Trane Air Handler Fan Constantly Running

Comments

-

Yeah in this case I know what I don't know and when to call it quits, not worth the risk.

Just curious though - I understand that the unit's nameplate typically states how much refrigerant is inside the system.

My unit's nameplate is faded and I'm unable to read how much refrigerant is in the system. In addition, the manual that I found online states that this unit does not ship with any refrigerant.

Therefore, to determine how many pounds of refrigerant the unit needs, would we need to contact the company who installed the system and check their records on how much refrigerant they charged? I understand that records need to be kept for at least 3 years per EPA, but I think this system was installed around 2017.

If not, does one just calculate how much refrigerant the system needs by knowing the size of the unit + adding/estimating the length of the refrigerant lines?

0 -

no requirements to keep records for small systems.

you would charge it by measuring the outdoor ambient, indoor return wet bulb, then the superheat or the subcooling of the refrigerant depending on if it is a txv or orifice system. it really isn't as hard as the fearmongers are making it sound.

there is usually a spec by weight in the manual for given condenser and indoor coil combinations with some range of lineset length and the amount to add for additional lineset.

1 -

there are some exceptions for working on your own system though i'm not sure if that only applies to automotive systems and if it is actually part of the regulation or if it is case law.

0 -

Got it, yeah I mostly just like learning about how these systems function even if the work is starting to go beyond the diy realm. If anything, it allows me to have a better discussion with the service tech and understand what they are explaining/proposing.

0 -

-

-

That pic is the only freon police I know about. The nosy neighbor that has nothing better to do but call the HOA and any other three letter organization that will listed to them because they don't have a life. I still like that statistic about the number of homeowner EPA 608 prosecutions and convictions since 1995. I guess we are all following the rules. Such a perfect law. 100% adherence to the law…. WOW 😮

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

-

In the article that @pecmsg posted, the copper thieves were stealing condensors on a regular basis, so the cops had under cover personnel looking for the thieves. When the officer saw the copper line get cut, that is when he knew that the federal clean air act violation was in play. The cops called the Feds. The Feds have stronger penalties than the local PD has when it comes to just steeling an appliance. Good Call for the cops on this one!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

So I've been doing some reading on the topic and had a conceptual question for all of you.

The system has 407C refrigerant, which from what I understand is a zeotropic ternary blend. Therefore, it is at risk of fractionation.

If there is a small leak in the system, the vapor of one of the components would be released more than the other components due to different boiling points, resulting in the percentages of the blend to become out of whack. These imbalances can cause inefficiencies in the system and issues with the compressor.

When one goes to repair the leak you would vacuum that "imbalanced" refrigerant blend out of the system, perform the repair, install a new filter drier, and recharge that refrigerant back into the system with additional new 407c refrigerant to the appropriate specs.

Technically however, isn't the total new blend still out of proportion? Should one not be placing the old refrigerant back into the system (seems wasteful and cost inefficient) or is the imbalance not enough to notice a real-world difference?

0 -

It is probably less of an issue with a leak than when charging from a tank. as the refrigerant evaporates rapidly from the tank as it is charged in to the system you would have one refrigerant evaporate more than the other which is why you invert the tank and allow the liquid mixture to leave the tank and charge it slowly enough that it can evaporate before it enters the system. When it evaporates very slowly as the system leaks slowly the evaporation is likely to be more even although it could still lose more of the refrigerant with the higher vapor pressure.

Assuming it has service valves and I think the first picture showed them, you would probably just close the discharge service valves and pump the charge down in to the condenser, assuming the leak was elsewhere.

There may be so little refrigerant left in the system now that it won't matter much if the mixture is off because it is only say 20% of the charge has a ratio that is off by 30% and it will only be off a very little once you add the missing refrigerant.

0 -

-

Yes as @pecmsg said blends have to be charged as a liquid.

Steve Lav on U tube is installing Goodman because they are R-32. He went to install a Rheem and his supply house told him a 20lb can of R454B was 2k

0 -

Got it, yeah it has to be charged as a liquid so that the blend ratios remain true. I was just curious if you had to figure out a way to calculate the percentages of current system's blend after a leak or it is just assumed that the difference is negligible once fully charged.

Would you say R32 is more future proof or will at least have a stronger inventory supply as compared to R454B? From what I understand, R32 is a more commonly used refrigerant outside the US.

0 -

-

When 410A first rolled out, there was lots of noise about the blend changing composition due to leaks, just like you were discussing. That gradually went away, it apparently had no significant impact on comfort AC. I hear it may still be a minor concern with blends that exhibit a large glide, but I don't work with those.

1 -

Happy 4th everyone!!!

Yeah I guess if the glide is not large enough, the proportion's shouldn't be affected significantly and can probably be ignored.

So this unit has a TXV valve in place, therefore one should be referencing subcooling when charging the system.

However, I was reading the installation manual and it states to not go by subcooling. Instead it provided its own table that takes the outdoor dry bulb and indoor web bulb temps and provides a liquid pressure.

I haven't seen anything discussed about online or on any videos that describes this method - most go over referencing superheat/subcooling. Is there a reason why this system wants us to ignore subcooling for charging?

0 -

If you're the factory, you can charge the system mathmatically by volume, then operate it at different conditions & see what the pressure is & write that down. I don't care for it too much, it seems to me that it'll only work when the indoor & outdoor units are shiny clean, i.e. a new install—not to helpful for servicing a dirty old unit.

A lot of the larger stuff I work on (12-80 tons) use a charging curve, which is liquid pressure vs liquid temperature, with different curves (not lines) for different SSTs. Technically subcooling, but not a flat "12°" or whatever.

I print out the one page, laminate it, & plot on it with a dry erase marker. It takes a long time to charge a microchannel coil, the juice goes in ¼ lb at a time. Even on, say, a unit with a 150 lb charge.

I've seen some smaller stuff, Lennox splits I think, charged by approach (liquid temp less outdoor air temp).

1 -

Sub cooling has historically been the way to go with a TXV. You need liquid at the TXV for it to work and feed the coil properly. With no subcooling you may not have liquid at the TXV. With sub cooling you will. The question is how much subcooling do you need. In the old days 15-20 deg was common. Now many systems are 10-12 degrees. Same with superheat they used to say 20 now usually lower.

I usually try to charge it the way the MFG wants but once in a while you get a unit that just will not "line up" on the chart. Then you have to look at superheat, subcooling, compressor amps and clean the coils and come up with a compromise that works.

its not always one size fits all.

1 -

Got it, that makes sense.

Is the change in subcooling/superheat parameters because of efficiency improvements in the metering devices, refrigerants, and/or coils?

0 -

though the guy that installed my ac 25 years ago before i understood this used the pressure /indoor/outdoor chart to charge it i thought that chart was just a quick check and measuring subcooling was the proper way. the more subcooling you have the more work the compressor is doing so you want it as low as it can go without going to 0 at some condition so ideally you'd set it based on a curve that accounts for the current operating point the same way you set superheat on an orifice system.

unless it is certain types self contained appliances there is a range of charge where it will function and perform about the same.

1 -

Ok so it's been a little while, but I wanted to post an update. Turns out there was no refrigerant left in the system at all.

Tech wasn't able to identify the leak and after discussing the pros/cons and the current supply shortage, we decided to just try topping off the system to see if it would hold us off for the summer.

Unfortunately, after about 1-2 weeks of proper cooling, we noticed that the system was no longer cooling efficiently again. The leak must be large because the system is completely empty again.

So unfortunately we're now deciding on a new system (condenser+air handler). I had one company quote a Rheem condenser/handler and another quote a Goodman. The Rheem was double the price for an equivalent 4 ton model.

Since Goodman/Amana/Daiken are all R32 vs Rheem/others are 454b, would you guys recommend I go with the Goodman due to better refrigerant supply and half the price?

I also have a follow-up question. Since I have hydronic forced air heating throughout the home, would it be worth it to consider investing in a heat pump for AC + heating when the weather is mild and then transitioning to hydronic boiler heat during colder temps? Or would the additional costs and installation of the heat pump not be worth whatever savings I would get by just sticking with hydronic heating and traditional AC?

0 -

-

Yeah I had 3 other techs come out and no one wants to do a leak test. They say it's not worth it for this 407c system…

0 -

I was thinking of even just trying myself to spray around and do a bubble leak test. But if I have the system running, is it even possible for the bubble leak test to work since the refrigerant pressure is 0?

0 -

-

Yeah I'm watching a few videos, I may just give that a try before throwing in the towel on a new system.

I'll have to acquire a tank of nitrogen, but would you recommend a regulator like this:Seems like they make a 500 PSI and 650 PSI version

0 -

-

Oh that's good to know, thanks! Just googled and found 2 welder's supplies near me so I'll give them a call tomorrow and see if they can help out.

0 -

Ok so I was able to rent a 40 lb tank of nitrogen and picked up a regulator. I removed both Schrader valves using valve core removal tools and ran about 78 PSI of nitrogen through the entire system.

After about 30-35 minutes, the pressure dropped to 75 PSI (accounting for outside temp change as well). So definitely a leak. Is that considered quick?

I'm going to leave it overnight to continue to watch it.

I got home later then I hoped, so by the time I set everything up it was starting to get dark out.

However, I sprayed the common culprit areas with Nu-Calgon blue leak detector spray (brazed joints, filter drier inside of the condenser, etc.) both outside and at the air handler and did not find any bubbles. Also from the limited visualization of the evaporator coil, I don't see any obvious oil staining either.

I'm going to give it another shot tomorrow/Thursday to see if I can find anymore bubbles and will also try to borrow an electronic leak detector.

0 -

so you can close the service valves to isolate the condenser then you know if the leak is in the linset or evaporator or the condenser. there is usually a gasketed connection for the txv or a connecting tube with an orifice piston at the inlet of the evaporator. usually inside the casing. do you have specs o the test pressure? if you can increase it to maybe 200 psig or so you may be able to hear it.

2 -

Oh nice that makes sense. So if I use a ratchet to close the service valves at the condenser and the pressure holds constant, then that means that the leak is within the condenser? If the pressure continues to drop then the leak is either in the line set or the evaporator coil?

I don't believe there is a TXV valve, I looked everywhere for it. I can take a picture of the air handler tomorrow as it's up in the attic now, but I believe it's a fixed orifice piston meter at the inlet of the air handler/evaporator. I believe it says something like 0.8 fixed orifice.

The evaporator coil says its test pressure can handle 300 PSI, however the outdoor condenser said 166 PSI so I was playing it safe with a lower pressure.

Should I try increasing it to 150 PSI? If I close the condenser's service valves, I could technically go higher to 200 like you recommended as long as I remember to release some of the pressure before opening the condenser's service valves again.

Edit: Nevermind I actually found a previous picture I took. There is a sticker underneath that fitting that says fixed orifice 0.83 or something to that extent.

0 -

make sure you put the caps on the service valves and wrench tighten them after you close them while you're leak testing. they rely on the metal cap to make the seal.

higher pressure will leak faster and be easier to find. in systems of the past 15 to 20 years or so evaporator coil and condenser coil leaks are common. those may or may not be fixable depending on where they are.

1 -

Ok I'll bump up the pressure tomorrow, tighten and cap the service valves, and see if I can isolate the leak(s).

One of the techs that had come by the other day said that the orifice entering the air handler was no longer to code. Stated it used to have a lot of issues with leaks and therefore is no longer allowed.

I was hoping that it was the leak, but I didn't notice any bubbles around it.

0 -

-

those tubes usually have a teflon gasket, that shouldn't leak if tightened properly. what did leak were quick connect fittings on linesets which i think went away in the 90's. i don't think they were inherently bad but frequently didn't get tightened until the metal parts sealed, the ones i have seen instructions for had o-rings to keep them sealed during piercing and had a metal seat that sealed them metal to metal if they were fully tightened.

1 -

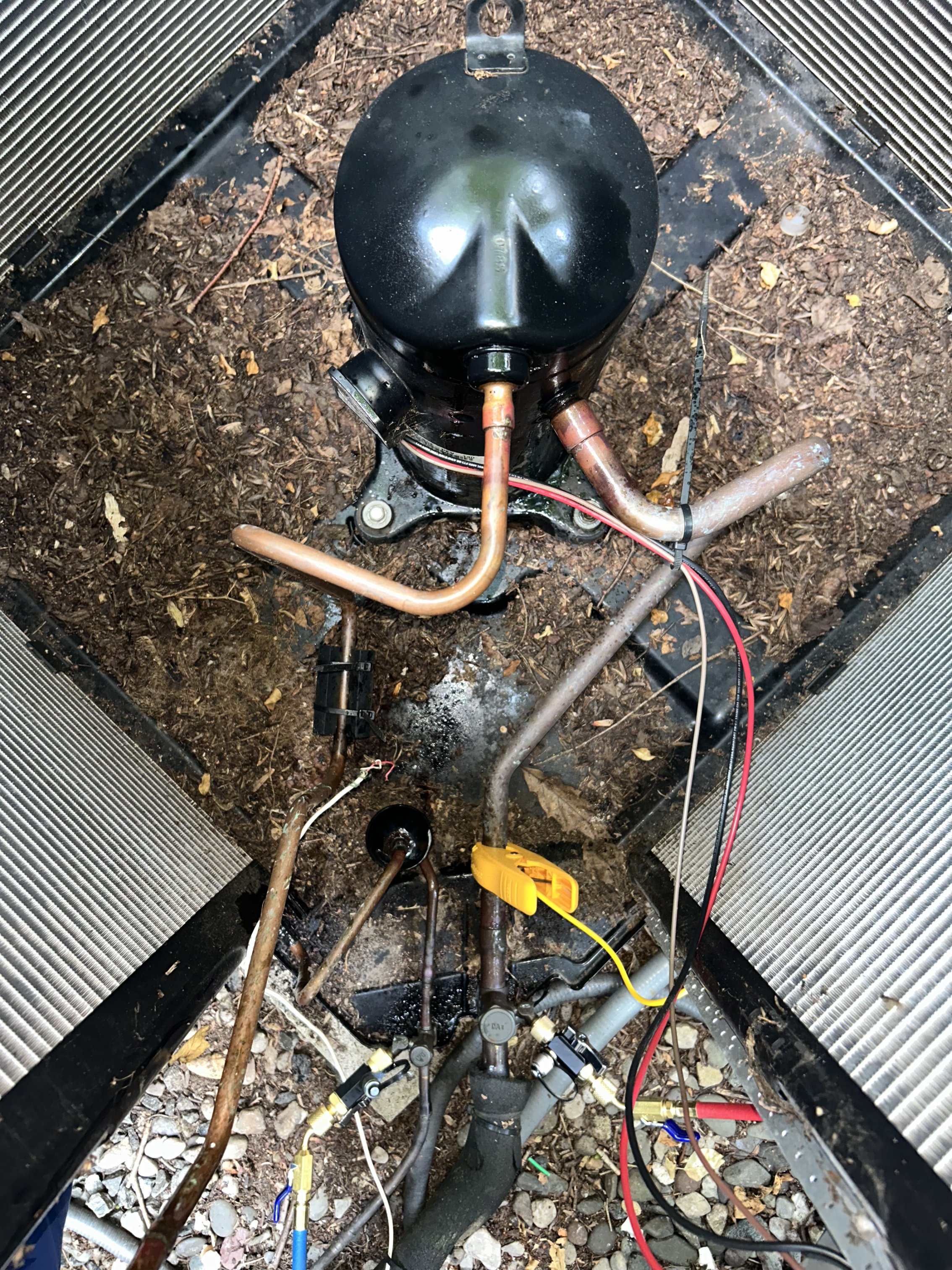

That crusty area over the distributor tubing was actually frost as it’s no longer there, now it’s just normal clean copper tubing.

So I pressurized the entire system to 150, however didn’t heat any obvious leaks.

I closed off the condenser’s service valves and pressure remained constant for an hour. So it appears that the leak is somewhere on the condenser side.

Unfortunately, I sprayed all of the connections throughout the copper tubing on the condenser side and no leaks were identified. I’m assuming that the leak must be within the condenser coil which would be unfortunate as I read that this is a micro-channel coil and therefore leaks in the coil are unrepairable.

I can borrow an electronic leak detector this weekend to try and locate where the leak is within the condenser coil, but I’m not sure if it’s even worth the time now.0 -

-

the good thing about the condenser is that you can spray it with soap then hose it off, just spray the whole thing and you'll find it. keep it under pressure so the water doesn't get inside though it might require a good evacuation and new drier to get the moisture out now anyhow.

i know radiator shops can seal off a bad tube in that style radiator, i bet someone has figured out how to do it with a condenser coil.

2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements