Oversized overtall chimney?

I own an older home with an atmospheric vented gas steam boiler. Boiler rated 480kbtu input but substantially downfired (mainly to match connected load). Due to leakiness of window/doors etc we have struggled with draftiness primarily in the step-down living room. I added a automatic vent damper years ago and that helps some on off-cycle, but the draft really seems to rage when boiler is running. It was suggested to me that a static damper could be added to the stack to trim the draft rate during firing. I should add that the boiler which calls for 10 inch flue (on 15 foot chimney i think) is vented to a 12 inch square flue of 30 foot chimney. So roughly 150 square inches vs 76-ish. Then downfire to around 225kbtu and flue is at least 4x oversized. I have a graph from somewhere that tries to address the stack height. 10 inch on 15 feet good to 480-ish; on 30 feet good to 650-ish. So another 35% oversized. You may begin to see my challenge.

On a whim I installed a manual stack damper last fall and began experimenting (cautiously) by tweaking back from wide open, while testing for spillage at the draft hood. What i found was that I could limit the excessive draft rate, but the damper angle was a function of the outside air temp. Colder could take more throttling to balance. Warmer weather significantly less so. So much for set and forget.

Longer term solution probably calls for a ss liner, but what size? Eyeballing my graph suggests maybe 7 inch on 30 foot stack for 225kbtu input. Yet I have a feeling no installer is going to stray below the stated flue size for 15 foot stack.

Appreciate your thoughts.

Steward to 1923 Spanish revival near Chicago - 2 pipe steam 650 EDR shiny new Peerless 63-06

Comments

-

-

That oiler have a draught hood on it? Atmospheric — it should. If so, you really have two separate issues: draught through the boiler, which should be controlled by the boiler's dampers, and draught up the chimney

It's the draught up the chimney which needs to be controlled. The stack damper is really the simplest (and cheapest) way to do that, but as you have found it isn't set and forget — or, actually, it is: you set it for adequate draught on warmer days, and on nice cold days off it goes. Bad news: any fixed restriction on the chimney will do exactly the same thing — stack damper, reduced size liner, you name it. That's the way chimneys behave…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

Hi, Two things come to mind that could work together to help. One is the makeup air @mattmia2 mentioned. The other is to enclose the boiler so it does not draw on indoor air. This would mean walling it off, or somehow enclosing it. No doubt a blower door test of the house could help with the drafty room also.

Yours, Larry

1 -

I wonder if a mechanical exhaust system might be in order. You could install something like a Field Controls PVG-300. That can be dialed in to the exact draft required to maintain proper boiler venting without the constant changes caused by weather. Seal off the chimney and vent thru the side wall. For more control over the drafty house, add the Field Controls Fan-in-a-Can. or maybe just a combustion air inlet from outside to the boiler room.

You can then seal off the boiler room and the boiler can operate independent of the chimney and the rest of the house for combustion air and exhaust.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

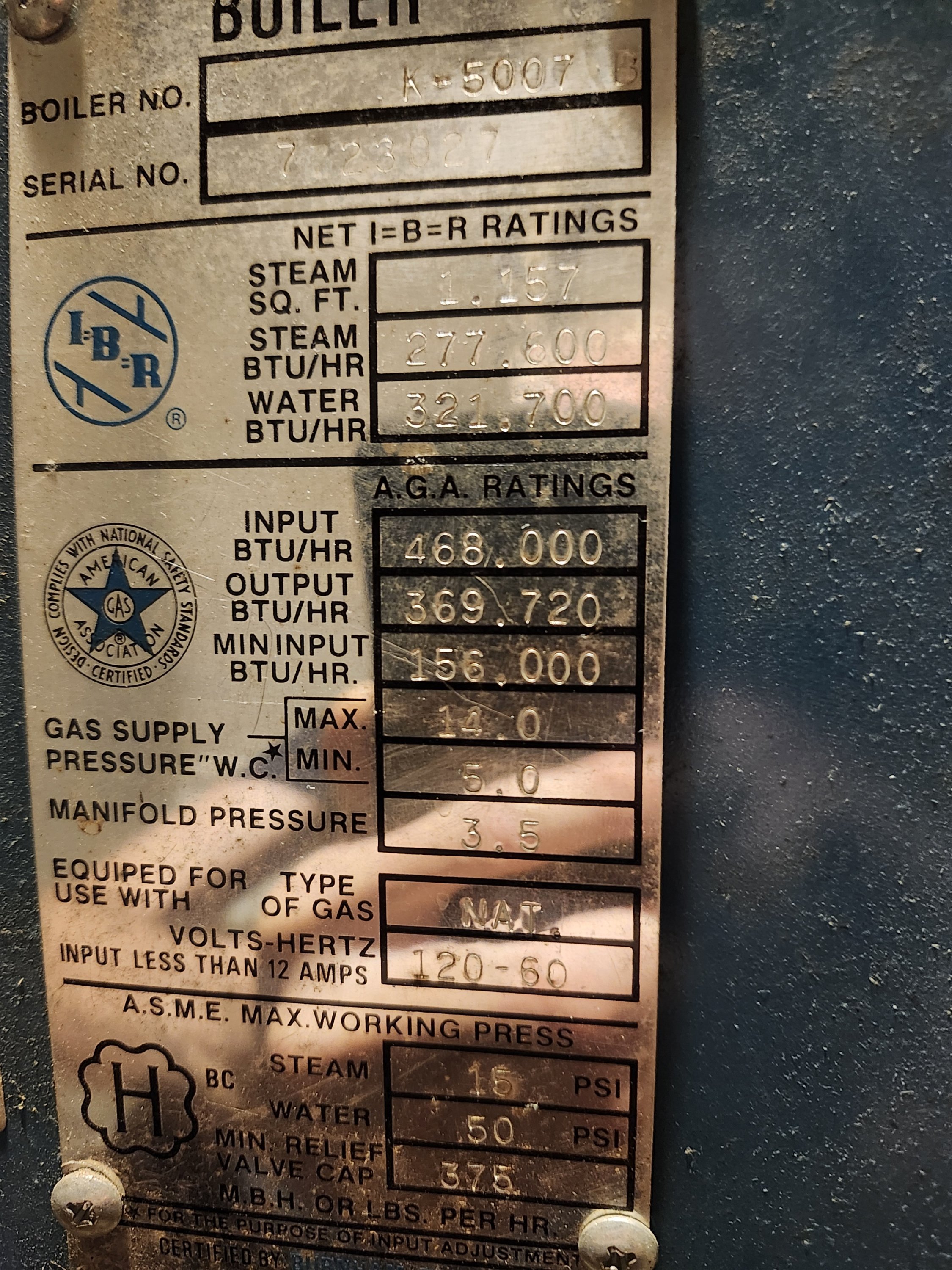

@dandub1960 , what make and model is the boiler?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

-

Install a "fan in a can" near the boiler. You obviously don't have enough combustion air available for the boiler if your drafts increase when the boiler is running. The boiler needs and is looking for combustion air. With a "fan in a can" you can bring in somewhat controlled combustion air. Then invest in weatherization of your house. Having drafts thru windows,walls and, doors like that is very costly on your fuel bill. there are so many government programs to help with the cost.

1 -

Would a simple dryer vent be just as effective by placing the vent flap hood inside the room where the boiler is?

0 -

If the boiler was starving for air, wouldn't there be a lack of draft?

The chimney is pulling air from the same space as the boiler, no? Wouldn't the draft absolutely have to increase when the boiler is running due to hot air being produced?

I'm very confused,

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

All draft is is the difference in weight of a collum of air at a lower temp versus a column of air at the stack temp. Of course, if the flue id restricted, or a lack of combustion air, the wrong chimney cap or some trees can affect things.

I think it is legal on a gas atmospheric to install a flue restrictor (that's not the correct name which I can't remember) and with the correct MU air and correct burner adjustment on a warm day it will help control the draft. But the draft may increase on a cold day not a 100% fix.

0 -

-

The fix for that on an atmospheric gas burner would be a double swing barometric damper on the flue pipe, and an unrestricted supply of combustion and dilution air.

—

Bburd0 -

Quite the contrary, there is more than enough combustion air. That house is so leaky that there is more than enough combustion air. When the chimney starts to draft to its capacity, the air rushes into that boiler room and chimney from all over the home. installing a Fan-in-a-Can will only add more combustion air to the boiler room, it will not throttle the exhaust out the chimney. As a first step, sealing off the boiler room will accomplish the desired result. That may be easier said than done in that home. I would think that plugging off the chimney, and venting with a fan that can be adjusted to match the combustion air needs of the boiler as it is currently operating is a better use of that money. Finally a Combustion Air Inlet ducted to the boiler room would finish off the job, No need for motorized inlet and motorized exhaust. One motor should be enough.

Next step is to start the sealing up process, caulk, windows, insulation, and all things related to sealing up the conditioned space so those drafts stop altogether. Without this step, a windy winter day will have the same amount of draft thru the home as any chimney can cause.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

I believe that is what a combustion air inlet looks like but the flap is missing and replaced with a mesh screen to repel critters. That said, a common dryer vent is only 4" and that would not be sufficient for the amount of combustion air required for that boiler. I might guess that @dandub1960 might require an 8" or 10" intake hood. Since field controls only lists the IAH-6 as the largest part available for their combustion air systems, @dandub1960 may need to have one custom built in the size required using the IAH-6 as a template for the larger one needed.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

-

There are bigger hoods for kitchen and bath exhaust fans. Also made by sheet metal fitting manufacturers although it looks like all the brands i knew of for them have been bought and renamed.

0 -

You're thinking of a "neutral pressure point". @Tim McElwain is the one to talk to here.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

-

Thank you for all the insights. I should have mentioned i have an air intake blower (200 cfm i think) interlocked to the main gas valve, so that helps some. Maybe i should go bigger? Also the basement is deliberately not too tight. The boiler is a Burham K-5007. Two outside burner tubes removed, but mainly downfired at the gas valve regulator. I check my firing rate by clocking the gas valve proofing dials.

I would love to seal off the boiler room from the rest of the house but finding room for an air intake is challenging right by the front stoop. I'm intrigued by barometric damper or mechanical exhaust. At least i now know the temperature effect I've seen is expected.

Thanks all, Dan

Steward to 1923 Spanish revival near Chicago - 2 pipe steam 650 EDR shiny new Peerless 63-06

0 -

@Steamhead yes a 'neutral pressure point" TY

I was trying to remember where I saw this I Think it was in one of Timmie's books that I have i will have to look

0 -

@HydronicMike "Chimney's can never be too big"

Yes, they can. The boiler or furnace has to be capable of heating the chimney up to create draft. A chimney that is really oversized will not draw well.

0 -

I think Jim Davis would disagree in this scenario.

0 -

Hi, I dealt with an atmospheric draft water heater with a 4" vent, going into a 12" chimney. It never could establish draft, so just spilled into the room. I fixed it by continuing the 4" vent up. Certainly there are many flavors of this with every situation having its own set of facts.

Yours, Larry

0 -

That is just mean Chris. I know of many professionals that are incompetent! I trained several of them to competency before they went into business for themselves. At which time they became incompetent businessmen.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

3 -

You just said it was the magic of DIY.

I'm not sure how else I could take that?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I just would like to mention that a professional might baulk at converting a boiler with a 480,000 input to operate at 225,000 input. That is less than 1/2 the rated firing rate. Even an inexperienced professional would caution against that. When asked how this might happen, I could only think of one answer. Someone experimented with their own equipment. Since the results did not burn down the house or cause any of the residents to pass away from CO poisoning, then the experiment was a success and the system was left to operate that way ever since.

Nothing wrong with that assumption IMHO. I have downfired many a coal conversion from over 1.50 GPH (the rated BTU of the original boiler) to less than 0.90 GPH by placing a flame retention burner in the firedoor of the boiler to put the fire black in the place it was designed to be. Does that make me incompetent? The customers with the lower oil usage don't think so. And those boilers were still operating 15 years later just before I converted them to new gas boilers once the Gas Co. buried mains down the street.

Then they saved $$$ again with ModCon boilers. Repeat business. The glory and reward of doing the right thing for the customer. A professional job for a fair price.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

-

@HVACNUT said: "No other criteria other than the house is still standing, and no dead people for a safe 'successful' operating system?"

What other criteria does a DIY usually require?

I think that falls into the "I don't Know what I don't know" stage of unawareness.

Lets add to that criteria: "It's heating the house!"

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Many say you can't down fire a boiler and I agree that with a gas atmospheric there is not much to control. It comes down to removing and plugging orifices or putting in smaller ones or playing with the gas pressure.

I would never attempt it without combustion testing. With oil we used to down fire all the time with the old boilers especially the old coal fired ones. A firebrick in the flue pipe and adjust the barometric damper , watch your stack temp and combustion #s. You can overdo it like a match heating a tea kettle.

1 -

I have checked the specs on B-vent and not one tells us what temperature it has to be heated to vent. Chimneys are not mechanical devices. They are chases. You don't have to heat ductwork to get heat to flow. Can you oversize a steam pipe? look at some old chimneys on commercial buildings and their massive brick chimneys. Think they get heated before they vent. And why do chimneys vent in the summer when nothing operating?

Draft is a sign of combustion air. The higher the draft the more combustion air is available. The taller the chimney the higher the draft.

A neutral pressure point is also called a blast gas. Back in the 80's there was a product called a Thermizer that was a flue restrictor for residential and light commercial. They were very dangerous on drafthood equipment if you didn't understand venting and combustion air.

The chimney is too big was created by manufacters to make contractors look bad and then really pushed by liner companys.

Blast gate, barometric combined can do the trick.

And bring the firing rate back up some

3 -

Nameplate on the K-5007 says it can go from 468 down to 156 kbtu or 33%. I didn't initially believe it either but it lights off smoothly, makes steam quietly, and doesn't drive my 1950s remuddled distribution system to conniptions like it did at full firing rate. Been at this setting since 2013, through numerous polar vortices. I love my steam heat; I just hate the crazy draft it pulls.

Steward to 1923 Spanish revival near Chicago - 2 pipe steam 650 EDR shiny new Peerless 63-06

2 -

I have CO detector in the boiler room and near bedrooms. Have never detected anything but zero, not even briefly.

Steward to 1923 Spanish revival near Chicago - 2 pipe steam 650 EDR shiny new Peerless 63-06

0 -

It's remarkably difficult to tame a too big chimney successfully. Which, however, brings up a very real question: is it worth the hassle to do it? I know, I know, we're all about efficiency these days. But…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

-

When determining combustion air for equipment, draft hood units require 30 cu.ft. per 1000 btu or a 1/2 cfm per 1000 fan. These are for rooms that have no leakage. Equipment without out draft hoods only require half of that amount.

0 -

Guys,,, I really don't think the problem is a lack of combustion air… He's got a whacking great chimney there and is trying to find ways to reduce the amount of air going up it. I have seen a chimney that size develop enough draught to break a four foot a square piece of quarter inch plywood and try to such it up the chimney on a cold day with normal room temperature indoors.

If he really wants to reduce that draught he's going to have to drop a liner in there, sized to the appliance, and seal the space around the liner in the existing flue. That's going to cost, and other than the feel good of not having so much draught up the chimney it won't save enough on heating costs to make it worth the effort.

But folks, from the sound of it — don't worry about not having enough combustion air. That's not the problem.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Strongly disagree that a chimney can't be oversized. draft is caused by the temp difference of heated air versus combustion air.

You go to a cabin on a cold wet damp day. You have the door open, and you try and light the fireplace and its back drafting.

Nothing to do with MU air you have the door open.

You get the newspaper and kindling going and it starts to draft because the chimney is warming up. the bigger the chimney the more heat it takes to get going.

How many gas fired atmospherics have been ripped out and the existing gas fired water heater is left in the chimney with the boiler replaced by a MOD CON. Then the chimney may be to large for the water heater and you have to comply with the 7X rule.

So of course chimneys can be too big.

2 -

So at my current firing rate that'd mean 115-ish? Pretty close to the 140 cfm blower i have (not 200, I misspoke earlier, maybe i was looking at a 200). And my basement is far from tight, but I figured I'd give it some help, so that the pressure differential drawing across every other crack and crevice might be a bit less.

Steward to 1923 Spanish revival near Chicago - 2 pipe steam 650 EDR shiny new Peerless 63-06

0 -

Most basements in the average house if the boiler has access to the entire basement for combustion air the house leaks enough there will never be an issue.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements