Data Analysis Needed (Insulated heat pipes in basement)

I am hoping someone could help analyze the data below.

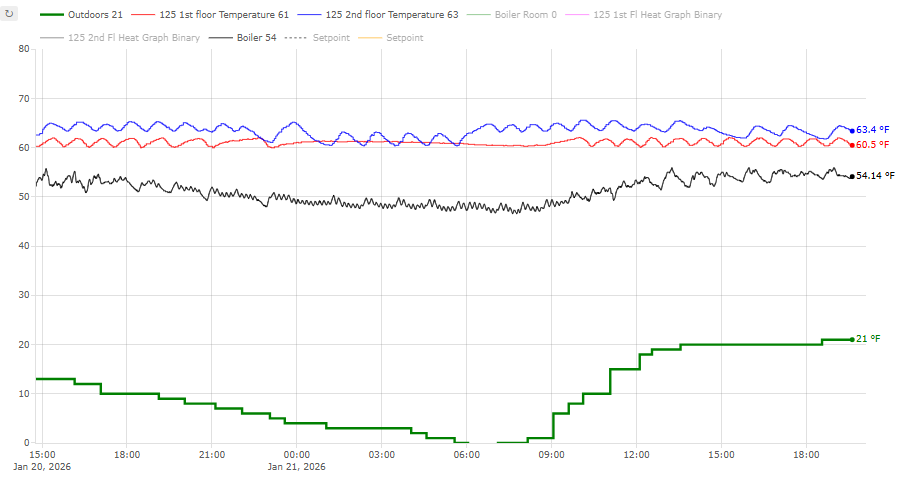

This home is in Sullivan County, NY, where today's temp started in the low teens and rose to low 20's, F.

The 2 story house uses an oil fired, 20 year hot water boiler, baseboards, with each floor its own zone.

Until this afternoon, the copper pipes in the unconditioned, uninsulated basement were exposed to the basement air (which is indeed affected by the outdoor temperature). To be clear, the heating pipes were uninsulated.

This afternoon I installed foam insulation on the heating pipes from the boiler to where they go upstairs.

I monitor and collect data as much as possible.

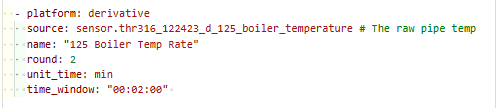

The sensor I use for monitoring the boiler is a simple temperature sensor hanging an inch next to the exhaust vent pipe. At best, the readings can be considered realiable across time, but the values are definitely not useful for their absolute values.

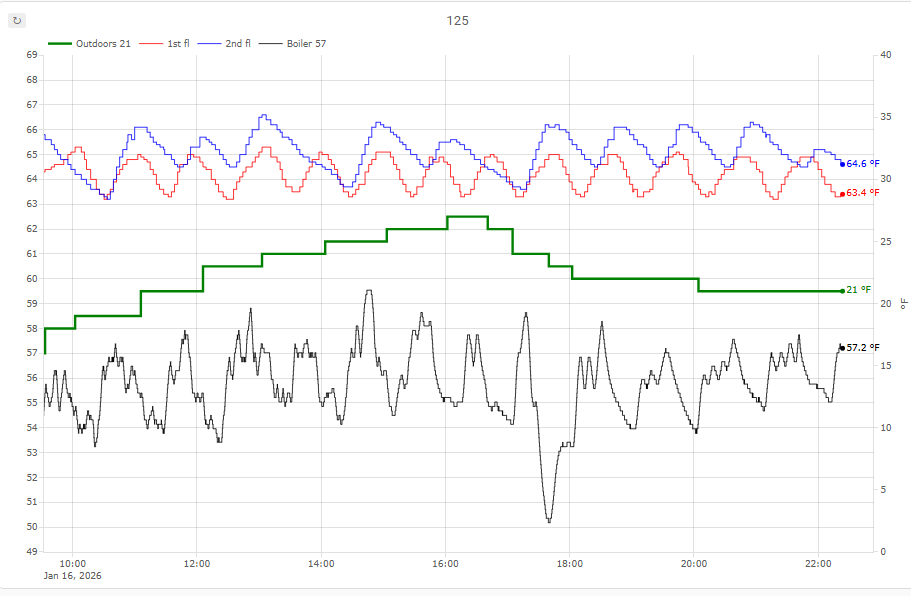

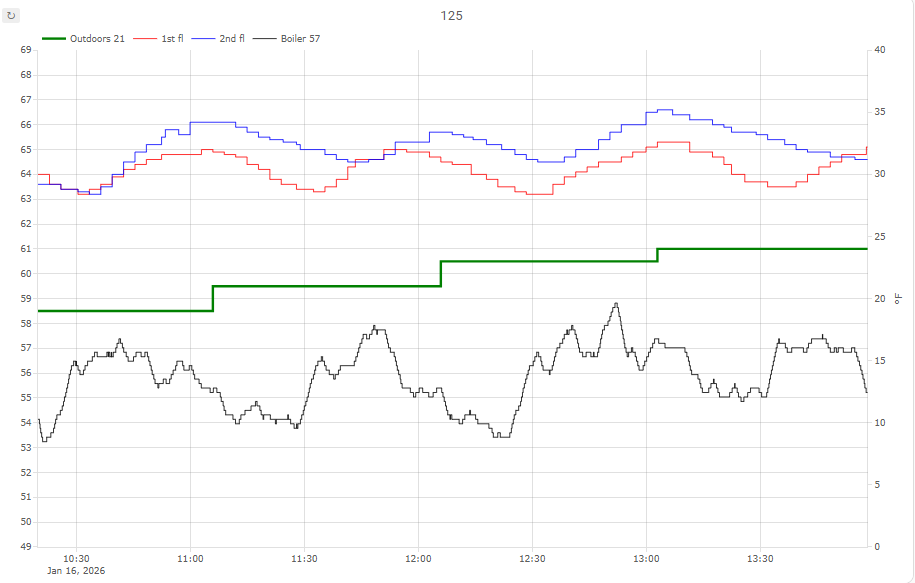

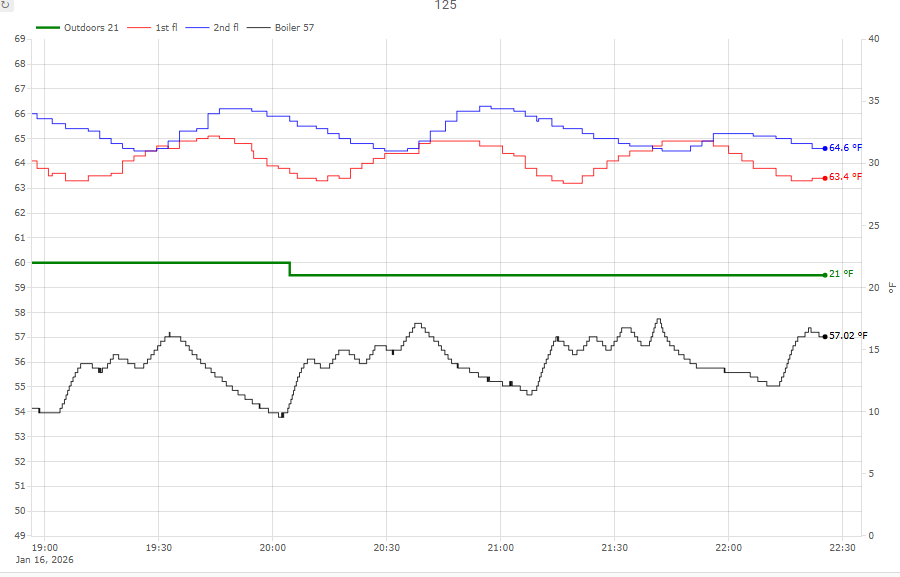

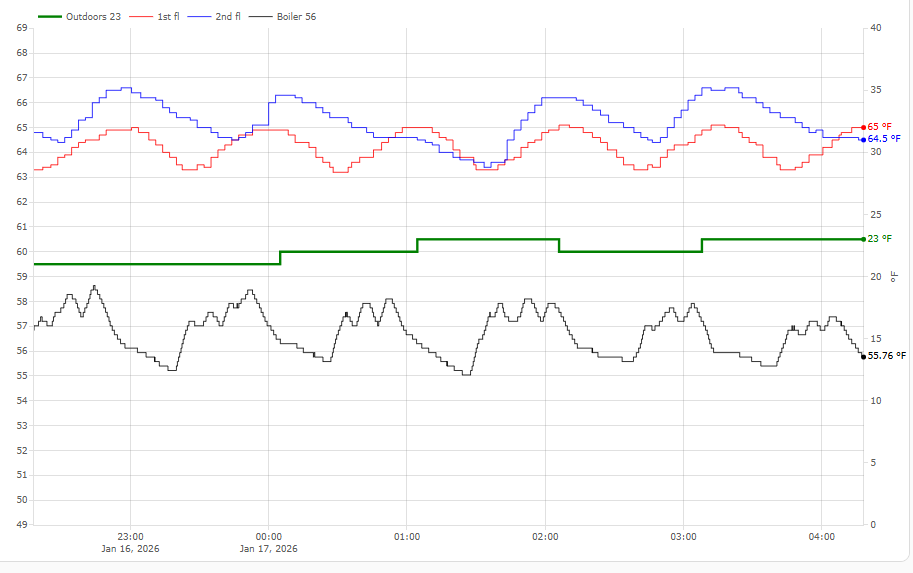

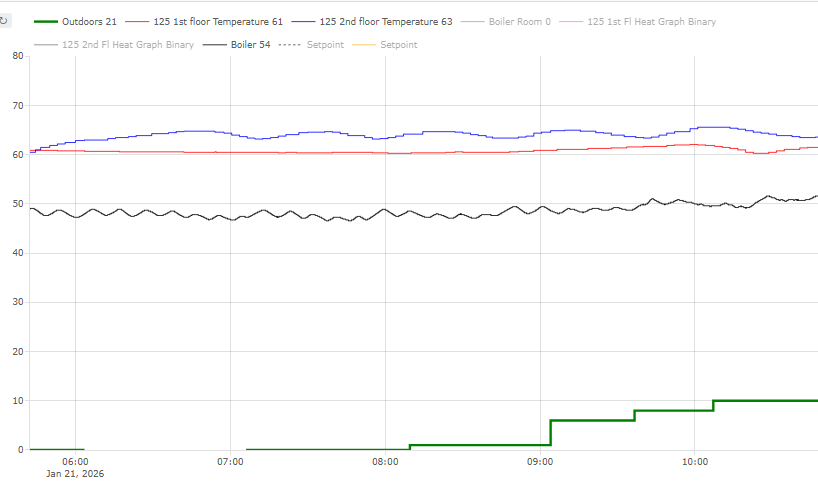

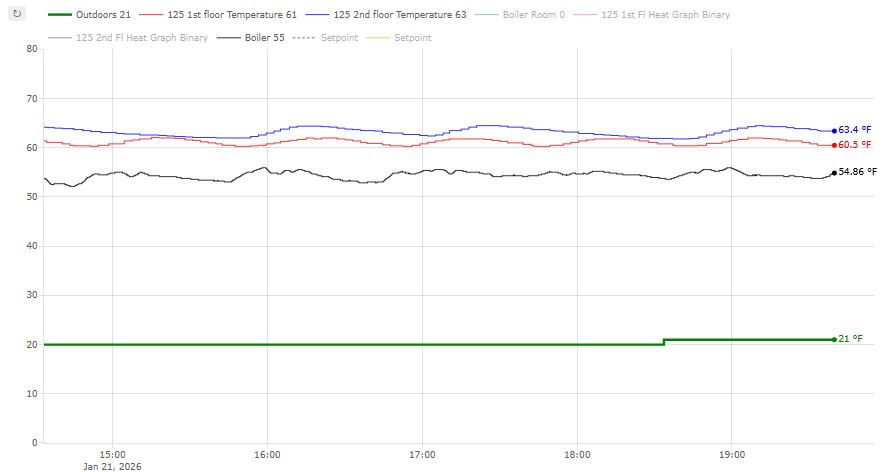

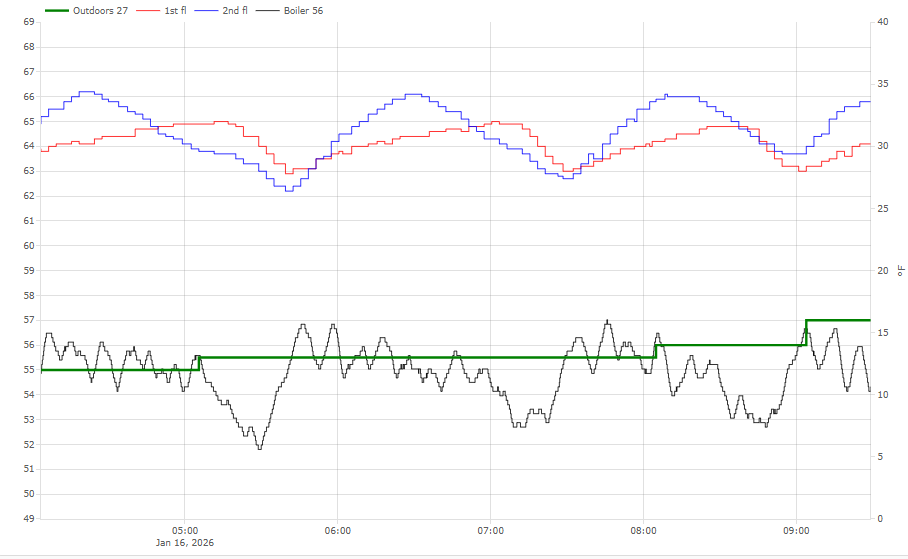

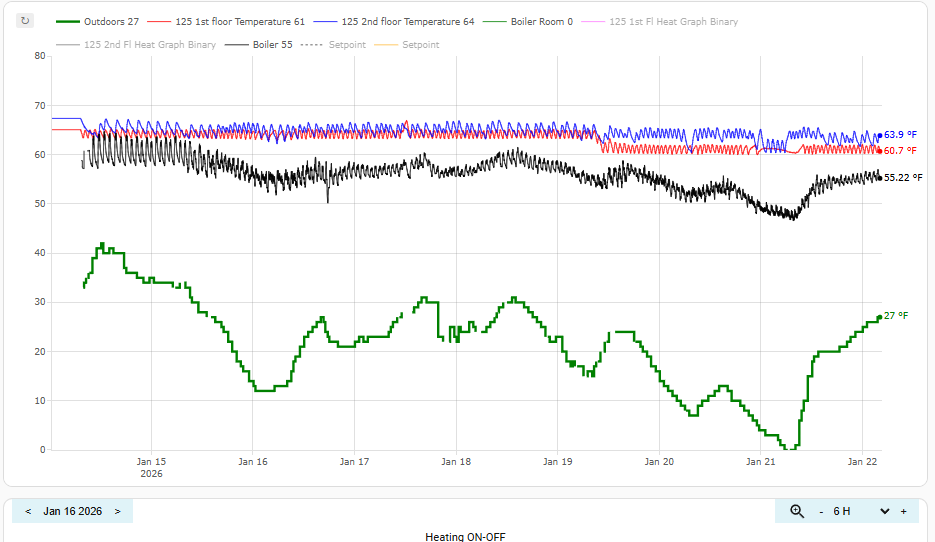

I have attached the full day's graph, as well as zoomed in periods before and after the insulating of the pipes (disregard the boiler pipe heating from 2 to 7).

The shape has definitely changed, but I don't know what to make of that change.

Does anyone have any insights about what the shape of the data says about anything?

Thank you!

Here are the graphs:

Comments

-

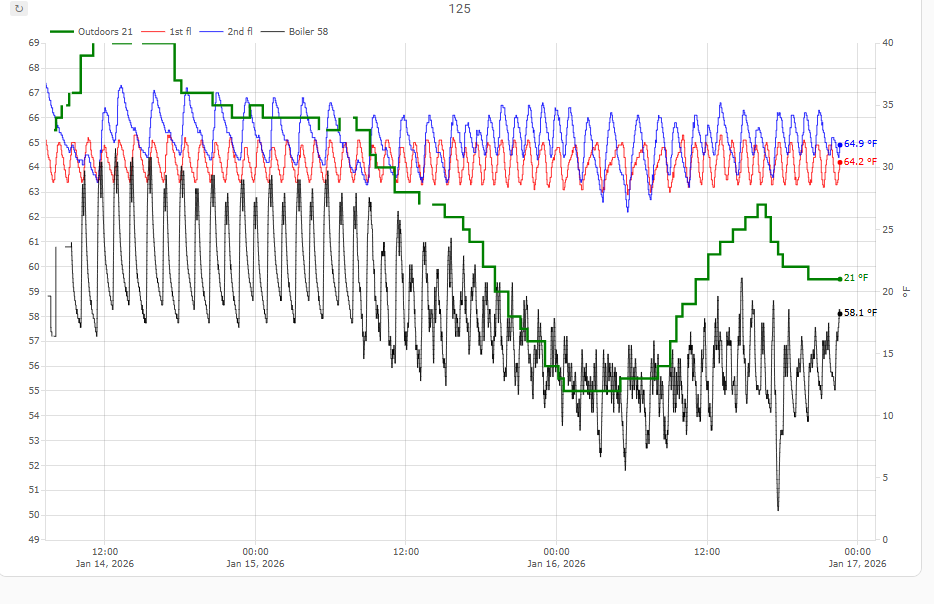

In case anyone is interested, or it is useful to see a longer time:

0 -

Could the 'noiser' pre-insulation versus the post-insulation, be wind / draft related in the boiler room and just coincidental ? There seems to be a ripple there either way, maybe gas line pressure variances changing the boiler's output a slight bit.

" (disregard the boiler pipe heating from 2 to 7). "

Have no idea what this means, 2 to 7 what ? AM, PM (14:00 to 19:00) or something else ?

I would think insulating the pipes in the basement would just lower the average temperature in the basement during the winter heating season. Shorter boiler run time to heat the desired space. May save some fuel too.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I'm not sure you'll be able to gain much info from this to conclude difference between before and after insulating pipes.

If you could measure how much fuel you burned before and after….on exact weather days, that could tell you something. In general, I see about 8 thermostat cycles in 12 hrs (blue line) when is 5F outside. What is the 99% design temp? It looks like you could turn the supply water temperature down to smoooth out some of the peaks/valleys in red and blue lines.

0 -

I insulated my basement steam pipes. What is clear is that the basement is a little cooler.

Does that save me any measurable fuel, or does it just make my level 1 floor be less comfortable? Or both?

It’s very difficult to say. It didn’t noticeably affect anything else.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@109A_5 It certainly is possible that there is (or was) a draft that affected the flame. I'll have to take a look to see if there is some regularity to the flame variation that would point against that.

I meant 2:00pm-7:00pm (1400-1900), sorry. The insulation was being installed, and then I better insulated around the basement door to fill the gaps. I hadn't thought about a draft or wind, but only maintaining the temp.

It sure indeed look like it lowered the temp in the basement.

@bjohnhy I wish I had a direct way to measure fuel consumption. I tried a tank gauge that ultrasonically measures oil height and sends the data to the cloud, but I don't believe the data for a second. I've come to use an inferential measurement of time_firing * nozzle size for a rough idea (and day to day comparison).

99% design temp is 2*F.

I don't think there is a water supply temp adjustment, but I could very well simply not understand. The boiler is an on/off type with safety controls (of course).

@ethicalpaul My basic understanding is that a cooler basement in Winter means more of the heating plant's energy is going to heat the upstairs. Isn't that what we want? I hadn't thought about the 1st floor's floor temp. I'm all about comfort, but it would seem that the energy needed to heat an uninsulated basement would be nearly all wasted and a tiny bit would heat the 1st floor's floor. Did you notice a difference?

Here's the overnight graph. The heating cycles are interestingly similarly shaped.

0 -

- 1) It looks to me that the boiler-off times (the amount of time between firings) increased almost double, from 25-30 minutes to almost 50 minutes after installing the insulation. The boiler is cycling less frequently.

2) The boiler temp tops are flatter.

3) The basement temp is roughly the same, so the underground nature compared with the improved basement sealing from the outside is do its job. But, the rate of drop of temp is slower.

0 -

I'm doubtful that insulating the basement pipes is helping much. In our 100-year-old 4-unit condo building in the Boston area, we have two oil boilers in the unheated basement, along with the original uninsulated gravity conversion hot water piping.

The basement ceiling is not insulated, so the exposed subfloor planks in the basement and the oak strip flooring in the first floor are basically at the basement temperature, which hovers around 60 degrees. This means that all the flooring on the first floor is losing a lot of heat into the basement. And the colder the basement, the higher the heat loss through the floor.

So if your building has similar construction (ie no insulation in basement ceiling, and wood subfloor/floor above), you're in the same boat. The colder the basement, the more heat you lose to it through the flooring.

So for every BTU you save by insulating the pipes, you'll lose some fraction of that BTU through the first floor back into the basement that's now slightly colder. I don't know what that fraction is, but it could be large enough to make the juice not worth the squeeze.

0 -

That's a great analysis.

However, doesn't the substantially extended interval between running (firing) time in conjunction with the same temp inside the zones indicate that the btu saved by insulating the pipes is indeed substantial?

I think it's reasonable to say that the above statement means that substantially less fuel is needed to keep the zones comfortable.

0 -

@josephny I don't think you're interpreting your data correctly. Before insulating, your boiler was running about once per hour. After insulating, your boiler was running…once per hour. Look at the actual room temperature lines (blue and red). They follow the same 1-hour periods before and after.

Trust me, I've done the same kind of temperature monitoring/graphing/boiler run time analysis on our building, and it's easy to fool yourself into thinking some tweak you made is suddenly saving you a lot of energy.

The best possible data "collector" you can get is an ecobee smart thermostat that records boiler run times. Using the beestat.io interface on the web, you can collect detailed stats on daily, weekly, and monthly boiler run times. Because your oil-fired boilers run at a fixed input rate, you can calculate exactly how many gallons of oil you burned based on the ecobee's run time data. In our case, each boiler burns 1.2 gallons per hour of run time. I check our ecobee data from the beestat.io website at the end of each week, and I log the weekly run time totals. I now have 1.5 years of weekly run time data, plus 10+ years of oil consumption records.

Things I've learned the hard way:

(1) the effect of changing weather will overwhelm your ability to parse out minor energy savings from, say, insulating basement pipes. Wind effects alone can increase our building's heat loss by up to 40% on any given day. So even when you try to compare boiler run times from days with the same outdoor air temperature, a 10 mph difference in wind speed will have a major effect on boiler run time. So you'll imagine you just found a 20% energy savings. No, it was just less windy that day, sorry.

(2) you only really know you saved energy at the end of the year when you add up the total run time. Our total run time is about 30,000 minutes per boiler per year, or 60,000 minutes total for two boilers. That's 1,000 hours, or 1200 gallons burned at 1.2 gal/hr. But then you have to adjust for the number of heating degree days (HDD), which will vary annually. There will also be some variability due to wind effects, which are impossible to quantify because the HDD data does not account for wind effects. So even after you correct for annual HDD's, there will still be a difference from wind effects that you cannot quantify.

(3) the net result is that, even after you have 2 years of ecobee run time data, you will still not know how much of the annual difference was due to your building envelope improvements and how much was due to variable wind effects. In our case, I have 10+ years of oil consumption data because we kept records even before I installed the ecobees 2 years ago. So I can see that our combined attic insulation and window upgrades several years ago did produce an average of about 10-15% savings in oil consumption averaged over several years. But any smaller improvements in the building envelope are basically invisible in the data.

So, my best advice is: (1) get an ecobee thermostat and use the beestat.io website to log weekly boiler run time totals, (2) you will not be able to see any real (vs imagined) energy savings without having years of data logging or oil consumption records for baseline comparison and without subsequent major improvements to your building envelope like large-scale air sealing, insulation, window upgrades, and (3) any minor energy savings you think you see without doing the above will be mostly or entirely imaginary.

1 -

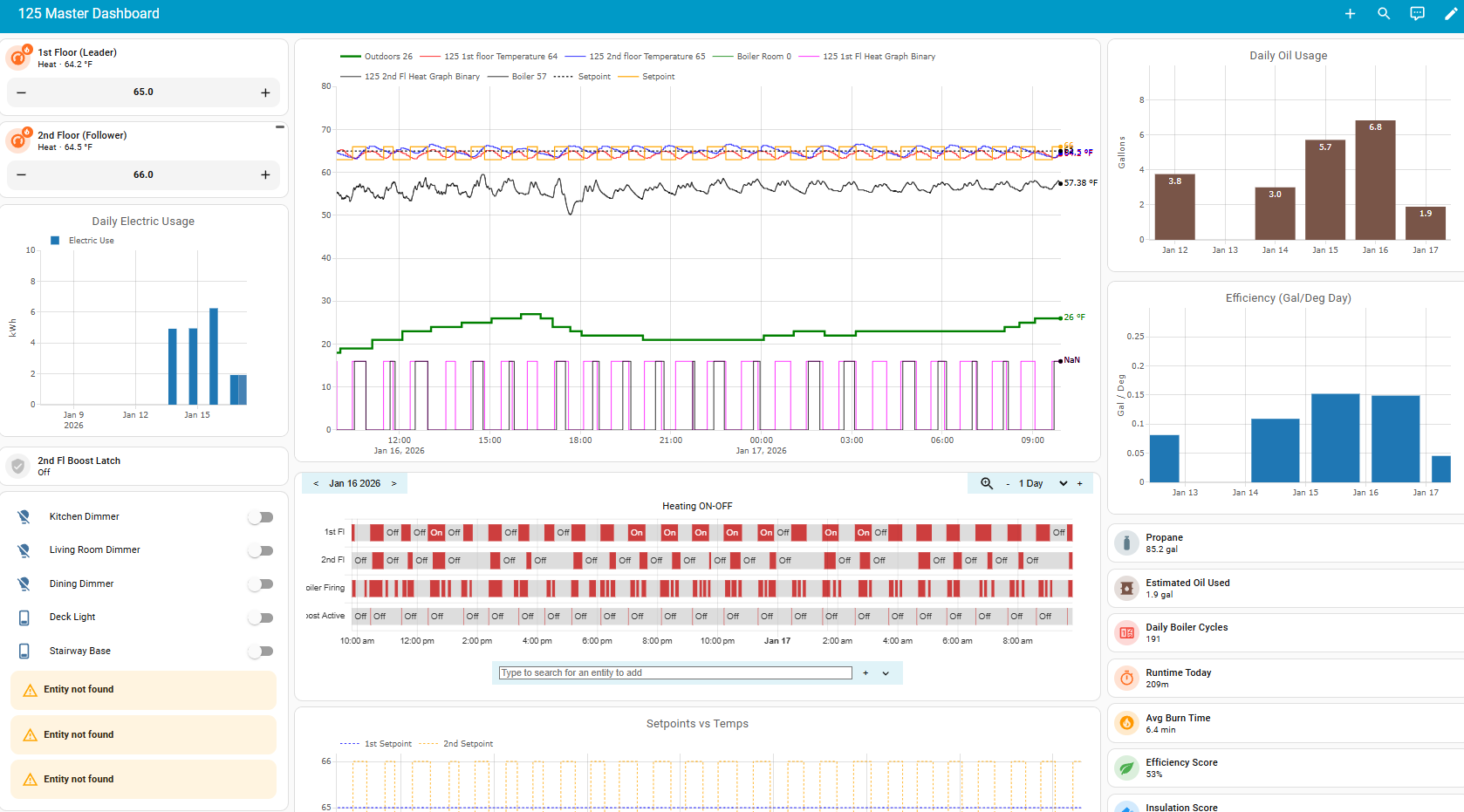

Funny you should mention Ecobee. That is what I use here (one for each zone) and many other locations.

I don't use beestat because I have my own data gathering system through Home Assistant.

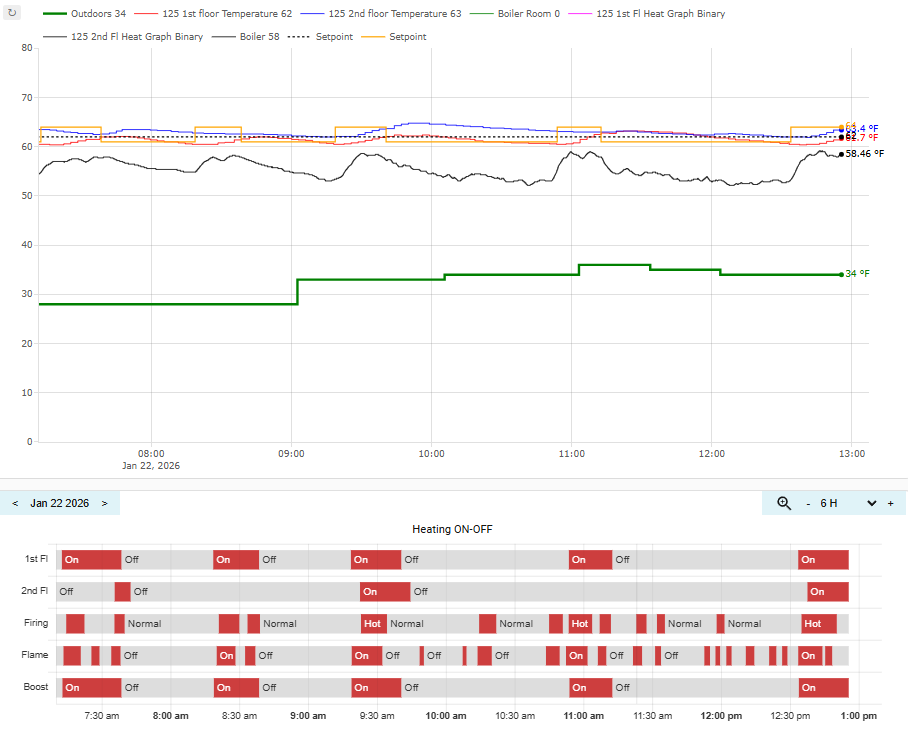

Below is part of the dashboard for this location.

I use separate temperature sensors outside the Ecobee system to fill in where the Ecobee cannot. In this case, for example, the sensor measure the heat near the boiler's exhaust. That tells me when the boiler is firing, whereas the Ecobee does not (it only tells me when the Ecobee is calling for heat).

Be careful with Home Assistant — it is highly addictive and there is no end to how much one can learn about it or how much it can do.

1 -

Great, you have all the data you need. But you still need to interpret it correctly. The boiler is still firing about once per hour, according to the boiler temp sensor. So insulating the basement pipes didn't change anything measurable in that data set, and I wouldn't expect it to. At most you might see a few percent savings at the end of the year, and then you'll have to decide how much of that percent change was due to HDD's variation, how much was due to wind variation, and how much (if any) was due to whatever insulation/airsealing/etc you did before or during the heating season.

1 -

" and then I better insulated around the basement door to fill the gaps. "

I don't know what type of boiler you have. Or how air tight your basement is.

Don't cut off your combustion air supply to the boiler. Flue gasses exit the the boiler and then exit the building, fresh air has to get to the boiler somehow.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System2 -

Yeah this casual comment about insulating a door really concerned me too.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

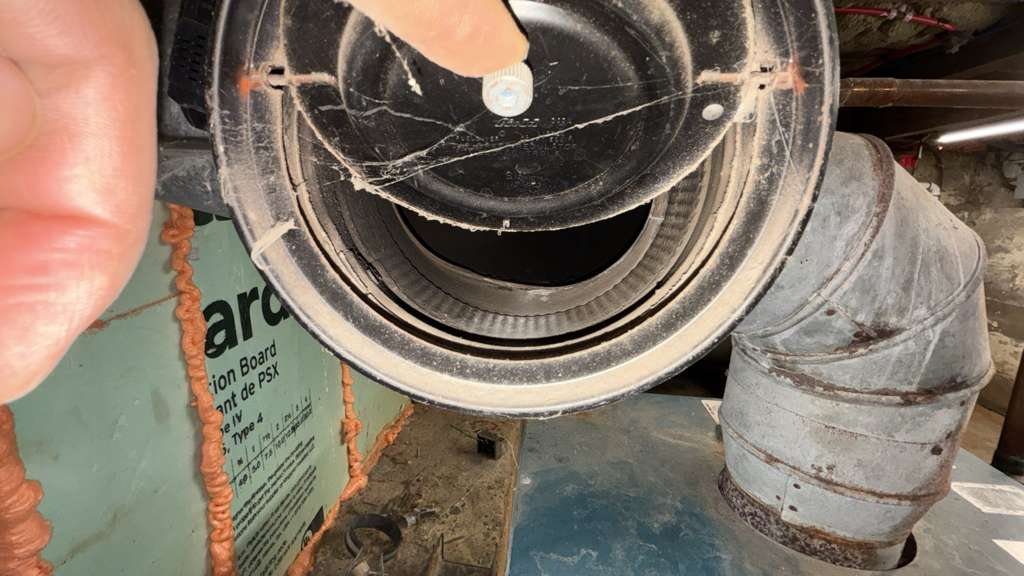

Thank you all for the important reminder about ensuring enough fresh air. The house is 100 years old and the basement is not finished. I know that statement in and by itself tell us nothing definitive about the amount of infiltrating (correct word?) fresh air.

Is there a simple way to determine if there is sufficient air?

I'm not too worried because I still haven't done anything about sealing around the exhaust pipe, on recommendation here:

Which, thanks to you all, now looks like this:

Good idea to seal this up?

0 -

Is that double wall (B vent) or is that single wall vent?

0 -

I don't know.

Do either of these show which one:

0 -

That's single wall.

In the earlier picture you can see where the foam melted.

Get that foam board further away also.

0 -

Got it — thank you.

Roughly how many inches?

What should I use to seal the gap between pipe and foam board to prevent drafts? How's concrete board (like hardiboard or durock?

0 -

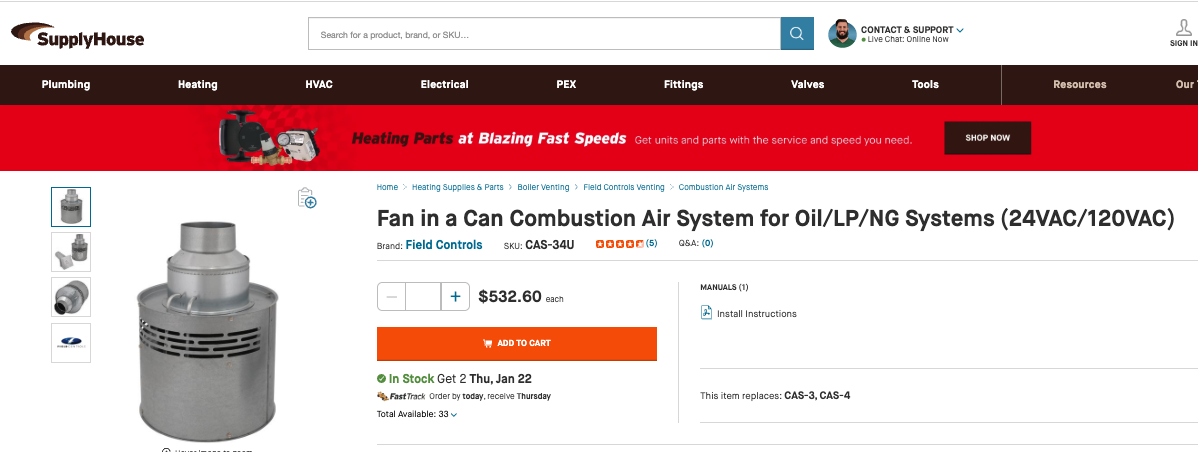

To determine air leakage you can have a blower door test performed. It would be good to know what the air leakage number is in the home.

Also the test can usually identify where the leaks are, around doors and windows, framing to foundation, etc. Then you can seal areas increase comfort and lower heating and cooling costs.

There are mechanical ways to direct air to the boiler if the basement gets sealed tightly.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I've dreamt of doing that at all my properties for years, but have never done one (so I'd have to learn how) and there's always been more pressing issues. (I have odd dreams.)

It remains "on my list."

0 -

foam is give 12” above.

You could use concrete board or any other fireproof material. Is it worth the expense? Personally I don’t think so. That opening is peanuts compared with all the other leaks you gave.

As said by @hot_rodBlower door test to know how much and where.

0 -

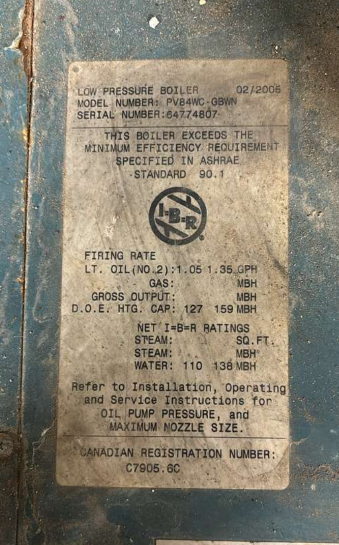

what size is that boiler, and how many feet of fin tube do you have, total?

I get suspicious of short, cold run cycles if this is rust at the vent pipe and fittings?

Or maybe a humid basement.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

Yikes. I think in the past the basement had quite a lot of moisture/humidity. I fixed that when I bought it about 5 years ago. I've tapped on the exhaust and it feels solid.

This is the plate on the boiler:

0 -

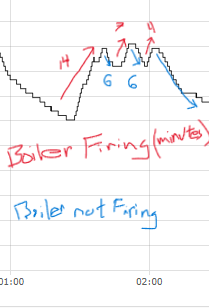

The ripples that you reference, I believe this is the boiler cycling on and off.

The thermostat cycles about once every hour. But the boiler firing on and off is more frequent. When thermostat calls, Boiler fires ~15 minutes, off 6 minutes, on 7 minutes, off 6 minutes, on 4 minutes (Thermostat call met), boiler off ~30 minutes, thermostat calls again. This is with outside temp 23F. @josephny mentioned this sensor was near boiler exhaust.

@hot_rod mentioned concern for short cycling based on exhaust vent corrosion. Could these ripples be a sign of short cycling, one could argue it is. @josephny would have to confirm with onsite eval.

0 -

This is interesting (to me), and I hope I'm not getting too caught up in semantics.

In my journey through understanding this, I'm at a point where I prefer to differentiate between different kinds of boiler "cycles:" (1) The rythmic, almost repeatable heating/non-heating, (2) the calls for heats, and (3) the actual firing or burning of fuel.

I've come to realize that a boiler doesn't necessarily fire when it is told me, often because safety controls don't let it.

In this particular situation, the rythmic cycling includes very short periods of non-firing. I've been attributing those to safety controls preventing the boiler from firing. But, I still consider it part of the ON portion of the cycle because (1) the tstat is still calling for heat and (2) because the boiler is still hot and, in some way, "producing" heat.

I make a distinction because I think calling the ripples "cycling on and off" doesn't tell the full story.

As you allude, however, when the outside temp drops (or, at least I think that is the connection), the ripples go away — presumably because the boiler gets to work harder and still not hit the safety limits.

That would, I think, disprove the idea that the ripples are caused by a failing exhaust.

I'm not certain or even moderately confident of any of this, so if I'm off the wall, please let me know.

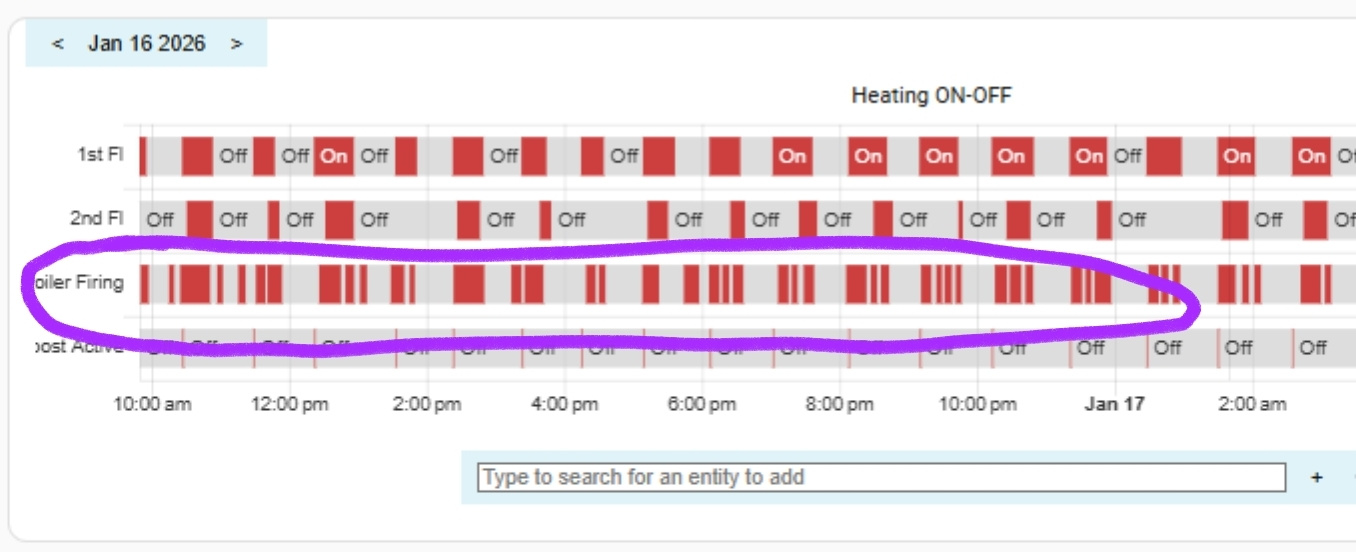

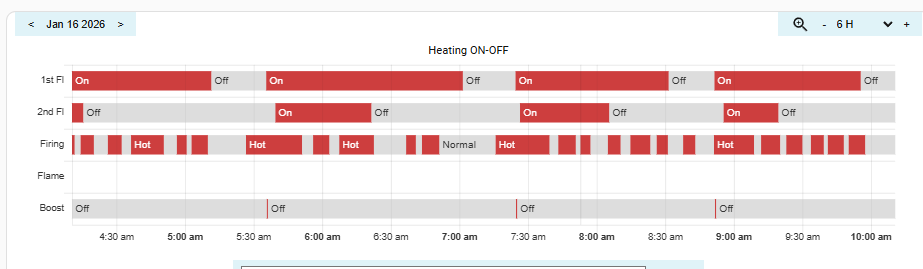

Here's some more graphs.

Zoomed in:

0 -

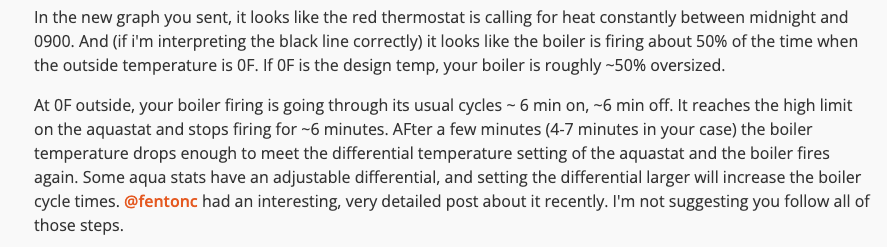

I'm not suggesting that a failing exhaust is causing the variations in the black line.

In the new graph you sent, it looks like the red thermostat is calling for heat constantly between midnight and 0900. And (if i'm interpreting the black line correctly) it looks like the boiler is firing about 50% of the time when the outside temperature is 0F. If 0F is the design temp, your boiler is roughly ~50% oversized.

At 0F outside, your boiler firing is going through its usual cycles ~ 6 min on, ~6 min off. It reaches the high limit on the aquastat and stops firing for ~6 minutes. AFter a few minutes (4-7 minutes in your case) the boiler temperature drops enough to meet the differential temperature setting of the aquastat and the boiler fires again. Some aqua stats have an adjustable differential, and setting the differential larger will increase the boiler cycle times. @fentonc had an interesting, very detailed post about it recently. I'm not suggesting you follow all of those steps.

0 -

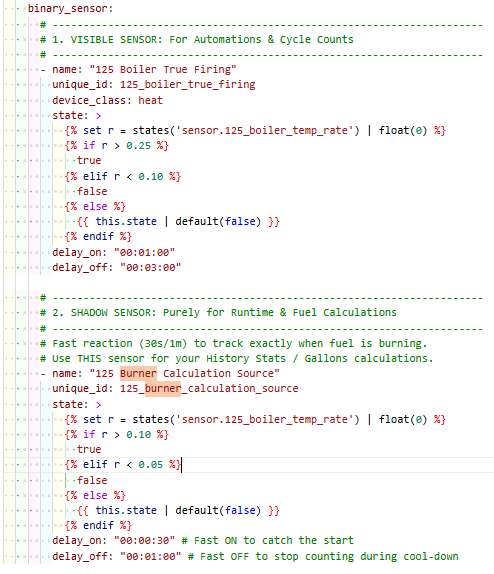

I just noticed this data line in your log. What do you use to capture this boiler firing data?

Can you post your log (screenshot) for "boiler firing" for that same time frame with 0F outside, maybe zoomed to just 2 hour frame ~0600 to 0800.

0 -

Here's my analysis: the temperature of the basement doesn't seem to have changed much after the pipe insulation was put on, it seems to still be in the high 50's. As such, there's no reason to believe that the whole house heat loss has changed at all, so I wouldn't expect any impact on comfort or fuel usage.

2 -

Good catch on the heating history timelines .

The 1st fl and 2nd fl lines (the first 2 lines) show the times when the tstat calls for heat (based simply on whether the temp in the zone is below the setpoint, subject to the swing setting).

The Boiler Firing line (third line) is based on the rate of change of the temp sensor, as follows:

When the rate of change (over a rolling 2 minute window) is:

- greater than 0.25 (rising at a rate of .25*/min or more) consider the boiler firing; or

- less than 0.10 (rising at a rate of .1*/min or less) consider the boiler not firing.

The deadzone between rising >.25*/min and rising <.1*/min is to prevent the ripple or chatter.

Here is a very zoomed out view that shows the general temp variation in the basement:

0 -

In case anyone is curious:

And:

0 -

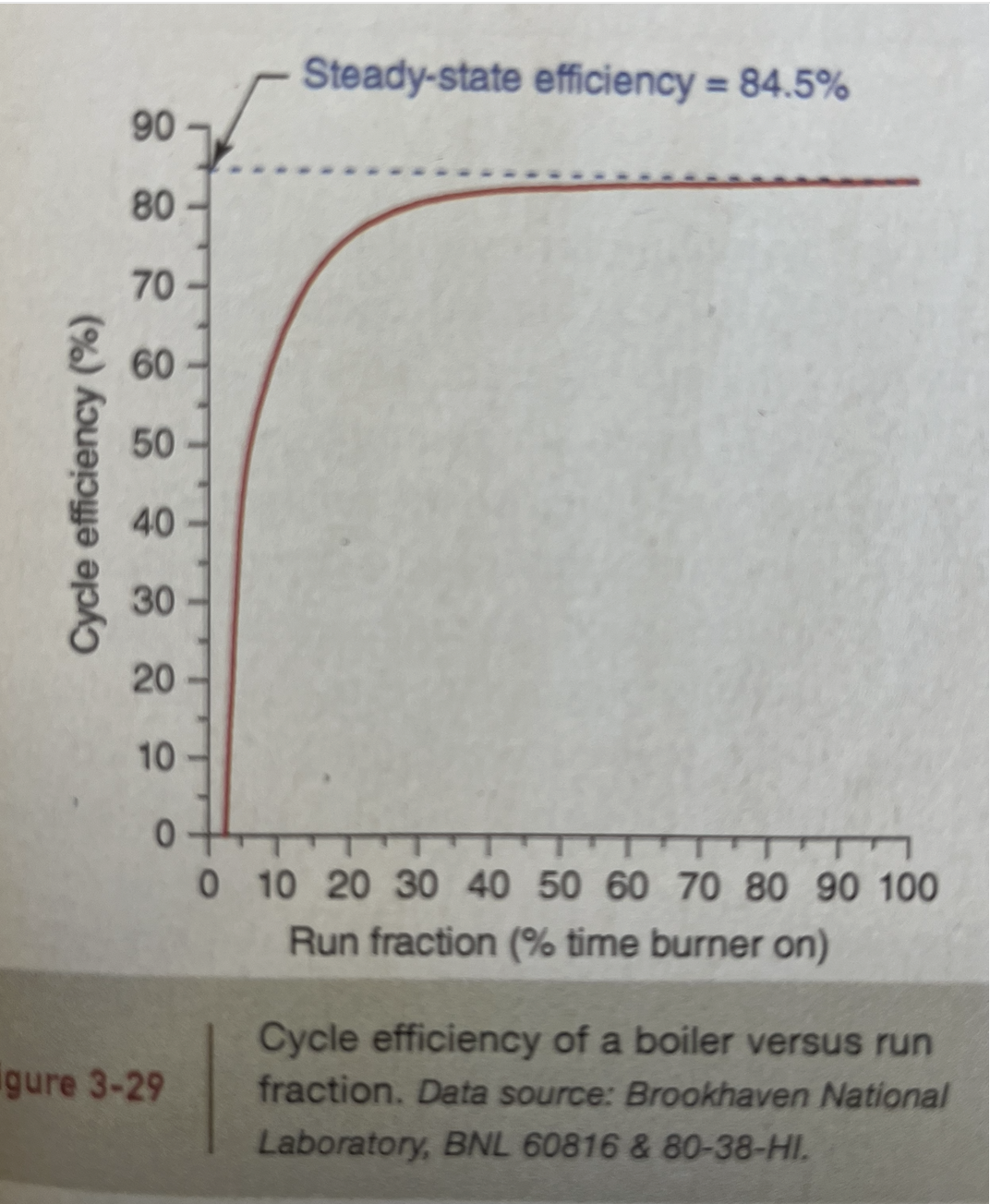

If this is accurate?

Run Cycle 6+6= 12

6 ÷12= .5 or 5%

5% on the bottom axis of this chart, run straight up to where it intersects the curve, cycle efficiency to the left axis. So at 6 minutes on 6 minutes off at 0°? 30- 40% boiler efficiency.

Generally you want the boiler to run 10 minutes every time it lights off. This helps assure the combustion chamber and all the flue up to the roof drys out, gets above condensing (dew point) temperature. If not you start to see corrosion around the parts of the combustion area and flue piping. The joints in the flue pipe is where you can see moisture has been working on the metal.

So a few undesirable things are at play with an over-sized boiler.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The problem is I am not clear on what "ON" means, for the purposes on efficiency/duty-cycle.

I don't think it means 'tstat calling for heat', but does it mean actual flame or does it include both flame and coasting?

Here's a 6 hours graph. Not the differences between tstats calling for heat, firing that includes some coasting, and strict flame on. (Ignore "Boost".) The latter 2 are derived or inferred from the relative temp of the exhaust pipe.

0 -

^^^ let's all remember this when people talk about how much savings one will get from insulating their mains

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

burner on, since that is what is using the gas or oil.

A data logger on the electric supply would show electrical consumption, which is some of the cost of heating.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements