Explosive steam being released from discharge pipe

I have a Williamson steam boiler gsa 125 n sp. Had it for about 18 years in my home. Just had the main steam vent and discharge relief valve replaced. But now, when the system heats up (all radiators are working well) there’s an explosive bursts of steam that comes from the discharge pipe. PSI is 1 and sufficient water in the boiler. What’s going on? Appears to happen only after everything is heated up Maybe 2-3 bursts a few minutes apart. See attached photo

Please help!

Comments

-

Bad Valve?

Is your gauge accurate?

0 -

Gauge could be bad as PSI is 1 prior to steam release then jumps to 2 per picture. Which valve could be bad? The discharge valve was just replaced.

0 -

Your boiler water does not look clean. Does the water in the gauge glass surge up and down when the boiler fires?

Your pressure gauge appears to show 2PSIG.

Does the boiler have a skim port?

When was last time that the boilers base and mud leg were cleaned and wanded?

Has the pig tail ever been cleaned?

Is the pressuretrol original to the boiler?

0 -

I did drain some of the water out yesterday and the day before. When it refills, it stirs up some sediment, but overall, it’s clean water.

There is no skim port.

The pigtail and pressuretrol are original to the boiler.0 -

The important question of the above ones is: has the pigtail been cleaned and checked to be clear of blockages.

Although I admit it's very suspect that this just started happening after the PRV was replaced (if that is in fact true). Why was the Pressure Relief Valve replaced?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

no, the pigtail has not been cleaned.

Plumber replaced a ruptured main steam valve on the main line. Then I started getting this explosive steam. Plumber thought it was the relief valve (guess he thought the steam was constantly being discharged and figured there was some sediment keeping the valve partially open).

He seems to think it might have to do with the automatic feeder but I’m not so sure that’s right. This is a pressure problem not a water feeder issue.

0 -

-

I watched him replace it a couple of days ago.

0 -

OK, thanks. Well to get to the bottom of this if it were in my basement, I would buy a low-pressure gauge and some 1/4" brass fittings to add it onto the pigtail along with the existing pressuretrol. This would let me know the true pressure at any given time.

When installing that, I would take off the pigtail and run water through it to determine if it was blocked and to clean it. If it is blocked, the pressure is not "seen" by the pressure control.

Actually let me edit that to say I would just clean the pigtail now before waiting for the gauge to arrive.

Then see what the gauge tells me on a call for heat.

I have a feeling the old Pressure Relief Valve was doing its job and the new one is too.

I agree, the autofeeder doesn't seem to be involved from where I'm sitting.

I think you need to replace your steam contractor in addition to those other parts.

PS: I am more than a little curious about this "ruptured steam main valve" he replaced…was it a main vent? The old PRV never did this before he did this work?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Was the original main vent replaced with the same size vent?

-1 -

Water does seem to be clean. Heres another picture. I agree about the pigtail

0 -

yes, the ruptured main steam valve was replaced I’m sure. I had to cut the Sheetrock away because I heard the steam coming through. He replaced it (and I was able to see the rupture) with a bigger valve. When he came back and replaced the pressure release valve, the steam issue was still present. I said we only had this issue after he replaced the main valve. So he replaced it with a different model again.

As for the water in the boiler, when I drain it (which I did a few minutes ago) it only runs rusty for maybe 2-3 seconds and then turns clear.

1 -

Based souly on my experience with 2 faulty hydrostats and the knowledge of 66 other failed units I would also replace the safeguard system with an Xylem/Bell & Gosset/McDonnel and Miller RB-122-E low water cut off switch. The McDonnel and Miller RB-122-E low water cut off is designed to be self cleaning by spinning the probe as the water flows in the boiler.

I would also suggest that the boiler water be treated as well after it is wanded, flushed and the old original parts replaced.

If you have the headroom I would install a drop header or double drop header and a Hartford loop in the summer as they are cheap insurance to protect the steam boiler and deliver dry steam to your radiators.

0 -

Yeah please clean the pigtail now. The water is fine.

I suspect the old main vent (I don't like to call it a valve) blew out because it was holding 10-15 psi for extended periods. Its failure is probably what kept your pressure from going above the 15 psi rating on the pressure relief valve.

When he put on a new main vent, then the system pressure was able to go above 15 psi and make the PRV open.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

old one (silver)

is first picture, new is the brass one

0 -

I believe that 2" plug is where the mud leg should be installed to allow the boiler to be wanded and flush cleaned and you have to be able to pour boiler treatment in your water or use FERNOX to protect the boiler water too.

0 -

ok, pigtail and pressuretrol seems to me the likely issue.

I’m no plumber, clearly and heatinghelp.com is awesome for answers. Thank you all for your contributions.

I just don’t understand why the pressure is building up to a point why it’s being explosively discharged. Aren’t the pigtail and pressuretrol just tools to measure what’s happening, but not actually controlling the pressure?Sorry, I don’t really understand, can you explain in real basic terms? I’m googling as much and as fast as I can!

0 -

The pressuretrol turns off the boiler when the pressure gets to its setting (typically like 2psi). The pigtail just connects the pressuretrol (pressure control) to the boiler so it can "see" the pressure in the boiler. So yes it is not just to measure.

It doesn't directly "control" the pressure, it turns off the boiler when the pressure reaches the "cutout" point and that lack of heat makes the steam production stop, the pressure goes down to the "cut-in" point where the pressuretrol lets the boiler come back on.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

thanks!

So, basically the pigtail might have sediment in it and it’s giving a flawed reading of the PSI (keeping it artificially low). So low in fact that the pressuretrol isn’t triggered to shut the boiler down. So the pressure continues to build. The relief valve is set to discharge once the PSI builds to 15, and that’s when I get those explosive bursts.

so, in hindsight, as you mentioned, that main steam vent was ruptured as it couldn’t contain the constant buildup of pressure.

Whoa, did I just get that right?

1 -

Yes that is what I am suspecting from here in my living room. That old main vent sucked anyway, the one on there now (it's a Gorton #1) is much better.

The pigtail can fill up with gunk after several years without service (any steam contractor worth his annual bill would know to clean the pigtail at least every couple years).

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@Lastname1 , let us know if the pigtail was plugged. If I had any money I'd bet that it is.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting3 -

is there a high pressure safety with a Manuel reset on that boiler?

0 -

Probably not. Very few residential boilers have one.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I reached out to my contractor and explained what I (we) believe the issue is. He responded back saying 1) there’s most likely an issue with the highest radiator air vent and 2) the p-trap on the steam system needs to be cleaned.

Not that he was adamant that the pig tail could be the issue, but was dismissive about it.Apparently, I can clean the pigtail myself with maybe a coat hanger. I looked at some videos and have an idea how to do it, but going to marinate on the upcoming steps.

And a p-trap? Seriously?

0 -

-

I agree with @Steamhead , @ethicalpaul and others about the pigtail being plugged.

Also the gauge is on the same pigtail as the pressure control. so that could be why the gauge is not reading high pressure when the relief valve blows off.

This is not rocket science. If you can turn a wrench you can fix it yourself.

Kill the power and take the pressure control gauge and pigtail off the boiler. Make sure everything is clean and re assemble . You can use teflon tape or any pipe dope.

If the pigtail proves to be plugged and you can't clean it put a new brass one on.

If you cant get a new pigtail easily just use 1/4" brass or black fittings nipples elbows and tee to get it running. You can change the fittings later when the weather warms up

1 -

you can't compel someone to do something they don't know how to do…

0 -

-

Once you get this resolved, you may find that your radiator air vents have been damaged by the high pressure and will need to be replaced. Once you get the pressure under control, keep an eye on them toward the end of a long heating cycle and see if they close properly when steam reaches them.

—

Bburd0 -

Update: That pig tail was 90% blocked. Barely got any water through it. Ended up using some garden wire to work both ends of it to clear out. I cleaned up and removed all old tape and used new teflon. The boiler is now on and all radiators are heating up. Got a little condensate in the gauge, but right now, so far so good.

0 -

Excellent. Hopefully it was 100% blocked because otherwise we don’t have a good reason your pressure was getting so high 😅

Now, lower your pressuretrol cut-in pressure on that from scale to .5 psi (the bottom)

The pigtail will fill with water and block steam from getting to your gauge (which commonly is already broken anyway)

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

also check the differential wheel inside the Ptrol, it should be set to 1,

known to beat dead horses0 -

-

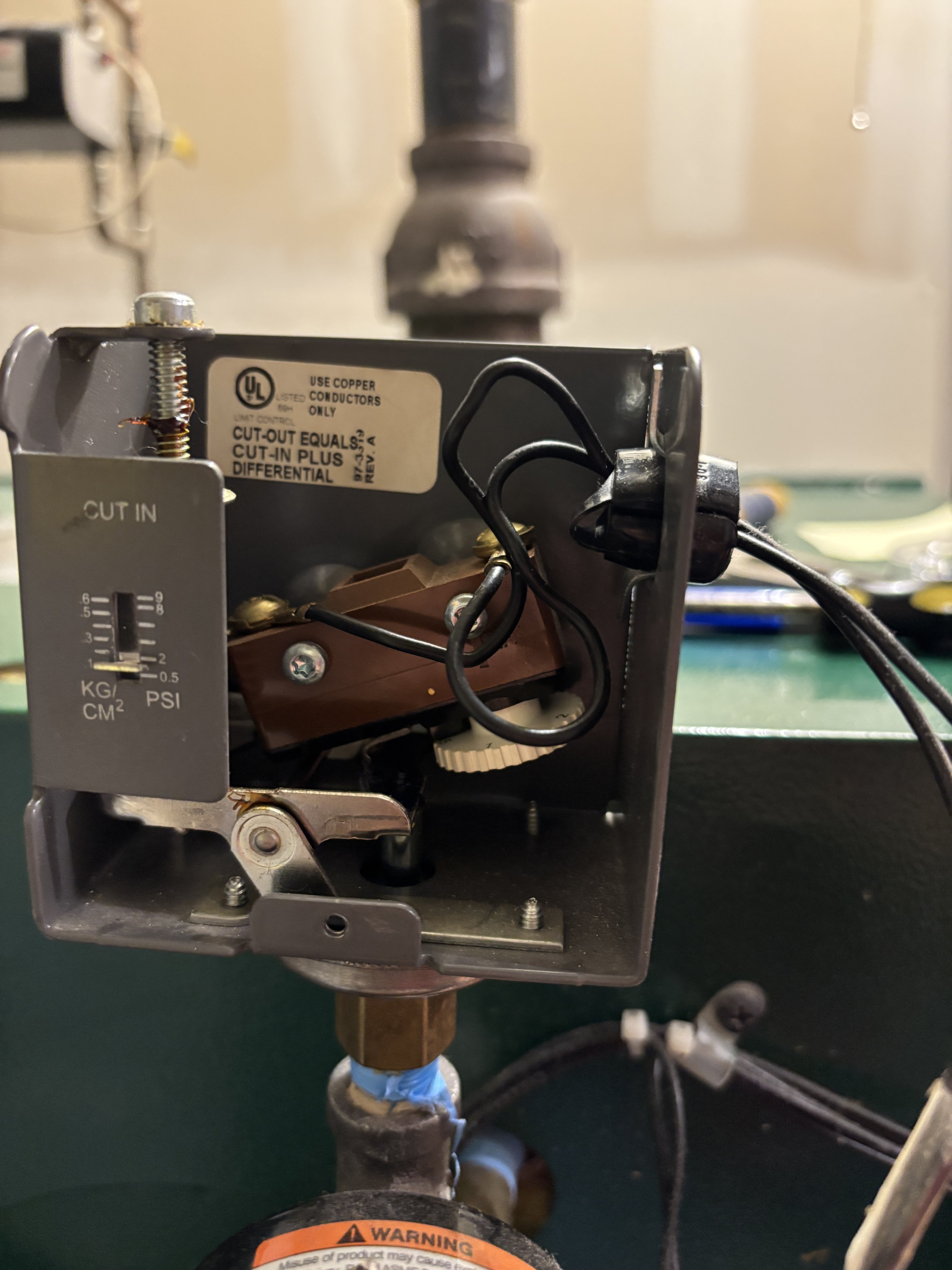

I don’t think I have that option to adjust the differential wheel.

0 -

Yes, you do, it's that white dial wheel on the right there. It should have a number "1" visible from above. It looks like it might be there already. It comes set to "1" from the factory.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

oh! Ok, so if my cut in is .5, the differential is 1….and if my math is mathing, then my cut out should be 1.5?

0 -

Looks like it was set to 1 at the factory

0 -

Yes your cutout "should be" 1.5 but these devices are notoriously mal-adjusted from the factory and so your cut-out is more likely to be 2.5 or so.

Consider buying this low pressure gauge to temporarily install in place of your almost useless and/or broken existing gauge: https://www.amazon.com/MEANLIN-MEASURE-Diaphragm-Pressure-Adjustable/dp/B0CBFB7YRK/

I've been told that code requires you to have a 0-30 psi gauge on this boiler so hold onto your old broken one. Apparently the code doesn't care if the 0-30 psi gauge is broken, because they all fail within like a year of being installed.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements