Burnham boiler question

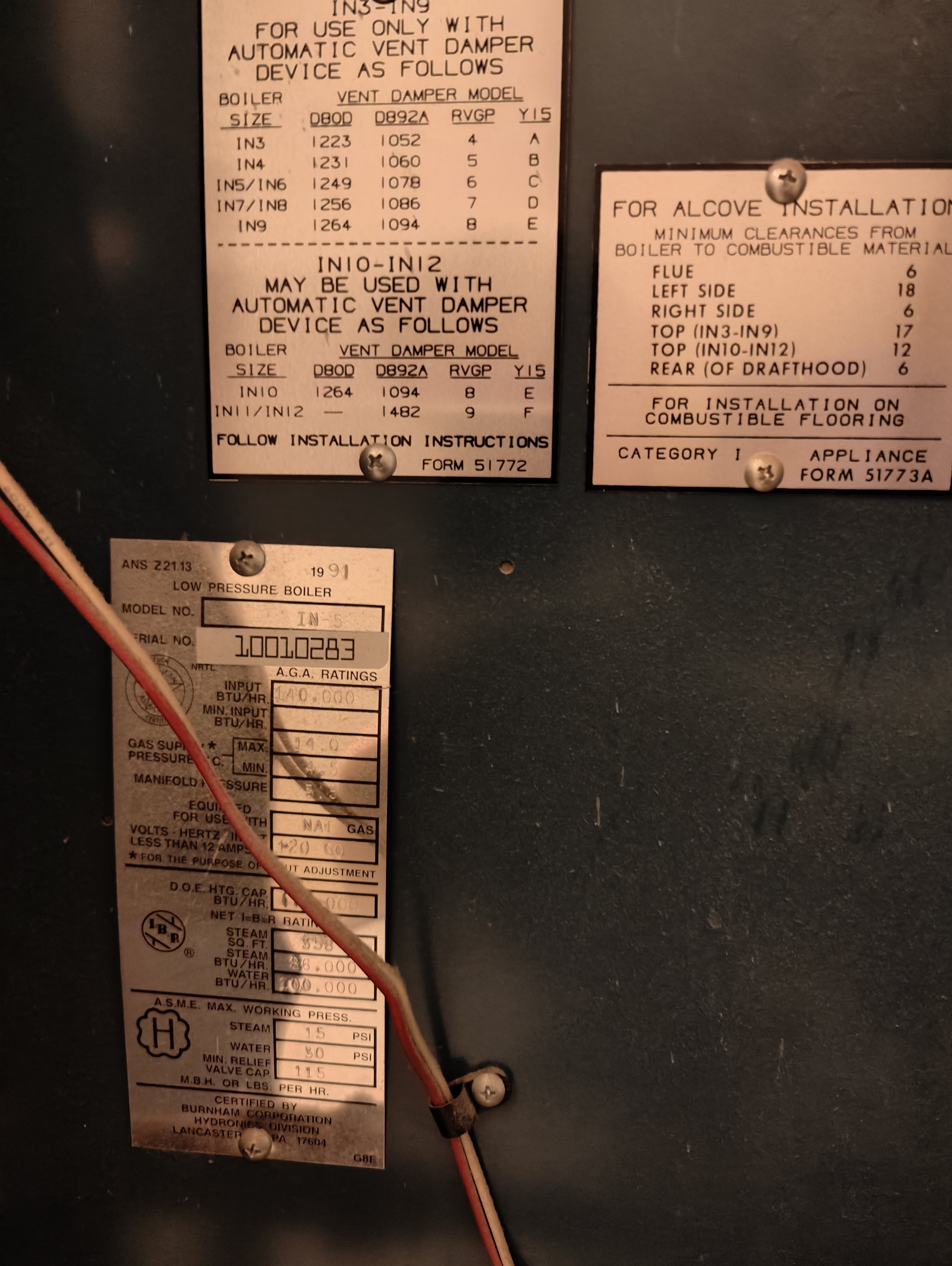

I have an old Burnham boiler made more than 30 years ago. The manufacturer did not respond to my inquiry for the user manual, so I'm posting my questions here.

I have marked the water flow direction based on my understanding. The pipe where I marked "hot water" should be hot steam output, but further splits left me confused on what is going where.

How to turn on this boiler for a test run?

Thanks

Comments

-

The pipe circled with the question mark is closed off by the ball valve with the yellow handle. If you are new to this boiler I would recommend getting in a professional to walk/talk you thru everything.

The valve is closed for a reason. Maybe your coil is bad and it will immediately over pressure/flood the boiler.3 -

-

-

-

-

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thanks. I have got the kindle edition. One night is not enough though.

The boiler is in a townhouse that I have not moved in. The gas company will turn on the gas next Fri. I placed a space heater in the boiler room, and already shut the main water gate valve in the basement to prevent freezing damage. Though the inside temp is not likely to drop below freezing, to be safe, I want to also drain the boiler today before the cold snap hits tomorrow.

So the question is, how to properly drain the boiler and system piping?

0 -

The easiest approach is to turn on the power switches and turn up the thermostat. That can only be done, once the gas is on. I am not sure why you want to drain the boiler. And I am saying this only in a constructive manner. From your questions, it is very clear that you do not have a very good understanding of the system. But hats off to you for wanting to learn. With some minimal reading, I am sure that you could become well acquainted with your system and all of its intricacies. But before that point, it might be advisable to have a professional come down and check things out. Particularly on a 30 year old boiler.

1 -

A cold snap is on the way and the outside temperature will drop to 14f tomorrow night. Since the house is not properly heated yet, water pipings are subjected to freezing risk. So I closed the water in and drained all faucets. I'm considering the same preventions on the boiler and water heater, at least make sure they are not filled up to capacity. Do you mean the boiler will not damage from warer freezing?

0 -

I drained about 5 gallons. The glass gauge is completely empty now. The water level was in the middle of the glass, and the initial drain was brownish color.

What does each of the upper and lower gate valves do? Both are in full open position.

The manual only mentions the "lower (gauge glass) fitting has a small drain valve (for draining samples)". The small drain valve and the red gate valve should be different things.

0 -

The red valves just close the top and bottom ports, handy if you break the glass and don't have a replacement.

But it's not realistic (but I suppose it is possible) for us to teach you everything you need to know about a steam boiler…earlier in the thread it seems you didn't know it was a steam boiler.

If you're going to drain 5 gallons, you might as well drain it dry if you really think the basement is going to freeze. And every pipe connected to this boiler that is lower than this part is water-filled unless you drained it so beware:

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

It looks like the yellow handled ball valve is closed to prevent upward water flow from mixing with the water heater output, so it works as a separation between the potable hot water and the contaminated boiler water system, correct?

0 -

I have already left the building.

Didn't bring the winterization fluid with me. Hopefully the p traps or toilet bowls will not get cracked. I'll see next weekend.

0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

-

-

I thought that broken handle was shut off and then broken intentionally.

the "Programmable water feeder" only has a momentary FEED switch, how is it supposed to be programmed?

0 -

It's wired to the low water cut off. If the LWCO is functioning properly it will trigger the feed. I noticed in an earlier picture that the service switch if open/off?

Miss Hall's School service mechanic, greenhouse manager, teacher, dog walker and designated driver

0 -

I am only guessing at the reason that valve is there but some folks thought that adding cold water to a hot boiler would somehow damage the boiler

There is a notion that still persists today, that water in the water heater has already had some of its air driven out of suspension due to the heat, so that would be less corrosion triggered inside the boiler. I don't know if it's true or not, but it's rather common to pipe makeup water from the domestic hot water.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

I think that it's because people are worried about thermal shock.

0 -

yes. I will turn it on this Friday when the gas service is scheduled to start.

under what conditions is the momentary Feed switch used?

0 -

Silly people

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

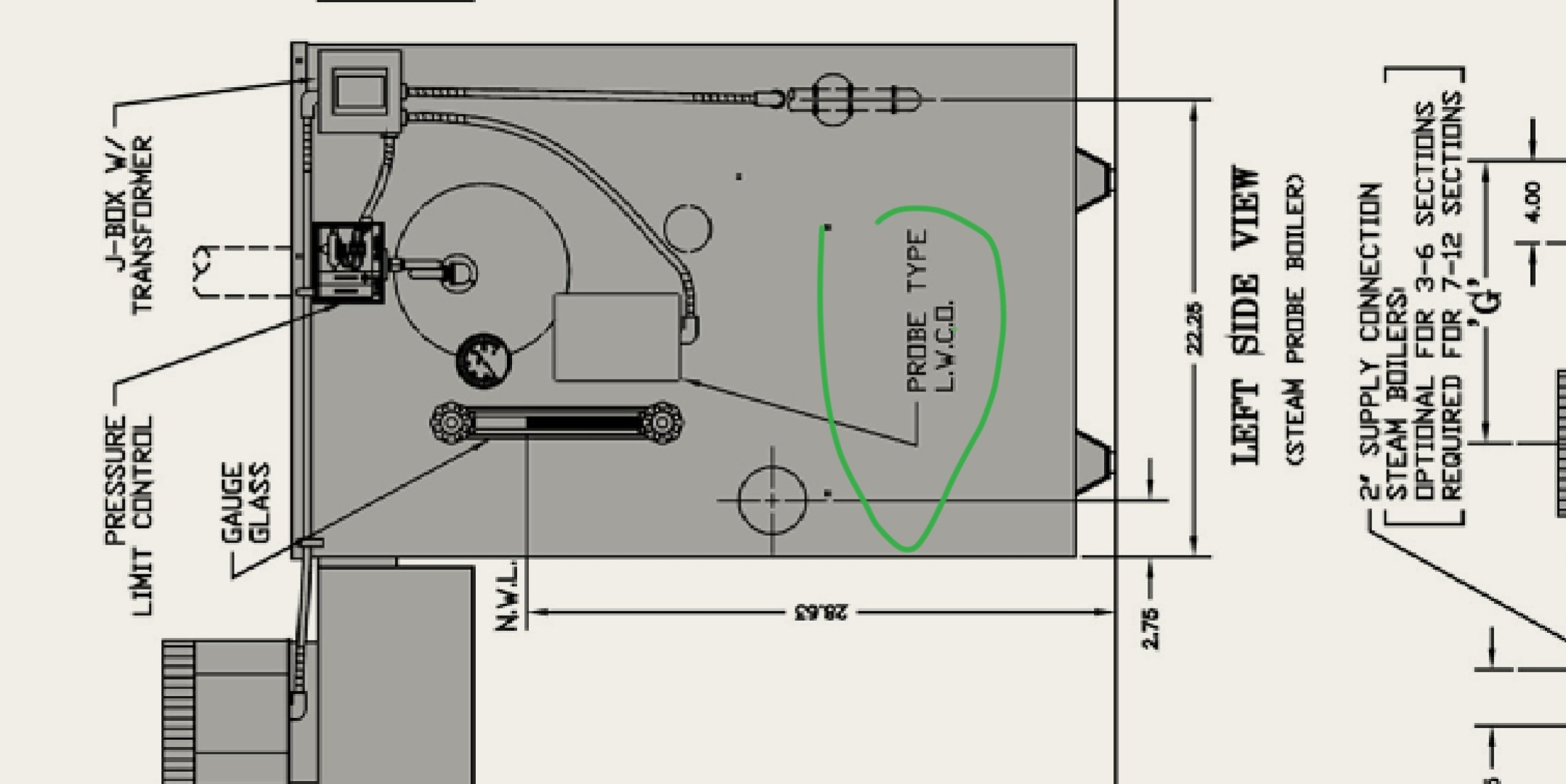

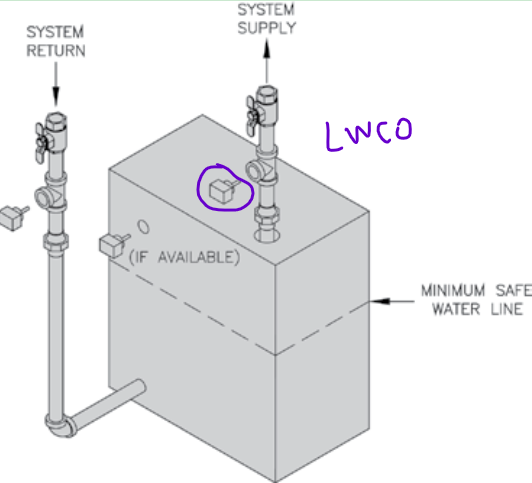

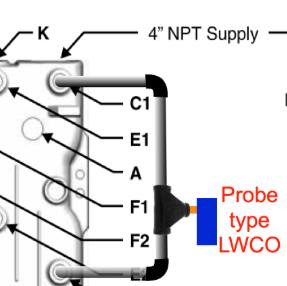

Haven't started. I was reading the manual in your post. It says the boiler has a probe type lwco device that should be inspected and maintained annually. Based on the plot, this seems to be the device under the psi gauge, correct?

0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

The books mentioned the accumulated sediment can lead to isolating the water from contacting the cast iron.

Is it possible to physically scrape the mineral deposit off of the cast iron?

0 -

-

It's not a business, it's more like a public service 😅 but thank you just the same!

The "mud" can definitely add up over time, perhaps to the point where operation or efficiency is affected. My original boiler in my house did have this sediment and I could never get it all cleaned out…I used 8-way boiler additive over time to remove a lot of it, but when I took it out of service it was clear there was still a lot of gunk in there.

However, I don't think it affected my boiler very much. I wouldn't put any acid into any boiler as a matter of principle. It might help clean it, but it also might cause removal of iron that would be worse than just leaving it a little dirty.

If you asked me, I would add a little 8-way to free up some of the scale/sedimented rust and to increase the pH a little in order to slow future rust creation. When you do that, it makes the water look more muddy (since the mud is brought into solution), and you may have to do several cycles of draining, filling, adding a little 8-way until the water starts to stay clear).

When the water is clear with some 8-way in it, that's when you will have minimal new rust creation, but it's a process to get there.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Is the valve where I drained in my quoted post the same as the "valve at the bottom of the mud leg" mentioned in the book?

What does a mud leg look like?

0 -

The gas technician came yesterday but was not able to turn on the gas. He told me the inlet pipe needs repair service and the company will submit a working permit to the city. so it will be weeks to wait.

I already filled winterization fluid to the p traps and toilet bowls. last weekend I already closed the water main valve and drained all faucets, but yesterday when I tested the faucets, there was still abundant water flowing out, so I let all the water drained out again. There could be water remaining inside the piping that couldn't be drained completely. do you use something like an air compressor to blow out all the remaining water?

1 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I have a metabo pancake 6ga 4 cfm at 90psi. It should work at 30psi using a garden hose to pneumatic adapter, connected to a faucet and leaving other faucets open [to avoid potential misleading, refer to the next post for correct guidance]. I will keep an eye on the temperature and do it if it becomes too cold.

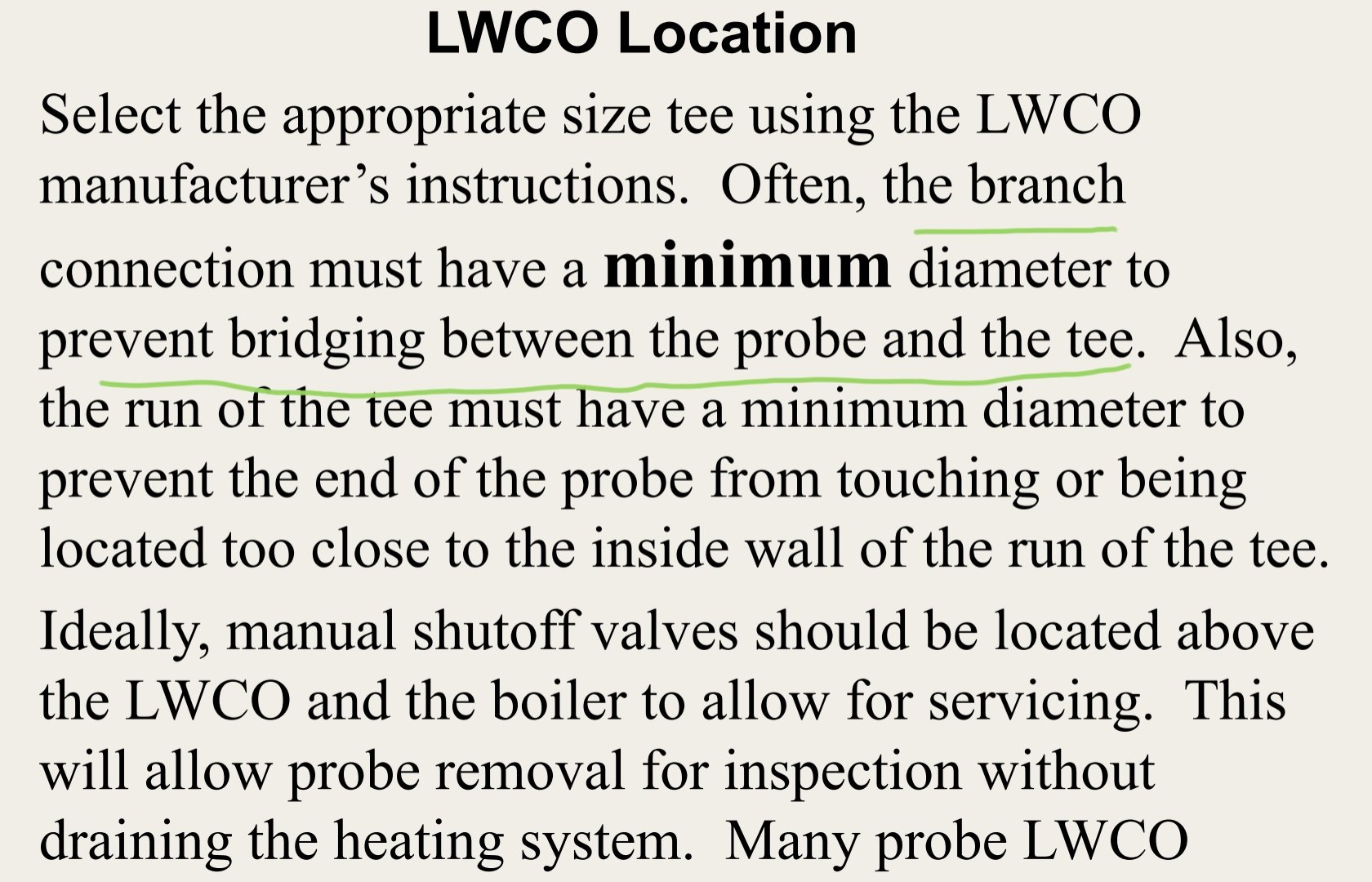

One question from the manual. I know a little about run and bull but didn't fully understand some language. What does bridging b/t the probe and tee mean?

0 -

-

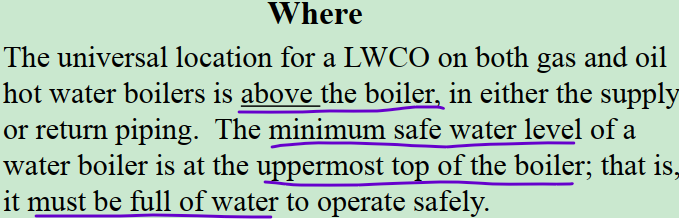

the manual says the min safe water level is the uppermost top of the boiler, that is illustrated in dashed line in the plot. does this say the min safe level is also the max water level of the boiler, because the boiler is "full of water" at this level? I thought the lwco should be brought in at the same dashed level, but its position in the plot is way higher

my boiler does not have a "lowest permissible water level plate" on the jacket left side panel. what level in the gauge glass should the water be filled up to?

0 -

-

So that plot is a water boiler, that why the shut off valve is above the lwco.

what level in the gauge glass on my steam boiler should the water be filled up to?

0 -

-

-

the shape of the T is interesting, it's the first time I'm seeing this.

when I see the U shaped piping joined with elbows without swivel parts, I always think they are hubbed.

are this triangle T and the two street elbows joined with lead oakum (hubbed)?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements