How much does size matter?

I plan on replacing my 97 year old furnace with a Weil-McLain AquaBalance Heat-Only Wall Mount Gas Boiler. My option is 65,000 97000 or a125000 BTU unit. After a quick calculation I should need a 93000 BTU unit. Just how close do I have to be to the 93000 for thing to work right?

Comments

-

Is 93,000 btu/hr the heat loss of the house that you calculated? Since it is a modulating boiler it can fire at a lower rate much of the time. I would go with the 97,000 btu/hr output model though the actual output may be a little less depending on what type of emitters you have and how well they deal with low temp water. Are you heating DHW with it or just space heating?

0 -

Just space heating with cast iron radiators.

0 -

-

A 97,000 input will be around an 84,000 output, derate for efficiency.

If you trust the load calc, go with the 125, it will turndown about the same.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

-

that calculator gives me a load of 103,554 BTU/hr. My boiler is an 85k mod/con and when I checked up on it this past winter when it was -15f outside it satisfied a call for heat in less than 10 minutes. That calculator is pretty far off, that being said a 125k with a 10:1 turndown is going to be fine, I just don't think your actual load is anywhere near what SH suggests.

2 -

How much does size matter?

This question is better asked in private with your significant other.

As far as the boiler size is concerned…

If you do the load calculation based on I=B=R form 1504WH or ACCA Manual J, you will find a much lower requirement. I have a feeling that you will be able to use the WM AB-80H with a 65,000 NET output, and have the most efficient setup. If you don't want to go to the trouble of an actual Load Calculation for your home where you measure the actual amount of doors, walls, windows, ceilings and floors, then you will be guessing that you have something less that 97,000 NET and I would choose the WM AB-120 with the 97,000

NET output. Either way, the boiler will only use the amount of BTUs required to heat the home and rarely fire more than actual load requirements. Where you will waste fuel is at the low end when you only need 6000, BTU on a spring evening and the turndown ratio only goes to 9700 BTU so the boiler will cycle on and off to provide the lower BTU requirement.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

I recommend the process detailed in this article for sizing based on actual fuel usage:

https://www.greenbuildingadvisor.com/article/replacing-a-furnace-or-boiler

0 -

-

-

That is what I did and was able to size down my boiler and save approx. 8% on my gas usage. 2 heating seasons so far and no problems keeping things warm in the winter.

0 -

https://www.greenbuildingadvisor.com/article/replacing-a-furnace-or-boiler

I've used a method like this for decades and it works quite well. However, some of thier assumptions are quite off.

Heat loss of a structure is not close to linear. Heat movement through most materials is nearly linear at typical design temperatures. However, air leakage rates increase nonlinearly, so heat loss accelerates as it gets colder. The old ASHRAE charts show the design air leakage rate of a medium "tight" construction as 0.6 air changes per hour when its 50F outdoors. At 0F , the number of air changes per hour increases to 1.1, nearly double the air leakage and at big delta T for that same structure If you have a leaky building, this can really increase heat load dramatically.

Also, the other big error is the efficiency of equipment. A typical 80% gas efficiency atmospheric boiler without a damper that is 3 times oversized is running about 62% efficiency on a typical winter day ( which is about 1/2 of design load). A 3 times power burner boiler boiler tends to fare much better at about 68% efficiency.

This is why I really like running staged boiler heating plants in larger buildings Sized and controlled properly, you can take the typical day 62% or 68% efficiency and bump that up to 80% to 85% with a properly sized heating plant with two smaller boilers. On the buildings I've done this, fuel usage reduction typically runs from about 20% to 60% and you still have very simple long lived equipment that is inexpensive to repair.

To learn more about this professional, click here to visit their ad in Find A Contractor.0 -

@The Steam Whisperer, I'm curious about the staging. Do you often (or ever) do more than two stages? Asymmetrical stages (like 1/3 & 2/3)? Pressure control vs temperature vs time?

0 -

I typically do 2 stages, unless I'm trying to stick with residential pre assembled boilers on larger loads. I have used asymmetrical stages, especially in unusual load situations like church structures that are in setback must of the time and only are heating a small space. For control on Hot water systems, I've used Tekmar for staging controls and reset, but its been quite awhile since I've done these. For steam, I use two stage thermostats quite often with orificed two pipe systems. On some steam systems you need both boilers to prime the system and then you can drop to one boiler. An aquastat at the end of the slow to heat main usually can take care of that. R&D controls makes a 2 stage steam control that will drop out the 2nd stage after the temp rises to about 60% of the differential. I probably will be trying one of these soon.

To learn more about this professional, click here to visit their ad in Find A Contractor.0 -

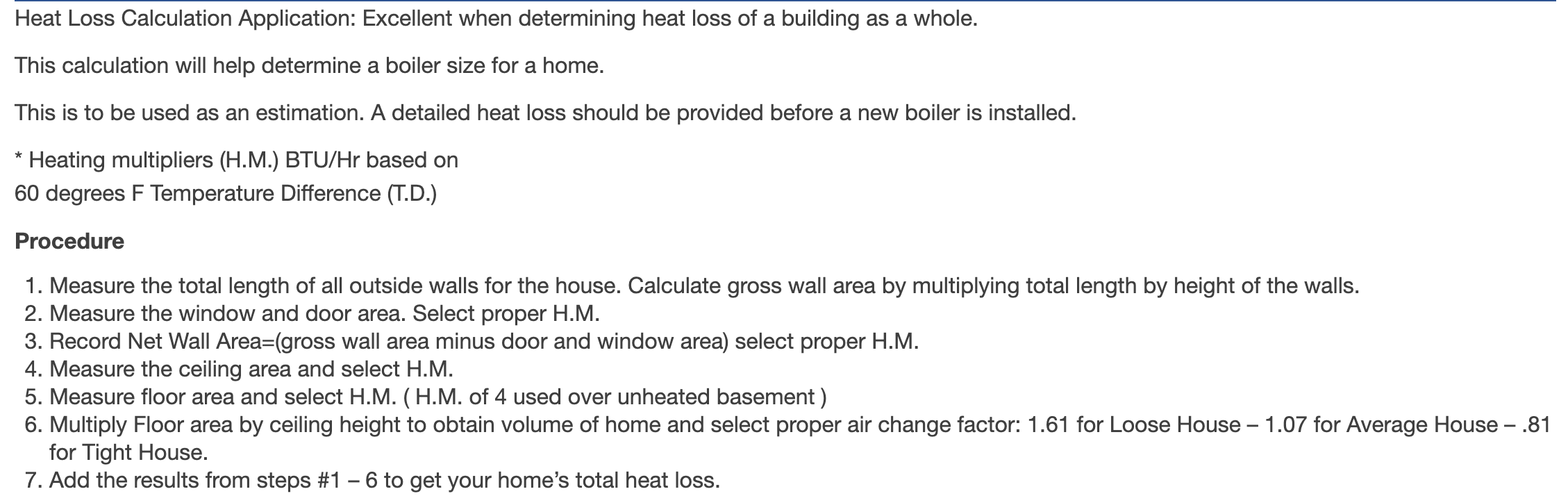

How dose this look for a more accurate information? What would be the width? Each room?

0 -

This particular U.S Boiler calc is looking at the home as a whole, measure outside walls, windows, doors. Follow the Procedure paragraph

A more detailed load calc would be room by room. So use the same input data sheet and use the room dimension. A 10X 10' bedroom 8' tall for example.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The part I don't like about that is "select proper air change factor." In the end, you're just guessing. You could do a blower door test and actually measure the leakage.

0 -

In a house with significant solar gain this method will underestimate the design load.

0 -

How much does size matter?

It's an interesting question. Design conditions may only occur for a few days or weeks a year. And many boilers, especially cast iron units, are oversized most of the heating season.

At my house we're tolerant of 60° f indoors during design conditions so a boiler that's undersized for a few weeks a year is fine......

0 -

Infiltration is always a guess and always was a guess without a blower door test.

Hot water boilers have a built in 15% piping and pick up factor and steam is 33%. So if the boiler selected is the "perfect size" you would still have some extra capacity.

0 -

Can some one explain the math they want on windows? ft2? one window measures 41x51 inches. Just round off to feet? like 4ftx4ft

0 -

Yes, round to closest square footage

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

One problem. It just hit me. Going room by room will make all walls insulated. Including inside walls.

0 -

-

An overview of getting a "heat loss" number: You are expected to calculate the total cubic volume of the heated space of the dwelling, surrounded by the total insulated envelope of the walls, ceiling and floor. Calculate the entire area of windows and doors as a factor that detracts from the aforementioned. The air-change number is also important as a factor that measures the quality of "how well" all of the materials were "put together" (and any degradation of that). When you get The Number, imagine then…yourself in the house on the coldest day of the year in your region…on a windy day. IF your number falls between 65K and 97k , say its 75K…go with the 97K boiler model.

0 -

It depends on your mood. Do you want it cold, too hot, or as comfortable as possible? Hmm. I would hazard a guess that you want it as comfortable as possible. Crunching the numbers with more than one heat loss program is a good idea.

Years ago, I had to do heat loss calculations by hand. ( Ok, I used a calculator too, I'm not that old.)

Does anyone know where those calculation formulas can be found? Does Slant Fin still have theirs out there? Is there a calc? That can be reliably used?

0 -

-

Here is another option, in an Excel sheet format, try several of the options offered on this thread to you find the one that works best for you.

They are all based on a Manual J formula, some allow you to enter more details and get a more accurate number.

The infiltration will be a guess unless you have a blower door test done. But easy enough with a spreadsheet to change ACH and see how it changes your load number.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Blower door tests are in the $250 - $500 range.

Well worth the expense.

0 -

Of course even with a blower door test you're still guessing what the infiltration will be on a cold day, it's just a more informed guess.

0 -

it gives a starting point

0 -

how does infiltration change? cold day to hot day?

known to beat dead horses0 -

I think some of the load calc programs allow you to enter wind speed. That could change the load numbers based on infiltration around doors and widows.

Not many heat load programs take into account internal gains, passive solar gains either. So the load number is a best guess

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

temperature deference and wind direction.

0 -

The maximum (heat loss) for a building will occur when it is unoccupied. Lighting, refrigeration, people add heat to the space which is not used as a credit to the heat loss.

With air-conditioning these gains are considered in a heat gain calculation.

0 -

The temperature difference between the inside and the outside creates a pressure differential which drives infiltration. The greater the temperature difference the greater the infiltration.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements