Main air vent location

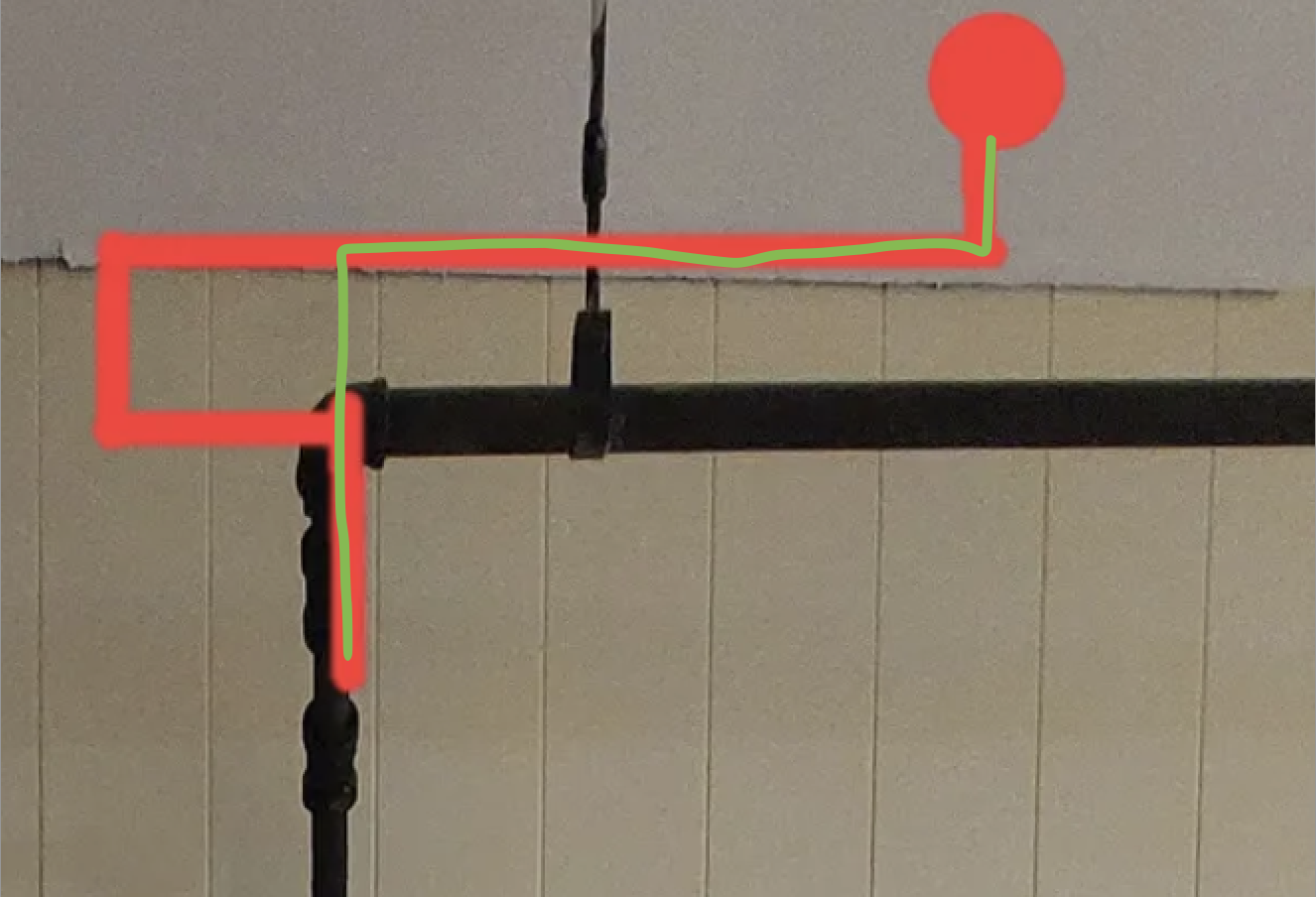

Hello folks, I've got a bunch of mains that need venting and I'll be using B&J big mouths. I understand that it's recommended they be installed 12" before the end of main to protect them from water hammer. Several locations look basically like the photo below I'm wondering if I'd be ok doing it this way:

This I can do myself without paying someone to cut and thread in a Tee in the existing pipe. With the number of lines I have, this is significant savings. I should add that I don't have any water hammer, the boiler is operating at 1.5psi and the pipe will all be insulated.

Comments

-

-

Yes. 2 pipe all parallel flow mains.

0 -

-

I'd run it like this. You will get the appropriate pitch for free if you do it this way, and it's plenty to protect you from the commonly overstated risk (in my view) of "damage from water"

Also note that Big Mouth vents provide a LOT of venting and may be overkill. They require quite a bit of steam to get heated enough to close compared to Gorton, for example, due to their rather massive…mass.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

If you have no water hammer and the rads heat fine, what is it you are fixing. Two pipe systems will vent into the condensate side through the steam trap. Maybe you don't need 'em?

Steward to 1923 Spanish revival near Chicago - 2 pipe steam 650 EDR shiny new Peerless 63-06

0 -

... aside from those being the skinniest steam pipes I've ever seen.

Steward to 1923 Spanish revival near Chicago - 2 pipe steam 650 EDR shiny new Peerless 63-06

0 -

Certainly appropriate to feed a single 2-pipe radiator however

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Thanks Jamie, I appreciate the sanity check. I'll be sure to keep things pitched for drainage.

0 -

-

Yep that's a lot of main!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

There's no hammer but the boiler needs to run for about 3 hours to get heat to these 2 rads which are at the end of a 270' main. I've rebuild the traps with Tunstall capsules which needed to be done but slows venting even more since they don't vent as quickly as the original trap elements. This system started out burning coal and nobody thought to add mains vents when it was converted.

1 -

-

Are you sure this is just ordinary 2 pipe steam? Many vapor systems needed to vent the mains in to the returns through crossover traps and have the only vent to the atmosphere be at the boiler near the boiler return trap.

0 -

I can't say what it was in 1910 when it was coal fired. The mains vent into the returns through appropriately sized F&T traps. The layout of the building (long but not tall with rads, in some places, on the same level as the boiler) necessitates pumped returns with vented tanks. There are some gravity returns that are vented at the boiler feed tank. No sign of a boiler return trap ever having been installed. Regardless it's 2 pipe now with regular pressuretrols, standard radiator valves and thermostatic traps etc. I'm sure it worked great when some forgotten soul would light the coals at 5am so by 8 all the air had worked its way though the traps and the system stayed under pressure until the boss went home.

0 -

Thinking on this a bit more, I wonder if those condensate returns are a bit problematic? They may have been okay to be that skinny when new, but how clear are they now. And the apparent lack of pitch makes me think they may be nearly full of water a lot of the time (and thus corrosion products).

Have you opened any of these lines and tried to blow through them (with compressed air)? I have some unpitched dry returns i suspect of constraining my venting on certain radiators.

Steward to 1923 Spanish revival near Chicago - 2 pipe steam 650 EDR shiny new Peerless 63-06

1 -

You're very perceptive. The floor is deceiving as it has a pronounced bow that makes the return appear backpitched from some angles. There's not a great slope on it but it is slightly pitched in the right direction. Could certainly be better though. Once the line is vented and insulated, I'll reevaluate.

0 -

-

@Gateacre I would pipe the vent as @ethicalpaul said but I like raising the vents up in the air as high as possible.

I would bust the elbow off and put a tee in its place. Come off the tee pointing up as Paul showed the pipe will be crooked due to the pitch of the main pitching down. Put a short nipple on the tee then a 45—-nipple——45 then a long riser pipe—-big mouth vent.

Raising the vent gives it more distance from the water hammer….maybe

1 -

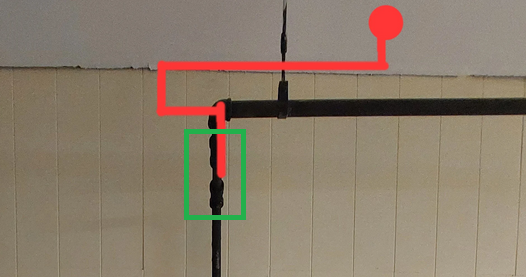

Inside the Green box are those 45s or 90s ? If 90s the vent could be Teed into the one closer to the wall. Which is maybe what you meant with the Red path but the camera angle does not show it well.

If that radiator return pipe is always flooded I'd put the new vent on the return side of the radiator, as long as that existing trap is not actually flooded. That way the radiator actually gets vented. Or just have two vents one for the main and one for the radiator.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

That's 1" on the horizontal with a 3/4" bushing in the outlet of the downward 90. The 3/4" drops about a foot before a short dog leg back toward the wall then down to the valve. I'd like to vent off the 1" in case I need to add more vents than 3/4" can handle, the main is ~270ft long.

The wide lens and bowed floor make the return look super flat but it does have pitch. It could stand to have more but it does drain.

0 -

Ed, unfortunately I don't have the height for that. The white you see is the ceiling. I'm going to swap the 90 for a Tee, come up with a 4" nipple then 90 back towards the boiler for 18". Finally I'll 90 up to a Tee for 2 big mouths since this is such a long main. I've never experienced any hammer on this line.

0 -

OK, I see your point venting the main via the 1" part. I just thought the smaller pipe may be easier to work with.

Will the radiator actually vent through the return ? Just to vent the air from the radiator.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

It's pitched. The floor has a hump in it that fools the eye. I had to check it with a level myself because it looks so flat.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements