Burnham boiler question

Comments

-

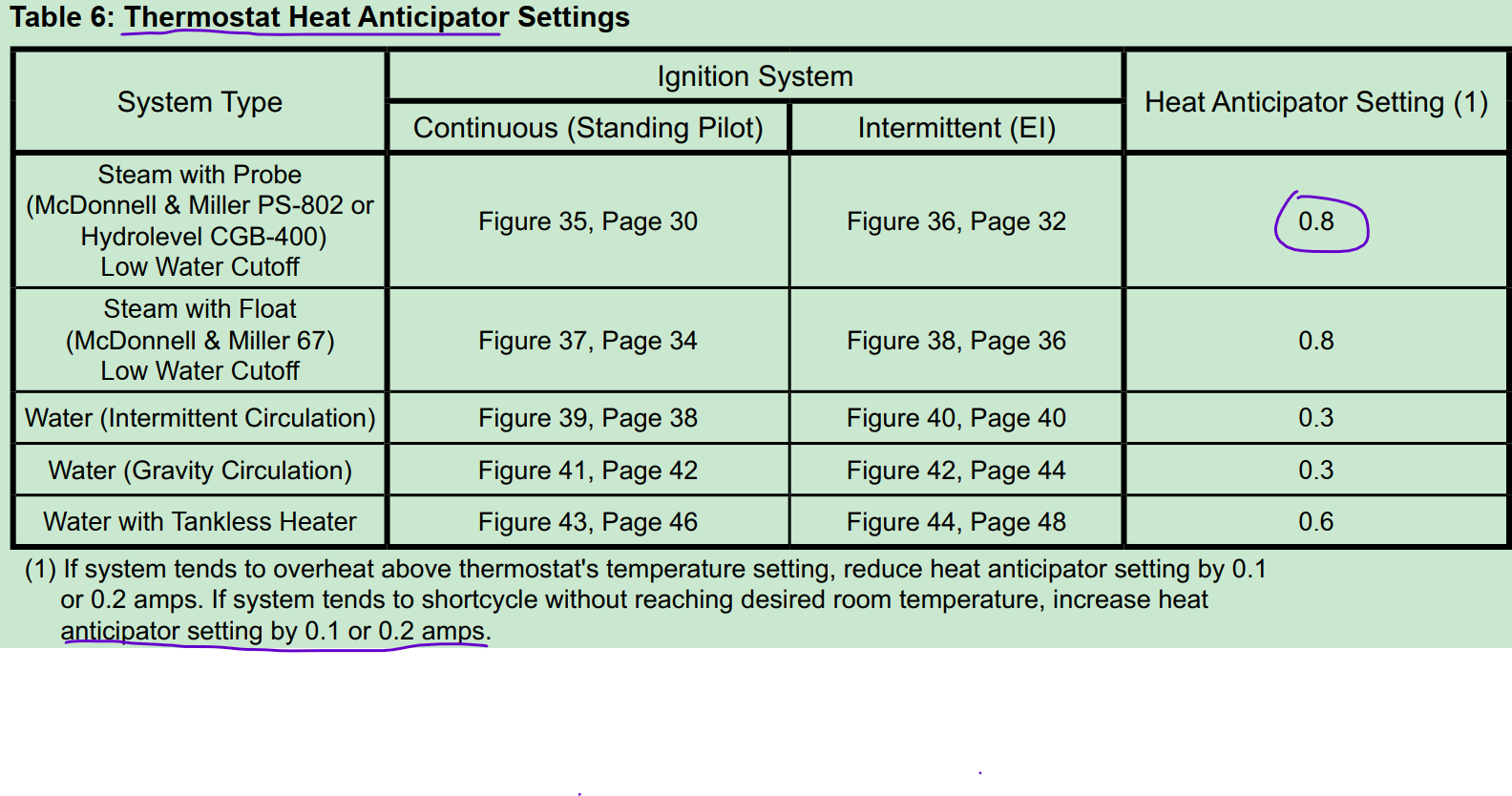

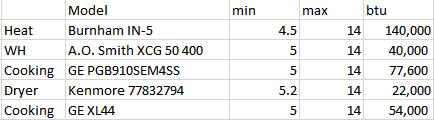

the manual says to increase the tstat setting by ~0.1 amp to avoid short cycling. how many F degrees on the tstat is equivalent to 0.1 amp in this table?

0 -

-

Thanks.

I was not concerning the pipe materials.

I was asking weather the joints of he pipes with elbows, and the pipes with the T (in that U shape assembly) are lead hubbed or tapped threaded. it's all hubbed, or at least hubbed where the two elbows tie to the two horizontal pipes (the other 5 connections can be threaded), right?

I have had some experience with diesel fuel system, I'm just curious about the domestic water plumbing where things are different.

0 -

-

Thanks for the reminder. I should blow all water out asap. I thought to place some temp sensors and keep monitoring the inside temp. The gas servicer has not filed the working permit yet. I complained to the city, hopefully Nationalgrid will call me about a timeline next week. I visit my new place every weekend. The plan regarding the steam boiler is to measure the probe this weekend, and bring my wrenches there in the following visit, I will also take a photos.

i'm going to use rectorseal 5 when reassembling.

when you say wrong, do you mean all 7 connections (each elbow has 2, T has 3) can be tapped threads?

0 -

-

i remember the system supply steam pipes are all 2" or 3" cast iron ones, on my steamer.

now that you highlighted it, i recall the manual has a paragraph that disapproves using cooper for steam piping, mainly due to high thermal expansion and heat loss.

0 -

-

-

-

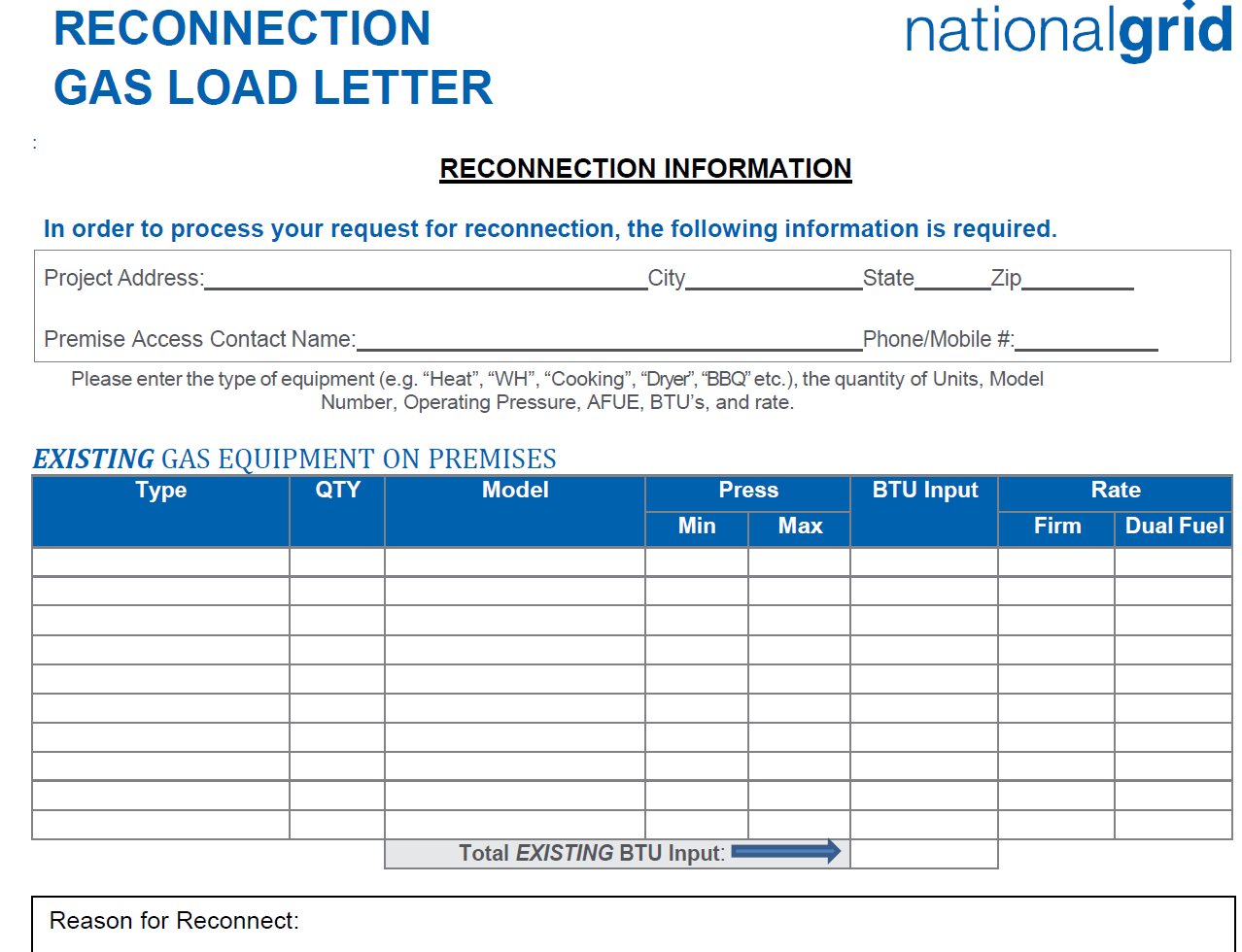

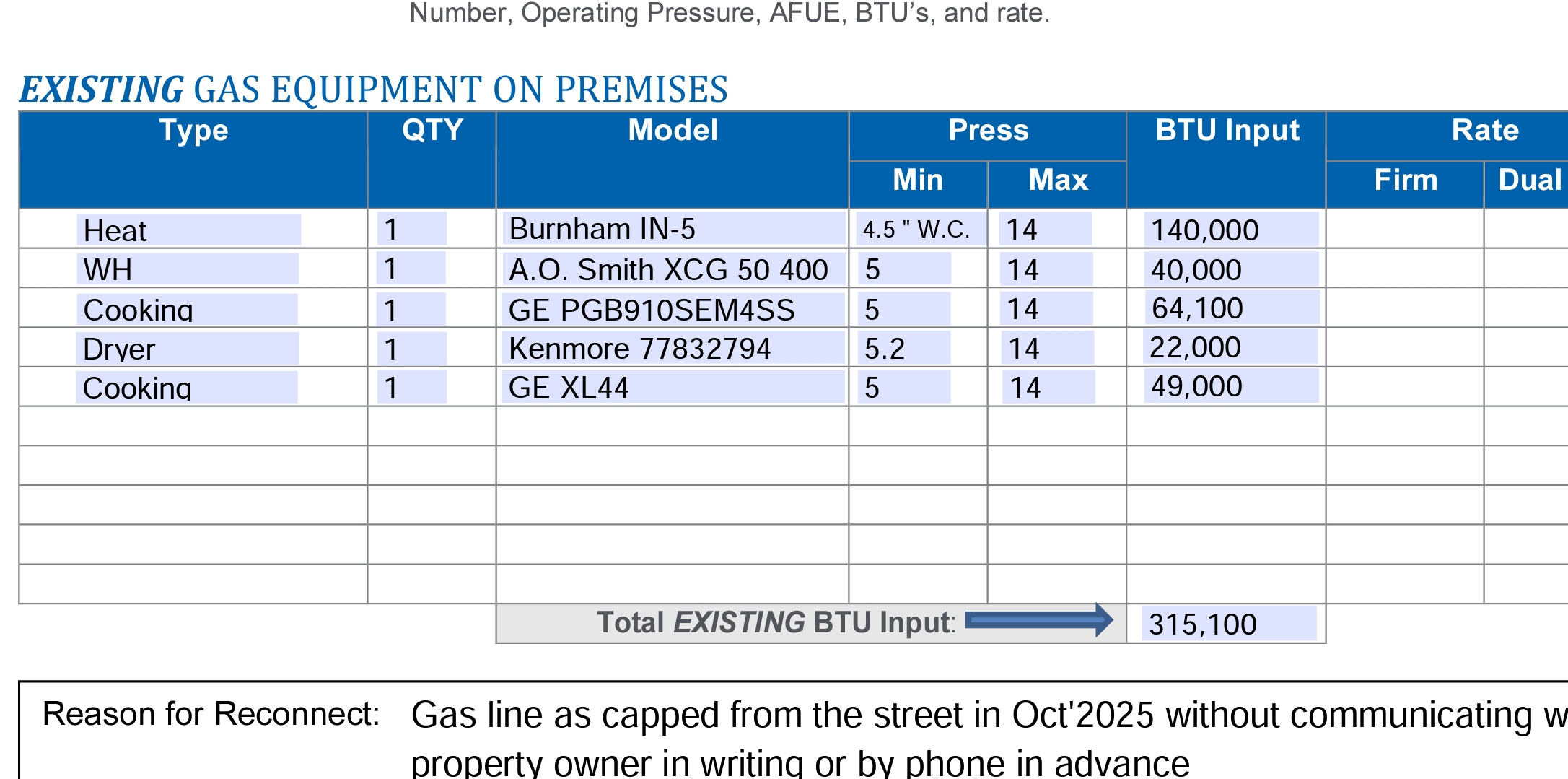

I thought the gas company just need to restore the gas line to its original condition before it was capped, but the company's clerk just emailed me a gas load form that I have to fill and sign.

in its "terms and conditions" part, it says -

"In the event that the equipment identified on the front of this agreement (i.e. the table attached) is not installed and in use within three months (Existing Homes) or six months (New Construction) of the date of installation of the service line, the Applicant agrees to pay National Grid the actual cost of installing and disconnecting the gas service line plus the actual cost of any required main work minus any payments already received "

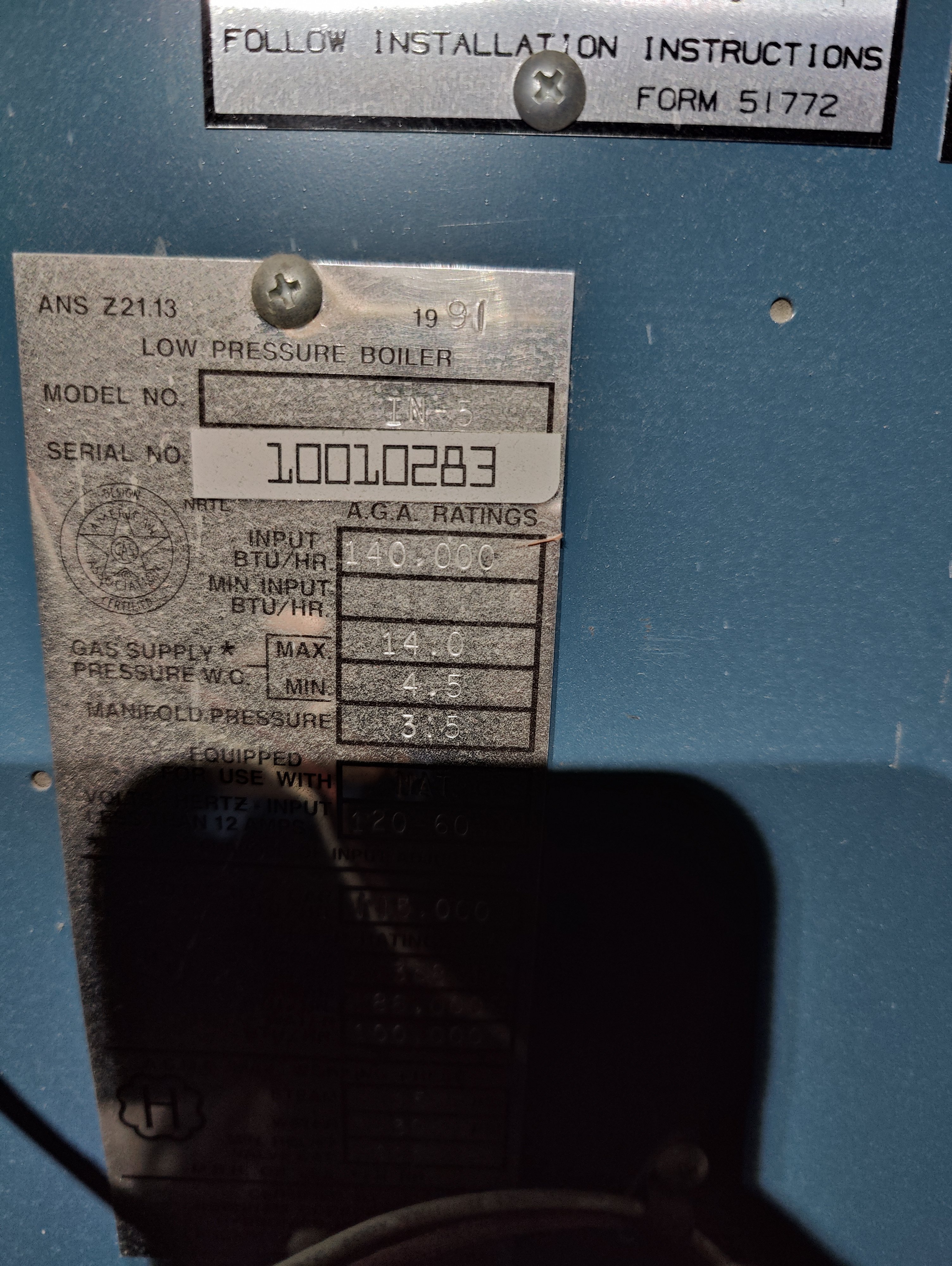

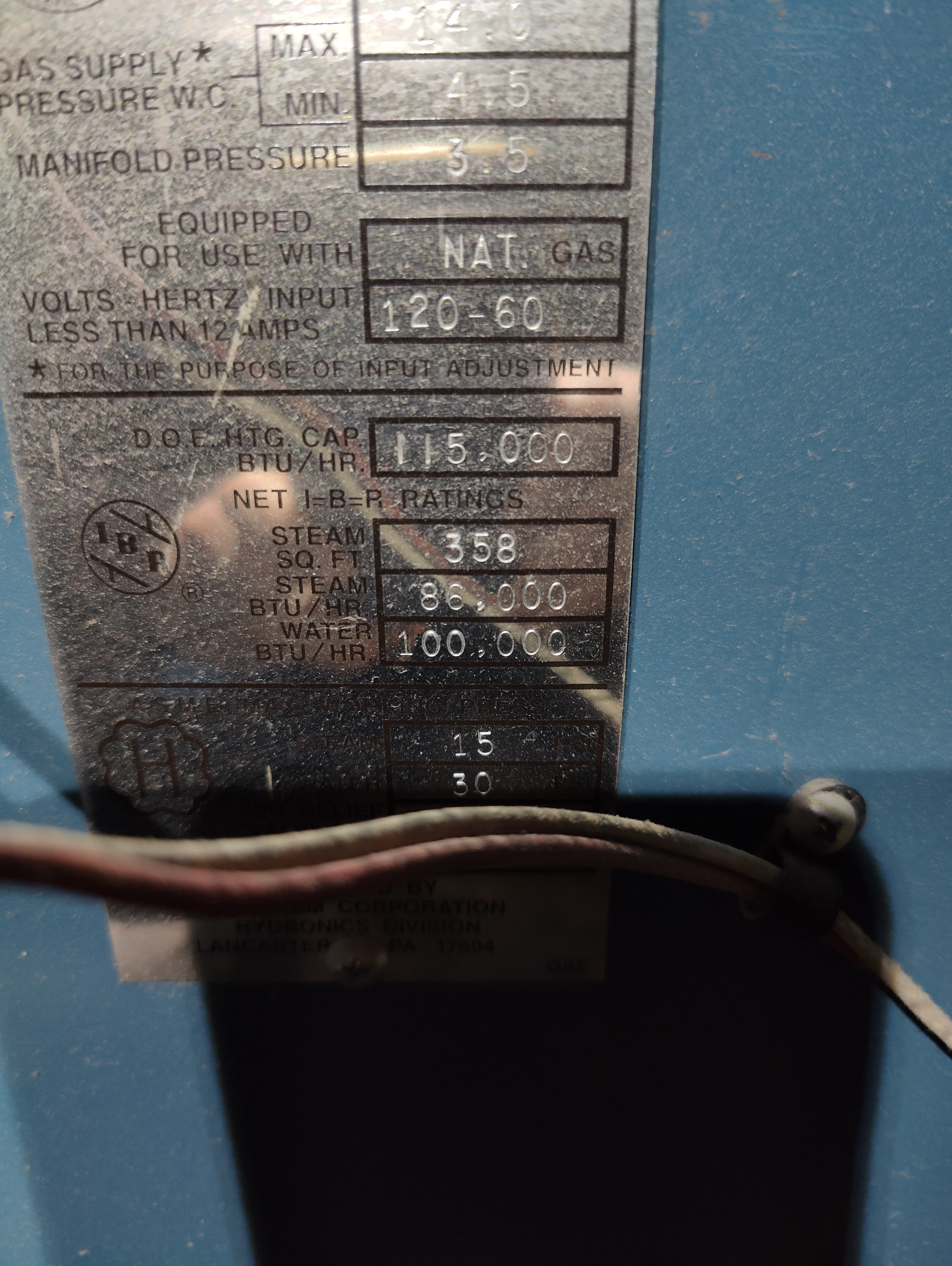

the gas equipment include the steam boiler, hot water heater, gas dryer, range/oven. How to find the min and max inlet pressure, and BTU input for each? what does Firm/Duel Fuel Rate mean?

0 -

I followed the supply main but didn't see any air vents or plugged T like said in the book.

Could those vents be located in those sections above the ceiling or behind the drywall?

0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I signed the forms back but the clerk replied that the table need to be filled up, because they are missing that info on their end. May be their policy is being enhanced.

The steam boiler rating label has more than one btuh, which number should be included in that table?

0 -

@paulga , clearly you need a pro. Where are you located? We might know someone whop can help you………

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

Brooklyn, New York. that said I'd prefer doing the form myself, rather than having a plumber bill just for the clerk nonsense.

0 -

-

Thanks. So the column btuh is for input btuh, then the column "rate" must be the output btuh.

The supply steam piping directly from the boiler shown in my earlier post, and the vertical riser in the living room as shown below, are not insulated.

Should I wrap these exposed pipings with say 3" batten insulation and aluminum foil tape?

0 -

-

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I found this stuff on Amazon. Where do you add it?

When the lwco is removed, I can transfer some in from the tapping. But after the water is filled up, there is not a port for adding this cleaner.

0 -

the numbers match the rating labels. I have filled the table and sent to the clerk.

0 -

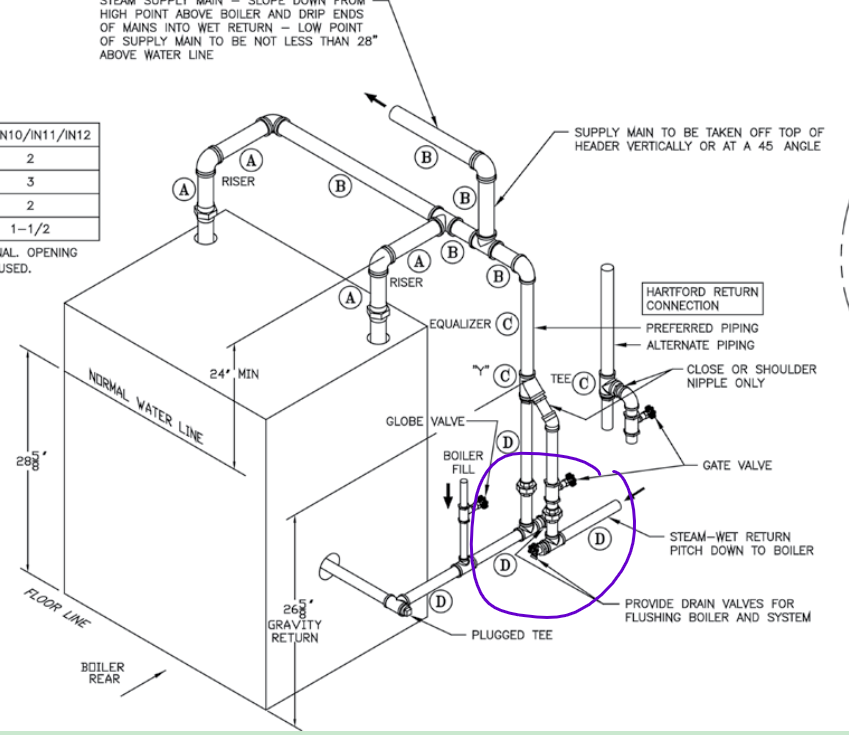

This is the return piping ends where the rust flakes and crud settle. Other than the plugs A and B, I haven't found any shut off valves that isolate the return sections for pressure cleaning. How to clean out the crud from the inside of the return piping?

0 -

-

they are the steam return piping at the back of the boiler

roughly this area

0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thanks. Is there corrosion concern in coupling a brass valve to a steel fitting? My search returns a "dielectric nipple", is this often used in the trades?

0 -

-

Thanks for confirming.

Right under the so called hardford loop there is also a stand pipe cut short and capped that I labeled as C. What was this piping used for?

0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

This is the form I sent to the clerk. She told me today -

"After reviewing the load letter, the BTU load amounts are too large for the existing pipe to carry, which means a new service will be required"

The existing pipe as I heard on the phone is 1". Is 315,100 btuh really too large for 1" pipe to handle, or did I fill wrong information?

0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

The home has two stoves. There is a gas stove in the basement kitchen area that is not connected to gas. I thought to include all equipment.

they opened the pavement just outside of front door when they capped the gas line two months ago. so the gas main goes along the street under the pavement, and the distance to my gas meter is about 10ft?

if the gas main provides outmoded low pressure gas, that's the only choice. what do they need to do to deliver high pressure gas?

0 -

If the gas main is low pressure, you size your pipes to deliver the right amount of gas at that pressure. Simple.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

The front yard is concrete paved 10 years ago. Do they need to dig it all up to upsize the pipe?

They didn't ask one thing when they capped the line. Now they have so many questions for reconnection while the actual gas pipe and equipment have remained the same.

0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

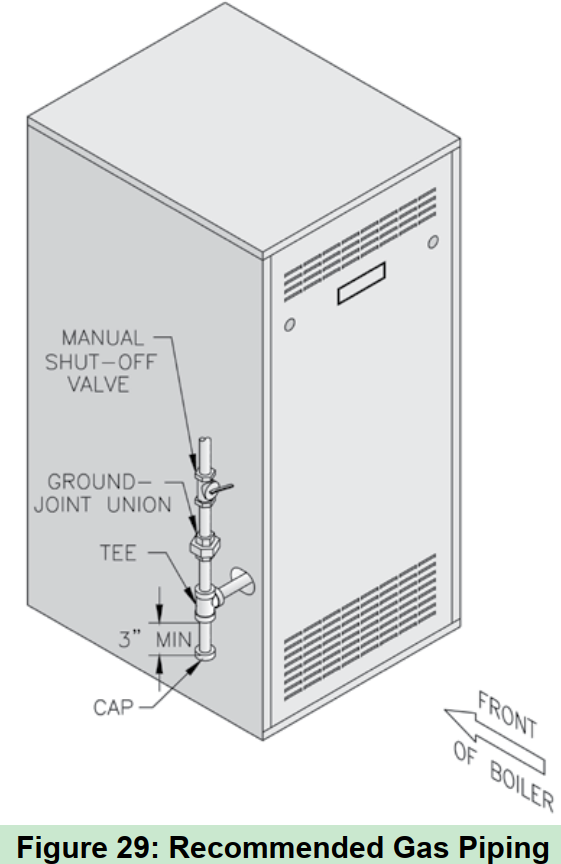

the 3" minimum sediment trap as required on the manual is missing on the inlet piping. is this important to have this trap?

It is present in the hot water heater gas inlet.

0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements