Boiler still leaks after changing out relief valve, Expansion Tank, Regulator, Air Vent....

Hello. I had a previous post from a year ago that i had leaks coming out from the Relief valve and my boiler reads 30 PSI all the time. I received suggestions on changing out component and i have done that already , however it is still leaking. I am at a point that i am unsure what to change next. Yes i am aware that my old post was more than 12 months old, and life got busy with different things, and i just let it leak into a sump pump … and my sump pump recently failed (I am guessing may be due to water temperature from the leak?) so i want to fix this problem.

Question: How do i continue from here, and what else could be the problem? The PSI is constantly at 30 and i believe thats why the water is leaking. (So it is doing its job)

Old Post Link:

I did have an handy man to help me change out the relief valve and the regulator because the relief valve was in a very awkward position and i am a bigger guy and couldnt fit my elbow/hand into that area. While he was here, i also asked him to change out the relief valve… we did drain the system to replace all these components. The only thing i regreted was i had bought a Taco regulator for him to replace, but he didnt see it, and replaced it with one of "his" usual ones. When i saw it, it was already replaced, so i just left it. It seems to read the same specs.

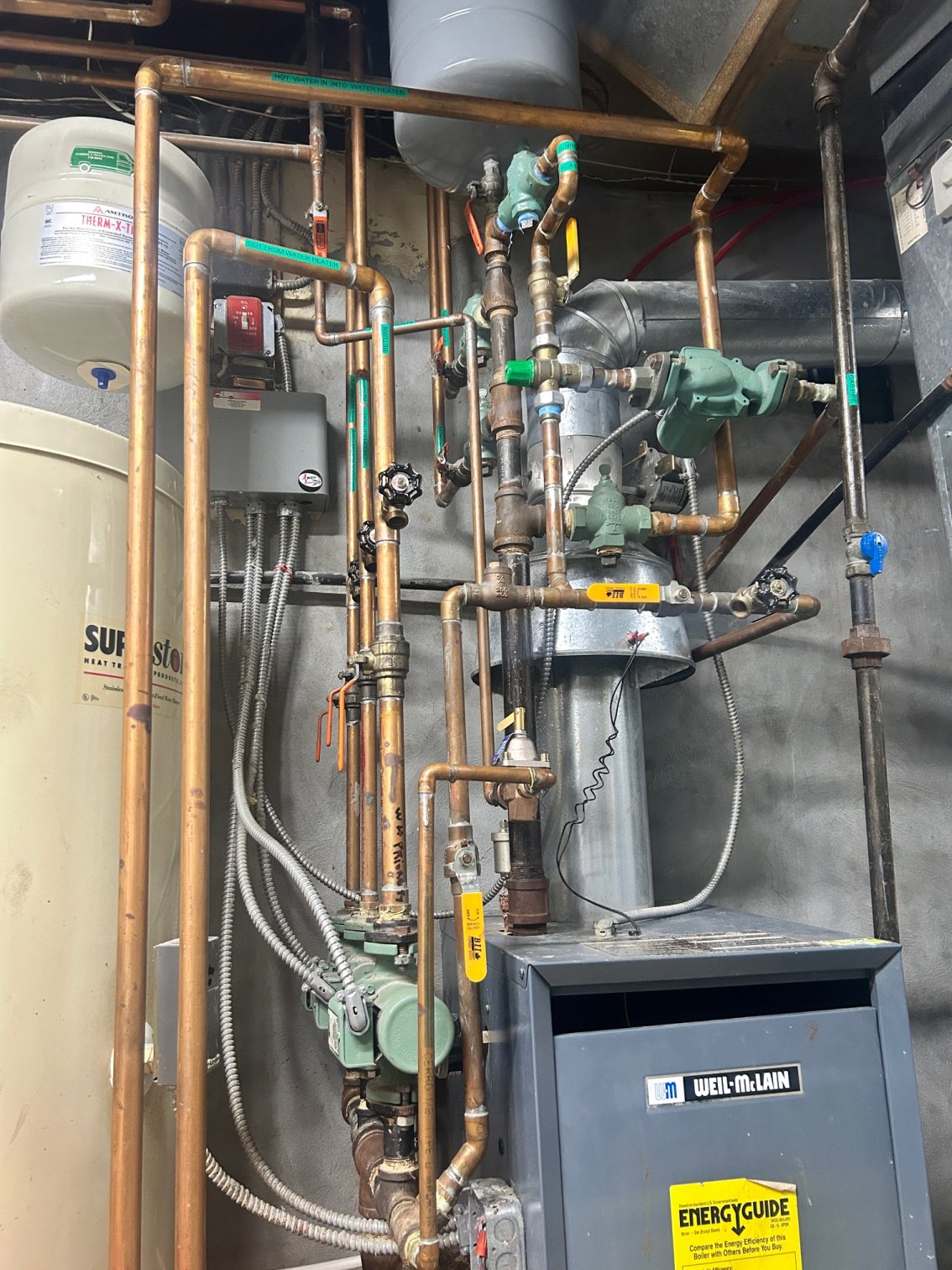

The boiler is a CG Boiler (CG-5-SPDN Model) and it is a rather complex system (I feel)… It has 4 zones like this,

- 1st floor

- 2nd floor

- Sunroom (Radiant heat)

- To the Indirect water heater

Things already replaced:

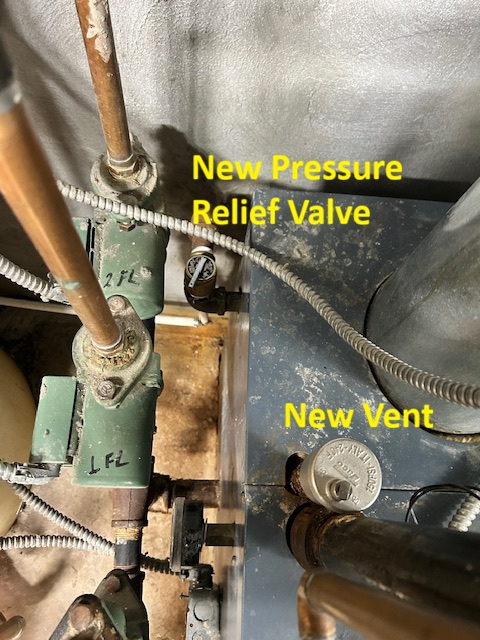

- Same exact pressure relief valve from Supply house

- Same Expansion tank from Supply house

- Same air vent from Supply house

- New Regulator from the handy man. (It was a green Taco)

The water leak is like a little water stream now, and it is no longer dripping. It first started as a drip a year ago and now it has developed a small water stream… See picture below.

Here are a new set of Pictures that shows the replacement.

Comments

-

Right off the top of my head I suspect the coil in the indirect water heater has a hole allowing domestic water pressure at perhaps 60psi to pass into the the boiler side which should be around 12psi. You can test this by closing the cold water to the water heater for some amount of time. You can hasten this by draining a bit of water out of the boiler to lower the pressure to about 12psi and see if it climbs or leave it and see if the dripping stops when the pressure get to a tad below 30.

Miss Hall's School service mechanic, greenhouse manager, teacher, dog walker and designated driver

5 -

With the fill pressure lowered in the system to 15 psi, turn off the new fill valve. Does pressure increase?

This would eliminate the valve leaking past.

Was the expansion tank pre-charge checked before it was installed? does the tank feel heavy if you tap or shake it gently? It may be waterlogged. On rare occasions the diaphrams are stuck in the tank and they do not allow expansion.

The SuperStor tank could have a tiny leak in the coil, so water pressure from the tank is over-pressurizing the boiler. This would be my bet if everything else is new and checked.

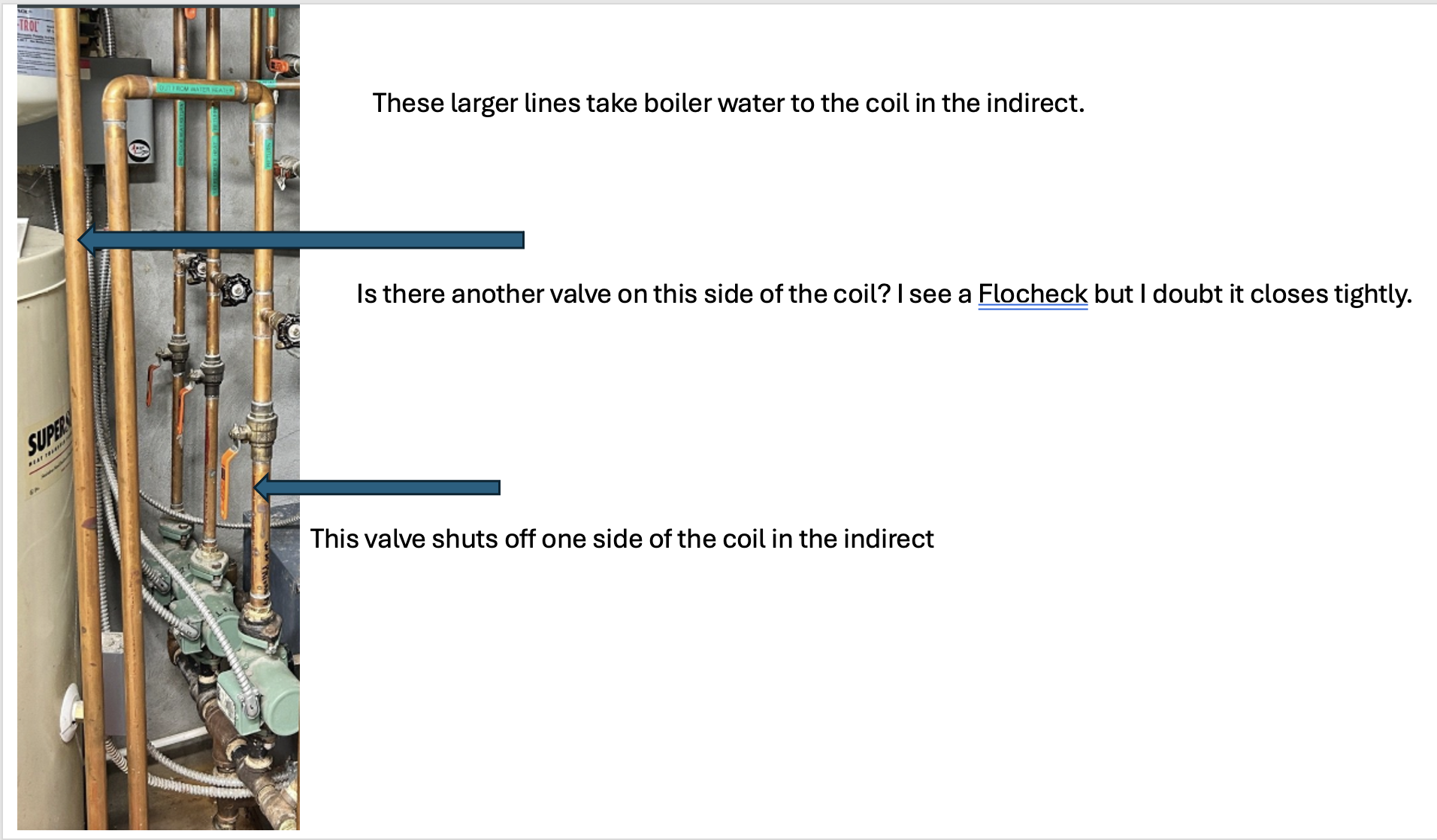

I see a valve on the pump that supplies the SuperStor, is there a valve on the other side of the tank? You need to isolate both sides of the tank coil to rule this out. How old is the SuperStor?

Seems like a lot of checks on the system, but I don't see that the expansion tank is checked away from boiler expansion, so that is okay.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

The expansion tank was pre-charged, and i have checked the PSI level before installing. I knocked on the tank for the "ping sound" and i can feel the half hollow and half solid which i believe is working correctly.

the superstor is likely about 15 years old.

Which valve near the superstor pump are you referring to? I am attaching another photo that shows the indirect water heater.

I am also not following this comment. Can you elaborate? —> but I don't see that the expansion tank is checked away from boiler expansion, so that is okay.

0 -

-

The red handled valve that's next to the ladder in the picture stops the domestic cold into the tank. If you close that the street pressure will stop feeding into the tank. The over pressure will drop if in fact there is a leak in the coil.

Miss Hall's School service mechanic, greenhouse manager, teacher, dog walker and designated driver

0 -

That is another option.

If you shut off water to the tank and someone opens a hot faucet, dropping the house pressure then boiler water could be pushed into the tank from the 30 psi in the boiler. If there is a coil leak.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I see what you mean now. And no there is no more valve on the other side.. There is only 1 valve to shut off the water going back into boiler (The return). It passes through the green flow check valve and then into the water heater directly.

i have attached a few more pictures to show the system.

Q1) Could i just somehow got a bad expansion tank even tho its new? it was prechecked at 12 PSI before i installed it. If i use a tire pressure gauge to measure hte PSI now, i will accidentally let some how, is it safe to pump air back in while the heater is in operation?

Q2) You said, "With the fill pressure lowered in the system to 15 psi, turn off the new fill valve. Does pressure increase? This would eliminate the valve leaking past." Did you mean to adjust the new handyman regulator (aka the Fill Pressure valve?) to 15 PSI? How do you lower the pressure to 15 PSI to begin with? ANd by turning off the new fill valve, you mean turn off water into this new handy man regulator? (Regulator and fill valve is the same thing, right?)

0 -

1 yes on rare occasions the diaphragm in the tank is stuck to the connection nipple and will not allow expansion in.

But at 30 psi you should feel water in the tank, shake or tap to see if it has fluid in it. It should also warm up if fluid is being expanded into it

2 you need to get the pressure in the boiler below 30 psi to track down where and why it is getting to that pressure

My thought is the indirect, if in fact you have checked the other possibilities

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

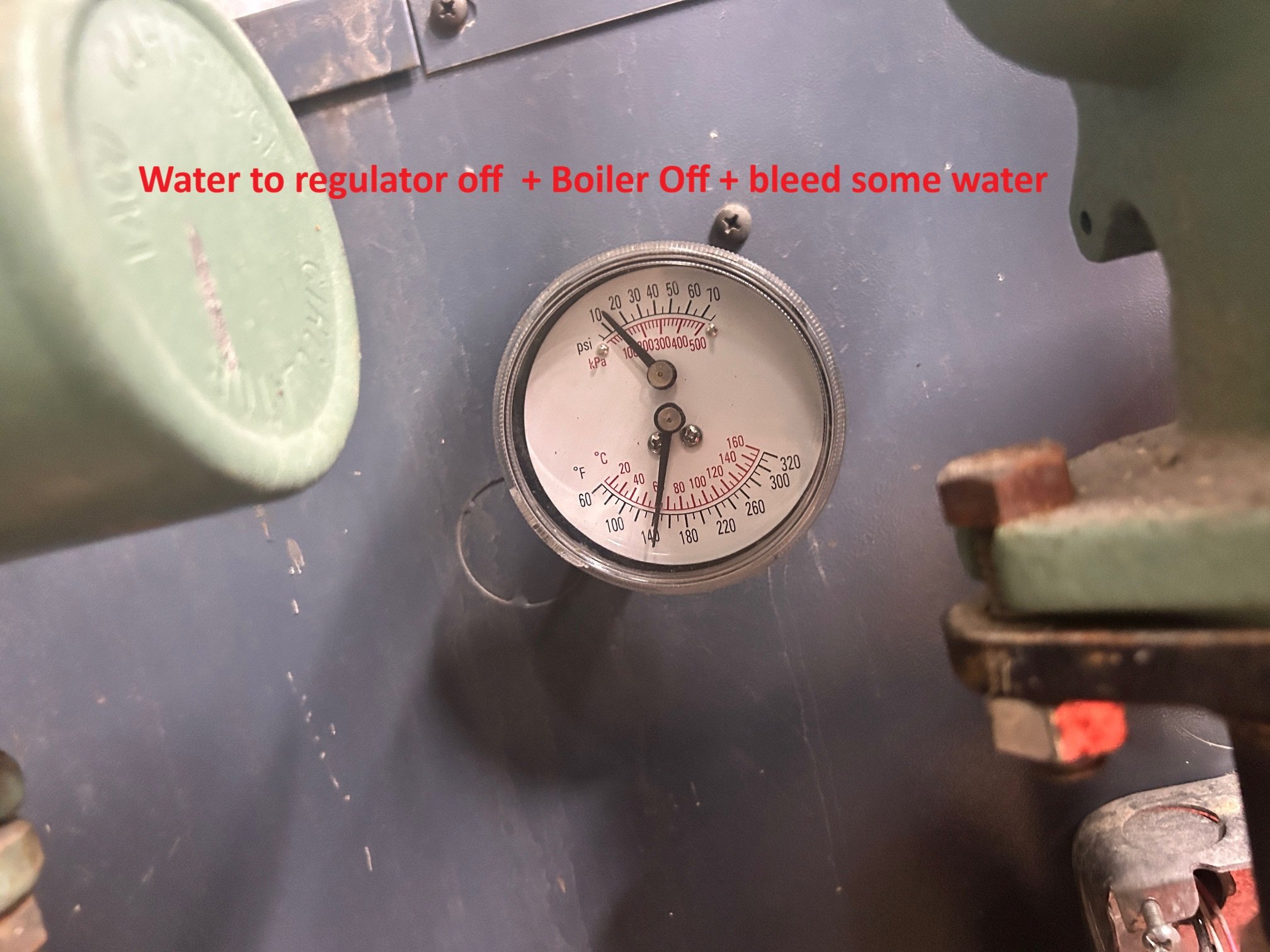

I just did a test following steps to test..

1) I hand feel the pipe where water feeds into the regulator, i can feel water flowing inside...

2) turn off water supply into regulator and turn off boiler.

3) release some water through the hot water heater valve. (See picture of the green hose).

4) I was only able to get the pressure to about 15 PSI after bleeding some water out from that hot water valve for the return water..

5) the leak stopped and temperature slowly dropped to 140. (was 150-160 to begin with)

6) I hand feel the pipe into regulator and this time no more water movement.

7) I turn on the water into the regulator and i still do not feel water movement. Pressure remains at 15 PSI and no water leaks.

8) Turn on boiler, and boiler fired up right away... and i can feel water movement inside the pipe going into regulator and out of retulator.

9) pressure reached 30 again, and leaking starts again.

I did not adjust regulator, as i need to research into how to. i believe this is the one i have from the handyman.

http://hydromastersupply.com/product/show_product.php?id=1080

0 -

@yekasi , you need to call a pro. Where are you located? We might know someone……………

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

I am in New York, Long Island, Nassau County near LIE Exit 37. I would like to get someone who knows how to diagnose this and fix this problem.

Please recommend someone if you can. Thanks.

0 -

There are several folks who work in Long Island. Click on the "Find a contractor" tab.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

This is a long island. Can you narrow it down a little bit?

0 -

Long island Nassau county. 495 highway near exit 37.

0 -

That narrows it down. TY

0 -

Exit 37 ?!?! LOL… That sounds like a New Jersey resident. All of us in NJ live near an exit from some highway. I was exit 17 on the Parkway. When I lived in Philadelphia I lived in a parish. Holy Child and then Incarnation. Even my Jewish friends knew what parish they lived in. LOL.

You can click "off topic" below

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

The pressure regulating valve is a Hydro Master 0571300 valve. A Watts knock off, I suppose, so, you can use the Watts instructions to adjust it. If the boiler is cold and the boiler gauge reads 15 PSI after bleeding it down, it's set correctly.

There are only three ways pressure can build up in your sys. The Hydro Master fill valve is leaking. The water in the boiler heats up and expands and the increased water has no where to go. The heat exchanger in the indirect tank is has a hole in it allowing street water pressure into the boiler sys as @Grallert and @hot_rod stated.

You won't see street pressure in the boiler sys as the maximum pressure is set at the boiler pressure relief valve, 30 PSI. Follow @hot_rod's advice and shut off the cold water feed to the indirect heater.

As a further note, the Ex tank is positioned wrong. It is upside down and installed in the wrong location. It should be installed on the return line to the boiler before the pumps. A cast iron boiler has very low pressure loss thru the HX, so you are essentially pumping into the Ex tank instead of away from it.

0 -

@HomerJSmith said: As a further note, the Ex tank is positioned wrong. It is upside down and installed in the wrong location. It should be installed on the return line to the boiler before the pumps. A cast iron boiler has very low pressure loss thru the HX, so you are essentially pumping into the Ex tank instead of away from it.

How do you install an expansion tank before all of the pumps? You can install it before one of the pumps …but you can't install it before all of the pumps unless you go all the back to the boiler where all the zones branch off from the boiler's supply …and that is only a short distance from the current location.

Unless you have come up with something I have never seen before!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@EdTheHeaterMan, It was only the boiler pump that I meant (but we have 3 boiler pumps). I like pumping into the greatest pressure loss. I not sure what all the pumps do except the 2 boiler and indirect pump. I would have pumped into the indirect tank instead of away from the tank. The two rear pumps on the boiler return are on heating circuits, baseboard? I assume that the pump on the thermostatic mixing valve is going to a radiant circuit.

So, Ed, you have a valid point. When you have 3 boiler pumps which do you connect the X tank to? I would say to one of the rear pumps that runs the most and is the longest circuit, greatest pressure loss.

The system isn't piped correctly, but what is, is. When I zone with circulators, it's always pipe primary/secondary with a single boiler pump. Oh well, what da I know.

Question: I'm not getting it. Is the Thermostatic pump pulling all its water thru the boiler and where is the return connection from that circuit?

1 -

Hello. I think i may have found the issue, it seems like the problem is with the indirect hot water heater.

This is what i tested...

Test 1 - turn OFF water into Indirect hot water heater, leave boiler ON and water into boiler regulator ON.

1) at 11:31PM, It was at 30 PSI and it was leaking from relief valve. Temp was at around 165-170.

2) i shut off cold water supply into indirect water heater. The boiler is on, the regulator is untouched.

3) bleed some water from the same zone that i was using, got it down to 17 PSI. Water stopped leaking from pressure relief valve.

4) waited for 15-20 min, looking at the pressure every minute, and it stayed at 18 PSI.

5) The boiler came on once when the temp dropped to 145 (not sure how it dropped so quickly? may be because i bled some water?). It went back up to 170 and stopped.

6) Pressure remained at 18 PSI and no leaks.

7) At 11:48AM, i turn cold water back on and let it feed into hot water heater. At this point it is at 18 PSI and 170F.

8) At 11:55PM PSI went to 22 and temp is at 145.

9) at 11:57PM PSI is at 28 and temp is at 145.

10) at 12:00 PSI at 30 and temp at 165 and water started to leak.

Test 2 - Leave water supply to hot water ON . Shut OFF water supply into boiler regulator. Boiler is ON.

1) Started at 12:02AM and it is at PSI 30 and temp at 180 after last test. I drained water and now it is back to 15 PSI and 180Temp.

2) 12:04AM , PSI 18 and temp at 180

3) 12:11AM, PSI at 21 and Temp at 160 (Why did the temp drop?)

4) 12:17AM, PSI at 30 and temp at 175. Water started dripping fast.

At this point, i just turn the water supply into regulator back on as i believe i found the culprit.Now onto next question, it sounds like its not fixable, and the water heater needs to be replaced. If i have to replace the water heater, i would be interested in changing it into a gas fired water heater rather than indirect. My boiler - is also very old and i dont want to lose heat and water at the same time. Would install to switch to a gas fired be very problematic job? or it should be similar to replace a indirect? Thanks.

thanks0 -

New York Nassau county. I don’t know about the electric rate or gas rate….

4 people and 4-6 showers a day.0 -

I would go with a similar sized indirect tank if that has supplied your needs all these years?

I don't think your DHW usage is a good match for a heat pump water heater.

You already have a boiler, pump, piping and wiring, so the cost of the tank and labor.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

I'll reply just cause I'm sitting here. Unfortunately the coil in that particular water heater is not replaceable.

It looks like you've performed all the tests necessary to confer a failed indirect water heater.

Miss Hall's School service mechanic, greenhouse manager, teacher, dog walker and designated driver

1 -

The coil is not replacable, did you mention how old it is? 4-6 showers a day plus other DHW use, it probably has some miles on it.

High chlorides in the water can be tough on stainless tanks. If you were to have a water analysis do e and you see levels above what stainless tanks suggest, a steel glass lined tank is my favorite.

Hardness, TDS and chlorides are good % to know.

Here is the water spec from the folks that build that SuperStor tank. It would be similar for other stailess tank brands.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

My assumption is no anti freeze in your sys that may have turned acidic.

0 -

Just sending an update, i got a licensed plumber out and he confirmed that the hot water heater has a leak in coils and suggested me to change out the indirect. I have some updated questions.

We are a family of 4 and 2 full bathrooms where we may simultaneiously take showers at the same time. may be 20-30 minutes shower. Right now we have a 60 Gallons indirect and the plumber said we have a first hour recovery of 266 gallons based on his calculation. I told him i want to change it to a gas fired water heater so i do not need to tie to the old boiler... My Boiler has 4 zones.... 1) Indirect hot water 2) a baseboard heat a room used as office 3) baseboard in a bedroom that we do not turn on heat 4) Radiant floor heat in a sunroom. So if the other 3 zones do not have heat due to boiler breaking down - it is not an urgent issue for me.... my boiler is 30 years old and i dont want to get a new hot water heater to tied to a 30 year old boiler. I also dont want to change it out just yet since it is functional.

The plumber said there is no gas fired hot water heater that can give me the current recovery rate. And he suggested me to just swap it out with a indirect 60 gallons hot water heater.

If other family of 4 can live on 60 gallons of hot water in a 2 bathroom house - why wont i be?

I have no issue with gas line, its right next to where the hot water heater goes.

Any advise/suggestions?

0 -

Say 2 showers simultaneous, 25 minute each. Each shower is 1.5gpm***, that would require 75 gal of 104F water. If your entering temp is 40F and you store water at 135F, using a mixing valve = 50 gal tank with 35000 btu/hr burner… That would be enough.

An 80gal Heat pump 120v model, wouldn't quite make that demand. But this is a type I would go with. Everyone has there preference. Worst that can happen, cold shower.

0 -

The boiler and indirect will run 82-85% efficiency

A gas fired tank more in the 70's% efficiency, and less recovery.

Most people are now running tanks at 140 and mixing down. At least 4 states require mixing valves on all DHW devices.

If you have a 60 gallon indirect now and it is adequate???

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

what’s the cost of operating an 80 gal 120 volt electric water heater?

0 -

Hi, I think you'll find there are various commercial water heaters that can easily meet your BTU needs.

Yours, Larry

0 -

Just depends how much water is used. 2 to 3 kwh per day in summer for 2 adults/ 2 kids. 6 to7 kwh per day in winter (Seattle). 15 minute showers or less, 1.5gpm or less.

....I thought you were asking about heat pump water heater usage

0 -

sorry - i was just wondering how come the plumber didnt even quote me on a gas fired one - he just simply said there is no gas fired hot water heater that can meet my demand.

yes i may have said would love to keep the same as how it is now - but i didnt mean that i must have an equivalent…

I did look at the shower heads, they are currently a 1.75 GPM and a 2.5 GPM. With 2 teenangers in the house, they may take showers at about the same time usually, so we are talking about 30 minutes * 4.25 = 128 gallons.

Right now with a 60 gallons indirect - it is sufficient… my wife can go shower right after the kids with another 20 minutes shower and there will still be a hot water.

Can you guys give me some advice what to tell the plumber? I just want to be able to achieve this,

- I want a gas fired hot water heater

- He confirmed he can put a Y into the current boiler Flue and convering it will be fine. (At first i asked about teh direct vent but he said if power is out, then the boiler is out - so i rather get traditional one)

- I only have a gas stove and a gas force air heat - he looked at the pipe and meter and said it should be fine.

- What kind of setup can achieve, 1) 2x shower (2 kids) at same time with 25 min each… 2) and 1 more person can go for another 20 min shower after #1 - that would be perfect…

Thanks

0 -

i asked chatgpt and i understand the "mixing down" now. This is what ChatGPT suggested

Option A: Best balanced choice (most common)

75-gallon atmospheric gas water heater

- 75–76k BTU burner

- Store at 140°F

- Thermostatic mixing valve

- Vent into existing chimney (your plumber already confirmed)

This will:

- Easily handle 2 simultaneous showers

- Allow 3rd shower right after

- Behave like a 100+ gallon system

- Be independent of the boiler

0 -

Putting a Y in the boiler flue pipe?? Maybe. It could not Y into the flue pipe we see.

Gas fired tanks are 7, maybe 10 year throwaways. How long did the current indirect last?

More standby loss in a gas fired HW tank, it has a big hole through the center of the hot tank that goes up to the roof :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

for that boiler flue - he said he can "Y" it in the boiler pipe there in the picture.

i think the current indirect lasted a long time, probably 20+ years. However… i am just worried about the 30 year old boiler, and i was thinking (I dont know how) that may be i can get rid of that boiler all together when it fails instead of replacing it…

And then for the 3other zones that the boiler heats today (office, guest bedroom, Sunroom radiant floor heat) — may be i can do split ac/heat system in the office/ guest BR… That takes care of 2 zones… and for Radiant floor heat in Sunroom…i am not sure what other s ystem can be used to replace the boiler. Is there any other heating system thats more cost effective just to get the floor eat going?

0 -

@yekasi the house will never be comfortable in winter with mini-splits or forced-air. Don't even think about that.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

A properly operating hydronic hesting system is hard to beat. Blowing luke warm air from a mini split may be a big disappointment

But you have a point about a 30 year old boiler, it may not last 20 more years as the nee indirect could

So determine if you will replace that when it fails , that makes the indirect choice for you.

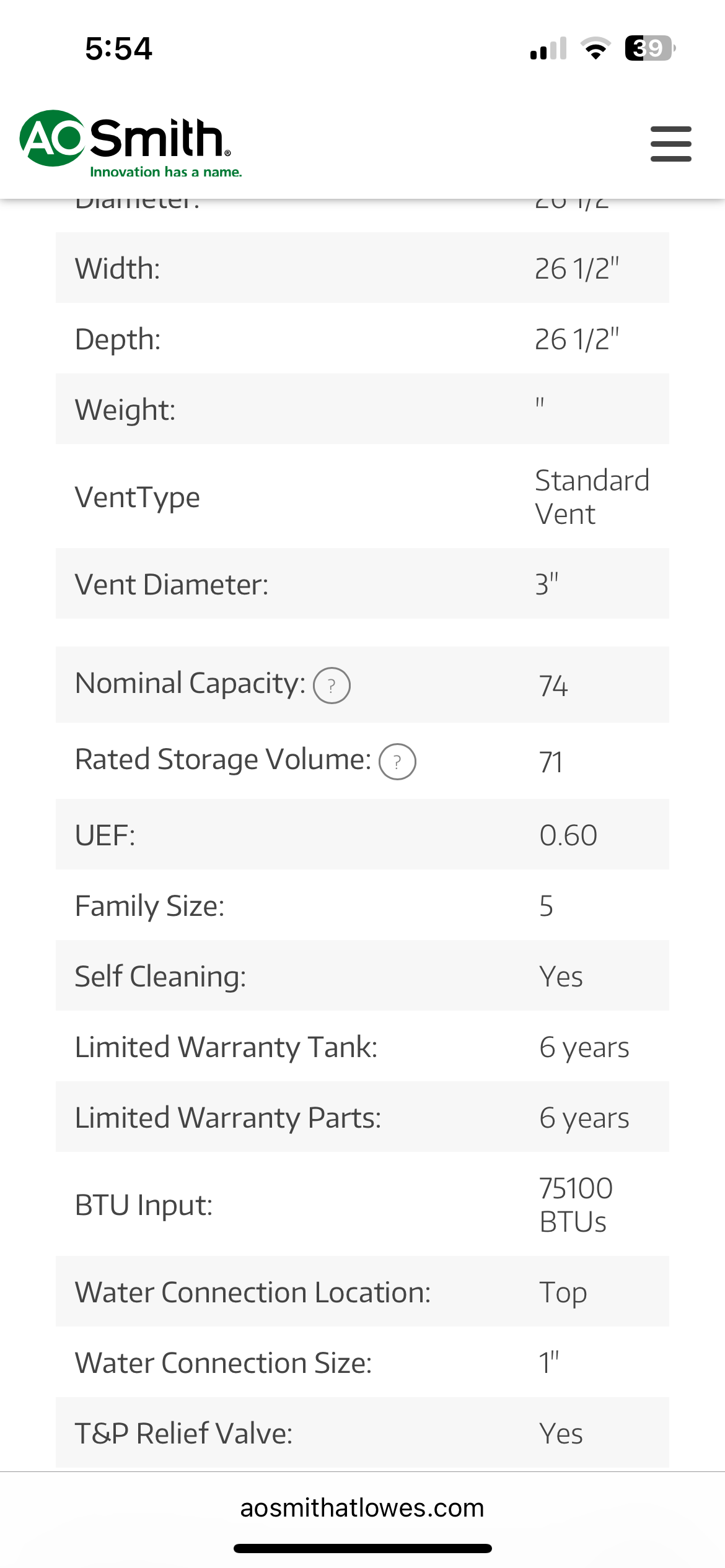

Here is a typical 75 gallon 75,000 tank water heater

The UEF number is the efficiency

So 75,000x 60%=45,000 btu goes into the tank, the rest $$ up the flue.

With the boiler 119,000 x 84%=99,960 BTU available to the tank

So twice the btu and 24% more efficient

I’d get a second opinion about cutting another 75,000 into the boiler flue pipe

Are new water heater installation required to have a permit and inspection in your area?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

thank you @hot_rod . The screenshot you gave me is a gas fired hot water heater, right?

What you said made me re-think - i mean my only concern with teh 30 year old boiler, is just worried it will break down in middle of winter causing no hot water for anyone..etc.. thats teh only concern..

But the efficiency and supplies is making me re-think. Can you tell me if indirect still a popular choice nowadays? Is it something being obsolete or still going strong?

Is boiler replacement more expensive than indirect or is indrect more expensive in general? I want to get an understanding of the cost here as well. The indirect replacement with another SSU-60 has a quote of 6k installed.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements