copper pipe feedback

We just moved into an old house with steam heat. A new boiler was installed just before we bought the house. Reading on this forum (and the book) about boiler installation it sounds like use of copper pipes can cause problems. I attached a few photos. Does this use of copper piping seem ok or am I in for eventual trouble? We are also encountering some loud banging in parts of the house but that is probably for another discussion. Thanks for any input!

Comments

-

-

You bet. Here are a couple more. The installation just happened in September so only installed

a couple months ago.

0 -

-

That boiler looks huge.

Get Dans book's and educate yourself

Store | A Pocketful of Steam Problems (With Solutions!)

Store | We Got Steam Heat!: A Homeowner's Guide to Peaceful Coexistence

1 -

I have the book. Just arrived yesterday which is part of the reason I am having concerns. We were initially super excited that our house had a brand new boiler. Now that is turning out to be more of a problem. We are in Lawrence, Kansas. A few weeks ago I called the people who installed the boiler to complain about loud banging and non-responsive radiators and their solution was to crank the PSI to 8. Obviously I have learned that this is the worst solution and it raised my alarm that there are likely other troublesome things that they did. I would LOVE some suggestions of people to call in the Kansas City surrounding area. Help!!

0 -

the boiler looks huge and the pipes look tiny. I hope you negotiated the replacement in the price of the house. Not only is it piped wrong but judging form the size of the mains that boiler is several times oversized. It is likely a total redo.

0 -

Oh no! The new boiler was actually a selling point of the house. Obviously we had no idea that the installation was flawed and assumed it was done properly and would serve us for decades. It is a big old Victorian house (maybe 4000ish square feet) with around 12 radiators spread over two floors. So you think the boiler is too big for the house and needs to be replaced with a smaller unit? Is there any way to keep this large (and brand new) boiler and re-pipe it properly or is that just asking for trouble?? Really appreciate the feedback and hoping someone has a reliable steam person in the Kansas City area that we can reach out to for help.

0 -

You would need to add up the EDR of all the radiators in the house and then look at the rating plate on the boiler to know if the sizing is even close. Given the piping, I doubt they know how to size and probably just went off the old one, but the EDR numbers would tell the story. If you need help with this, let us know, it's easy and we can walk you through it.

Do you know if this is one pipe steam or 2 pipe steam? Pictures of a radiator will tell the story if you aren't sure.

Can an oversized boiler be made to work acceptably? Yes it can, but expectations need to be realistic about performance. You should be able to get it to heat quietly and comfortably even if oversized, it's just going to take some figuring out.

That said, that boiler piping will not allow any amount of fiddling to get there. What is truly infuriating about this is that manufacturer actually sells a piping kit for those boilers to help the contractor not screw it up.

Post a pic of the rating plate for the boiler we can look up the proper piping. It's not just about pipe arrangement, there is also pipe sizing. That boiler should have a 3" header, you currently don't even really have a header. It's a mess, got to think baby steps here.

I would not have high expectations that the contractor will make any effort to correct this even though they should. I'd be prepared to spend some money, if you can find a contractor that is either knowledgeable or willing to listen to direction on what needs done.

Couple things to always keep in mind along this journey. Steam should heat comfortably, evenly, and quietly/silently. Don't let anyone tell you otherwise. Steam making noise should always be considered a cry for help.

5 -

you might see where the disclosures from the seller gets you too. if they said that worked right, obviously it does not but if you can recover anything for that or not kind of depends on how much effort you have to put in to it, small claims court or them voluntarily doing it probably is feasible, if lawyers have to have more than a little involvement then that will likely cost as much as the fix.

0 -

Whoever did that is clueless about steam and probably too proud to read the manual.

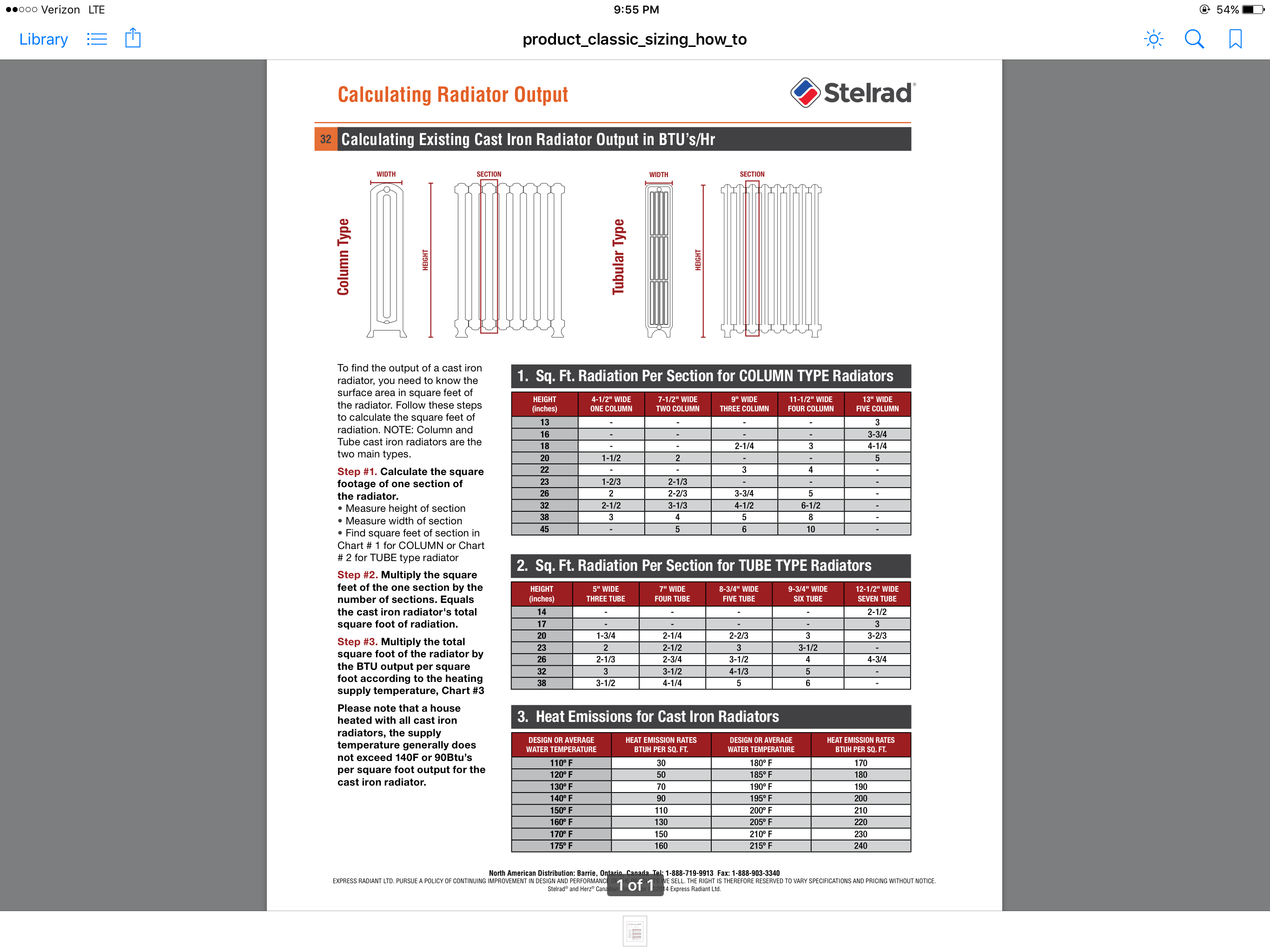

Attached is a chart for determining the EDR (surface area) of your radiators. That will determine their btu output.

Once you determine the square footage of your radiators, compare that to the “square footage” rating on the boiler tag to see how closely they match and let us know.

As mentioned, there’s really no excuse for that piping mess when the manual clearly shows how to do it and the manufacturer offers the header kit with all the necessary pieces pre-cut and threaded.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

it could be the right size but unless those 12 radiators are monsters it likely is very oversized. If piped and controlled correctly it will work but will run very short cycles.

is it 1 pipe or 2 pipe?

0 -

Here are a couple photos of a couple radiators. One was re-piped by the same contractor who did the botched installation of the boiler and I notice there are copper lines. The other looks like original piping. I will get photos of the other stuff that was requested shortly. The house is pretty big (sq footage prob closer to 4500) with very high ceilings (maybe 11 foot)… not sure if that plays into things or not. Thanks to everyone for all this help, even though I want to crawl into a corner and cry.

0 -

Oh, those are convectors. You will need to find some specifications for that model convector to figure out the edr of the convector.

It looks like it is 2 pipe air vent but it might be some sort of vapor system that someone incorrectly added air vents to. Is there a brand name on the convector element or cabinet?

Do all of the convectors have radiator vents on them?

0 -

I have opened and looked at at least 1/2 of the radiators (just learned they are convectors) and all of them have the bullet shaped air vents. I didn't see a brand name on the convectors that are currently opened but I will check some others. For what it's worth, a couple of the convectors were not generating any heat a couple weeks ago but started working once the old bullet valves were replaced with new ones. Also, attached is the spec info that is on the side of the boiler.

0 -

This thread might help to determine the EDR of those convectors. If you take the measurements and compare to some of the information in the below thread that should give the EDR of the system. If you get stuck, just let us know and we can assist. I'm not well versed with convectors, but plenty of others are.

That boiler is rated for 717 sq ft of steam, 12 convectors similar to the picture, my money is on oversized, and not just a little.

That boiler is to have 2-2" risers into a 3" header. There is sort of a header there, but it is not arranged correctly, and almost certainly not 3".

0 -

maybe the boiler isn't as oversized as it initially looks depending on how big the other convectors are.

What happens to the returns from the convectors in the basement? Do they all individually drop down to the floor and connect to a return at floor level? That seems like a weird way to do a system that is probably from the 30's or so.

Maybe it was floor standing cast iron radiators that were replaced with convectors in the 50's or so.

0 -

Based on other changes made to the house, my money is on floor standing cast iron radiators that were replaced in the 1950s or so. That would make total sense.

It looks to me like the returns all snake along the ceiling in the cellar and join into a main line that goes back to the boiler. Definitely no pipes running along the cellar floor.

0 -

Are there steam traps under each convector in the basement? There needs to be some way to control the amount of steam that goes in to the convectors so that it doesn't pass through in to the returns. That could be a steam trap on the return or some sort of orifice or metering valve on the inlet. Some convectors have built in orifices.

0 -

Maybe built in steam trap?? I honestly don't know and don't see anything obvious in the basement.

Regarding the EDR calculation for the convectors, do I need to measure the actual convectors or the exposed portion of the case that encloses the convectors? The cases are different sizes so I imagine the convectors inside are variable sizes too. Some are floor mounted and a few are located higher up on the walls. The convectors all appear to be partially recessed into the walls. Sorry if this is a dumb question about the area to measure but I tried reading through some threads and couldn't figure that out. Certainly won't be my last dumb question either. Really appreciate everyone's input/guidance!

0 -

Some others might have some rule of thumb to estimate the edr of convectors, but you really need to find the manufacturer's catalog for those convectors. The size of the element, number and size of fins, and height of the cabinet all affect the output. The cabinet draws air up and through the element so with the cabinet the element has far more output than it would just sitting in free space.

0 -

I looked again and really can't find anything about the manufacturer. I attached a close up photo of one of the area of fins. The convector portion with the fins on this one measures 40" long x 6" deep x 2" tall… in case that helps. There is variation through the house but those are the dimensions of one in the living room. There is another of identical size right next to this one.

0 -

The charts shown in the other thread should get you close enough to determine the output of your connectors.

A steam boiler (unlike a hot water) must be sized to match the connected radiation, not the estimated heat loss of the structure. However, the estimated heat loss can give some degree of guidance in determining how the original sizing was done.

I’ve been doing heat loss calculations for 45 years and my guess would have been that the original heat loss for your house would have been around 35 btus per square foot. Your boiler is sized at 38 btus per square foot. Again, that’s an experienced guess, but probably not far off.

Again, please calculate the EDR of your radiation based on the charts in the other thread and let us know what you come up with.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Based on that other thread, I think I am supposed to measure the enclosures? Then those numbers need to be slightly adjusted? I am likely wearing out people's patience but below are the raw numbers for the convector enclosures along with some associated info. If you could let me know if these are the required values (and if they need adjustments), I will take a stab at the EDR calculation.

Everything listed as Height x Length x Depth in inches. Depth is distance from the wall. Most are partially recessed unless noted.

33.5 x 38.5 x 4.5 (floor)

21.5 x 46.5 x 2.5 (floor)

21.5 x 46.5 x 2.5 (floor)

21.5 x 46.5 x 2.5 (floor)

21.5 x 46.5 x 2.5 (floor)

33.5 x 38.5 x 4.5 (floor)

22.0 x 66.5 x 4.5 (floor)

27.0 x 36.5 x 2.0 (wall/bottom of enclosure is 83" above the floor)

14.0 x 18.0 x 4.0 (small, free-standing unit in a bathroom)

22.0 x 44.0 x 7.5 (floor/not recessed in wall)

26.5 x 36.0 x 6.0 (floor/likely not recessed in wall)

26.0 x 36.0 x 2.0 (wall/bottom of enclosure is 10" above floor)

26.0 x 36.0 x 2.0 (wall/bottom of enclosure is 42" above floor)

0 -

Please convert those to EDR using the charts in the other thread as a guide.

It doesn’t have to be perfect.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

The ones that are recessed, measure the depth of the cabinet, not the depth protruding form the wall. you can stick a wire or a thin stick like a paint stirrer or something through the grate to measure to the back.

0 -

I don't have a ton of confidence that I did it correctly but if I use the Dunham chart and account for "semi-recessed," "free standing," and "wall hung" and then select the closest dimensions in the table, my total EDR is 380. Does that seem reasonable?

Here are the revised enclosure measurements with total cabinet depth…

33.5 x 38.5 x 9.0

21.5 x 46.5 x 6.75

21.5 x 46.5 x 6.75

21.5 x 46.5 x 6.75

21.5 x 46.5 x 6.75

33.5 x 38.5 x 9.0

22.0 x 66.5 x 8.5

27.0 x 36.5 x 9.0

14.0 x 18.0 x 4.0

22.0 x 44.0 x 7.5

26.5 x 36.0 x 6.0

26.0 x 36.0 x 9.0

26.0 x 36.0 x 9.0

0 -

Unless i missed something, the dunham chart only has 4" deep cabinets and most of yours are at least twice that deep so they will have significantly more output than that chart. The t&b chart has 7.5" deep cabinets which is closer but if most of yours are 9" deep they will be more output than you'd get from that chart.

0 -

Haha, I figured I would probably screw this up. This is all way outside my knowledge base. I looked at the other chart just now but the values didn't seem like a great fit based on my measurements of the cabinets. If I select the closest values I got 616.50 but I still don't have too much faith in that number and that I did it correctly. I may have a lead on a contractor in my area. I guess I can see if they can come out and help with the EDR calculation unless someone can hold my hand and walk me through it in the meantime.

0 -

Also, this won't come as any surprise to anyone monitoring this conversation but I reached out to Crown Tech Support and they confirmed in writing that the installation was totally botched. They thought the current piping could be removed without damage to the unit. They also thought the proper installation would help resolve some of the hammering throughout the house. Obviously the way it is currently piped also voids any warranty on the unit. This will be very valuable information when I reach out to the contractor who did the installation. Guess the next step is to confirm whether or not the boiler is an appropriate size and, if not, determine how to deal with that added complication.

1 -

I suspect that once you find some table with reasonable approximations for the edr of those convectors you'll find it to be 25%-50% oversized which isn't ideal but isn't the end of the world either.

The book "EDR: Every Darn Radiator" has a lot of manufacturers' spec sheets in it but don't know if it has yours. I don't want to tell you to buy a copy just to find out it doesn't have yours. There are also a lot of catalogs on the website side of this site, it may have your convectors or something close.

0 -

-

If you post a picture of the actual convector cover someone (not me) might recognize them although given the current weather those people are likely buried in no heat calls at the moment.

0 -

At the risk of pushing my luck, I am attaching some photos I took yesterday of the pressure gauges. There is one on the front right side (labeled as "gauge 2" in my photos) and one on the back right side (labeled as "gauge 1" in my photos). It seems like the back one is the one the techs have been adjusting. One company cranked it up to 8 psi and I called in another company and that guy backed it down. I am now learning that neither seems adept at steam boiler work. Can I leave the boiler at these settings for now? I suspect it may be at least a couple weeks before I can get a qualified person out here to start actually fixing things so I will make adjustments myself if anyone sees anything particularly alarming with the current settings. As always, many many thanks.

0 -

we didn't dig in to that after we saw the piping. That appears to be the mcdonnall miller low water cutout and mercury pressuretrol from the old boiler. no idea why they are still there or if they're wired to anything. that mercury switch pressuretrol is probably more reliable than the new one.

the pressurtrol with the cover missing looks like the new one, the differential looks good, you can turn the main down some with the screw on the top but don't go too far or the linkage may fall off. if it doesn't restart when the pressure drops you may need to increase it a bit until it does. as long as it is set under about 2psig with the way the near boiler piping is any more fiddling with it is just rearranging the chairs on the titanic until the piping is fixed.

1 -

Hi everyone- I wanted to provide a quick update and circle back to the original topic of copper piping…

- I met with the contractor who did the ugly boiler installation. He agreed to redo the near boiler piping (and use a kit from the manufacturer) at no cost to me. In theory that is great news if it actually happens, happens quickly, and is done correctly.

- Further exploration in my basement of the other piping running along the ceiling looks like much of it was swapped out to copper at some point. Most is insulated. Definitely pre-dating the work of the current guy. I am wondering if when the old radiators were swapped out for convectors (maybe in the 1950s) if the other piping was changed to copper?? Should I consider having this all replaced? Is the situation "not ideal" but functional?

Thanks!!

0 -

Allow me to be gently philosophical here.

But first — if the folks who did the boiler are willing to come back and repipe it with the kit, that is just marvelous! You may have some good honest people there who may be willing to learn along with you about your system. Be nice to them!!

Second, steam is odd. While there are definitely better ways to arrange things and worse ways, it is truly — and continually — amazing how flexible and forgiving of oddities it can be. This is because it is actually incredibly simple. As @DanHolohan , our fearless leader, has pointed out more than once, so long as the air can escape from the piping and the radiators, and any condensate can flow back to the boiler, and steam get to the radiation, it will work — and work reasonably evenly and silently.

If the boiler is piped reasonably well — and you are on the way to that — all that gets into the mains is steam, so all one has to do make sure than the condensate in the mains can drain somewhere and not back up (that's where water hammer and sometimes cold radiators comes from) and make sure that the steam can push the air out — that's where the vents come in..

Now in your system there may be some complications — particularly in the return piping from the radiators. Unless there is some way to keep steam from zipping through a radiator, it will — and get steam into the return line. Which in turn may prevent steam from getting into other radiators. However, with air vents on each radiator, this may not be a problem — and I'd be inclined to wait and see how it works.

It will work well. Just patience!

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Thank you so much for this feedback. I recently read Dan's book (which was fascinating and super informative) and it has definitely made me more knowledgeable about steam heat. That coupled with the amazing people on this site have made me able to spot red flags and "knuckleheads." Fingers crossed that the near boiler piping do-over fixes most of our problems. I totally agree that it is best to re-evaluate things once that is completed. Thanks again!

0 -

Keep in mind the piping kit isn't 100% full proof, even though it should be if the contractor reads the directions (which they already didn't do). They still need to tie the piping kit into your system correctly, seems easy, but pics we see on here all the time prove that wrong.

For example the piping kit comes with a single tee to go the the system. That doesn't mean you only make one connection to the system, that is if you have 1 main. If you have 2 mains, then the contractor needs to add another tee and bring that main into the header individually.

Not trying to scare you, just advising you stay on your toes with this stuff.

3 -

Yeah, i'll reiterate the 2 or more mains thing. If the mains go off in several directions from the boiler, they should not be teed together at that ceiling but should individually come down to individual tees in the header. There will be some additional fittings and nipples beyond what comes in the kit required to do that.

2 -

Another update for those that have been so helpful and (might) still be interested in our ongoing saga. In another unexpected twist, I found a steam expert in KC who I hired to come out and evaluate our system prior to any more work. He determined that we actually have a hot water system with convector radiators and that at some point in the distant past, someone incorrectly attached a steam boiler to it. I wouldn't be surprised if this happened many, many years ago and the previous home owners suffered through noisy, hammering winters and just chalked it up to being an old house. He drafted a plan to re-pipe the boiler, add a pump, and convert back to hot water. Might actually be less expensive than the near boiler steam re-piping. I feel confident that he knows what he is talking about and that this may remedy our situation. I guess this would remove my initial question from the "strictly steam" forum, haha. Hard to believe this mistake actually happened and wasn't diagnosed sooner, but hopefully we are nearing a solution. If not, I am ready to throw in the towel and install a forced air furnace! I welcome any final thoughts before the conversion back to hot water happens…

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements