Pressuretrol to Vaporstat with timer

I've ordered the L408J1009 Honeywell vaporstat to swap in with my two pipe steam boiler to run the system at lower pressure. I am also wondering how to add a timer to the vaporstat so that when the cut in is reached and the vaporstat closes the circuit, if the timer has not finished, the boiler remains off until the timer completes.

I appreciate any insight and the very helpful advice I've received here. I've taken my steam system from partially heated radiators and water hammer to radiators fully heating and a just a little hammer remaining due to improper return piping at the boiler which I'm working to correct.

My next task will be to calculate the EDR for all my radiators and length of mains to get a sense of my boiler sizing. Thanks again!

Comments

-

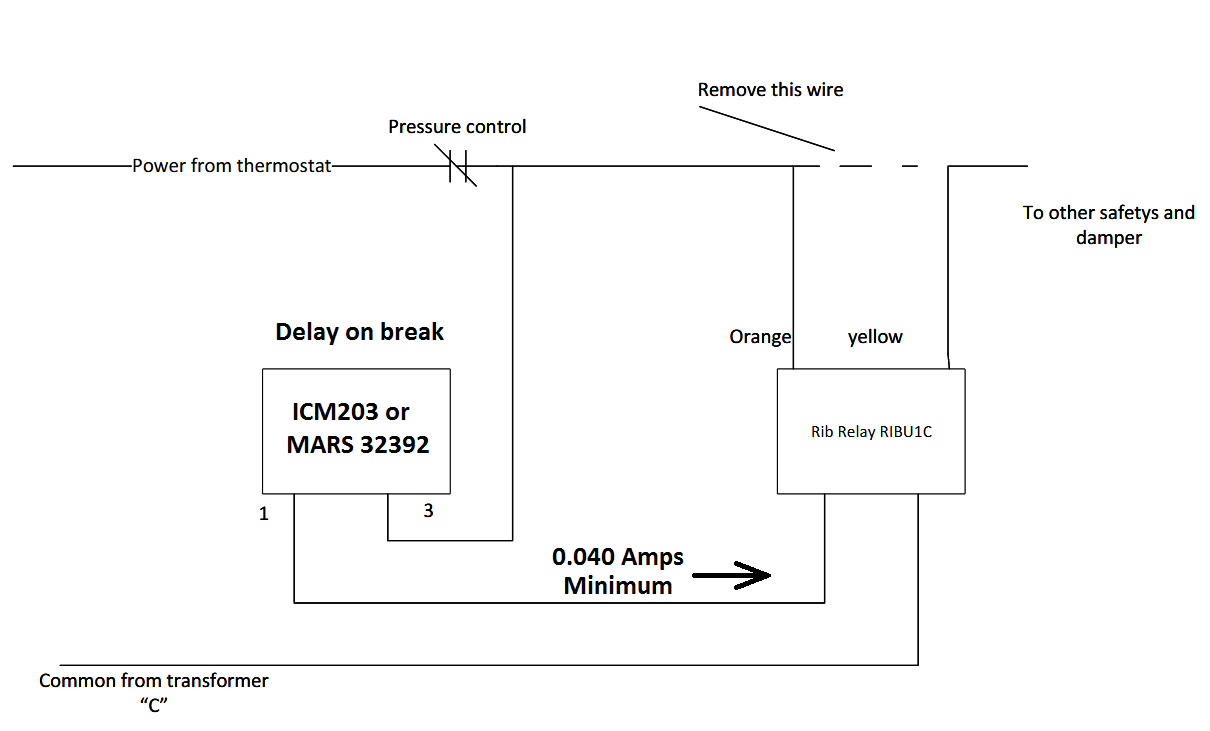

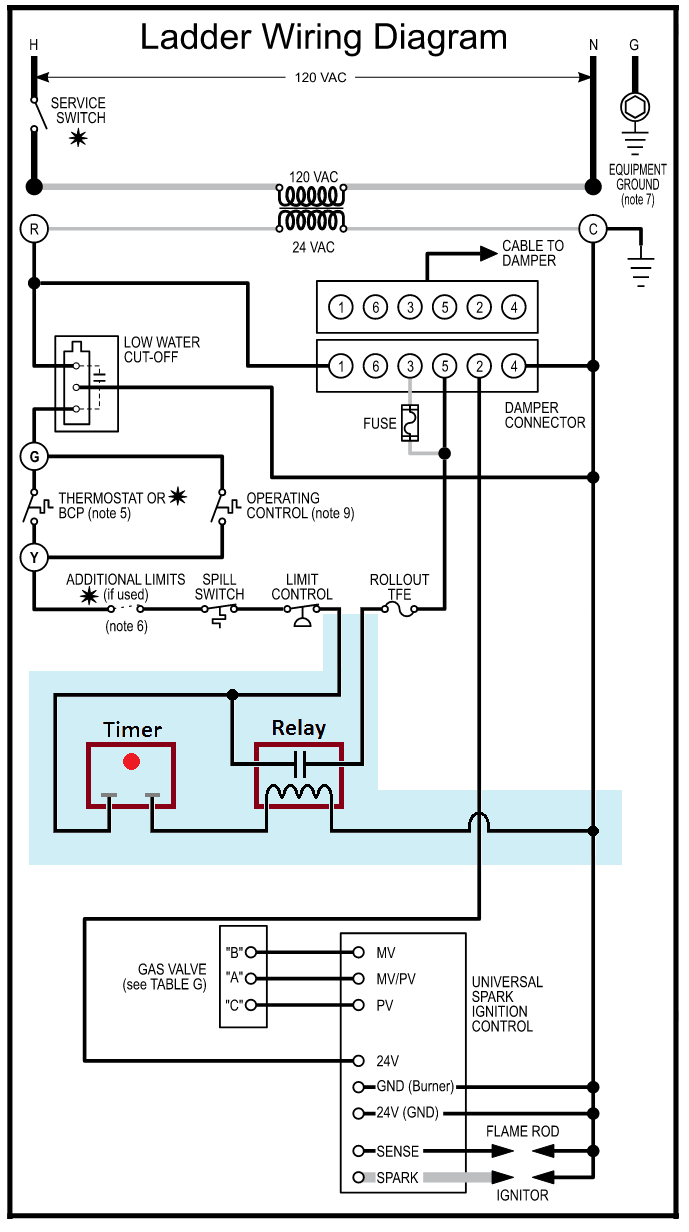

Your boiler make and model would help to find the wiring diagram. Anyway here is a few example diagrams you can chew on. Seems it is best practice to use a relay so the load signature of the damper (if you have one) does not mess with the timer. The relay coil provides a constant predictable load for the timer unit. The relay's contacts is what actually interrupts the boiler's control circuit.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

what I did was to interrupt my thermostat circuit with the timer relay

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Boiler is an HB Smith GB250-S-5H INT natural gas. 200,000 BTU input, 154,000 BTU normal output. I'll try to find the wiring diagram.

I'm liking the idea of an interrupt on the thermostat circuit. Any insight on that? Parts used?

0 -

I like the idea but do you have any sense of whether it is and how much your boiler may be overpowered? I think putting a vaporstat on my system (I don't know about yours) would be foolish because of the very short amount of time it takes for gauge pressure in boiler to drop to near zero after a cut-out of 2 psi. I mean it can't be much over 2 mins. My question in my case would be how low do I want to let absolute pressure go? If I had a vaporstat cutting out at 12 oz or something my boiler would go into negative gauge pressure pretty quickly. If vents were still closed I realize that negative gauge pressure in the boiler could still by supplying steam to radiators that go even lower gauge pressure from condensation but I wonder if it would work for me. Any timer would have to not be set long enough that any radiator vent opens.

I remember reading (Dan Halohan?) that the best place for the vaporstat was at the end of the steam main.

1 -

What, as @Captain Who said, is the purpose of the timer?

I have noted — at some tedious length — elsewhere that you should NOT allow the boiler to have an off phase of the on/off cycle maintaining pressure in the system any longer than can possibly be helped. The shorter the better, in fact Just about the last thing you want to have happen is for the boiler to cool while the thermostat is still calling for heat! Yes, you need to turn the burner off — briefly — to hold the desired maximum pressure, but only long enough from the rest of the system to catch up.

Introducing a time delay after the system cuts off, but with the thermostat still calling for heat, allows the boiler to cool. Then the boiler needs to heat up again. Guess what that does to efficiency. Nothing good.

Now if the problem is that you want to capture the residual heat of the radiators — you will, after the thermostat shuts off. If that makes the house overshoot, then the solution is to reduce the overshoot from the thermostat.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I think there are two factors to determine feasibilty of setting a timer so that you maximize efficiency. 1) You can't have any of the radiator or steam main vents open up (= timer setting was too long), and 2) In every steam main you have to have absolute pressure in the main be greater than the absolute pressure in the radiator, for each and every radiator, otherwise they stop getting steam (= timer setting too long). Steam goes from high pressure to low always. Another problem is that you may lose balance. I remember reading about a system with two radiators connected to each other and one wasn't heating. The guy even removed the vent completely during a cycle to try to get some of the steam to go to the one that wasn't heating. No go. That one had atmospheric pressure still at the vent but the one that was heating had a negative pressure relative to atmospheric. So the steam went there and only there.

It would almost take some sort of complicated pressure/temperature sensor data logger array to figure this out. I wonder how much gain there is. Interesting though.

0 -

-

The purpose of the timer is to have the boiler shut off on pressure (first cycle) when the control closes after a pressure drop the burner is delayed from firing so as to allow the radiation to give off heat. After this pause if the stat is still calling the boiler restarts and builds pressure and continues to rinse and repeat until the stat is satisfied with the burner running longer cycles and less short cycling.

That diagram looks familiar!!

1 -

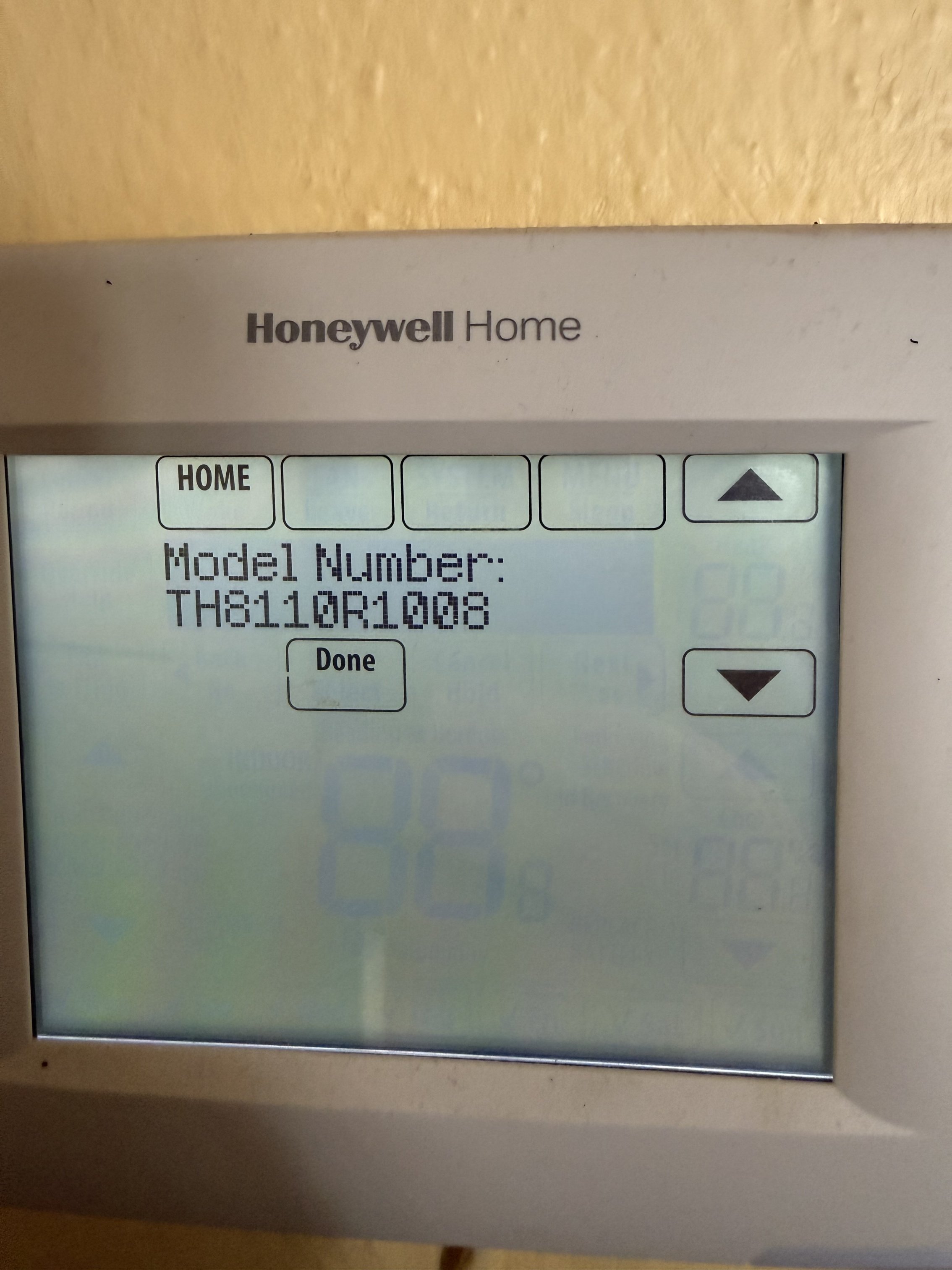

Running this thermostat:

My primary goal is to maximize efficiency. The current pressuretrol is is set to cut in at .5 and cut out at 1.5 psi. My 0-5 gauge is never showing over 1.0 psi, I have a 0-3 gauge ordered to verify.

On cold days during long burns, my system starts to hammer, likely due to improper return piping at the boiler, which I am working to correct. Looking for a short term solution which also offers most efficiency once return piping to corrected.

0 -

My timer relay is a module like this: https://www.amazon.com/dp/B097PPBG4J/

And the low pressure switch I use to signal it is one of these (they have different ranges):

https://ebay.us/m/5a29Ph

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

The highest efficiency of the boiler will occur when it is running continuously. A short break in firing — say a minute or two — will not drop that much, as it will still be at a very high temperature (it may still be steaming). As the boiler cools down for a longer break, however, it will take a corresponding time to warm back up — which fuel is NOT making steam and NOT heating the structure, and therefore is lost. That will drop the efficiency.

While it is not exactly true, think of it this way. The heat — and hence fuel — which heats your house gets there from steam. The boiler will only make steam after it has run long enough to get up to that temperature (try it with a teakettle on the stove — it doesn't boil instantly). So the only fuel which gets turned into steam is the fuel burned while the boiler is steaming. The fuel used to heat the boiler up is not warming your house. Now if you turn the burner off for a bit — say a minute or two — the boiler will still make steam, though not as much, and the pressure will drop back into the running range. Fire the burner back up and the steam production will come back up. And so on. No wasted fuel.

Multiple short cycles — say 10 or 15 minutes — separated by cooling intervals — say again 10 or 15 minutes — may get your overall efficiency down to say 60% to 70%. The same amount of heat delivered to your house but with short off periods may allow the system to run as high as 84%.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

BUT, the boiling point of water is a function of absolute pressure. So, as long as temperature never drops below Tsat, which is a function of pressure (which can be below atmospheric), it theoretically will never stop producing steam.

0 -

This is true, @Captain Who — but don't forget that not only must the pressure be down, there must be energy (heat) being supplied to cause the phase change. In a situation with the burner off (assuming no vacuum pump) that can only come from the heat stored in the mass of the boiler from the burner having been firing previously. This will cool the boiler., lowering TSat, and so on.

There's no free lunch…

It's interesting — but well beyond the scope of this discussion — to compare energy flows and refrigerant state conditions in heat pump type systems with those in heat assisted type systems…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

But as I mentioned previously, if pressure is greater in the boiler, which is greater than pressure in the steam main, which is greater than pressure in the radiator, steam will continue to flow from the steamchest through the main to the radiator. This "could" continue to persist even when the pressure in the boiler is sub atmospheric, as long as the vents remain closed. The enthalpy of saturated steam will continue to be delivered to the radiator but at a diminishing mass flow rate and at a diminished value (due to lower pressure) and without using any more fuel. Then when these conditions no longer are met, that is when you would want the timer to time out, starting the burners back up, with steaming commencing almost immediately due to the lowered Tsat. But how do it (the timer) know lol?

0 -

@ethicalpaul's method is similar and accomplishes the same basic thing. The examples I posted above use the existing pressure sensing equipment on the boiler (Vaporstat or pressuretrol). AFAIK @ethicalpaul's method uses an independent pressure switch to trigger the timer. You could use a relay after the boiler's pressure sensing equipment to trigger the timer that @ethicalpaul used. There are many ways to accomplish this task.

Unless you have an oversized boiler I would not bother with a timer, what is the point ?

As far as efficiency, to me the expectation of efficiency was lost when the oversized boiler was installed. Which is worse burning fuel to just build pressure or a slight reheating of the water to return it to a boil, I don't know. My boiler returns to a boil very quickly with a interruption of more than 2 minutes.

There is no guarantee that all the vents will be closed so I don't support that agenda either way.

@EBEBRATT-Ed Yes you are the author of the original drawing with just the timer and the relay, it is from another post and if you remember I edited it to add information and re-posted it in that other thread.

My personal opinion, I don't like the unnecessarily cycling especially if you have an oil burner, wear and tear has a price. I don's see the point of burning fuel to build pressure especially since (for example) my home heats just fine on less than 2 inches of water column (1.15 Oz or 0.072 PSIG).

There are other ways to minimize some of the the negative issues of an oversized boiler, measuring farthest radiator's temperature to manage control.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System2 -

I mean, you don't even know at this point that your boiler is oversized. "Maybe" it isn't going over 1 psi ever because it is perfectly sized except for maybe a polar vortex or something like another ice age and then it might not keep up lol. The other thing is, this is kind of bass ackwards at this point to be trying to scrape the last shred of efficiency out with this scheme when you are getting water hammer on cold days and long cycles. That's a major inefficiency caused by steam hitting pools of condensate. That produces very wet steam when that happens. I would fix that first.

0 -

The OP says" The pressure control cuts out at 1.5 psi and his gauge never goes over 1 psi" meaning is the boiler actually going off on pressure?

0 -

I was interpreting that as saying that the pressuretrol never hits it's cut-out setting of 1.5 psi because the boiler can't put out enough btu to hit that pressure.

It would help if we could get it cleared up. Maybe I got it wrong……

0 -

I’ve ordered a 0-3 gauge to see if the 0-5 gauge is faulty. Will have that Monday and report back. I do know the boiler is never shutting off from Pressuretrol, only tstat or lower water cutoff after observing for three hours sitting in front of the boiler.

0 -

-

I think you are thinking you want to rule out that you may have two defects simultaneously; namely the pressuretrol isn't cutting out at 1.5 psi and the pressure is going much higher than that AND your pressure gauge is showing a reading that is way too low and/or won't read over 1 psi? I forget whether you have tried to manually trip the pressuretrol to cut out? Have you removed your pressure gauge and blown into it to see if it can go higher than 1 psi reading?

0 -

-

I thought @ethicalpaul had that trophy.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System2 -

The thermodynamics of what pressure a boiler connected to a condensing system are insanely simple. For the sae of giggles, we will assume that our boiler has a reasonably constant energy transfer rate from fire to water over the temperature range we will consider.

So. Our condensing system, on the other hand, does not. It's condensing rate is a rather gnarly function of the temperature of the condensation inside it; suffice it to say here that, again in reasonable temperature ranges, it is a more or less linear function of temperature difference between the outside air and the inside condensation point.

With me so far?

Now what happens in a sealed system? If the boiler is producing more heat output than the condensing system can use, the pressure and, much more importantly, the temperature of the phase change will rise.

In principle, if the system is truly sealed, one could run as small a heat input as desired, simply by lowering the pressure and thus the temperature and heat output. Problem. That only works if it is possible to remove all non-condensable gas from the system and keep it that way (think heat pump or air conditioner). A more practical solution is to set the lowest operating pressure at roughly atmospheric. Then, as the pressure and thus temperature rises, all the air is pushed out and you use automatic vents to close to allow the pressure to rise.

It would seem, perhaps, that the obvious solution to an oversize boiler — or even an intentionally large boiler — would be to simply allow the pressure to rise until the radiation was hot enough to absorb all that heat. And, in fact,, that would work. It is somewhat undesirable, however, in that the temperature or the radiation could get impressively high (if the boiler were double the required size, you'd be looking at radiators running in the 400 F range. Some folks might object…) The minor losses — pipework and the like — would also increase, of course. So would the simple matter of fittings and pipework which could handle the pressure and temperatures.

So, since we operate in the real world of heating here, rather than the somewhat more interesting (perhaps) world of high temperature high pressure boilers, a far simpler solution is to modulate the power of the boiler to what the radiation can handle. Which is the whole purpose of the pressure control device— vapourstat of pressuretrol or what have you. (kindly note that if it is used this way, it is NOT a safety device. That needs to be a separate device, set higher). And, to avoid efficiency loss from starting a cold boiler, one wants to keep the off time as short as possible, assuming that the heat source is either on or off. Some gas boilers can, in principle, use amplitude — firing rate — modulation. I'm not sure why they haven't appeared for steam, but I expect that the expense and complexity and small market makes it unattractive. Instead, we use pulse modulation. To keep the efficiency up we use or should use as short an off period as possible, allowing the on time to make the overall duty cycle correct for the desired power output.

Oh well…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

Tonight I lowered the water level in the boiler to just below the top mark on the boiler and ran it. The system pressurized must quicker and probably like it should. I’m having to keep the water level higher to prevent water hammer from steam getting into the return. This is due to wrong return piping at the boiler that I’m in process of getting fixed.

I did find that my pressuretrol allowed the system to get to 2.5 lbs before tripping which is way too high for me. Going to swap in the vaporstat when it arrives to see if I can keep the system between 12-14oz cutout with a 6 oz cut in. The new pressuretrol is set to .5 cut in with 1.0 differential and should trip at 1.5 but it’s not so I’d wager I got a faulty unit. I’m going to see about building a tester like I’ve seen on YouTube to correct the pressuretrol.

During this cold snap I’m keep the system working while I get things sorted.

Thanks again for all the help, I’m not ready to give up on steam yet!

0 -

I would not give up on it. Once you get things corrected and dialed in steam is nice. I think it is very nice to have a quiet simple heating system. For the most part I don't even know when it is operating, the house is just warm.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

A pressuretrol can be recalibrated, you should be able to find the procedure on this site by searching.

—

Bburd0 -

On the Honeywell 8000, which you have, you can set the number of heating cycles per hour. No timer needed till you repair pipework. Just reduce the number of allowable heating cycles and the thermostat wont call the boiler to fire. Initial cold fire will bring home to temp, or pressure, following fire to maintain would be limited by the thermostat.

0 -

thank you, I set mine to three for the time being. Vaporstat and new gauge arrive Monday. I’m hoping to reduce water level with vaporstat installed so that the system will not exceed 1.5 psi which is when the hammering starts with current piping.

0 -

@Jamie Hall I knew it wasn't as simple as you are saying because heat of vaporization goes down with increasing pressure, whereas Tsat does increase. Then I started wondering about my situation where my cut-out was (used to be but now drifted to 2.0psi) 1.5 psi and my cut-in was effectively (by the time flue damper re-opened) 0.25 psi. Here's the difference that it makes when you ignore hfg and just base it upon temperature, with a typical radiator and ambient room temp. of 68 F.

Oh well…..

At 0.25 psig (14.95 psia):

- Tsat ≈ 212.85°F

- hfg ≈ 969.81 BTU/lb

- ΔT ≈ 144.85°F

At 1.5 psig (16.2 psia):

- Tsat ≈ 216.93°F

- hfg ≈ 967.33 BTU/lb

- ΔT ≈ 148.93°F

Without correction for hfg (i.e., based solely on the temperature-driven external heat transfer):

- The heat transfer rate is ~3.69% higher at 1.5 psig than at 0.25 psig.

With correction for hfg (i.e., scaling the above by the ratio of hfg values, as sometimes applied in simplified sizing estimates despite hfg not directly affecting external heat transfer):

- The heat transfer rate is ~3.42% higher at 1.5 psig than at 0.25 psig.

These values account for the slight non-linearity in convection (proportional to ΔT^{1.25}) and radiation (proportional to T_sat^4 - T_air^4 in absolute temperature). Condensate accumulation is assumed negligible in this theoretical scenario.

0 -

all of which is rather fun — for those who enjoy it — but not really relevant to trying to stay warm at —3F!

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

@Captain Who is quite correct here. Key is his speculation that steam could continue to flow from the boiler to the radiators with boiler off and the system sub atmospheric. And, more importantly, the time for the next firing is when this flow has or is near to stopping. This is precisely how I have run my system for many years. No need to speculate about this any more. I can confirm it.

There is little if any appreciation here for the significance of maintaining continuous flow to radiators at all times, likely due to lack of first hand experience with it. It is something an open vented system cannot do. A system running evenly spaced burns closed up and sub atmospheric in between them will win on comfort and efficiency over an open vented system cycling on pressure walking away. I have run both ways and it isn't close.

It is 5 degrees F outside right now and my system is doing 12 minute burns spaced by 18 minute waits. I've had 24 burns in the last 12 hours and the tstat was satisfied 7 times for a total duration of 105 minutes. So the system is calling for heat 85% of the time and firing 40% of the time. The boiler will return to full boil within a minute of fire after being off for 18 because the system will be at -7"hg at that point. What happens during these waits is a plus for net efficiency and certainly not a minus.

1926 1000EDR Mouat 2 pipe vapor system,1957 Bryant Boiler 463,000 BTU input, Natural vacuum operation with single solenoid vent, Custom PLC control3 -

I'd be interested in hearing more about your system, and what thermostat are you using, ie. does it know when the burner is on or not? I can't help but think that if we were still installing brand new single pipe steam systems in 2026, that by now we would have smart solenoid vents on the mains and radiators and the system would be designed to try to never allow the vents to open, especially on colder days, provided there was still that crucial flow to the radiators. That would be super cool (I mean comfortable lol). My vents most definitely spend a lot of the time open. I end up with about a 28% duty cycle (t-stat calling for heat that is) on even cold days around 10ish F outside, without the pressuretrol hitting cut-out usually (edit- just checked and at 20m cycleguard did it's level test and shut off burner and pressure was 1.35 psi, so it acted before pressuretrol could, then before boiler fired up again tstat was satisfied). My White Rodgers has a slow and a fast setting. I think I have it on slow IIIRC and temperature is pretty evenly maintained within the thermostat room. An app on my phone that receives data logging from a separate temp. sensor device I have shows that all day yest. temp. ranged from low of 64.2 and high of 65.1, and it looks like my boiler ran only 8 cycles for the whole day. There is a remote temp sensor for the tstat on the same floor in another area separated by a wall and I average those two temps as the input to the tstat. It's a pretty inefficient system I have going and the best I can do is try to keep the steam as dry as I can. When it is not super cold outside, I am decidedly not comfortable due to the radiators being cold a large percentage of the cycle time. I guess a thermostat that allows more control depending upon how much it costs, would be nice to try. My boiler is overpowered though and that may limit my upside as well as single pipe and too much EDR and low tstat setting (someone is too cheap here).

0 -

@Captain Who , my system control is on a PLC platform and my thermostat is just a standard digital one which provides the call for heat and nothing else. The firing of the boiler is controlled by monitoring the amount of steam and the amount of natural vacuum in the system. I use one remote temperature sensor and have an analog pressure sensor on the boiler header. The longer calls are the more even the heat is by definition so that is the goal. So there are multiple burn and wait periods in each call for heat - more as demand increases. What I know for sure is that if all calls end with the boiler running the heat is not anywhere close to as even as it could be. It is a two pipe system which is easier than one pipe by a lot from the venting perspective to facilitate running sub atmospheric between firings. I operate easily with one solenoid vent. The maximum pressure during the very short periods at the end of burns when the vent is open and leaked in air is pushed back out is never above 3 ounces. Peak naturally generated vacuum between cycles 5-7"Hg.

Happy to discuss in more detail anytime if you are interested. PM probably works best.

1926 1000EDR Mouat 2 pipe vapor system,1957 Bryant Boiler 463,000 BTU input, Natural vacuum operation with single solenoid vent, Custom PLC control2 -

Funny. My system maintains that continuous flow any time the thermostat is calling for heat… no relays. No timers. Just an old vapurstat… one old main vent… and good engineering to start with.

How very odd.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

My system was originally just like that too. The boiler ran on high no matter what the demand was until the thermostat was satisfied. It was not even heat or close, and no perfectly sized boiler could make it so under all conditions. Some form modulation is absolutely required. For goodness sake - the original coal boiler had it. How is it possible that anyone thought that modulation could just be eliminated with the switch to intermittent fire?

Also, what happens when the boiler is off really is significant. Letting air right back in kills the steam flow immediately because the void in the radiators created by the collapsing steam is immediately filled with air from the space and not continuing steam from the mains. And, having to push all that air right back out every time really does cost more, it really does. The net difference in both comfort and cost is not a small one….really.

1926 1000EDR Mouat 2 pipe vapor system,1957 Bryant Boiler 463,000 BTU input, Natural vacuum operation with single solenoid vent, Custom PLC control1 -

At some risk. First, pulse (duty cycle) modulation is modulation. Second, if the off time is short enough, the system won't drop into a vacuum and no air will rush back in.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

No risk and no worries @Jamie Hall . PWM and vacuum in residential systems have been unwelcome topics here for a long time. The very few of us who wish to pursue them are content to discuss them elsewhere. Occasionally I see someone post who has identified some of the key components of these subjects all on their own as was the case here. I offer them an avenue to pursue them further if they wish, that is all.

1926 1000EDR Mouat 2 pipe vapor system,1957 Bryant Boiler 463,000 BTU input, Natural vacuum operation with single solenoid vent, Custom PLC control3 -

I think it is a crying shame that this concept of vacuum operation was abandoned, especially if up to 30% efficiency improvements could be made on a single pipe steam system as the Hoffman Vacuum Vent informational pamphlet states.

Regarding the off time having to be short enough, that is totally impractical to be able to use that method of keeping thermostatic vents from letting air back in, probably in 98% of installs and weather conditions. That is hopeless to try to do away with a vacuum vent. Some sort of smart solenoid vent with microprocessor control is necessary to allow air out in those cases when it sneaks back in through some fault, servicing, off season, etc., OR someone needs to bring back the Hoffman Vacuum Vent concept with an updated modern version of them.

Just my take. I have only recently begun thinking about this. It is a crying shame to be giving up so much latent heat of vaporization of the steam to the air on every darn cycle.

1 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements