the rads. Over time it just went away.Two-pipe Trane vaporvacuum system; 1466 edr

Twinned, staged Slantfin TR50s piped into 4" header with Riello G400 burners; 240K lead, 200K lag Btus. Controlled by Taco Relay and Honeywell RTH6580WF0 -

-

Thanks for chiming in, @Dan Holohan !

Can you say in this particular situation whether cold skimming or warm skimming would be preferable?

0 -

I think it needs a wand treatment, as Gerry Gill shows in his video.Retired and loving it.0

-

FWIW, all of the above plus: vent mains quickly in basement, radiators slowly. Most of the smell will be vented in the basement as steam pushes smelly air through the mains.0

-

@Justin , Hot or cold skims both work. Oil will float to the top of the water as long as the waters are calm. Probably the only difference is the hotter the water the thinner the viscosity of the oil, the easier it may flow. A Cold skim will thicken the viscosity of the oil a bit but it will still be on the surface and will still flow.0

-

Even some newtimersDanHolohan said:I knew oldtimers who would work with a bucket of sudsy water. After they threaded a pipe, they'd use the water to clean off the oil. It made a difference.

5-10 secs per threaded piece will save you 50x that when it comes to skimming. I setup my threader so that the pipe is pitched so that the oil won't run back the length... it'll just stay at the end i'm threading. then wipe well with a rag.. then dip the threaded end in a bucket of Dawn dishwashing liquid and then use a wet rag with the same solution stuffed in the end and pushed thru with a smaller diameter pipe... kind of like cleaning the barrel of a gun4 -

Thanks!Retired and loving it.0

-

I'm not a pro. Just very interested and experienced Home owner. I've had great success working with the pros here and receiving their wisdom. Definitely get one of the pros here to work with.0

-

Is it possible it is a shipping plug that fell into the boiler. Just got done fishing for one.Cost is what you spend , value is what you get.

cell # 413-841-6726

https://heatinghelp.com/find-a-contractor/detail/charles-garrity-plumbing-and-heating1 -

@Charlie from wmass at those point I'd say almost anything is possible. I'd there a way that I could look for such a thing myself? What is required to get in there and look/fish something out?1

Categories

- All Categories

- 86.2K THE MAIN WALL

- 3.1K A-C, Heat Pumps & Refrigeration

- 52 Biomass

- 423 Carbon Monoxide Awareness

- 90 Chimneys & Flues

- 2K Domestic Hot Water

- 5.4K Gas Heating

- 99 Geothermal

- 156 Indoor-Air Quality

- 3.4K Oil Heating

- 63 Pipe Deterioration

- 913 Plumbing

- 6K Radiant Heating

- 380 Solar

- 14.8K Strictly Steam

- 3.3K Thermostats and Controls

- 53 Water Quality

- 41 Industry Classes

- 47 Job Opportunities

- 17 Recall Announcements