Equalizer

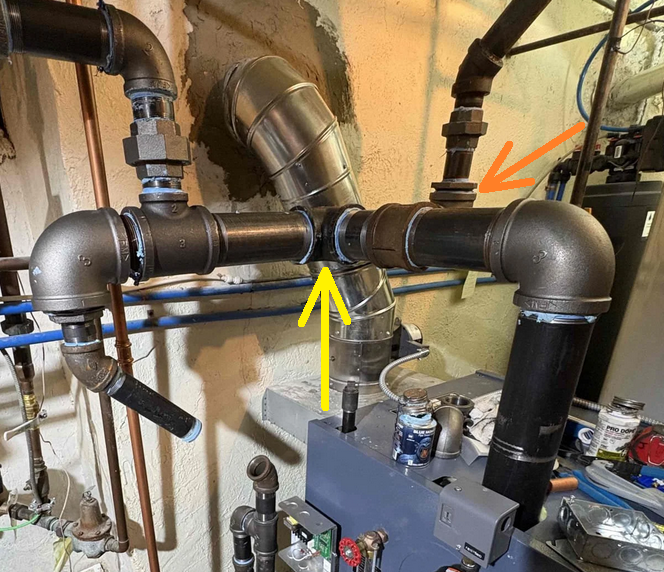

Would this be an issue to pipe this boiler like this with the equalizer on a 45.

Comments

-

No — that will work fine. I'm not wild about a 90 degree bend in the header, but if there is enough pitch it should be OK.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Why didn't you just pipe the equalizer on the other side of the boiler? or use the other riser coming out of the boiler to make the piping a little cleaner?

0 -

why the 90 degree dislike? It gives any water droplets another wall to slam into, no?

I like the equalizer too fwiw

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

-

@Captain Who i think that's a coupling. you can see the horizontal line in the fitting. I was thinking the same until i saw the line.

1 -

Would they void the warranty if the boiler is piped like this?

0 -

I don’t see anything that would void the warranty. What are you referring to?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Can you show a pic off the right-hand riser connects too? I agree the fitting on the header looks like a coupling instead of a tee.

Other than that riser everything looks ok

0 -

Is that a Tee at the Yellow arrow ? If not where does the pipe at the Orange arrow go ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I dislike the bushings. They make reducing 90s that most manufacturers prefer. Also reducing from 3 to 1 1/2 at the end of the header? Rule of thumb, although probably not actually necessary, is only reducing 1 pipe size from header to equalizer.

0 -

I am also not a fan of the bushings. But not such a big deal. That rule about reducing one pipe size is really counterintuitive and I don't agree. And neither do any of the boiler manufacturers. The larger the header, the less condensate you'll have, because velocity is reduced. So if anything, the bigger headers, should get smaller equalizers. But in reality, the only driving factor is really the boiler size.

0 -

Bushings seem to get a lot of dislike in general.

Like all of those who say you cannot use them on gas piping. The only note I've seen is cast iron bushings shall not be used. The rest are fine along with street fittings, except some areas don't allow them in concealed locations.

I am curious what that other pipe coming down in the backround is though. Looks like it's about 1 1/2" or 2" with a union?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

-

Again, I think you need to check the manual to make sure that equalizer is not smaller than the minimum recommended by the manufacturer.

What is the Boiler model and size?

0 -

The larger the header, the less condensate you'll have, because velocity is reduced.

I don’t follow this at all but regardless the size minimum on the EQ has nothing to do with condensate—we’re talking teaspoons.

It’s about carryover

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Some call for 1 1/4, others 1 1/2.

That looks like an EG-30. So a single 2" riser, 2" header and 1 1/2" equalizer.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I have the same question?

Miss Hall's School service mechanic, greenhouse manager, teacher, dog walker and designated driver

0 -

We have all been taught, the higher the velocity, the more water gets carried out from the boiler. The lower the velocity, the less water gets carried out of the boiler. If you follow through with that equation, that means that the larger the boiler steam piping and header coming out of the boiler, the less water there will actually be in the header. Which means, the drain function of the equalizer, can be reduced.

1 -

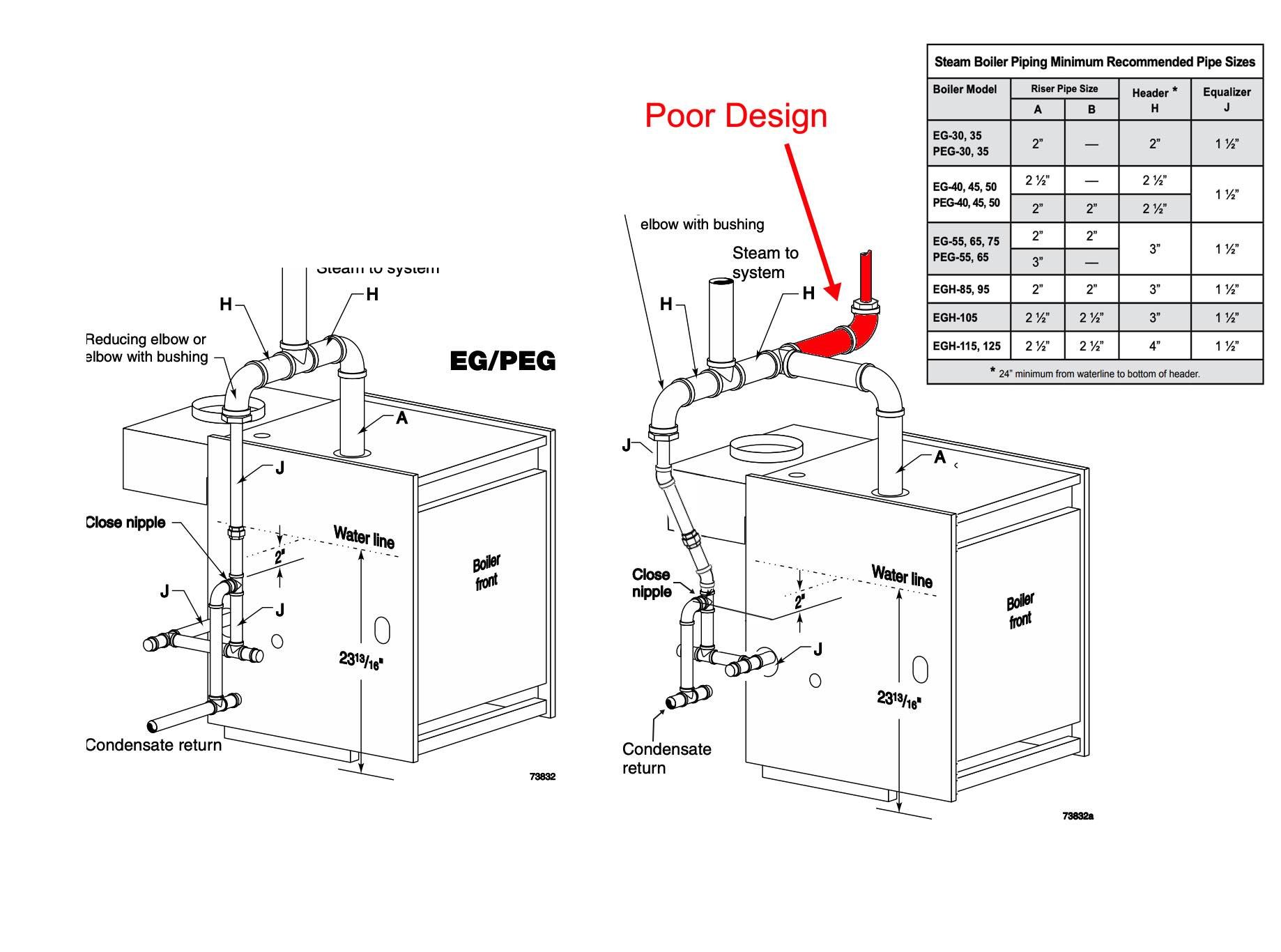

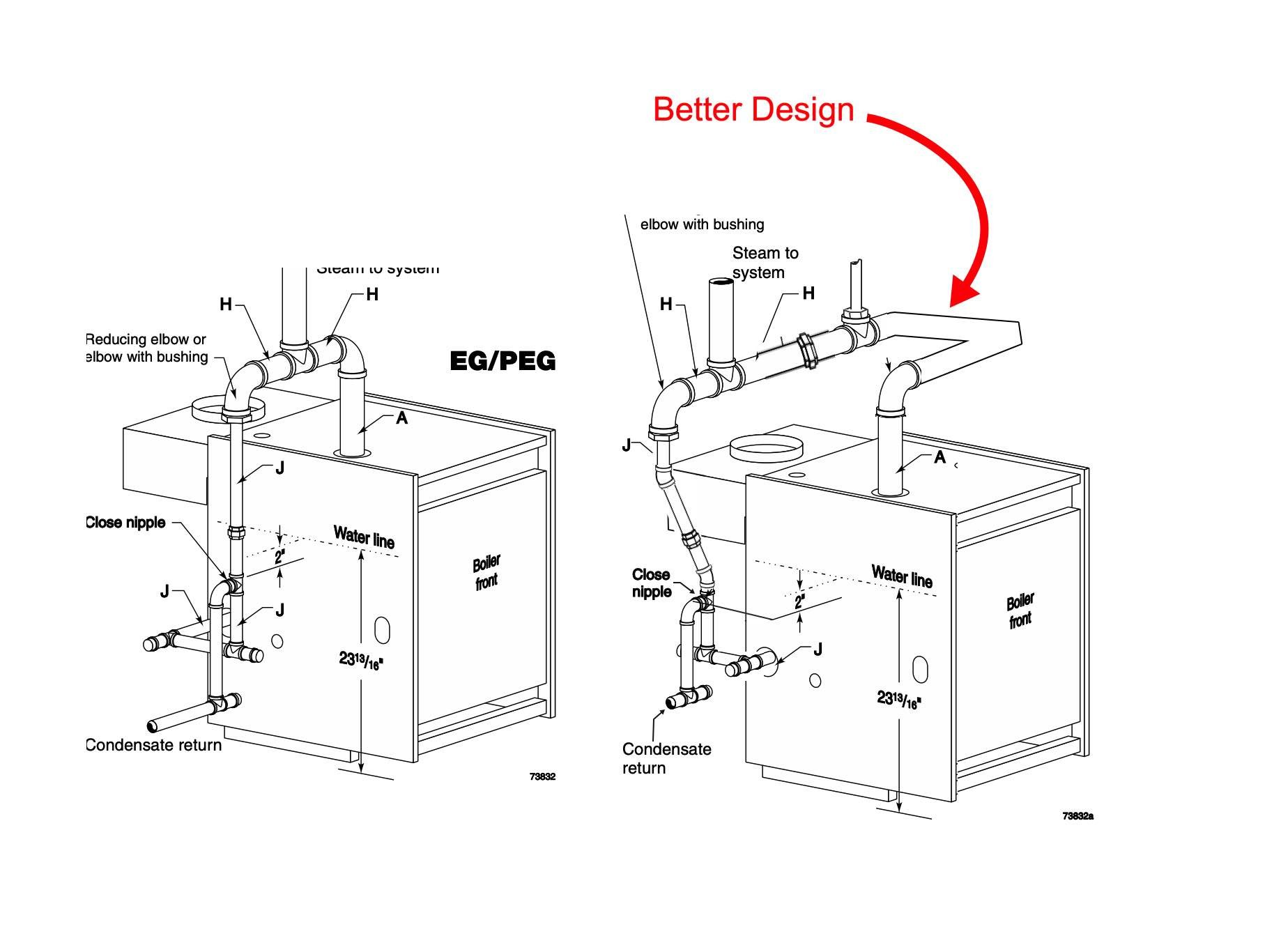

Here is the illustration from the manual on the left and I have made your piping arrangement on the right. I do not believe that your main rizer on the right side should be connected the way you did it. Red piping is not a good design.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

SMH. We need a sticky to tell people to give a few different view angles when submitting a photo. I didn't realize that was a Tee. A bullheaded Tee is a disaster in steam piping, when the steam flows in the other direction that it does here because it generates wet steam. In this case it is almost like another equalizer would be needed because you don't want the end of the header to be an elbow up into the main.

1 -

-

I'd use the other tapping and plug the one that's currently being used.

I'd also extend that left main over quite a bit so my equalizer is straight.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

@ChrisJ But that could get him in trouble with Weil McLain regarding warranty because the manual specifies that "Steam supply must be on the same end as controls"

@jmerrill Make sure your equalizer is 1-1/2" min. because that is what is specified in the manual.

0 -

I forgot about that rule.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

@jmerrill could always go overboard like Paul did and use a double riser from the boiler into a drop header the there sill be plenty of room to put the two main risers into the header. Wouldn't that look nice?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

i'm not sure if that is a tee or if the tee is to the right of it and the tee happens to have a casting ridge in the bottom of it.

0 -

It is a Tee

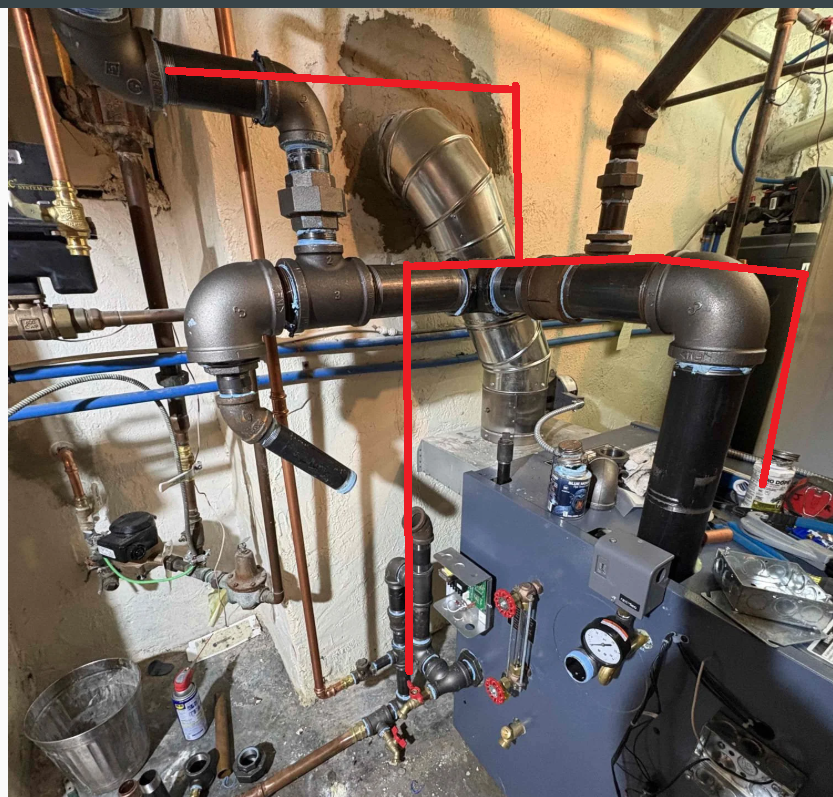

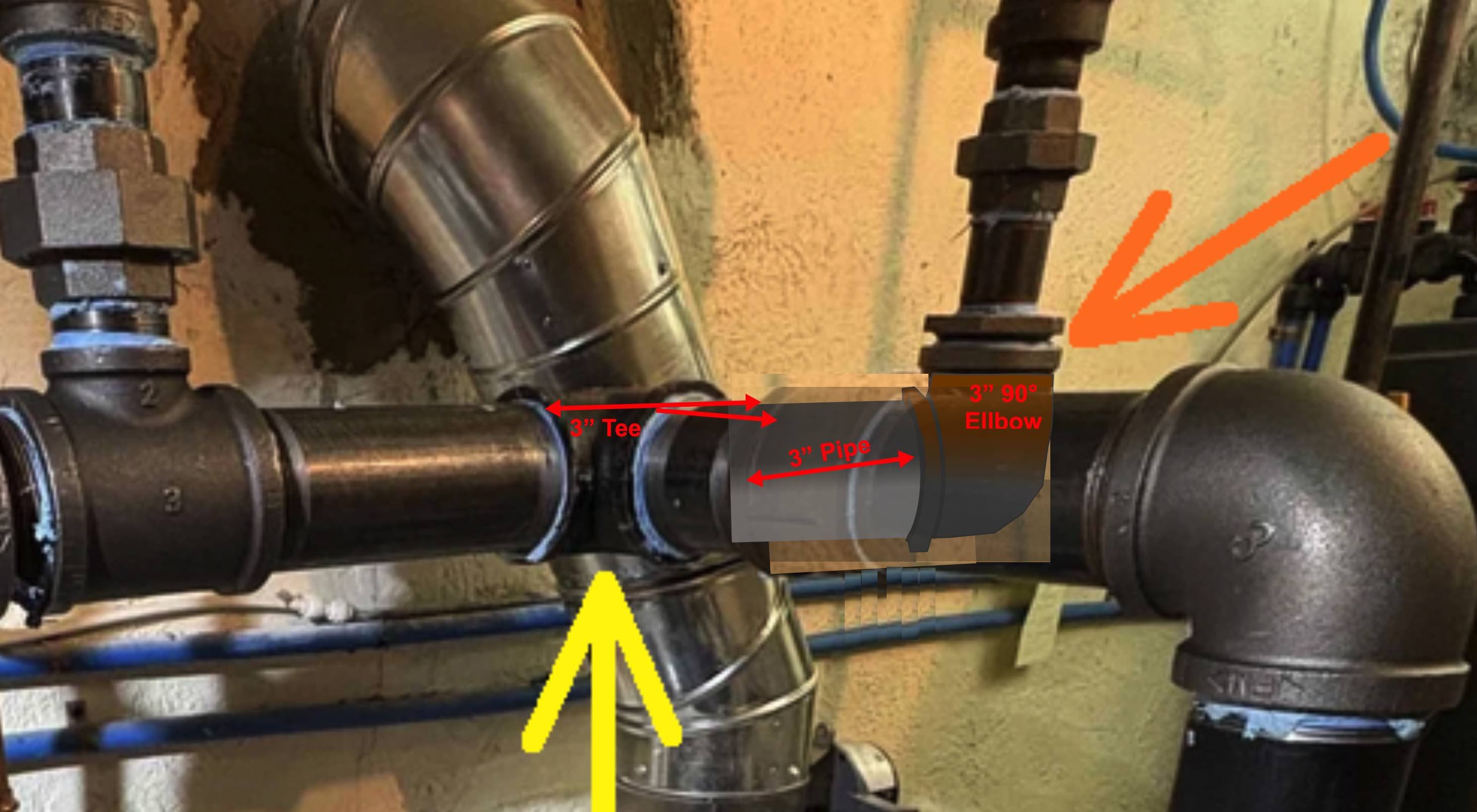

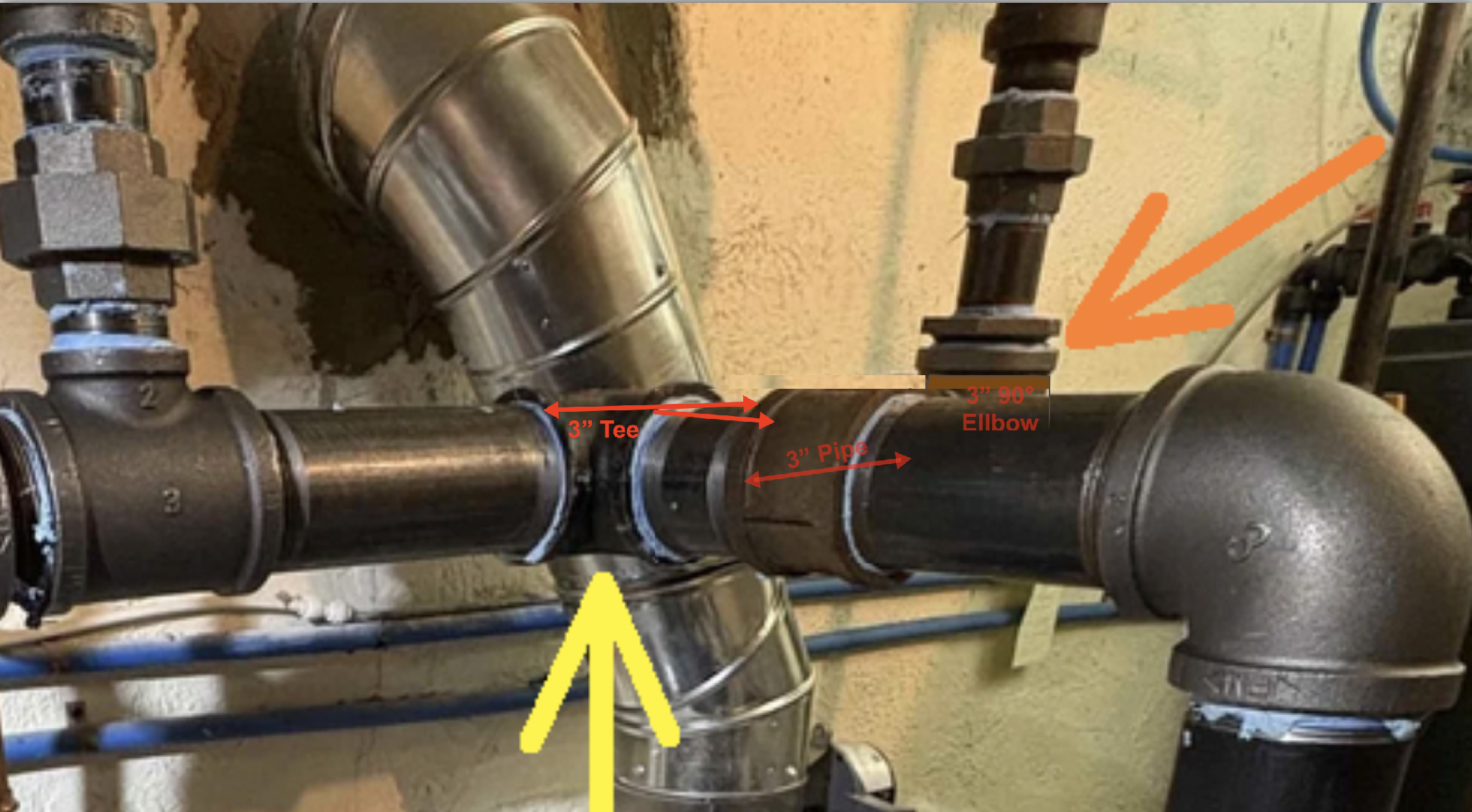

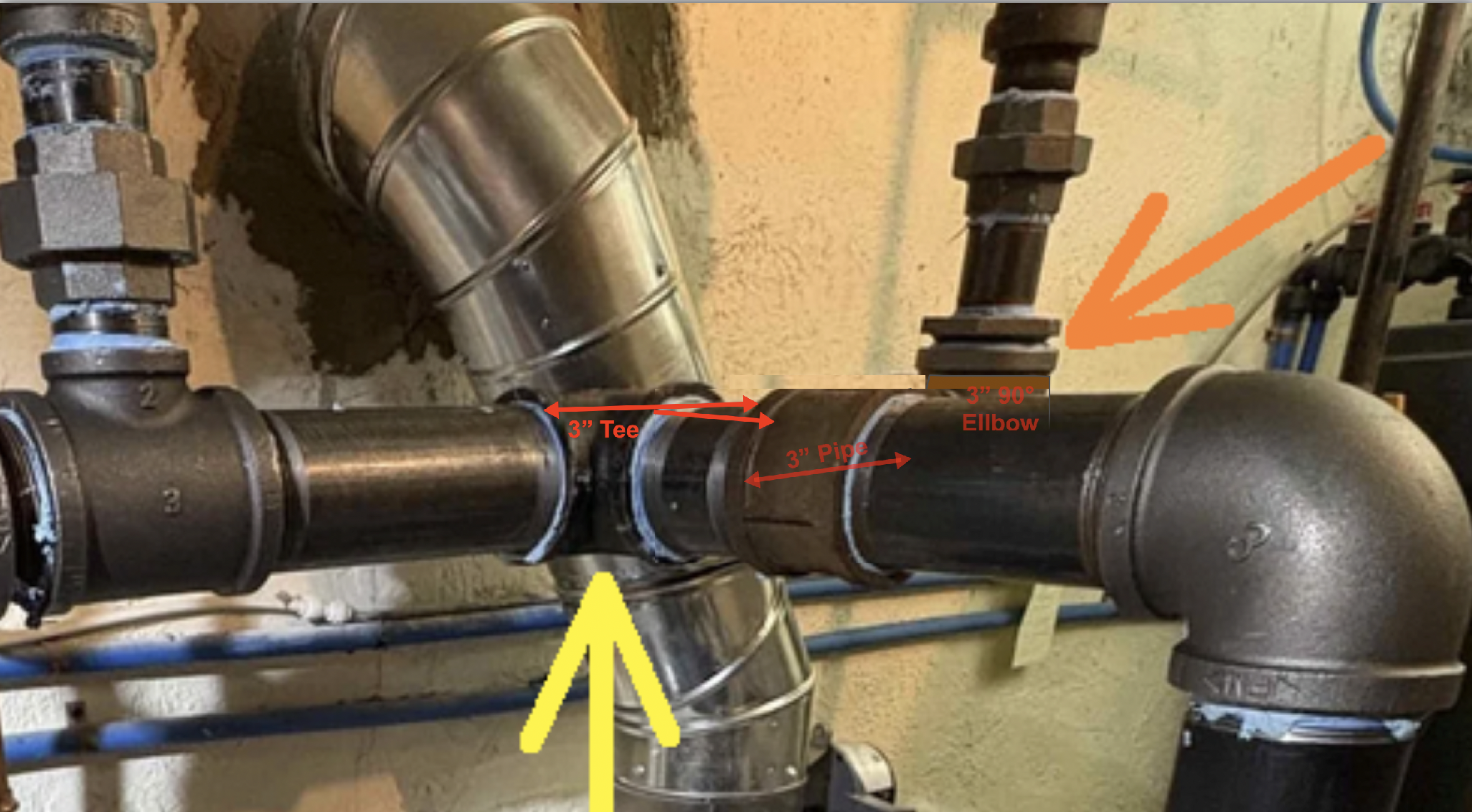

here is what I see behind that 3" header coming off of the riser.

What I see coming off of the 3" riser is from left to right: Yellow arrow is pointing to a 3" TEE < 3" pipe nipple < 3" coupling < 3" pipe nipple < 3" 90° elbow ^ 3" riser out of the boiler. The Tee in the header puts the steam in two directions ← → to get to to the different main risers. Not a good design!

Here is the same photo with the hidden pipe covered by the header:

Without

With

Without

With

Without

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

ahh thanks. Well that wouldn’t be condensate, that would be boiler water.

And despite ridiculous attempts, I can’t get water to get carried out of my boiler due to piping problems—only due to water problems.

A large header does not affect the velocity from the boiler through the supply but anyway thanks again for explaining what he was trying to say

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

just my 2 cents, not sure if you have the space on that run for 2 tees but would look much cleaner. & can me please cover and protect the top of the boiler, it’s not a work bench lol

0 -

-

if everything lines up just the wrong way and the tee is indeed in the corner that could cause some problems but it probably will be fine.

0 -

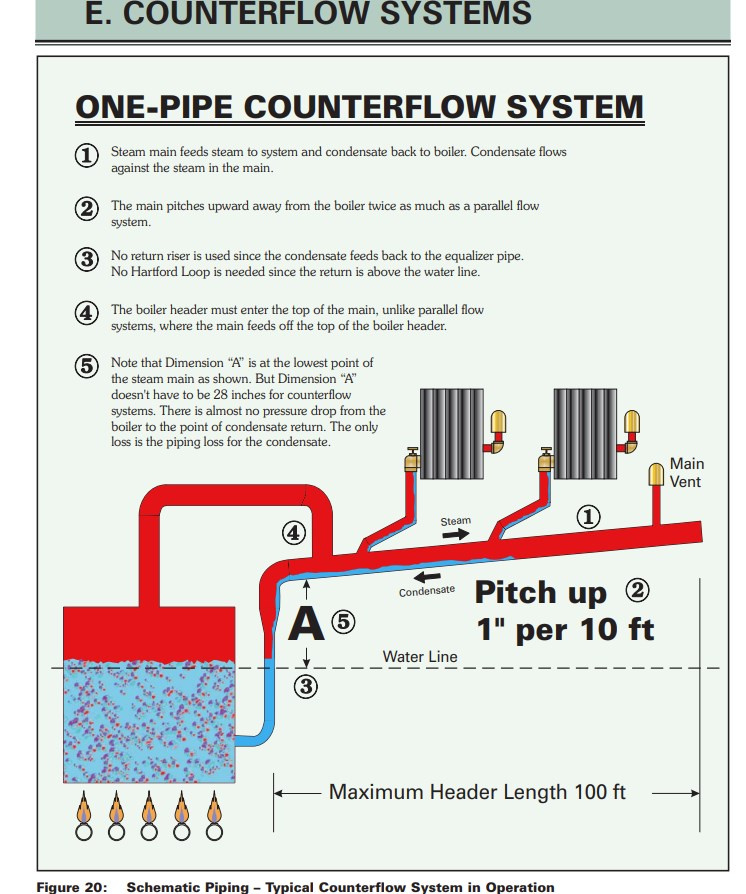

@jmerrill If you pitch the header downward towards the equalizer at 1" per 10 ft., then the section to the right of the Tee that feeds the main on the right will work as a counterflow header and the condensate will flow back wards towards the equalizer.

0 -

From my videos you can see that the amount of condensate in the header is minuscule—even uninsulated ones.

And a lot of it gets re-evaporated by steam going by.

Pitch on the header gets you nothing.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Mucking the guy's thread up but try making this work without pitch

-1 -

You were talking about the header, not the main.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

Steam and Condensate don't give a rat's a whether they are in a pipe that humans call a header or a main. The diagram from peerless depicts the concept of proper pitch needed when steam and condensate flow in opposite directions, as will be the case in that stub extension of the OPs header (if he pitches it correctly), to the right of the Tee. Don't know how to explain it any more than that, except to say that anything he can do to keep condensate from being blown up into that main on the right will be a benefit. Basics matter most when things go wrong……

PS (lol): Peerless says in the diagram "maximum header length 100 ft."

0 -

-

Refuting the basics of steam piping knowledge passed down by the Dead Men certainly is…….

-1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements