1920s Steam System - How to Add Main Vents

Hi,

I'm by no stretch a master at steam heat, but it's been pointed out to me on several occasions that the "main vents" in my steam system(s) have been plugged (I say systems because I have a duplex with separate boilers).

Long story short, I am wondering if A) it's a good idea to replace the plugs with new main vents (something like this) and B) what are the proper fittings and vents that I need in order to properly install main vents again. In one of my units it appears that there is only one plug, in the other it appears that there are two spots that have been plugged. Should any and all plugs receive a new vent?

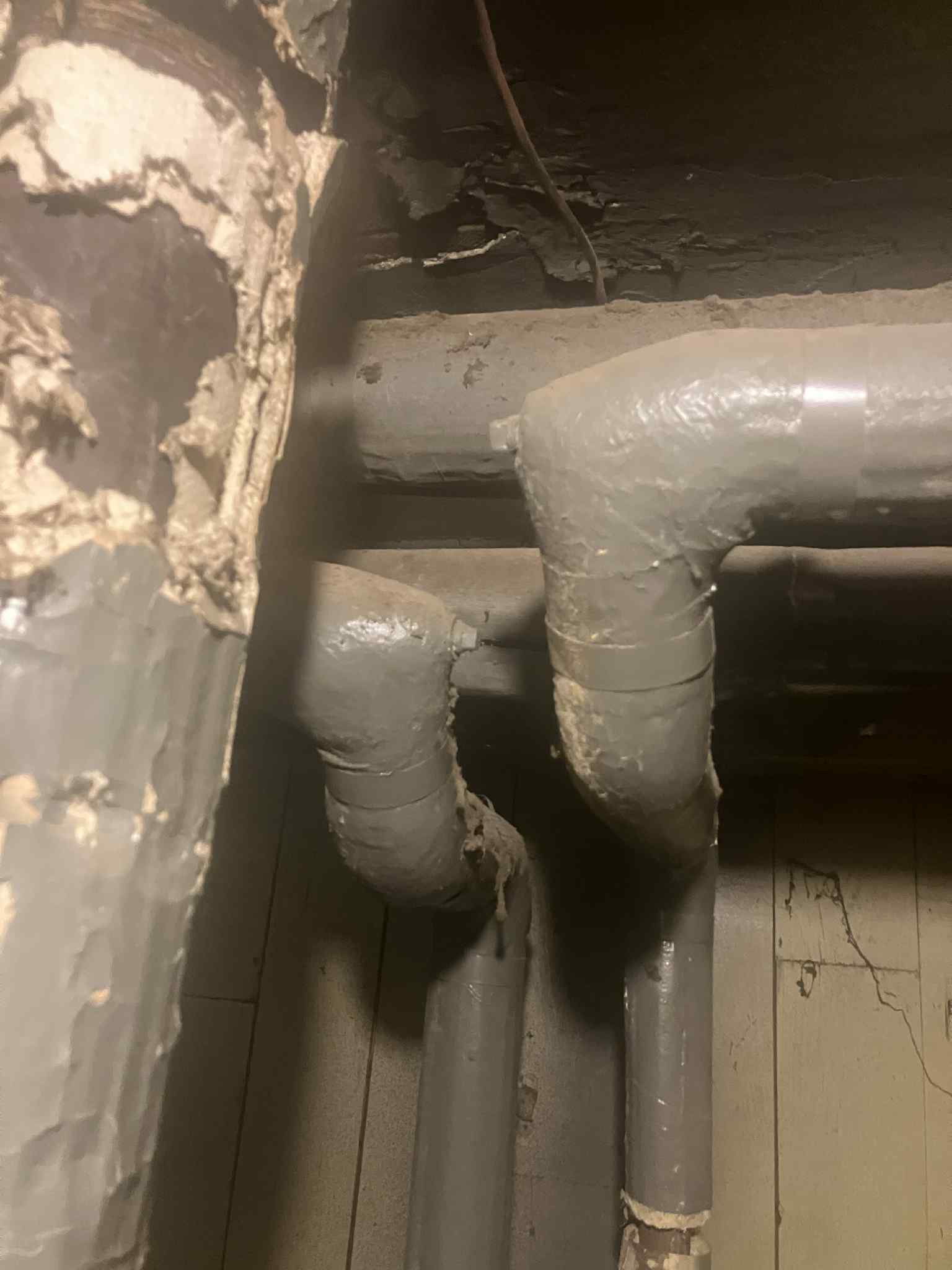

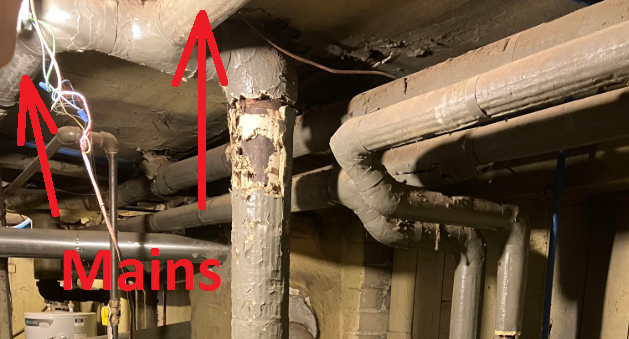

Please see the images below:

Unit A:

Unit B:

Comments

-

-

If there are no other main vents in your system, you would most likely benefit from installing main vents. Have you inspected the actual far end of the mains for vents. At the pipe transition from steam main to steam main extension, often called a dry return (typically the farthest point away from the boiler).

If those (pictured) pipe plugs are removed and those tappings are used the main vent should be offset vertically then horizontally so to minimize any damage from water hammer. Main vents usually have 1/2 or 3/4 inch pipe threads.

If there is more than one main from a single boiler, each main should be vented to best balance the venting of the steam mains.

Gorton #1 and Gorton #2 and Barnes & Jones Big Mouth BJ-2BM / BJ-3BM are popular main vents.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Does this installation look correct (just found this on youtube)? It has a small horizontal fitting, a 90 degree fitting, and then the vent itself is installed.

0 -

-

If I'm understanding correctly, from the dry line I should go:

- Short pipe meeting size of plug diameter

- 90 degree fitting

- 8" - 10" riser

- Bushing

- Vent

Or combine 1. & 2. with a male to female 90 degree fitting

0 -

Do you know of any thermal grade wrap that I could put on there? I believe that's what my inspector recommended way back when I bought the house.

0 -

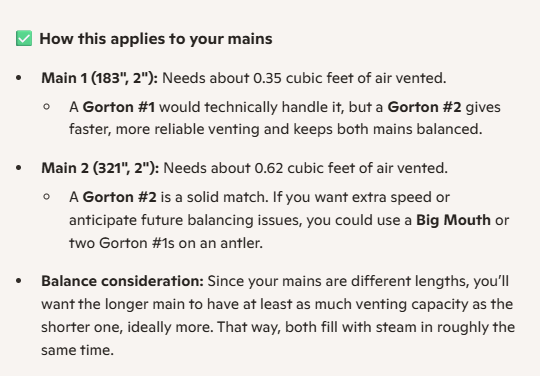

How would I decide what size Gorton I use? or main line vent in general

0 -

Something like this. The amount of venting depends on the size and length of the main and if any balancing is required with multiple mains of different length from the same boiler. Fiberglass pipe insulation.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

» The amount of venting depends on the size and length of the main

I would rephrase that:

The amount of venting depends on the ability of the boiler to provide steam. When pressure builds up before the main is hot all the way around, then you know you need more venting.

The steam can only go as fast as it heats the main above the boiling point of water.. you need enough venting to accomodate that, and more doesn't help.

What @109A_5 is saying is true in the sense that the main is typically sized for the system, and the boiler is sized for the system, so ideally it comes to the same thing.

A Tee with two vents on it is a good idea in any case because when one fails you'll still have heat everywhere. Below is my setup, with one Gorton and one Maid-o-Mist main vent, and it's plenty for my 2.5" 80-foot-long main. The MoM is a screaming bargain and lets plenty of air out. I went with a Gorton first because that's what all the cool kids get.

cheers -m0 -

Measure the length and diameter of each main and post the figures here. We can tell you what you need.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

This statement is also system dependent.

" The amount of venting depends on the ability of the boiler to provide steam. When pressure builds up before the main is hot all the way around, then you know you need more venting. "

My system never goes over 2 inches of water column regardless if the main vent is used or valved off. The predominant benefit (main vent versus no (or poor) main venting) is with a hot main the steam will propagate faster, purging the air out as fast as possible, filling the main with steam as fast as possible.

You want enough venting so when the mains are hot the steam will fill the main as fast as possible. There is a point of diminishing returns. Since even with a hot main the steam will only move so fast.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Ignore the beautiful electrical work going on connecting my thermostat and boiler. Could you help me understand which is my "main"? Thanks.

0 -

The "main". Start with the pipe coming straight up from the T on the side of the boiler in the first picture. That's the beginning of your main, and it remains a main all around the basement until you get to the very last radiator takeoff. It may split, in which case you now have two mains…

And it needs to be vented, which can be done anywhere after the last radiator takeoff and before it drops to the boiler.

Now it looks as though you have at least two drops — they're also in that first picture — and it looks as though one of them may have a pipe from a near floor level pipe, which probably picks up a drop somewhere else in the basement. Problem. Those to drops join above the water line, and that may give some problems. Have to see more to know.

Problem number two: the insulation on those pipes has asbestos…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

-

This would have been ok on the original boiler with a water line that was above this point, it is not ok with this boiler where it is now above the water line as @Jamie Hall said.

I thought i was looking at a mirror for a moment until I relaized there were 2 boilers.

0 -

If it means anything, as @mattmia2 noted, there are two boilers (house is a duplex), and the boiler in subject supplies heat to the 2nd floor of the house and nothing on the first floor, just for what it is worth.

Also, it sounds like you are saying that neither of these plugs are part of the line that would be considered the main.

The issue that you are both signaling, I presume has been there for a long, long time. I had to have a thermopile replaced on this boiler last winter, and the HVAC co. laughed when they realized how old my boiler(s) are (1970 - 1975 or so). I guess the point is… not knowing how much time I have left on these boilers, is it even worth doing anything at this stage on either the drop issue you are talking about, or adding vents to my main?

I plan to just wrap the insulation where there is asbestos, I don't see a reason to do anything else.0 -

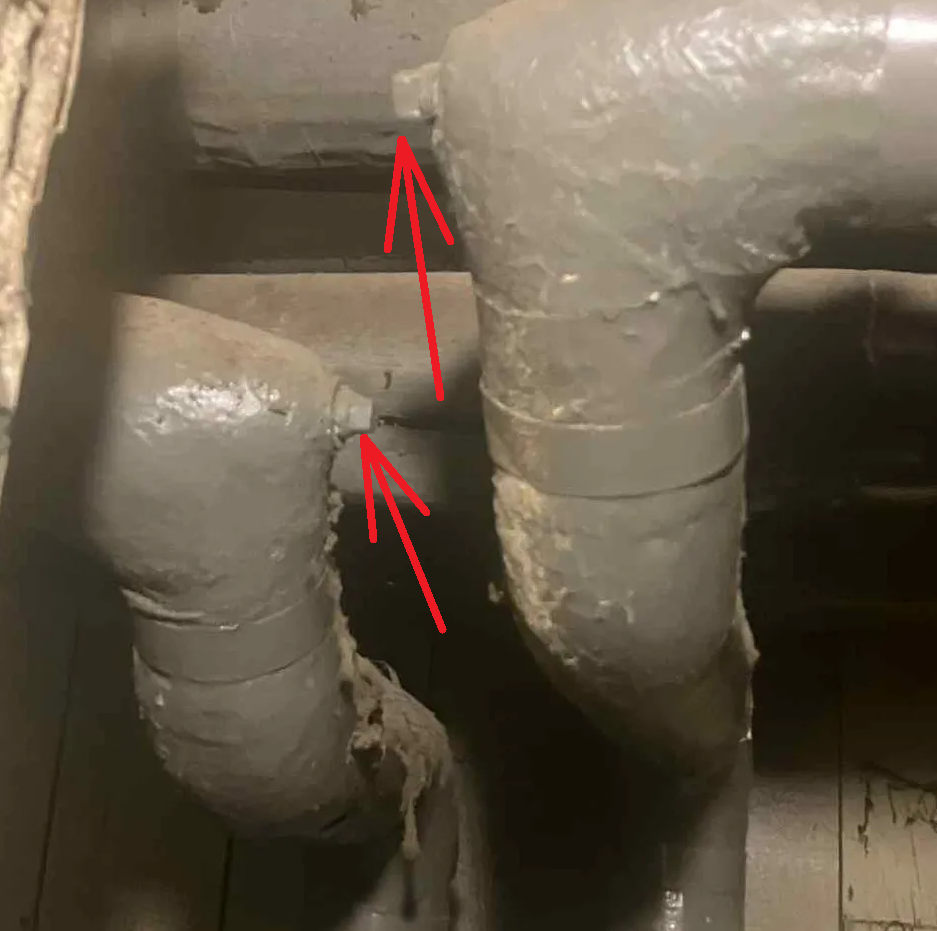

Those are probably dry returns/main extensions and those plugs are probably where the main vents were. Without main vents you will have the problem that having the returns connect above the water line causes all the time, namely that the air can't get out of one (or in this case both) of the mains.

That asbestos looks like it would come loose if you tried to wrap it in something.

0 -

-

Unless there are presently vents at the far end of the mains, the vents could be added here.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Thanks everyone for the help, learning a lot here.

To answer this question:

- The line that goes off to the right the right (from perspective of @109A_5's photo) measures about 183" or 15' 3" before it returns

- The line that goes to the left measures 321" or 26' 9" before it returns

- It's hard to tell because of the insulation, but I believe the mains are 2" in diameter. The return pipes are smaller, probably 1.5".

Let me know if this makes sense. One challenge that I am foreseeing is that there is limited space to work above these pipes if I am installing vents here, particularly with the pipe on the left (in picture below) as the main for the other boiler runs right above it.

0 -

-

There are no vents at the end of the mains presently from what I could tell.

0 -

-

Any advice on removing these small plugs? They are square and appear to be less than a 1/2" in diameter (I haven't actually measured yet). I briefly put a crescent wrench to one, but it felt a little bit delicate. They do not appear to be imbedded in the lagging, for what it's worth.

0 -

-

those are just cast to an approximate size, they aren't an exact size or frequently even the same size one set of faces to the other.

0 -

Some have a taper to the square also. A file may help fit it to a socket if needed. I think a firm grip of a socket is better than a adjustable wrench or a pipe wrench. I'm sure @eddymoney could measure it first instead of just buying any random socket. A 12 point may work too but the contact area may be less.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

To me a shear is more likely to start with less points of contact. I'd heat it first, maybe a few heat cycles, don't burn the house down. I prefer finesse to bull in a china shop almost every time. With restricted access I don't like to make myself more grief than needed to get the job done.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I've done this too many times to count when changing out old radiator angle valves, granted this is a much more confined space. The hole diameter is so small that I might have to use a jigsaw blade. Worst case scenario.

0 -

Okay friends - a couple updates:

I successfully removed the plugs. They happened to be 3/8" diameter squares, so what I ended up doing was taking a 3/8" socket drive bit adapter, placing the female socket side on the plug, and then using a crescent wrench on the male side (with a small piece of 1.25" cast iron pipe for leverage) to remove the plugs and it worked really well. I did add some heat which I think made a difference.

Here's my installs - I think they turned out well, and they were actually pretty fun to do (not as messy / involved as other house projects). I probably could have used a few less pieces but the store I went to didn't have every single side reducer / bushing / etc. I didn't remove any ceiling for smaller vent (I could have to add a taller riser), but I did for the larger Gorton. I needed to move that one out of the way of the main above it, hence the direction - I'm not sure why I used a 45 degree fitting for the first turn, other than that I was thinking it would vent more easily with 45 degree fittings vs. 90 degree fittings (could be wrong and it doesn't matter). I am little concerned that the small street 90's that I had to use for the initial fitting will wear down over time but I could always add some support with like a string to the joists to vent trees / etc.

I'm not sure how to assess how well they work, although I will say I have not heard any whistling from my radiator vents anymore (something that was pretty common before).

vent #1:vent #2:

let me know how they look - I need to do this exercise again for my other unit, so any feedback will help me with that install.

now, for a totally separate topic that seems to be completely unrelated to my main vent installs. I woke up last night mid-morning feeling pretty cold air, and assumed my boiler ran out of water or something (I don't have automatic feeders). It was indeed off, but I had no idea why. I've heard that the "float mechanism" (that turns your boiler off when the water is low) can sometime get stuck, so I lightly tapped this oblong shaped black thing with a hammer and the boiler fired right up - great news so I went back to bed. I woke up again three hours later and once again felt cold air, so I checked the boiler, tapped the black thing again and it once again fired up. This happened once again before I left for church a few hours later.

I could be wrong, but it seems like the float mechanism is getting stuck for some reason. Does anyone have any thoughts on why this might be happening? My boilers are pretty old (probably the understatement of the year), but it seems kind of random / odd. I last flushed my boiler when I first turned the heat on about a month ago.0 -

That float thing can and does get stuck. How often do you blow the float chamber down? That red valve underneath it? You should be blowing that down with a little pressure on the boiler about once a week — open the valve in short full bursts until you get bursts which are more of less clear

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

the machined brass street ell is probably a little more restrictive than a cast one but that can hold 100x the weight that you have there. the offset with 45's is a great way to do it.

0 -

are you blowing down the lwco regularly? the water level shouldn't be falling enough to turn off the lwco.

0 -

@mattmia2 yes, I agree that the brass street 90's seemed restrictive - the store I was at didn't have any cast iron fittings that small (could have used galvanized but I wanted to avoid that).

Thanks guys - to be honest I'm not sure what either of you are referring to (seems like you're talking about the same thing. To answer your question though, no, I've never done that since buying the house a couple years ago. Boiler tech may have when he looked at them shortly after I bought the house. I welcome any guidance you guys have.

Another question - what should the PSI reading look like when the system is running? I'm not really sure that it is reading anything currently as it always seems set at 0.0 -

Unless the water level was low recently I would not suspect the Low Water Cut Off (LWCO). If the float was compromised and sinking the LWCO may not recover from tapping on it.

I suspect the Pressuretrol is set too low for reliable operation. So tapping on the LWCO is actually vibrating the Pressuretrol. Turn the Cut in setting a 1/2 turn to 1 turn up.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Seems logical - technically, the system would have had a lot more "unnatural" pressure previously because there were no vents - is that a reasonable way to look at things? Anyways, I'll adjust and report back.

0 -

A Volt meter would help determine what is shutting down the system.

The McDonnell & Miller #67 LWCO should be exercised often (Red valve below it) to keep the float moving freely.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

is blowing down the same thing as "flushing"? In any event I need to fix the" discharge line" as that has corroded a bit and will empty too close to the boiler itself.

0 -

Blowing down the 67 does flush out the LWCO, it is not the same as flushing out the whole boiler by the boiler's drain valve.

Yes repair the drain piping for the 67's blow down valve and put a pail under it. With your 67 drain so close to the burners I would recommend a metal bucket.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements