Multiple temperatures on single zone with single circulator pump?

Comments

-

Actually no, I would not do that if the OP has an unlimited budget. I would suggest a Taco Iseries valve that has a motorized head with outdoor reset capabilities. 3 way ODR mixing valve 1/2" That way the ODR from the boiler can be set for the high temperature zone(s) needs and change the boiler water temperature based on the needs of that higher temperature heat emitter. 125° boiler temperature when the outdoor temperature is 55° and 180° water to the radiators when the outside temperature drops below zero. The Taco Iseries valves are discussed in this video at about time stamp 4:20.

But the actual valve is discussed in more detail in Part 4 of the series, here

However looking up the price of that Iseries valve that can be used to reset from an already reset higher temperature heat emitter zone, it is a little pricey for someone that is interested in keeping costs down. If you look at the OP's original design, to save on additional costs of things like a bronze or SS circulator, they were asking if the diagram would work. I believe that diagram actually has a mixing valve that is already on the job. That mixing valve is a fixed temperature or manual mixing valve that was used to operate the 4 loops that were existing. When two of the four loops became unusable and unrepairable for reasons not disclosed, the idea of replacing the heat in the area that was serviced by the abandoned loops, could be heated by 16 feet of copper fin type baseboard with a piping design that will clearly not work at all. That design was the brain child of the OP with the idea that only one circulator might work, saving the cost of a second circulator and the associated control. With this in mind I gathered that adding more parts than the bare minimum is not in the OP's budget,

So to answer your question about a fixed temperature mixing valve being the recommended option for the design using 2 circulators… My answer would be YES in this particular case. Sorry to disappoint but I have not been given the option to spend someone else's money.

Although not an ideal way to use the existing ODR water that is feeding that room/zone with two different heat emitters that function completely opposite of each other. (High GPM High Temperature v. Low temperature low flow rate). And there is no “fighting each other”. The lower temperature on mild days will still go through the fixed temperature mixing valve and will cycle based on the room temperature controller (slab sensor/thermostat/etc.) The existing (no need to purchase another one) fixed temperature set at say 120° for those two remaining loops would only mix more of the 140° or 130° water and less of the return water, to get the 120° low temperature water. There would be some reset when the hot inlet of the fixed temperature valve dropped below 120°, which could happen.Then the cold inlet would stay closed and only the lower temperature 110° or 105° or even lower temperature water entering the hot side of the valve would be the only water out the mixed port of the valve. So to put your mind at ease the OP will not need to provide boxing gloves to the mixing valve and boiler reset control to duke it out in the boiler room. This will be a fight free design.

I hope this helps you to understand why my design (drawing C) was not the most effective use of all that is available to make this system as best as it can be. I just wanted to let the OP know that the design (drawing B) was flawed and offer an economical solution. And the diverter valve idea will not work for the reason HotRod stated. one way in and two ways out. not a good plan at all. The design calls for two ways in and one way out. Definitely a mixing valve situation. Fixed temperature thermostatic or manual… must be two in and one out. I believe you will agree with that.

If only @inaun would come back and clear up some of these questions. I guess we will never know.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

" What would you rather? A thermostatic mixing valve with Outdoor Reset? So they can fight each other? "

I'm kind of lost as how they fight each other ? The thermostatic mixing valve just automatically limits the water temperature into the underfloor loops, if needed. If due to the Outdoor Reset the water temperature happens to be lower than the thermostatic mixing valve setting it simply does nothing. Where is the fighting ?

One is local water temperature limiting (thermostatic mixing valve) and one is more global water temperature limiting (Outdoor Reset). The global obviously has priority. Where is the fighting ?

The local (thermostatic mixing valve) limits the water temperature for that emitter type. If the Outdoor Reset limits the water temperature (when it does) below the thermostatic mixing valve's setting the thermostatic mixing valve simply does no water temperature limiting. Where is the fighting ?

@EdTheHeaterMan version 'C' provides the best control so probably the best comfort.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Most 3 way thermostatic need a 20 degree or more differential between hot inlet and mixed output, to maintain a stable outlet temperature. So the ODR could mess with a 3 way thermostatic.

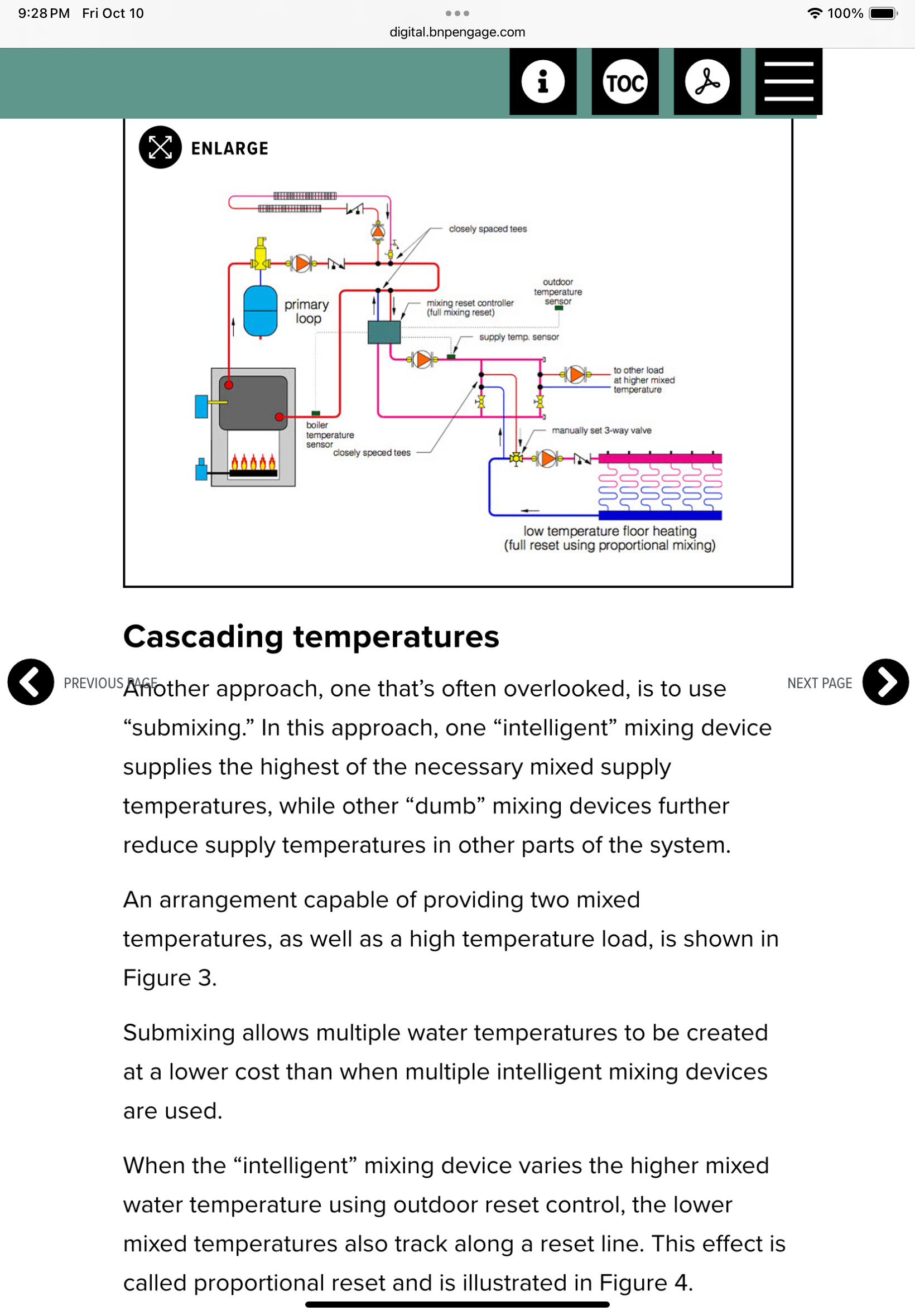

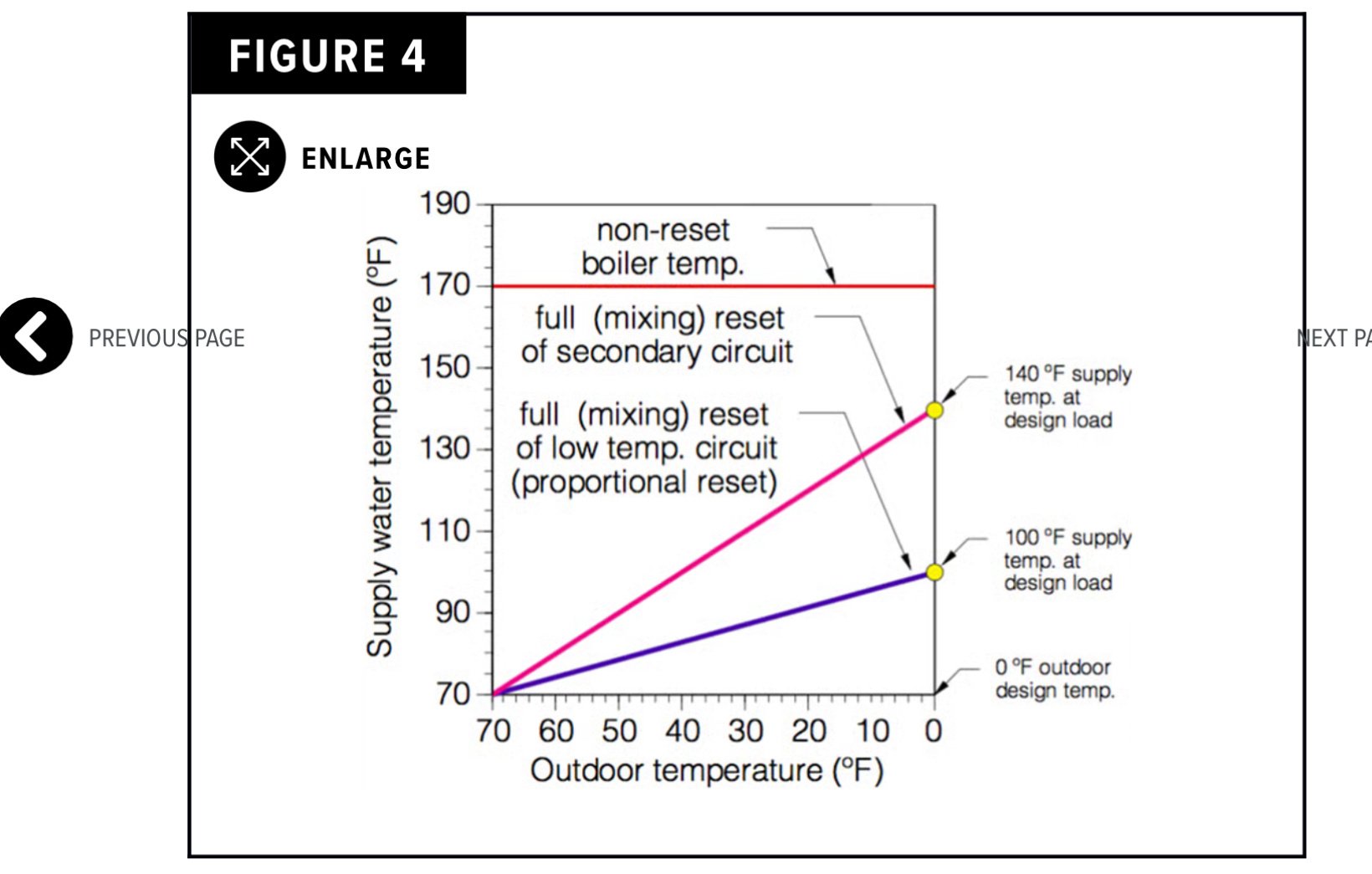

Early on I suggested a 3 way manual mix valve. It would float along with the ODR temperature, called proportional reset. Some limitations with a dumb 3 way…since it is flow dependent, zone valves in the high temperature side would change the gpm flow rate, a dumb mixer could not respond to that condition accurately

But not knowing what SWT the radiant requires at design, the ODR curve would need some trial and error

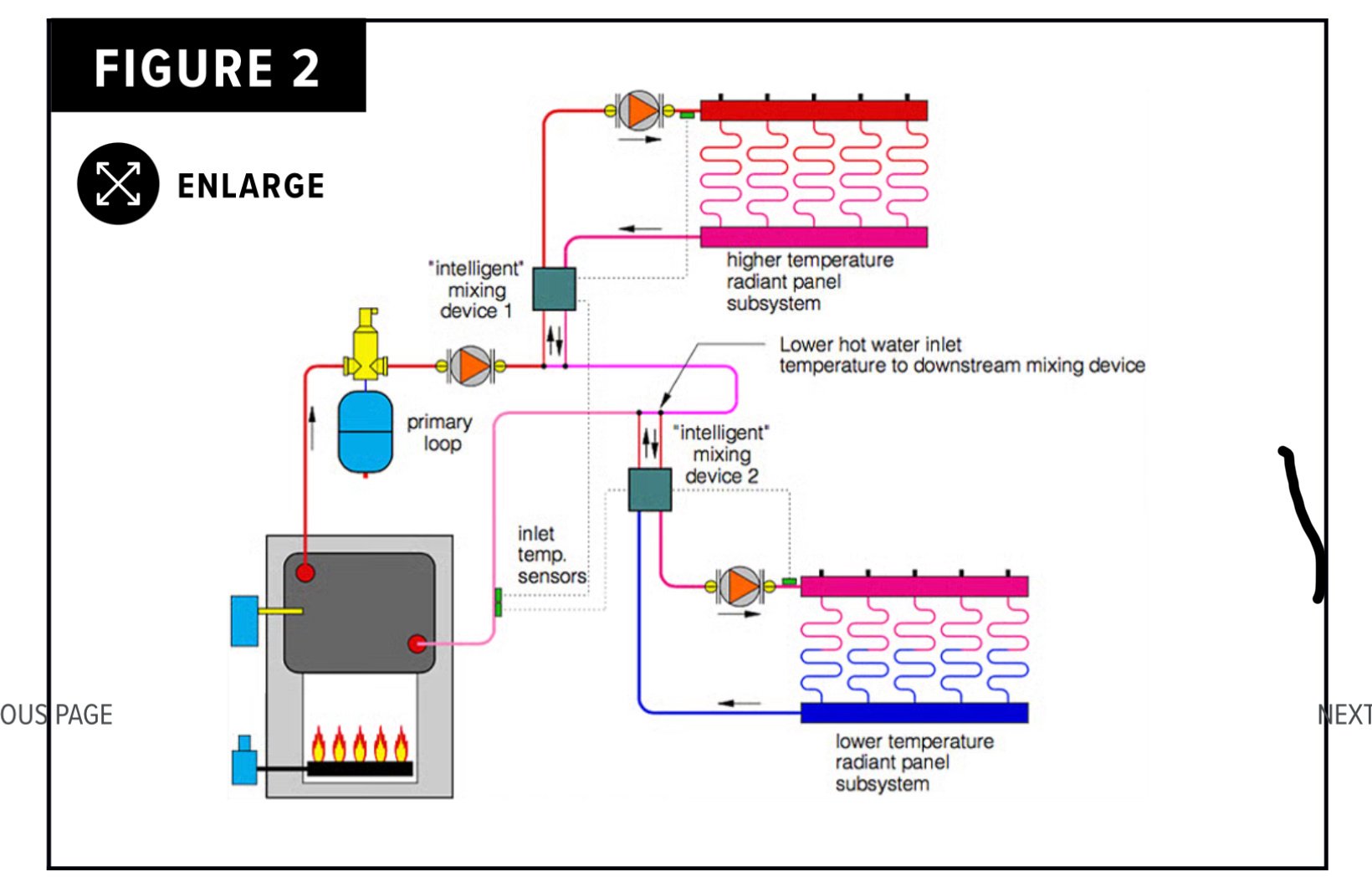

Some examples from a 2003 article in PM ENGINEER by John Siegenthaler

Figure 2 with two intelligent mix valves

Figure 3 one smart, one dumb mixer. The crossover bridge on the mixed loop, with balance valves assures both loads see the same SWT.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

@109A_5 asked: "I'm kind of lost as how they fight each other ?"

It depends on the actual brand and type of boxing gloves you provide. The main types include bag gloves, sparring gloves, competition gloves, training gloves, and specialized gloves for disciplines like Muay Thai and MMA. So determine the type of fighting you prefer your reset water temperature to be doing, select the proper gloves, and there you go!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I'm getting dizzy.

Back on October 5 @EdTheHeaterMan posted three of his lovely technicolour diagrams of this setup. A being the one in place (we think) and B and C being proposals.

Of these, only , with C two pumps wilt be controllable. I agree that Option B, with just the one pump, will work, but there is no way to control the relative heat output of the new baseboard radiation relative to the radiant. If you unwrap the diagram in a slightly different way, you find that the baseboard radiation is on what should be the primary boiler loop of the system ( presume there is a boiler circulating pump in here? We haven't heard much about it…) while the radiant floor is on a secondary loop. The problem being that mixing valve at the takeoff to the radiant, rather than that being just a T.

Use option C and treat the whole thing as a primary/secondary with a mixing valve or thermoostatic valve to control the temperature in the radiant loop…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

@109A_5: "I'm kind of lost as how they fight each other ? The thermostatic mixing valve just automatically limits the water temperature into the underfloor loops, if needed. If due to the Outdoor Reset the water temperature happens to be lower than the thermostatic mixing valve setting it simply does nothing. Where is the fighting?"

OP said the outdoor reset on the boiler has a range of 120F to 180F. The hottest water the floor is ever going to want is probably around 120F. So the water temperature is never lower than the thermostatic mixing valve setting. You have an expensive device on the boiler that varies the water temperature depending on outdoor temperature, then another expensive device on the floor that makes sure it always sees the same temperature. The two devices cancel each other out.

0 -

I was kind of in the impression both expensive devices already exist.

If the boiler water can be in the range of 120F to 180F you want the automatic limiting action of the thermostatic mixing valve.

Cancel each other out ? They work in concert.

" I should have also noted this is just one zone in a larger system. "

Something in the rest of the system may need the 180F. So the thermostatic mixing valve limits the water temperature to the appropriate temperature for that section of the system.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

@hot_rod : "Early on I suggested a 3 way manual mix valve. It would float along with the ODR temperature, called proportional reset. Some limitations with a dumb 3 way…since it is flow dependent, zone valves in the high temperature side would change the gpm flow rate, a dumb mixer could not respond to that condition accurately."

This is exactly what I am proposing, a "dumb" mixing valve that maintains a constant proportion to replace the thermostatic valve that is there. It will require a dedicated circulator on that circuit, but there are no zone valves in this application so the flow will be constant and the proportions will stay constant. I don't see why that dumb valve has to be more complicated than a tee with a balancing valve on each leg.

"But not knowing what SWT the radiant requires at design, the ODR curve would need some trial and error."

The ODR curve will be the same as the rest of the building. The output of any given radiator is determined by the flow rate and the water temperature, or really the difference between water temperature and room temperature. If the flow is constant than water temperature alone controls heat output. If you look at the graph provided by Seigenthaler both the mixed and unmixed curves are straight lines, they just have different slopes.

So if, as the chart implies, the rest of the building meets design load with 140F water, which is 70F above room temperature, with water at 105F, 35F above room temperature, all of the radiators are providing 50% of design load. If the dumb mixing valve is set to provide 100F mixed water when the supply water is 140F, when the supply water is at 105F, the mixed water will be at 85F and will also provide 50% of design load. Same curve.

0 -

I suppose if the OP wants to tinker and constantly make adjustments to stay comfortable. go for it. Plenty of room to experiment with hydronics.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you all for your help!

First off, apologies for the long delay. I have been fighting some personal problems that prevented me from getting back to read/reply.

I did decide to stick with traditional design approach using separate circ pump for the radiator loop. And of course the main loop is not interrupted by the mixing valve — closely spaced Ts off loop. Lots of good information here, and seems not worth experimenting on something that seems unlikely to work well. I really appreciate all of the thoughtful comments!

Comment to a couple of the posts — the mixing valve does properly regulate floor temperature to the set temp, while the furnace itself decides what the loop water temp should be. It's actually not an outdoor reset (though that can be easily added with an optional temperature sensor). Without the reset, the boiler uses some sort of "intelligent" algorithm based on overall system demand. I honestly don't think it does anything from energy saving perspective for the underfloor zones since their temperature is controlled by mixing valves so always at steady set temp. But I can see it being beneficial for the radiator zones.

Sadly, it is all cast iron. And yes, I fight the sludge problem (flushing every year and keeping chemicals in helps). One of the zones was totally plugged when I moved in, and initial flushing to get everything going was a PITA. Didn't really know why I keep getting dirty water until I discovered the PB issue and fact that it is not oxygen barrier. I met the plumber who did the whole thing to begin with, and he admitted it was his "first system" and he made "some mistakes". I've learned since then that basically the whole thing was done wrong. Had I known what I know now, I would have just pulled it all out a long time ago. After replacing the PB, I will have essentially replaced everything except one of the circulator pumps.

The system works properly in some parts of the house, but not in others. Two main is days. The loops were not done correctly, and I've learned that the worst of the rooms has no insulation under the floor (explaining why the basement room below stays sufficiently warm without it's radiator ever running). The tubes do not have heat spreaders, so as you can imagine I don't get nearly enough coming up through the floor. Fixing this would require tearing out ceiling under both rooms, so I'm inclined to abandon the underfloor for those two rooms and use radiators instead.

Second issue, as has been discussed, is I have PB and cast iron everywhere. Installed new boiler a couple years ago because the original was breaking down, and didn't know about the non-oxy-PB issue at the time. I'm starting to replace all the PB with poly to deal with this (as well as the inspection issues I will run into when I sell if I leave PB in place). Fortunately, I have fairly easy access to everything except those two rooms.

I'm now looking more closely at those radiators, and will probably start a new post on it if I can't find my error. I'm having a lot of difficulty believing what I'm coming up with on required length based on BTU calculations…because I've never seen a small room with as much baseboard as the calculators are telling me I need! BTU is calculating around 13,000 for a 138 Sq Foot room. That's 20+ feet per room for a 11 1/2 x 12 ft room! Way more than my original 8' that came from a generic estimator. My neighbor has all baseboard in a similarly built house, with nowhere near that much baseboard in his rooms. And I've never seen baseboard around here that covers two walls of any bedroom. But, maybe I just haven't been sufficiently observent.

2 -

PS, I'm going to do some actual heat-loss calculations since I'm really questioning the online calculators. I can't help but wonder if those calculators are assuming all outside walls.

0 -

-

Since you have existing heating system, the most accurate heat load is from past fuel use. From there you can "tweak" one of the on-line calculators to match this total heat load from fuel to come up with individual room loads to size rads. General rule of thumb, oversizing rads is OK as long as you have a way to turn it down. Larger rads mean lower temps which increases efficiency of a modcon.

https://www.greenbuildingadvisor.com/article/replacing-a-furnace-or-boiler

0 -

Thanks, Kaos. I do have heat loss for the entire house from when boiler was replaced. That is also part of the reason I was really scratching my head on what the online "BTU calculators" were spitting out for heating a single room. I did do heat loss calculation for the two rooms I'll be converting to radiators and came up with much more reasonable BTU requirement that translates to lengths more in-line with what I expected. I do plan on going a few feet longer than calculated, which will actually work well given the way the windows are positioned in the room.

For what it's worth, I also found that online "heat loss" calculators were much more accurate than online "BTU calculators" (curiosity got me, so I played around with this to see what I'd get). Not really sure what those BTU calculators are assuming, but with some quick calculations the only way I could match their estimates was by using all outside walls and using heat loss factors based on very little insulation.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements