Trane Air Handler Fan Constantly Running

Comments

-

Got it, I’ll spray it down and see if I can locate it, thanks!

0 -

-

I had slightly tightened the caps on the service valves yesterday before I pressure tested the entire system. And I'm pretty sure I sprayed the caps too to check for bubbles, but I can't remember exactly as I checked so many different areas.

However, after I pressurized the entire system to 150 PSI today, I removed the caps (in order to ratchet the service valves closed) and did not hear any hissing sounds coming out of the service valves.

0 -

The other place to check is the compressor motor wiring terminals. They are not usually a problem but if you can't find the leak anywhere you might check.

Microchannel condensers do not have a good track record and evaporator coils are a prime suspect as well.

If you replace it I would go R-32 Daiken/ Goodman.

R454B price is way out of wack.

Watch some of Steve Lav's recent videos on you tube he talks about it as well

1 -

Good to know, thanks! Watched a few videos, looks like I could try using MAP-Pro torch and some aluminum brazing rods to patch the coil if I can identify the leak. A few people even posted just patching it with JB MarineWeld, while certainly easier, I'm not sure how long that would even last.

Yeah I saw Steve Lav's and a few other guys discussing the topic. If I end up needing to replace this system or another in the near future, I'm leaning more towards R-32 Daiken/Amana/Goodman.

Would it be worth finding a replacement condenser coil or even replacing the entire condenser to hold off a complete system replacement for a few years until supply issues improve?

0 -

I've replaces no fewer than two compressors that blew out the terminals (& sprayed burning oil all over the roof!), just in time for the new A2L refrigerants.

Spray thickly along the connection between the extrusions (fins) & the manifolds on either end, inside & out. Also spray any dings you might see on the faces of the coil. 120 lbs will drop faster than lower pressure for the same leak, but if the leak is bad enough the soap will be blown off without forming bubbles. That'd be a pretty big leak, though.

It's possible to repair Microchannel coils, my success rate is about 60%. On the failures, I end up with too much melted Al on the accessible side of the break so I can't get to the back side of it. Probably a problem with my technique.

1 -

-

Plan is to tackle the condenser on Saturday, will definitely keep you posted!

0 -

Success!! Just wanted to thank you guys for the awesome help and advice. While at times frustrating, this whole experience was educational and rewarding.

After spraying the condenser with soap, I found a good sized leak at the bottom corner of the condenser. I removed the fins to better identify the leak and noticed a pinhole leak on the top of the microchannel tubing. After a few failed attempts of not getting the solder to adhere, I was finally able to get a good repair. It was a fine balance of getting the aluminum hot enough to melt the solder vs melting the aluminum away.

Pressure tested the system with nitrogen at 100 PSI and it held for 30 minutes without any loss in pressure.

I then removed the old liquid and suction filter driers. Replaced the suction line filter with copper tubing and placed a new larger liquid line filter drier. Once again pressure tested the system successfully.

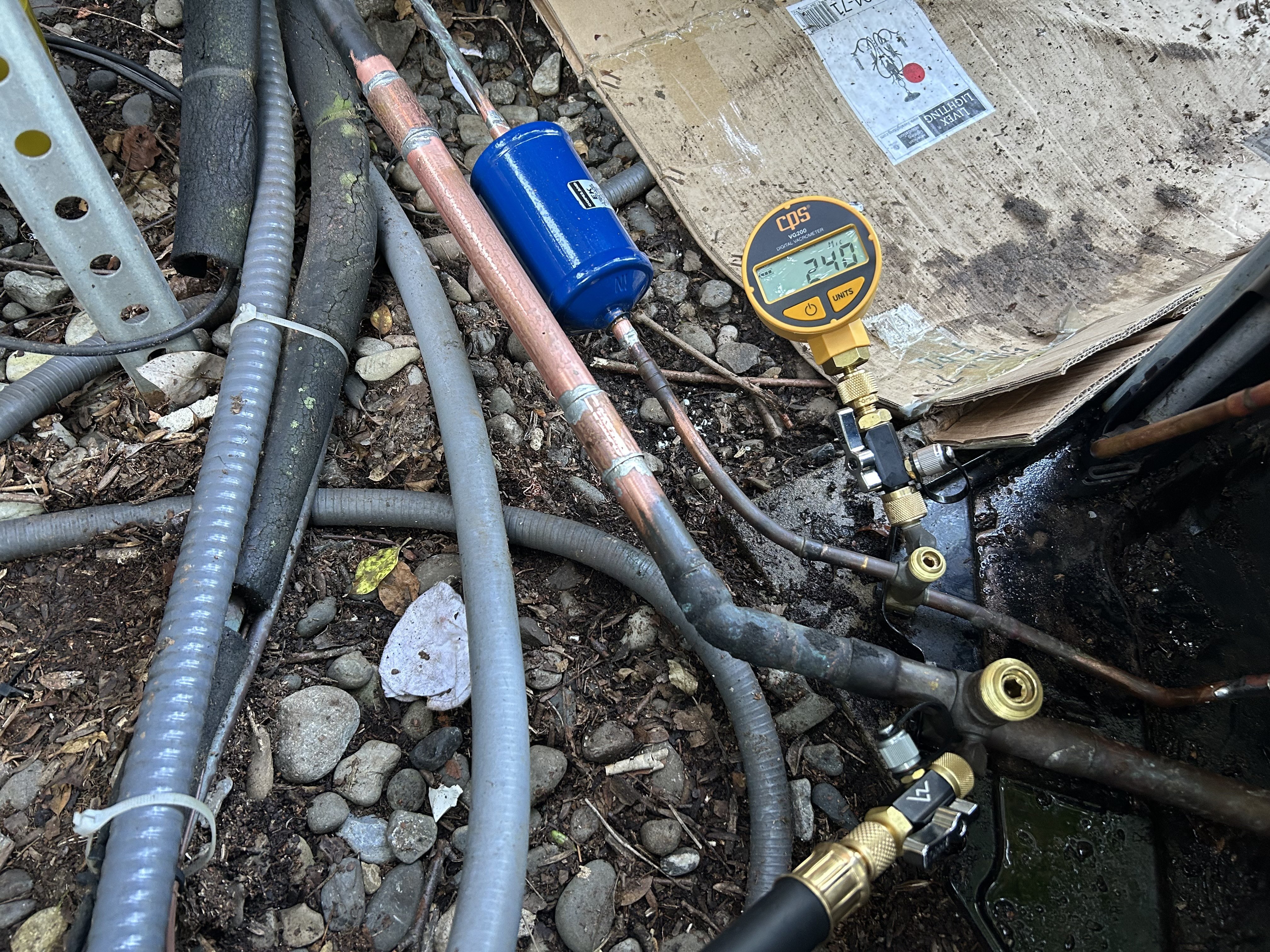

Performed an oil blowout test and then pulled a vacuum. I was able to pull down to 240 microns which held for 10 minutes.

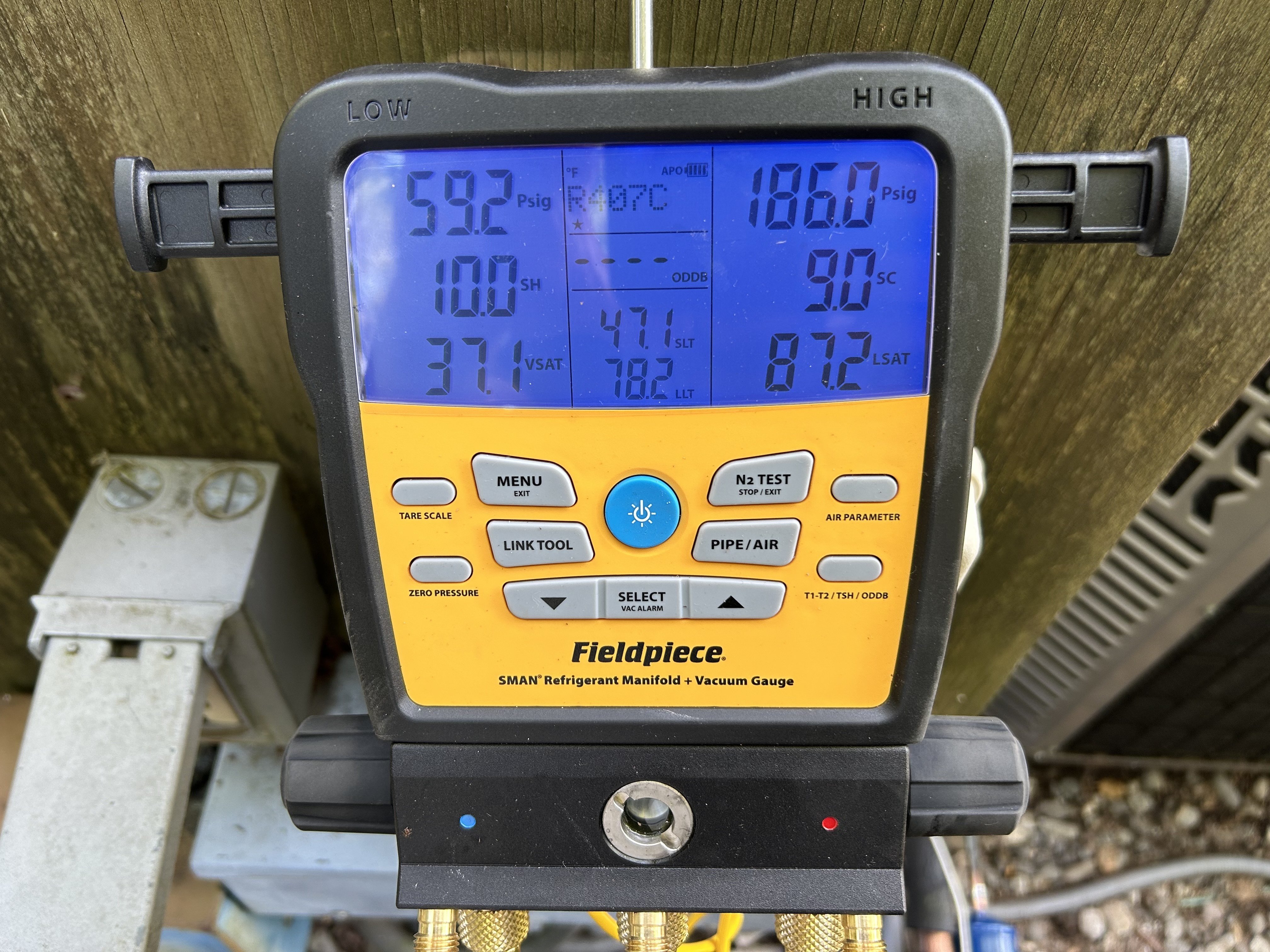

Filled the system up with 407c, this time it required a little over 8 pounds before getting appropriate superheat and subcooling numbers (though my system has a fixed orifice so superheat was the main priority).

System is back up and cooling! While it definitely is kicking the can down the road, at least I can hold off until supply chain and pricing issues stabilize. Thanks again!

1 -

did you soft solder that?

0 -

Yeah don't have access to an acetylene torch and went with Stay Brite 8 silver solder. I know it's controversial and not ideal for HVAC compared to brazing, but figured I can always have it switched over when replacing the system in the future.

0 -

Only thing I'm a little suspicious about, is my liquid line doesn't feel very hot to the touch compared to my other HVAC system and the condenser is blowing out warm air from the top, but the air is not as hot as my other condenser.

I've read that 407c refrigerant is not a very efficient refrigerant, but not sure if I can just blame it on that.

I'm wondering if I'm not getting enough air flow for heat exchange and should see if my blower motor has the ability to be wired to a higher speed. Either that or maybe there is a restriction in the liquid line?

Either way, the system is cooling, but perhaps not as quickly as possible.

0 -

you can braze something that small with a mapp torch or even propane. the issue with soft solder is that the flux contaminates the system.

you need more like 500 microns to get the moisture out. you might have to evacuate it for a while and/or heat it to do that because it likely got moisture in through that leak. if there is too much moisture in the vacuum pump oil you won't be able to do it either.

you would have to measure the airflow and wet bulb delta t of the system to figure out the capacity. since it is an orifice system you charged it to the superheat for that airflow, you set the charge to the operating conditions.

is more or less all of the evaporator producing condensate? if it is, it is filled with refrigerant and producing the capacity it can for that airflow.

i'm not 100% sure how to calculate it, but the delta p and size of the duct will give you the airflow.

1 -

-

Yeah I followed some tips online about avoiding putting flux too close to the inner part of the joint to prevent it from contaminating the system. Will try brazing next time, didn’t realize mapp would get it hot enough.

The vacuum did take awhile, which I assumed was due to moisture and contaminants in the lines. Broke the vacuum a few times and eventually was able to get it down to 240 microns. Used brand new oil in the pump to make sure it didn’t get saturated with moisture.

Will take a look at the evaporator in the attic tomorrow and see how it’s doing, thanks.

0 -

you can use flare fittings too.

0 -

nothing wrong with using Stay Brite #8.

flux the pole not the hole.0 -

I wasn't aware that Stay-brite would adhere to Al, with or without flux. I've always used the Al solder kits. Guess I have something to try next time!

I wouldn't be concerned with flux getting in to the system from a pinhole like that in any case, it's not like soldering a fitting, where the flux can just run in at the bottom of the joint once it melts.

Looks like that system was converted from 22? I'm unaware of any residential splits that came from the factory with 407c.

0 -

when R 22 is phased out they were shipping units and labeling them R407C but with a nitrogen charge

0 -

Sorry the repair of the microchannel was using Al solder, the StayBrite 8 was for the copper work.

Yeah the original unit was R22. I think the prior homeowners had a compressor burnout which is why someone placed a suction filter drier and replaced the condenser with this 407c one.

0 -

good to see someone did it right.

0 -

they used it for the lineset too. probably ok, but not the best of ideas. i wouldn't have any problem with using it on the pinhole.

0 -

I’ve been Using it since the mid 80’s

It’s fine.

no N2 needed.

less weakening of the copper.

On controls easier to change.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements