Is this the way they're going in now?

Comments

-

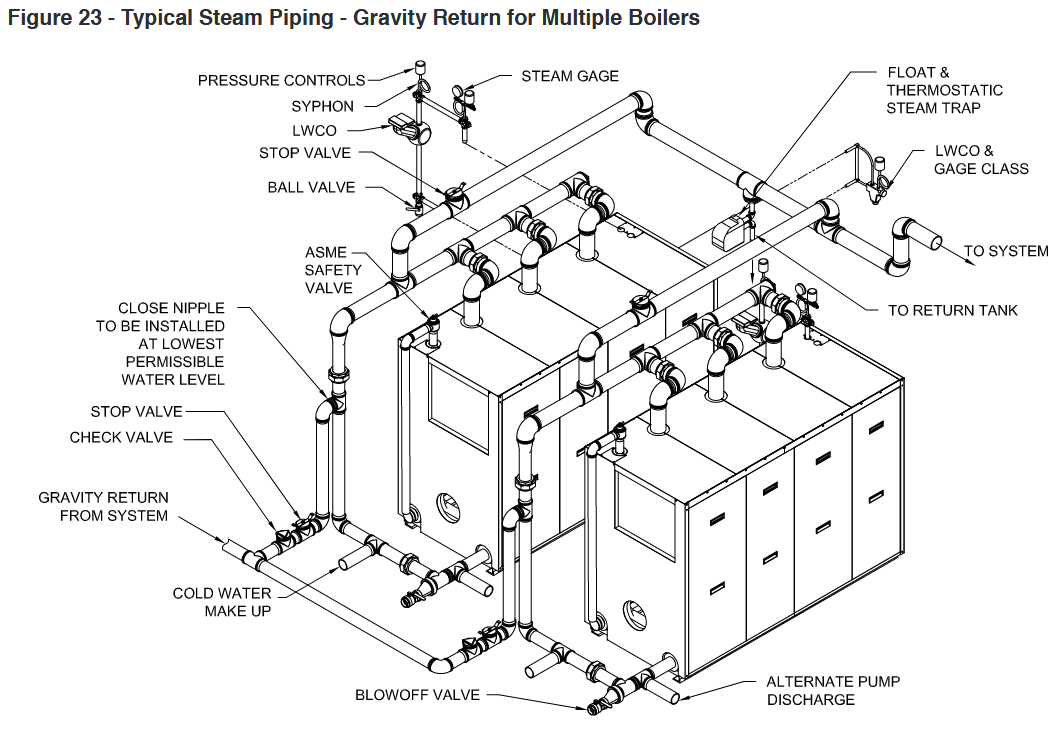

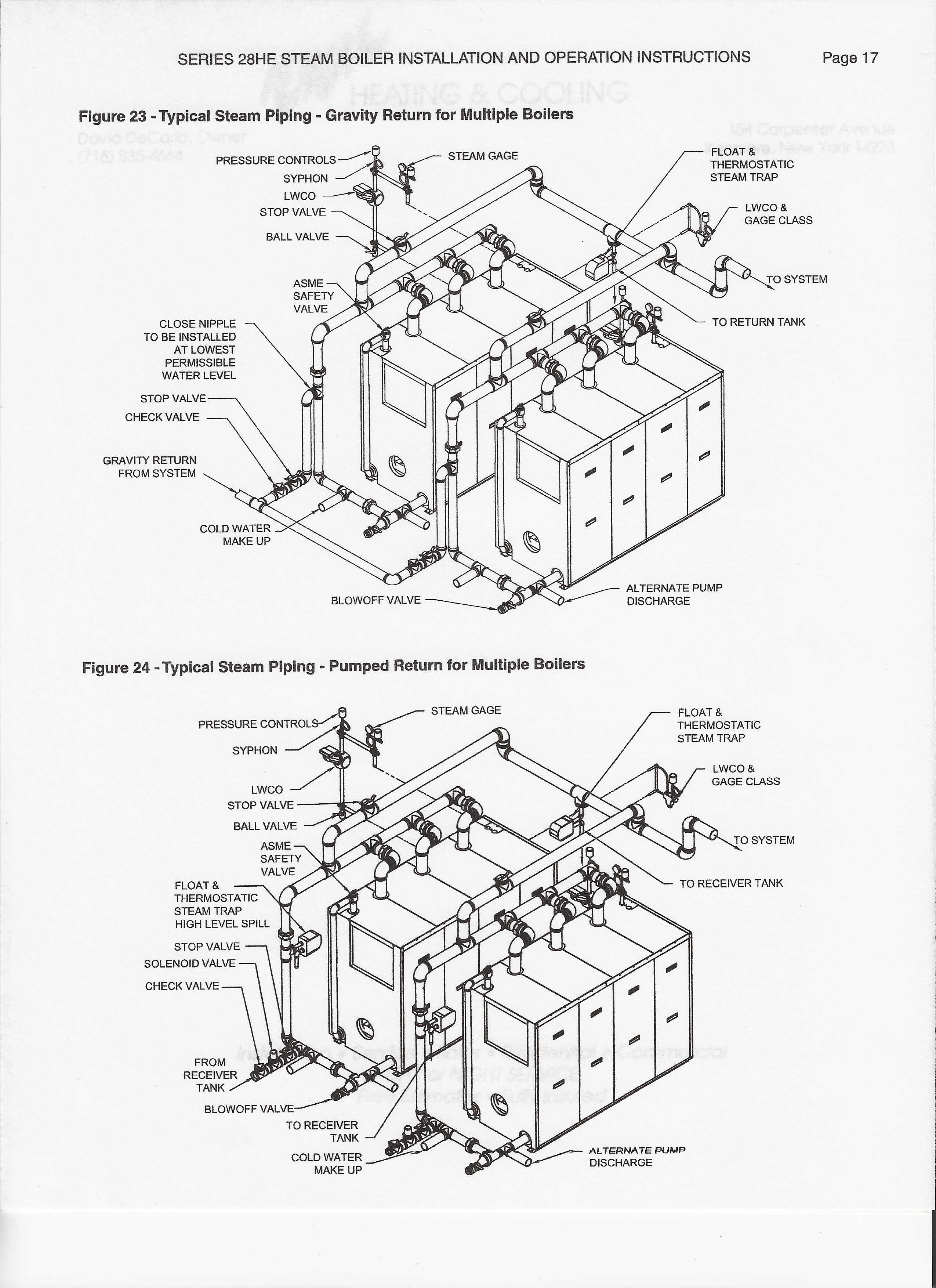

ISTR Smith has never specified if or how welded headers should be installed. But whoever did that work clearly doesn't know steam.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting6 -

-

The Smith 28 series has 5" risers. The header size varies but is at least 5" with more than 1 riser. This varies with the # of sections

Smith doesn't mention threaded or welded piping but the manual appears to show threaded fittings with a union.

I don't even think they make 5" unions so that is wrong. 5" flanges are available.

In spite of what many on here will post 99% of all contractors are not going to thread 5" or 6" pipe..Just not going to happen.

There drawing does show 2 elbows at the top of each riser also something that is seldom done.

1 -

-

On a pumped return for multiple boilers, what is the purpose of the F&T on the equalizing line?

0 -

I wonder how much those yellow handled valves are, and are they necessary. Are they for balancing?

0 -

Is this actually running right now? Colliding steam going into the main riser is wrong and it does seem that drip needs to be hooked up per the manual.

0 -

This boiler installation in not finished. They have some corrections to make before they run it. My guess is the colliding header would be full of water before the first radiator gets heat.

0 -

-

I'm thinking they are more orange. I bet they are expensive. Looks like it is a King valve.

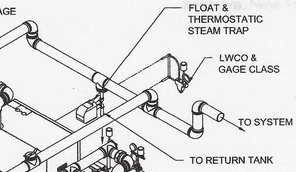

No F & T traps in the equalizer like the manual shows.

If they don't put the F & T trap (or some type of drip) in under the paralleling header, yeah it will fill with condensate, faster if they don't insulate it. looks like there is a plug there now.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

They still have lot of work to do. Orange? No. I'll give you Mustard color though.

-1 -

A trap on the equalizer is an overflow trap. It is used when you have multiple boilers connected to the same system where the boilers alternate or one acts as a standby. With the valves open to the header on both boilers and one boiler operating the idle boiler act as as a condenser and fills up with water to an overflow condition if the burner fires you could damage the boiler. The overflow trap should be piped to put this condensation back into the boiler feed tank.

The stub is on the main header for the trap to drain the header. The supplies to the main header should not be colliding but if only one boiler runs at a time its fine.

2 -

Thank you very much for that explanation. I don't get into doing jobs that big but from time to time, a friend or customer will show me what they have going on in their boiler room.

It is my understanding from time to time they will be running both boilers at the same time. I brought the colluding header to their attention before I posted. They do intend on addressing that issue. The installing company said they were also going to use threaded 90s at the boiler risers. (Ouch, 5" 90s, get out the chain wrenches. When I get an update I'll let you all know.

0 -

@HVACNUT These right ? If my Mustard looked that color I would not eat it. I do agree it is not as orange as the color of an Orange, the fruit.

These below are Yellow along with the Caution tape.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

gold and white

0 -

-

-

Rather than using 5" threaded 90s on the boiler risers, the mechanical contractor is suggesting unsing these. One on each boiler riser and one on the equalizing line for each boiler.

I've seen the these used on hot water heating but never on low pressure steam. There are flex connectors rated for low pressure steam.

Does anyone see any problem using them?

0 -

" Rather than using 5" threaded 90s "

So they are going to use a straight flex coupler and bend it to 90 degrees ? If so is there a bend radius specification ? In general that seems like a bad idea.

Or is the flex coupler pre made as a 90 ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Don't let him use those they will fail. They are made for linear expansion and contraction not bending and twisting.

they probably choked on the price of a 5" 90 or they can't get them.

Look online and search for 5" threaded elbows.

You will be looking for a while, probably not available.

Most contractors weld everything 2 1/2 and up

2 -

-

We had a guy up in the UP Michigan thread and fit 5".

0 -

-

-

The engineer of the building these boilers are being installed was told by the mechanical contractor that it would take 2 months to get the 5" 90s, so he did some checking himself. He was able to find a local supply house (Ferguson) that had 3-5" malleable 90s in stock and they showed they had 11 in California. They told him they could get them here in 5 days. Good to know in case I might need them.

1 -

Why would the price of the 90's bother them? Wouldn't that just be added into their quote for the job?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

If the sell price is too high they might not get the job.

0 -

We use these all the time to help reduce vibrations and very slight misalignment on pump piping, these are not meant to bend more than a few degrees. They are for very minor offsets, small expansions, contractions, vibrations. Do not even think of trying to use them as a bent 90!

0 -

I'm not thinking the mechanical contractor was going to try using them as 90s, one on each boiler riser and one on the equalizers drop. He would like to leave his 2 welded 90s in place.

If it were me, I would be using the treaded 5" 90s. The flexible connectors wouldn't be an option for me.

0 -

Isn't that similar to what's often used on car exhaust?

They sure seem to hold up under those condiitons…… 1200-1400F exhaust and being blasted by road debris / salt etc.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I think the exhaust stuff is different. The stuff for water and steam is a plastic tubing of some sort reinforced with stainless braid to keep it from deforming when it softens under heat and to increase the pressure rating.

The exhaust stuff I think is just densely woven stainless because the one piece of it I used as part of a catalytic converter had soot work its way out through it.

1 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements