Taming an Oversized Boiler - eliminating short-cycling and improving efficiency

tl;dr - A large aquastat differential and all-zone thermal purging eliminated short-cycling and significantly improved efficiency. My cast iron boiler is still 5x oversized for my heat loss, but performs well now.

Now, the long version…

I, like many other people, have a hydronic heating system that is wildly oversized for my house. At the design temperature (12F), which I've managed to hit for about 7 days in the last 4 years, my house's heat loss averages about 24K BTU/hr, and at the lowest temperature I've recorded (about -4F), peaks at under 30K BTU/hr. My 3-zone baseboard system can pump out about 90K BTU/hr with a 180F SWT, and that's connected to a boiler that's supposed to pump out about 117 KBTU/hr. This setup would be perfect if my design temperature were -160F, but as I live in New York and not Mars, it winds up being an exercise in inefficiency and short-cycling.

The ability to put out more heat than is actually needed isn't obviously a problem, but there are two main drawbacks.

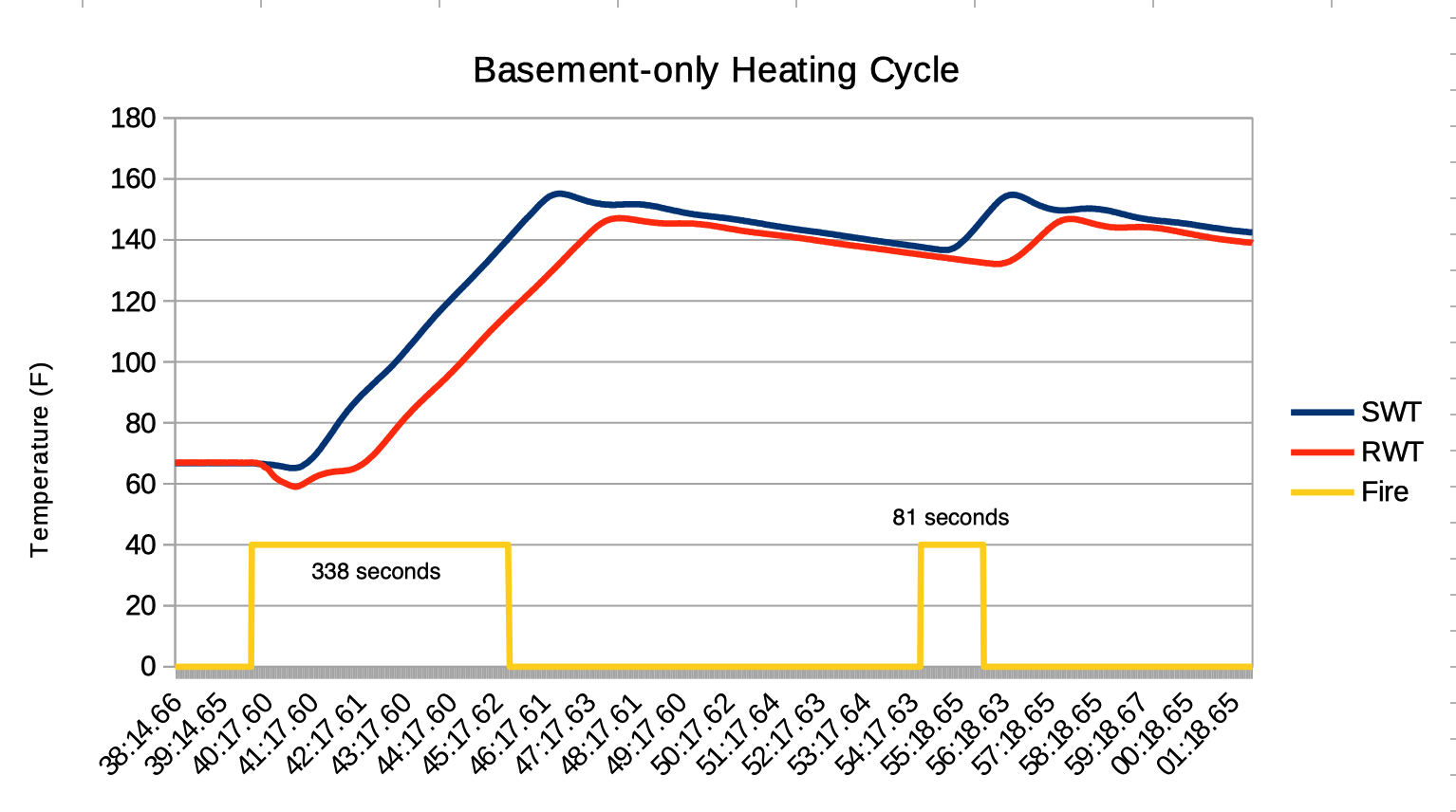

- Short-cycling: Electromechanical hardware wears out. Most of it has an expected lifetime measured in how many on-off cycles it can handle, and particularly when the boiler's ability to inject heat greatly outpaces the attached radiators' ability to dissipate that heat, it will rapidly cycle the gas valve, igniter, and flue damper as it fires up and is quickly shut down by the aquastat high-limit. Having a zoned system makes this much worse, as the attached amount of baseboard can now vary quite a bit (down to just 22KBTU/hr for the smallest zone in my case). The built-in WM Aquastat has a fixed 'differential' of 20F, which means the burner will fire until it hits the high-limit (say 180F), shut off until the water temperature drops 20F, then go through another burn cycle. As installed, my boiler was typically firing for about 80 seconds every 5 minutes or so. We can mainly think of this as a mismatch between the boiler and the attached radiation.

This is what a single cycle on the smallest zone looks like (with that 80 second burn pattern repeating until the thermostat is satisfied.

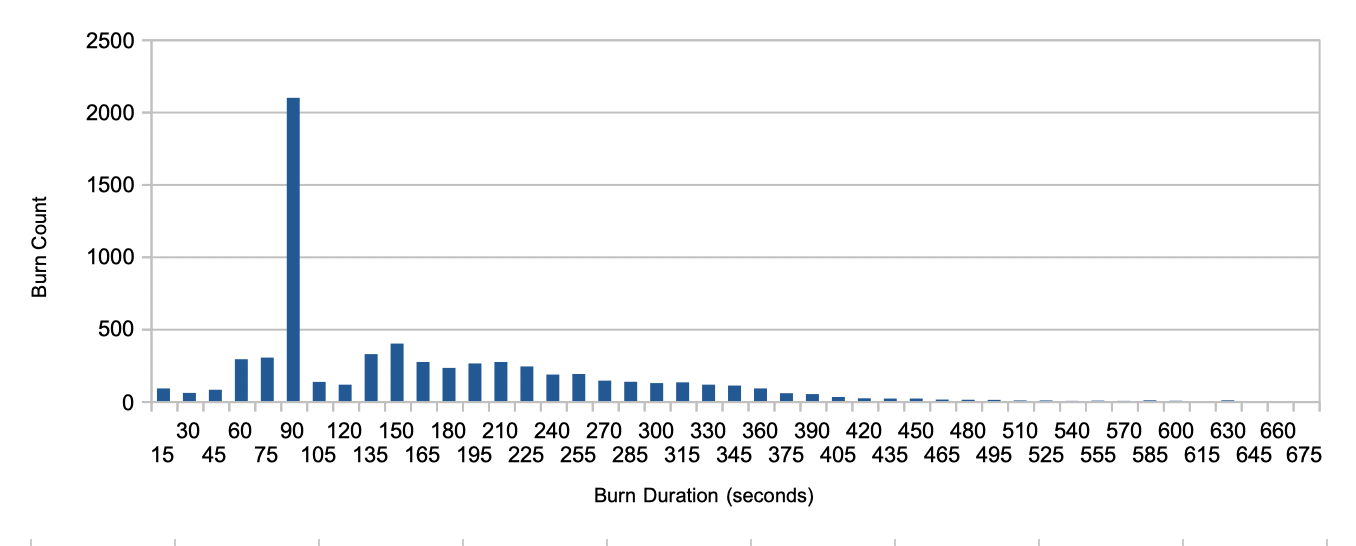

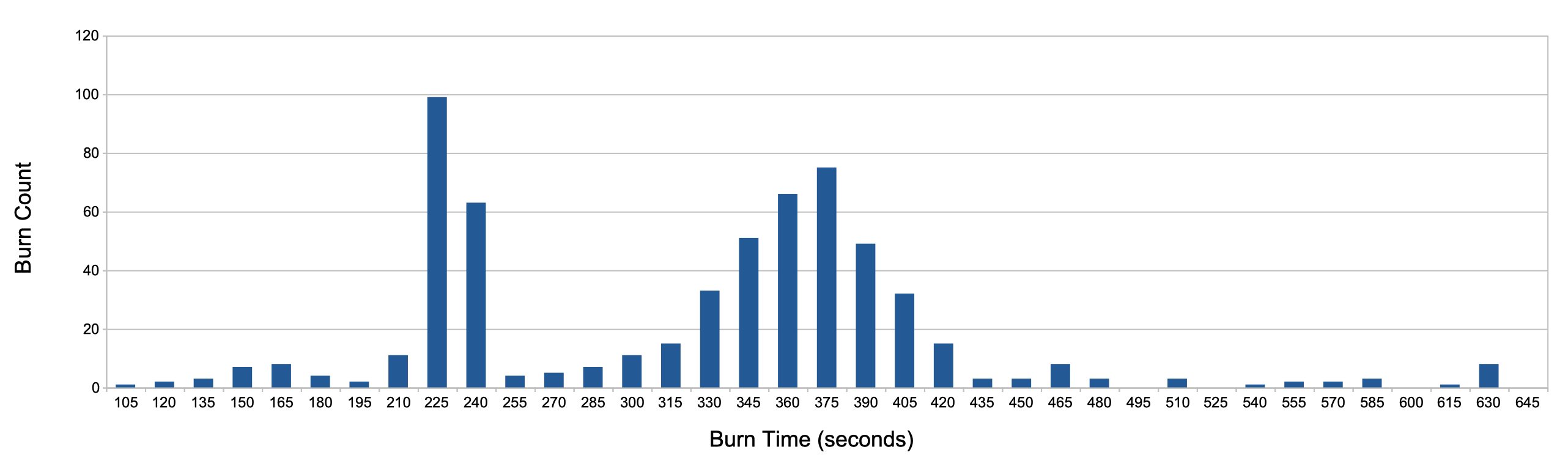

And this is what the distribution of burns looked like over the entire heating season, with those sub-90-second burns dominating:

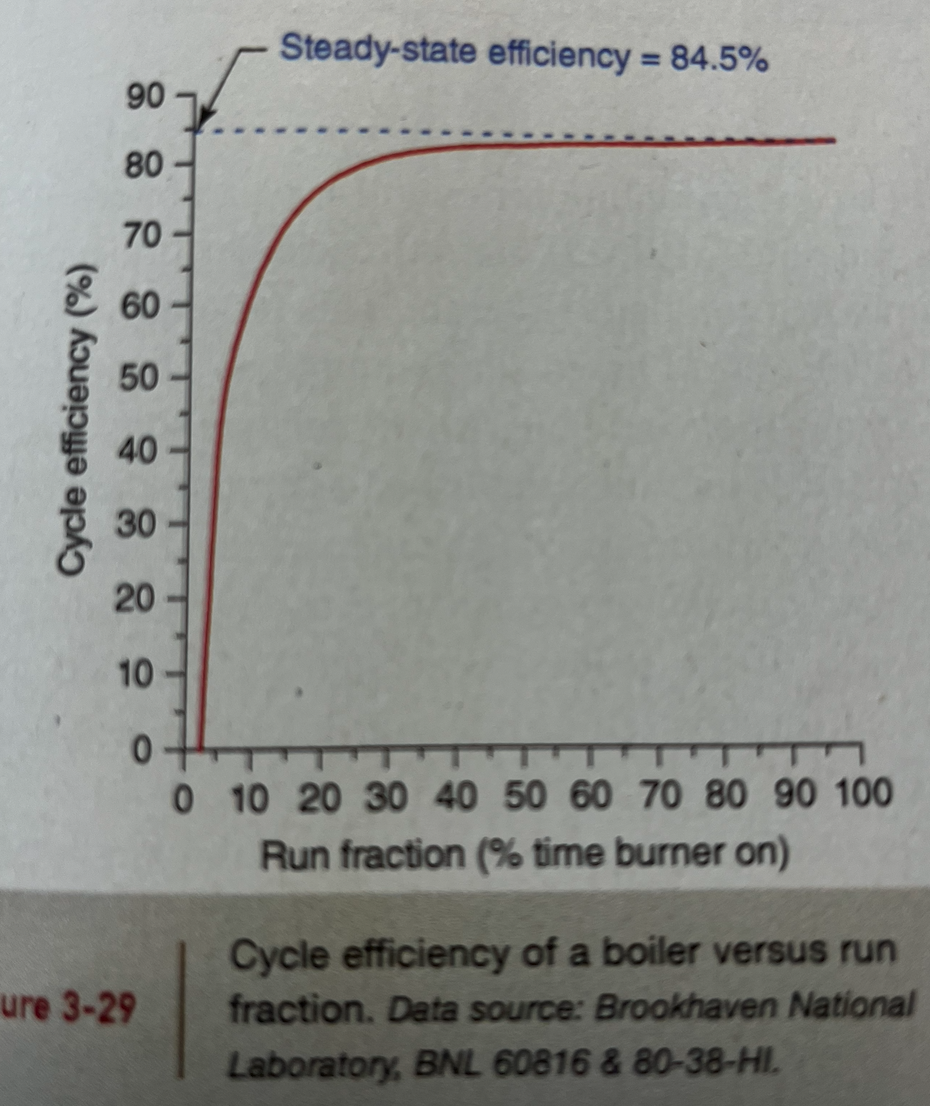

- Efficiency: This is related to short-cycling. There are many ideas and opinions about what exactly 'efficiency' means, but I will define it for my purposes as the fraction of BTUs from the burned gas that make it into the conditioned parts of the house. A boiler placed in a shed outside that maintained the water temperature all winter, but never circulated it inside, would have 0% efficiency with this definition. An open gas flame in an otherwise sealed house would be terrible for air quality, but would have 100% efficiency. When your radiators don't have a lot of thermal mass associated with them, and your boiler is in an uninsulated part of your basement, and your oversized setup can very quickly satisfy calls for heat, a lot of BTUs might go into heating up the boiler itself and then leak away into the uninsulated mechanical room without ever making it into the conditioned parts of your house.

Here is an excellent chart showing 'cycle efficiency vs run fraction':

My system, being ~5x oversized, operated nearly all season in the extremely inefficient part of this chart:

Comments

-

To address the short-cycling, I effectively wound up modifying the aquastat (using an additional PLC controller with a strap-on temperature sensor and an extra relay to inhibit the burner) to use a 60F differential, rather than the default 20F. This lowers the average water temperature in the baseboards, but they could actually meet the heat loss at the design temperature with 120F SWT. With my PLC, the aquastat high limit remains at 180F, but now waits until it falls to 120F before firing again. This obviously triples the run time for 'short' burns, but it also lowers the average heat output during a call for heat and allows for more overlap between the different zones calling for heat. The cycling is drastically reduced.

120F is nominally in the 'condensing' range for natural gas, but due to low gas pressure my boiler is slightly underfired, and the higher excess air puts the condensing temperature down in the 116F range when I had it combustion tested this fall. I have a 'cold-start' cast iron boiler, so it's frequently operating in the condensing range anyway (and I have zero evidence of any problematic condensation in the boiler's 10 year lifetime so far), but this was as low as I felt comfortable setting it.

This idea wound up being unnecessary, but I had initially considered doing an 'indoor reset' scheme, where I modulated the aquastat low-limit (rather than just leaving it fixed at 120F) so that I could increase the average SWT (and thus heat output) as necessary, based on how long the thermostats were calling for heat. I think this would be a very effective way to modulate the heat output of a CI boiler with zones if it's merely 'pretty oversized' rather than 'wildly oversized.'

1 -

Now let's move on to efficiency. To address the efficiency problems associated with low duty cycle, we had to consider what the actual causes were:

- The boiler was relatively separate from the main conditioned space, and it was surrounded by bare concrete block walls. Some BTUs 'trapped' in the boiler would make there way to conditioned space, but not nearly as effectively as if the boiler were in the center of my living room.

- The oversized nature of the radiation meant that calls for heat were satisfied relatively quickly, so frequently the boiler would heat up from room temperature to 180F in a few minutes, satisfy the call for heat after delivering a few thousand BTUs, then cool back down significantly before the next call.

- The cast iron boiler, although not 'high mass' by historical hydronic standards, still contained quite a bit of thermal mass compared to the baseboard loops on each floor. The boiler had a few gallons of water and a few hundred pounds of cast iron in it, vs a total of 150' or so of baseboard in the rest of the house. The boiler by itself, with ~180F water, stored 8-10K BTUs when a call for heat was done, vs maybe a few hundred stored in the water and baseboards for a given floor.

The larger aquastat differential sort of helps with #2, by slowing down the delivery of heat so that more time is spent radiating heat via baseboards instead of just the boiler itself (this is tempered in the other direction by the boiler staying 'hot' for longer, but even the reduced output still satisfies the calls for heat pretty quickly). After a lot of experimenting and researching, I settled on adding an 'all-zone' thermal purge at the end of a heating cycle. What's the quickest way to transfer the BTUs trapped in the boiler into the conditioned space? When the last zone is done calling for heat, open all three zone valves and run the circulator until the water drops back to room temperature. Any zones that had been inactive will likely be sitting on a loop of pretty chilly water that can rapidly mix with the water from the active zone and the boiler itself, and the large differential means that frequently the water is closer to 120-130F when the call for heat ends, rather than 170-180F.

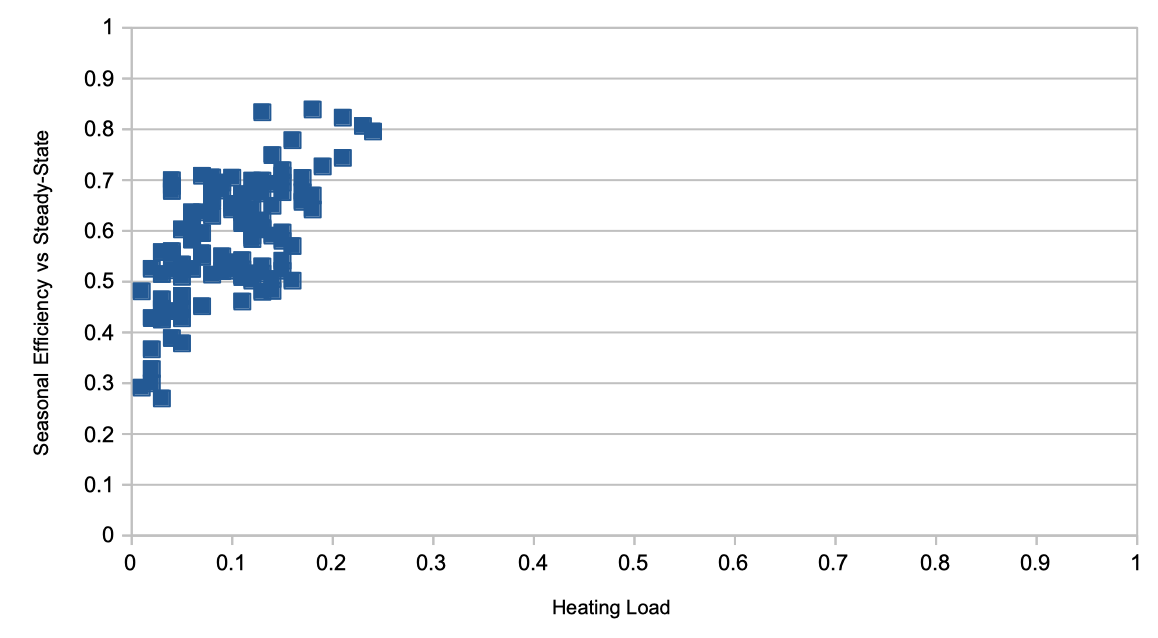

I detailed my experiments in a previous thread here. The effect on measured efficiency (my monitoring setup tracks the average temperature of each zone once a second and estimates delivered BTUs) was pretty dramatic, although I don't have a good way of estimating how many BTUs were finding there way into conditioned space just via convection from the boiler.

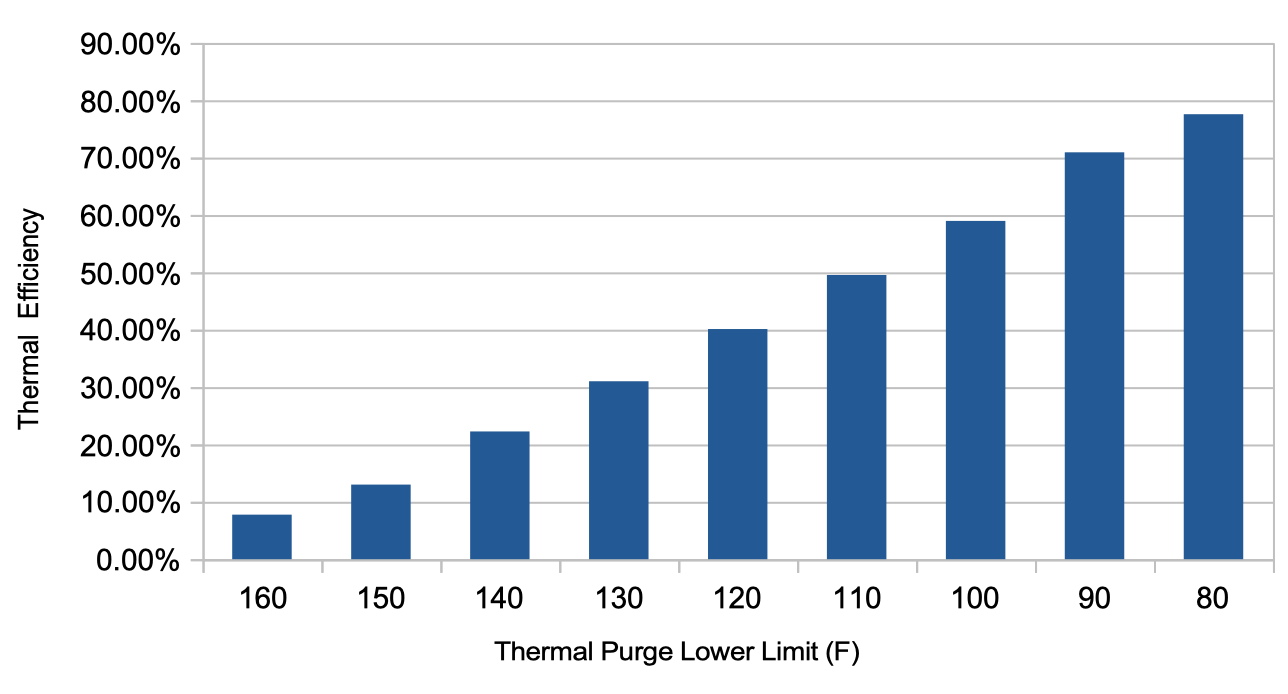

The best graph came from a series of isolated experiments where I just tracked delivered BTUs vs the temperature when I stopped purging:

BTUs escape much easier from radiators than the boiler itself, so it's extremely effective to just keep the circulator running. Looking at the daily results from when I started tracking all of this vs now shows that there is almost no dependency on estimated efficiency vs runtime:

What about overheating? The rate that heat is delivered depends on the temperature difference between the baseboards and the air temperature. Every zone is constantly losing heat, even if that zone's thermostat isn't calling for heat (ignoring things like solar heating for now) yet, so preemptively delivering heat at 1k-2k BTU/hr during a purge has very little chance to overheat things. I've never noticed any overheating in practice - I think the primary effect is to slightly delay when those zones will next call for heat. This scheme also has a very nice benefit in terms of freeze protection (particularly when using deep setbacks on some zones). When using an overnight setback of 6F on the main floor of my house, the purge cycles from the other two zones mean that water is never sitting still for very long.

1 -

What were the things that were tried and didn't work well?

- Adding a 'mild purge', where the circulator was only run until the aquastat differential of 20F was about to kick in. This probably helped a tiny amount, but not in a satisfying way. For thermal purging, go big or go home.

- "Zone Synchronization" - What if you try to solve short-cycling by getting all of your zones to line up their calls for heat? It barely helped the short cycling issue, and made the thermostat control way less predictable because it tied together floors with different heat losses and radiation:heat-loss ratios. Tekmar tried to commercialize this, but there's a reason this didn't catch on. Also, it's very upsetting to other people in the household when turning up a thermostat does not result in immediate action on the part of the heating system.

- "Freeze Protection" - I read about a device on here that would make sure each zone would call for heat periodically to prevent potential pipe freezes when water sits for a long time when it's cold out. I experienced a pipe freeze once, so I tried having each zone run for at least 5 minutes out of every hour, and the result was terrible overheating. There's relatively few BTUs moving around during a post-call purge cycle, but enabling a zone for 'freeze protection' when other zones are actively calling for heat resulted in immediate and significant overheating. Like 4-5F overheating. I think this lasted for like 4 days before I disabled it.

- Lowering the SWT. I can actually heat my house just fine with 140F-120F water, but it did little to address the short-cycling or getting the BTUs out of my boiler after a call for heat. It probably would actually help with the latter if I measured things carefully, as this is what 'outdoor reset' schemes are taking advantage of to increase efficiency, but I never tried lower than 160F-140F, and the purging was a much more effective way to accomplish the same thing.

What other things did work well?

- Heat Pump Water Heaters - I replaced my gas water heater (co-located in the mechanical room next to the boiler) with a heat pump water heater. In the summer it provides 'free' air conditioning and dehumidification in the basement, and in the winter it pulls BTUs out of the oversized CI boiler and stuffs them in an insulated tank with very low loss. The gas water heater not only had lower efficiency than the boiler, but it also came with an always-open flue as well. Whenever HPWH's are discussed, someone usually mentions 'but it's just taking BTUs from the boiler!' - this can really be a feature when the boiler is oversized.

- Temperature setbacks. An oversized system can pump out heat when needed, so recovering from a deep setback is easy. Even with my 60F differential, I can easily recover from a 6F overnight setback in an hour or two. Temperature setbacks save heat by lowering the average room temperature (since the heat loss is proportional to the temperature difference between inside and outside), and this translates into real savings as long as your heating system doesn't get less efficient when trying to recover. With a giant gas boiler, this is not an issue. The all-zone purging scheme also means that water still circulates fairly often, which can prevent pipes freezing (this happened to my 1st floor baseboard loop during a cold-but-sunny day with a daytime temperature setback enabled).

1 -

-

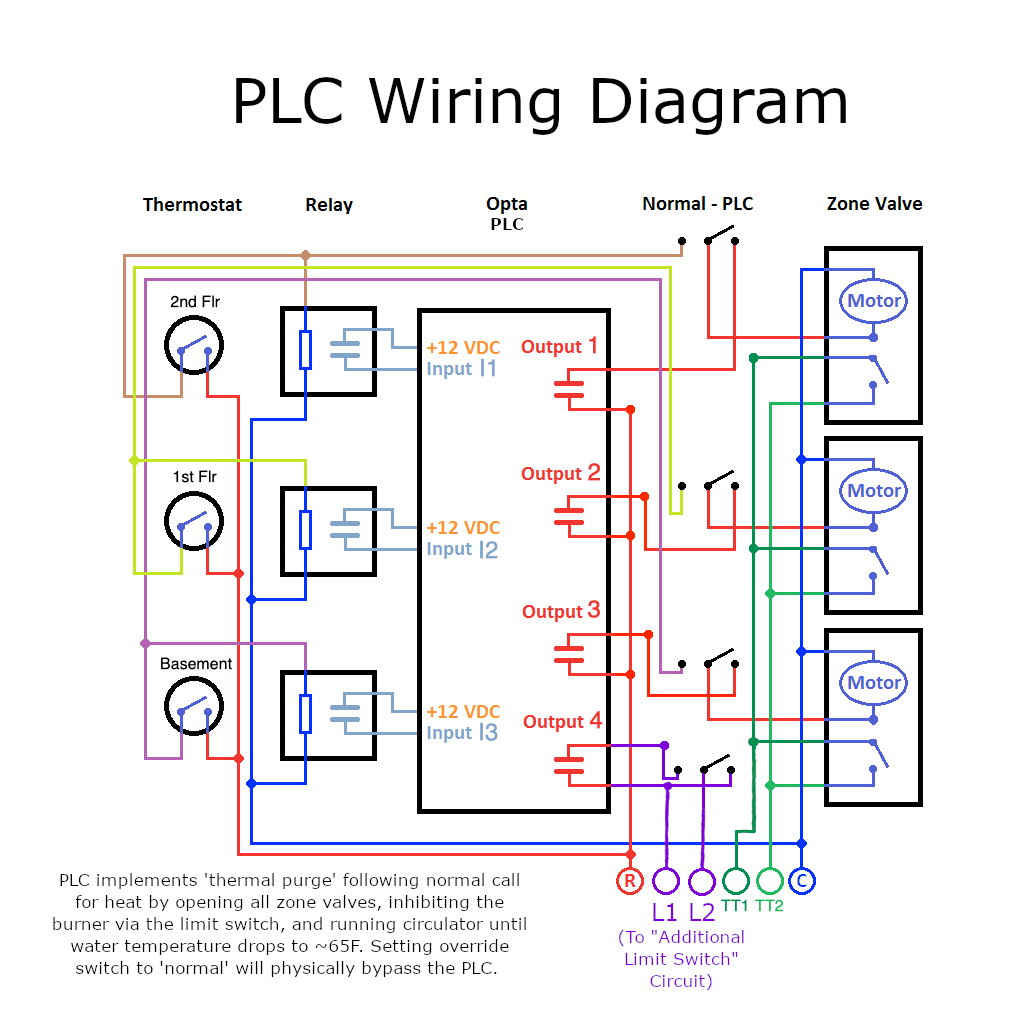

@Forge_Fixer88 - it's an Arduino Opta I mounted next to my boiler. Here's the schematic for the setup (there is an additional analog input that's not shown that connects to a temperature sensor strapped to the supply pipe right as it exits the boiler):

This PLC implements the post-call thermal purging as well as the 'aquastat override', and isn't networked to the outside world at all, but it has a serial port output that goes to a separate 'monitoring' microcontroller. The monitoring setup has sensors for the supply/return temperatures for all 3 zones (to estimate average temperature of that zone) and the 'circulate' and 'burn' LEDs on the boiler, and reports back to a logging script on my computer once a second.

1 -

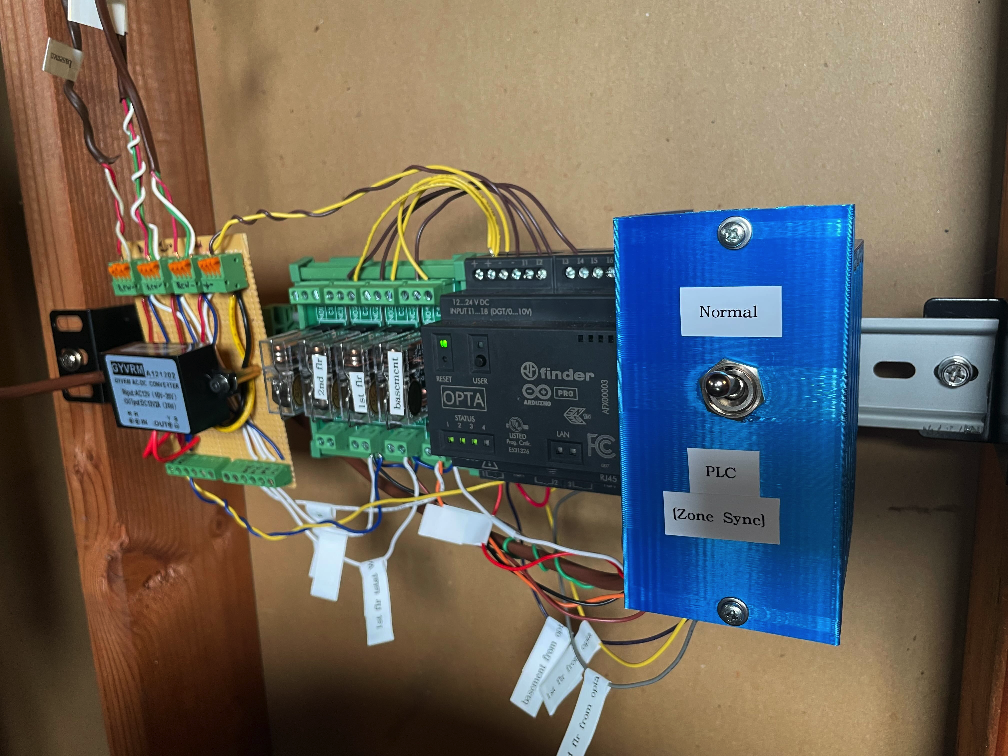

Here is what the setup looks like (from when it was initially implemented zone synchronization):

0 -

"A" for effort on the controls and data logging.

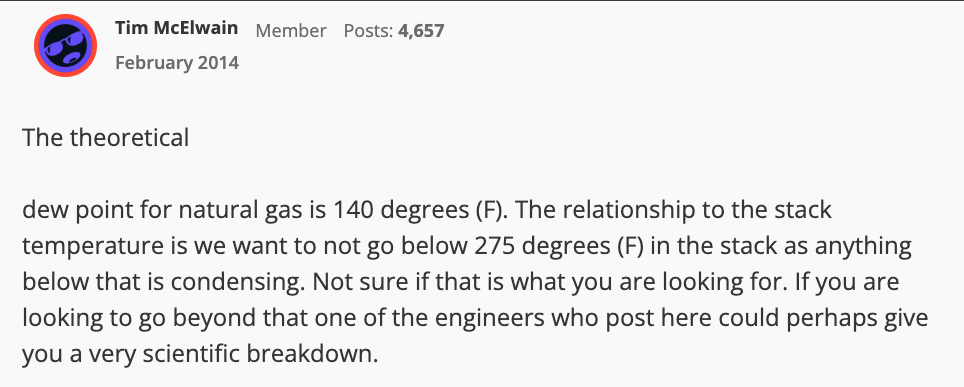

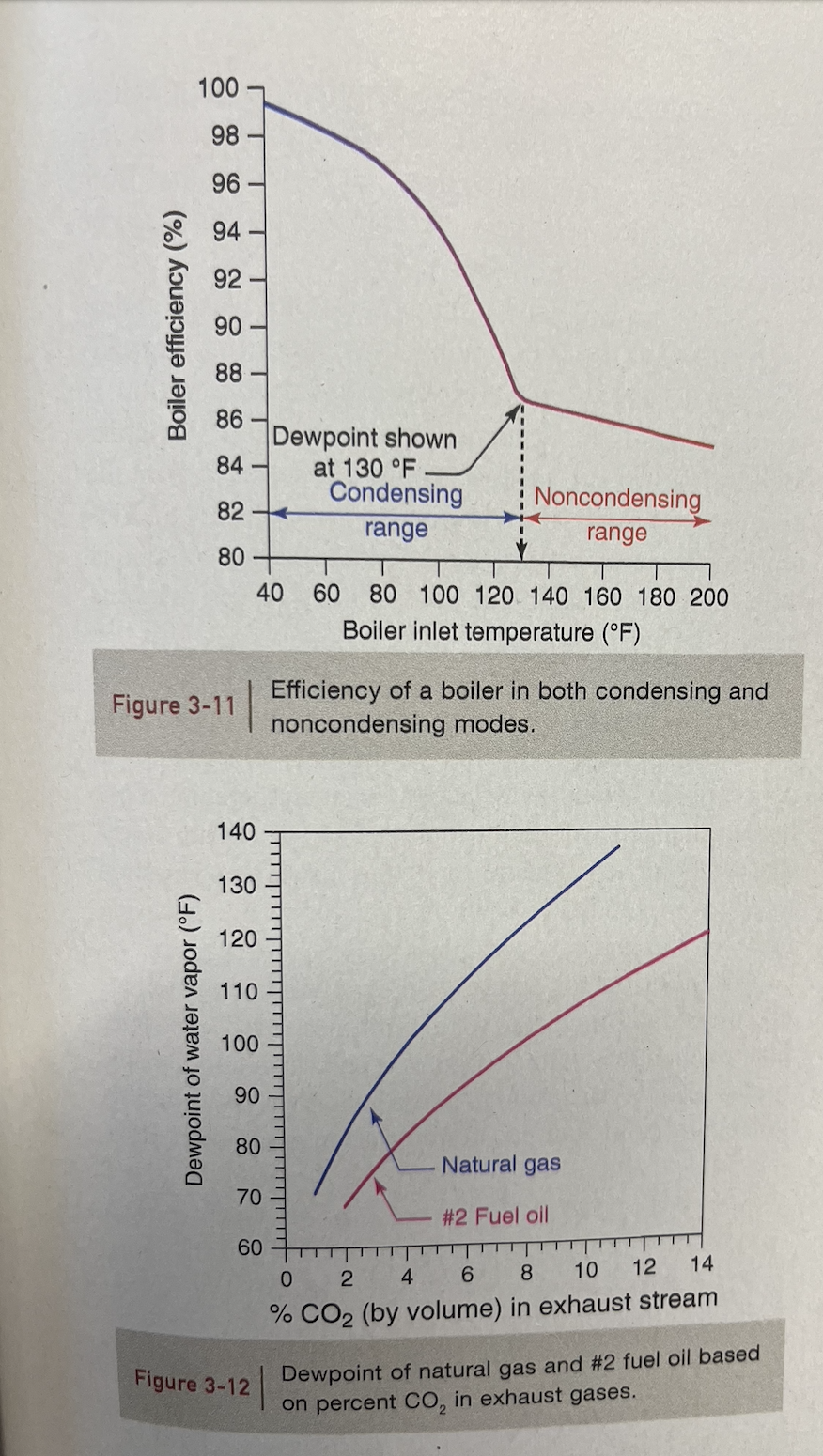

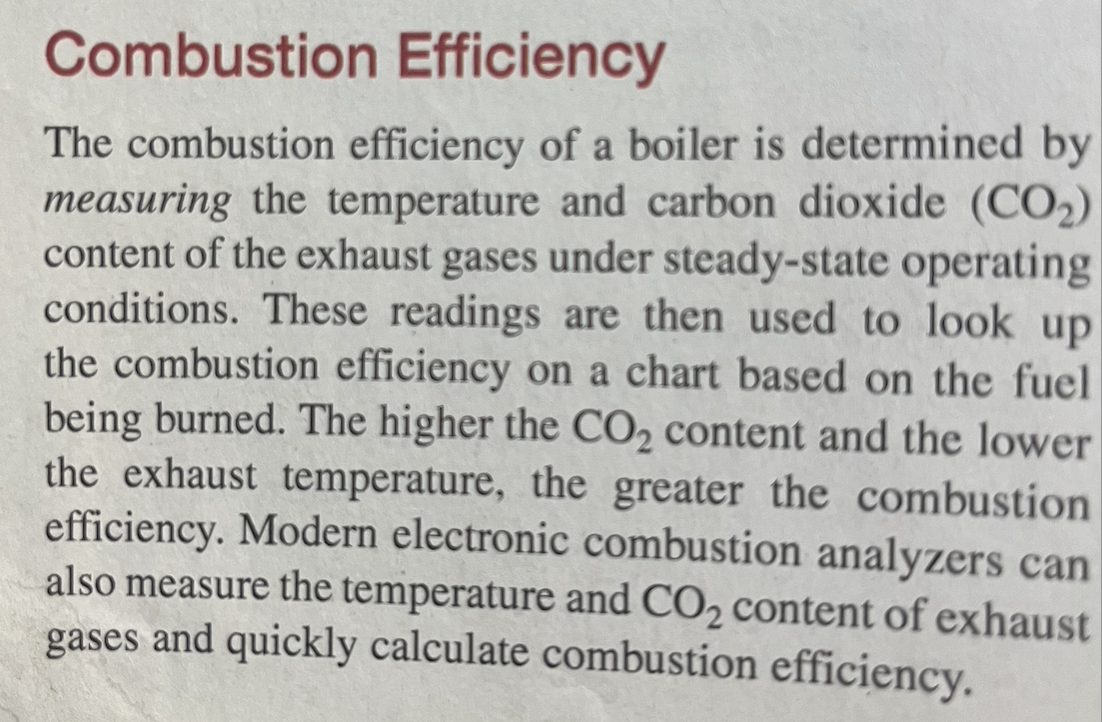

I'm not sure about your condensing temperatures? It has to do with dew point of the fuel and % of CO2 in the flue gas measurement. 130°F is the number I see most boiler manufacturers suggest for NG fueled boilers.

Do you have the combustion analyzer printout showing temperatures and CO2 readings? Reading are only useful if taken at steady state operating conditions.

If you are running low CO2, be sure to look at CO numbers

Steady State being when the supply and return temperatures stabilize, the heat emitters absorbing all the boiler can produce. SWT no longer rising, RWT stabilized.

Sounds like you may never get to steady state however if thermostats or boiler limits get involved and shutdown the burner before steady state is achieved?

Data logging SWT and RWT for a period of time would show you if you ever reach steady state.

Combustion readings taken as the boiler first fires doesn't tell the complete good story.

I would also suggest you measure your flue temperature, and look at the roof termination when the boiler is running, if you see a plume of steam or vapor I think you are condensing in the flue.

Plenty of posts over the years on boiler condensing that are not designed to do so.

Sage advice from Timmie

You must be oversized on fin tube also if you can heat the home adequately at 120 SWT? That can be the good news for future equipment selections.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Here was the most recent combustion test results on 10/30/25 (no stack temp for some reason):

- O2:9.4%

- CO:3 PPM

- AmbientCO: 0 PPM

- Excessair: 81.7%

- CO2:6.49%

- UndilutedCO: 2 PPM

I had found a chart of %O2 vs Dewpoint temp that I was using, but it seems to match your %CO2 vs Dewpoint temp chart above - 6.5% CO2 & 9.4% O2 == Dewpoint temp of about 117F.

@hot_rod - I'm very oversized on fin tube. The installer just put them along the outside walls of the house, which seems pretty common. The basement and 2nd floor both have about 6x their max heat heat loss with 180F SWT, and the 1st floor is about 4x. I think everything would probably work okay at the design temp with 110F water, hence no issues whatsoever running at 180F with a 60F differential.

0 -

Thanks! I've tried to be very thorough and data-driven with this. I'm going on my 5th season of boiler tuning, and usually try to do 1-2 experiments every season. It's satisfying that the schemes that seem to work the best are also pretty simple. I wonder if there are any off-the-shelf aquastats that let you do really big differentials like mine (30F seems to be the most common max). I haven't thought about it in detail, but the 'all zone purging' scheme could probably be done using some off-the-shelf relays. The PLC was for ease of experimentation, but probably isn't necessary.

0 -

bottom line. Tightening the envelope gives the best return on investment.

that Leeds to a smaller boiler and less energy usage!0 -

@pecmsg - If you also take the opportunity to 'right-size' your boiler, definitely! If you have an already-oversized boiler and tighten the envelope materially, you'll make it even more oversized and might lose some of the benefits to decreased efficiency/increased short-cycling.

0 -

exactly

Size it probably

Or pay the price for Oversizing

0 -

@bjohnhy - okay, time to play 'fantasy plumbing'!

- I have actually come to appreciate some of the simplicity of non-condensing cast iron boilers. If I were going to stick with CI, the Weil-McLain CGa-25 is pretty much perfect. It's rated for 38K BTU/hr input, approximately 30K BTU/hr output. If I understand hydronics correctly, my installed radiation can actually dissipate 30K BTU/hr with 120F average water temperature, so I would probably need to re-plumb for primary/secondary piping to avoid having it in the condensing range whenever more than 1 zone was calling for heat, but this setup would be simple, reliable, and heat the house just fine.

- If I wanted to max out efficiency but stick with gas, I would probably go for the smallest modcon boiler I could find that still had a 10:1 turndown ratio. I would also love to switch my 1st floor from baseboard to in-floor heating. That floor has the highest heat loss by quite a bit, and already has a lower radiation:heat loss ratio than the other 2 floors by about 50% (and the baseboards are frequently blocked by curtains or furniture). I don't have a particular model in mind, but having lots of settings to tweak would be fun.

- These things last for decades, so my preference would actually be to switch to an air-to-water heat pump and drop the gas connection to my house entirely. Just like with the modcon, my oversized radiation can really shine here. I'd also go with the in-floor heat for the 1st floor again (or just add more baseboard if the floor wasn't practical for some reason). I think a nominally 5-ton unit with EVI and an inverter-driven compressor would be super efficient and heat the home just fine, and also come with lots of fun settings to tweak. I'm not sure I can find anyone around here to install/service one, but maybe some day.

1 -

I think the path you are on makes sense. Design for the lowest possible supply temperature, first!

So large surface area generally wins. Radiant floor, wall or ceilings give you the most square footage for a "radiator" All homes already have these panels, you just need to warm them :)

120 is comfortable for A2WHP, but getting down to 110 or even 100SWT would be a goal to shoot for.

The A2WHP is fairly plug and play. Connect outdoor module with indoor and into system. A buffer or voluminizer may or may not be needed depending on zoning and HP modulation. Any hydronic savvy installer can do this. Not unlike mini split systems as far as being packaged and just needing the umbilical cords between the units.

A2WHP give you more distribution options compared to mini splits.

I like the idea of simple when it comes to control strategy, a custom control module that only one person understands may not be a way to future-proof the system for others to own or service.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements