Burnham boiler question

Comments

-

Yes. I measured the od of the gas inlet pipe and the exposed thread and got 1.0468", so it's 3/4" npt.

Should I buy this 3/4 x 4 inch black steel pipe and a cap?

https://www.homedepot.com/p/STZ-3-4-in-x-4-in-Black-Steel-Nipple-300-34X4/1005350310 -

Another question is, (I have not blown water using a compressor), with the main water valve off and all faucets drained, every weekend when I visit, there will be abundant water from the faucets in the basement and on the first floor. So I drain these faucets every weekend, but there will be water available again from the faucets the following weekend. Why does it take those latent water a long time to arrive near the faucets?

0 -

You should call a professional

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I thought the water was hiding somewhere.

The faucet on the second floor (top) remains having no water since I turned off the gate valve at the water meter. I checked the gate valve, it is already tightened by hand. If not, water should distribute to all floors, rather than just bsm and first floor.

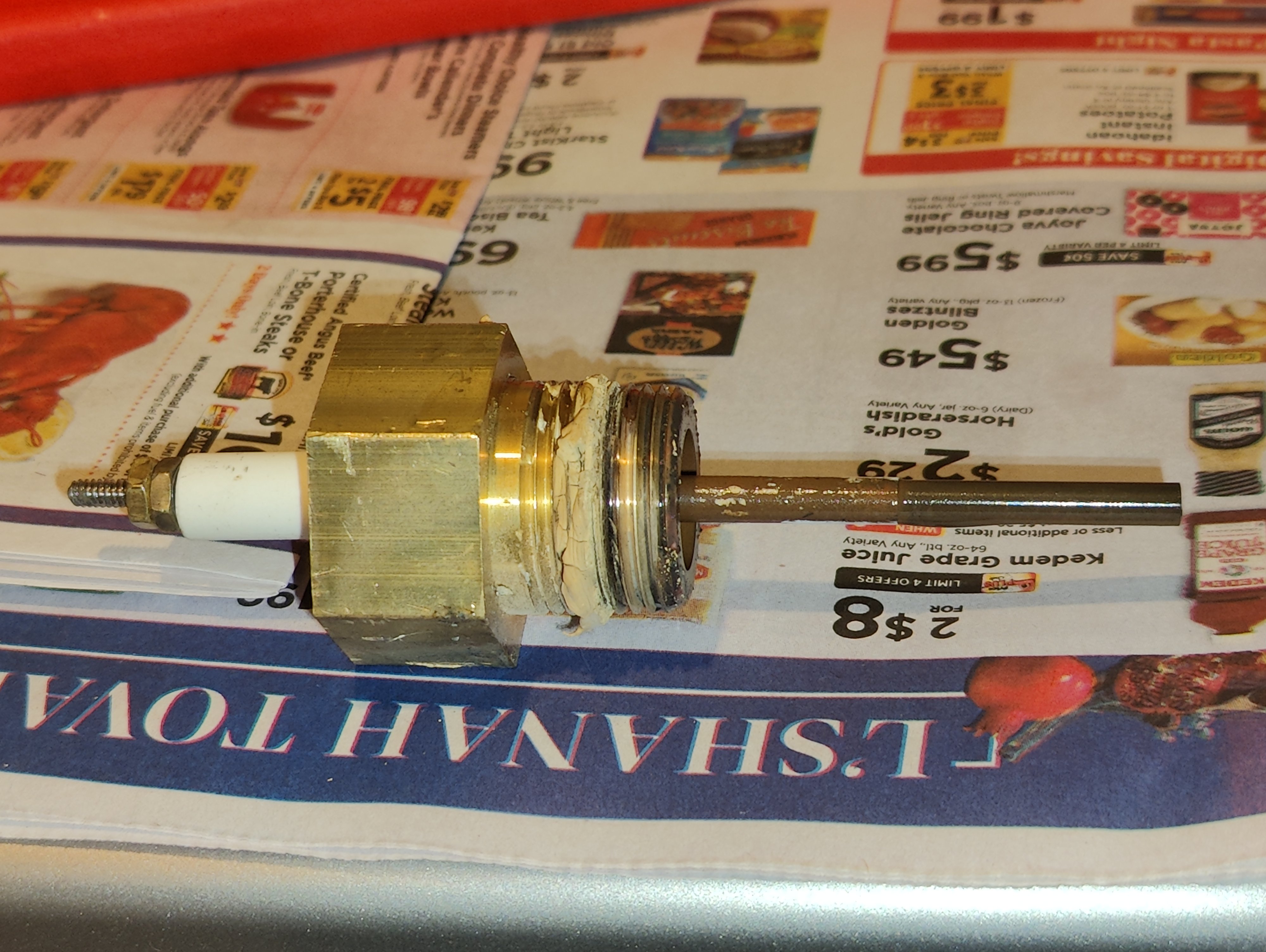

Btw, I removed the lwco probe. After some scrubbing with scotch Brite, the probe shows the color of cooper. I'll take wire brush next time to clean the threads, also bring the pipe dope and Teflon for reinstall. The inside of the tapping shows lots of rust and corrosion, will take pictures of that too.

0 -

-

the manual says the vent damper has a spring loaded blade that only opens when tstat calls for heat (p27) and closes when the call is satisfied (to prevent exhaust backup? ). But this vent damper is not wired to the transformer. how can it open?

0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I think you are saying the factory jumper plug on the vent damper receptable inside the junction box.

with the jumper, the gas valve does not need wait for the damper's cue to open.

I'm still confused because the damper blade should be normally shut. Is it likely jammed physically at the fully open position?

0 -

-

I overlooked the "remove the damper" part in your previous post.

the boiler has been working this way for at least a decade. The damper blade should be constantly open, correct? what I want to ask is how to peek into the inside to verify.

0 -

-

Thanks. I'm more hands on and careful than my questions may sound. I will take a look next time. I'm only there every weekend.

could you highlight the sections of the piping that need insulation in the photo below? The riser, header, further riser and main, equalizer?

0 -

-

Thanks, this looks authentic work

around unions are PVC union covers, not fiberglass tube, correct?

I was planning to use ceramic wrap for those transitioning

0 -

You should call a professionalEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Ed, is this radiator sufficient for a 2nd floor bathroom that is about 5'x7' with a height of 8'?

The radiator has 4 columns and 4 sections, with a height about 1'7"

0 -

The gas company mandated that the gas load form need to be completed by a plumber. Could you guys recommend one in the NYC area?

0 -

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

-

Thanks!

more recommendations please, guys?

0 -

They never replied to my email, or give me a call, even though the customer service told me that a plumber will call me within the day. Any other recommendations?

0 -

—0

-

@JohnNY ?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

@paulga I got your email last night. I suppose I could have responded sooner but in New York City this is not a small task you’re asking. Honestly, I’m not even sure I know what you’re asking. You sent me a form to sign taking responsibility for your self-written load letter to National Grid for gas authorization? We’re going to pass.

Thank you.Contact John "JohnNY" Cataneo, NYC Master Plumber, Lic 1784

Consulting & Troubleshooting

Heating in NYC or NJ.

Classes0 -

Thank you for your business.

0 -

I really can't believe that I need to teach a DIY handyman how to use a wrench. I have a 6 year old grandson that knows how to use a wrench. Are you really asking me how to use a wrench? If you do not know how to use a wrench already then I need to stop giving you advice on how to do any of this stuff.

Please forget everything I ever typed to you. I am going to go back now and delete everything I typed on this thread. You have a way of scaring me that I have never felt before.

Do you know that you are literally playing with fire in your home? I’m not talking about a pack of matches but a real burn your house down size fire right inside your home. I can not be a part of this anymore. I’m sorry that you fooled me this long. I can't do this. Please forget everything I ever typed on this thread.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Thank you for your help.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements