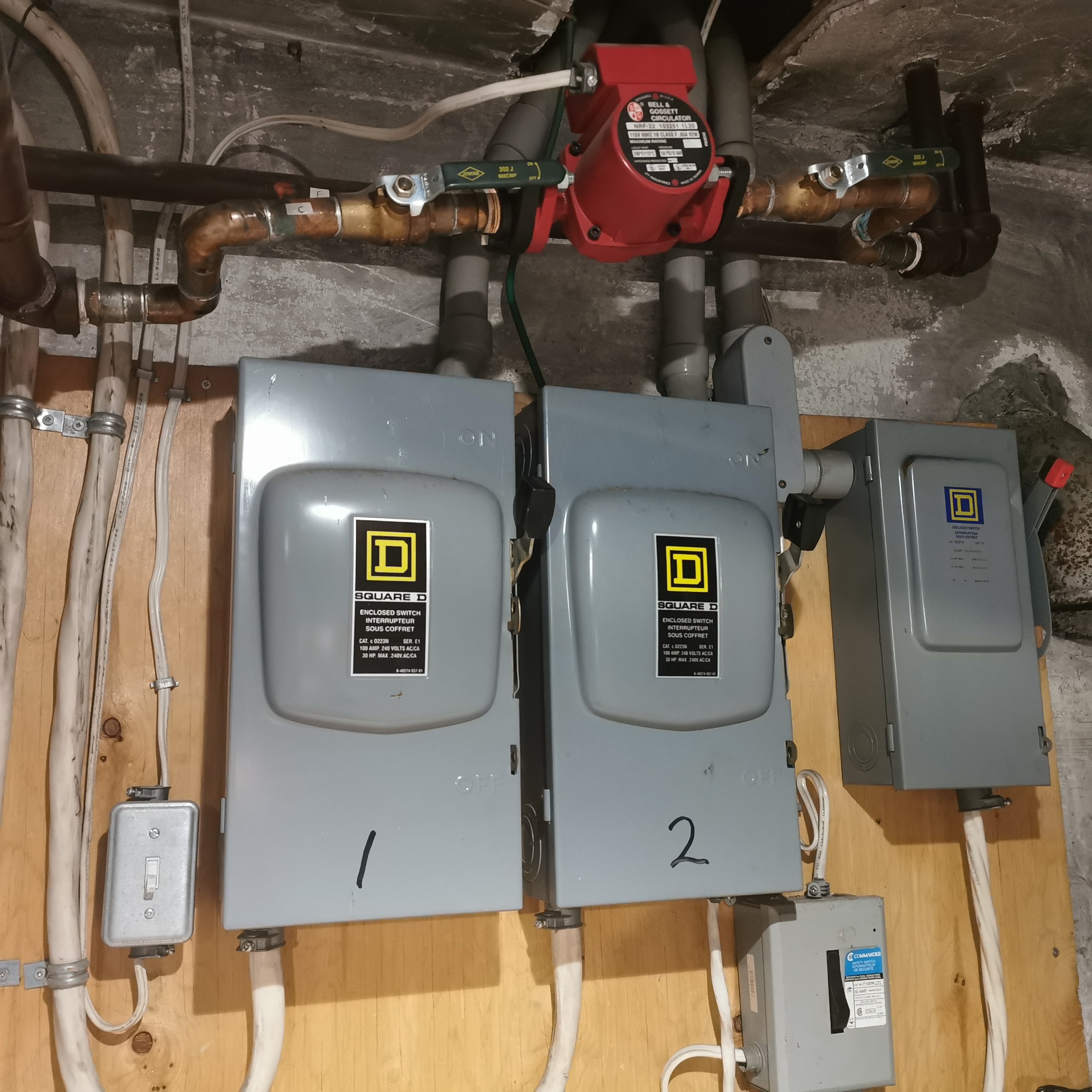

Bell & Gossett Circulator

I turned off the power to a unit for a few days so I could do some wiring. Then I turned it back on. To turn on/off the power to a unit, you pull the switch for the corresponding unit as shown in the first photo.

A day after turning it back on, I heard a whirring noise while I was on the main floor, which is directly above the basement panel room. It was loud enough that I thought the noise was coming from the street. But eventually I traced the source of the noise back to a Bell & Gossett circulator situated in the panel room. This circulator is controlled by the same panel 2 that I have been turning on and off as I run wiring in that apartment. Not only was it making noise, even though the furnace is shut down and awaiting removal, so it shouldn't be running at all, it was very hot to the touch. I was able to turn it off with the switch situated to the lower left of panel 1 while restoring power to apt 2.

I don't know why this is occurring. I don't think it's anything benign or that can be ignored. I don't believe I did anything to cause it - I never touched that wiring or the circulator during the work I was doing. Does this mean the circulator is bad and needs to be replaced? Or is there something else that could be causing this issue?

Close-up of circulator:

Comments

-

" the furnace is shut down and awaiting removal" (if the heating system uses a circulator, its a boiler) if the "boiler" is being removed it's possible that supply and return valves are shut and the circulator is being dead headed. I would follow the pipes on each side of the circulator and look for shut valves for starters.

But seriously if the system is being removed/replaced that circulator should not have power to it.

0 -

I did turn off a pipe valve leading to the furnace/boiler a few weeks ago because the furnace/boiler was constantly leaking. The relief valve wouldn't stop leaking, even though I had already shut the

furnace(I can't stop calling it a furnace) boiler off weeks earlier. Water was constantly running out of the relief valve, onto the floor, at ever increasing rates, and worsening the cracks in the slab. So my solution was to prevent more water from getting to the boiler. But you're saying that somehow, water is still making its way to that circuator anyway? And causing it to heat up? The circulator is part of the system and is not being 'deadheaded' if I understand what you mean. When they install the new gas furnace to replace the oil furnace slated to be taken away, the circulators are supposed to be in working order so the heating system can go back to running the way it did originally.0 -

The leaking pressure relief valve was most likely either that valve was leaking or had failed to shut properly or the pressure reducing valve feeding the boiler required water had failed. They both do. Very common — and inexpensive to fix — failures. Nothing to do with the boiler.

Now on the running pump. You're best bet — other than finding out what is causing it to overheat — is to find out what is causing it to run and, related, whether it should be or not. The most likely cause of it overheating is that it is deadheaded — a valve on the outlet side closed. Hard to say without knowing more about the control strategy for the building whether it should be running or not.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

- I know what the relief valve is, but what's a pressure reducing valve? Which one is it? Where would I look for it? Does it look the same as all the other valves (like the one shown in the 1st photo in my original post)

2. I turned off the boiler because the oil tank was empty, I had already cancelled oil deliveries, I didn't want any part of the heating system to potentially get damaged by a running boiler with no fuel fueling it. So I thought I had done the most logical and responsible thing. It did not occur to me and never would occur to me that there could be a circulator running on a separate circuit and wired in the electrical panel room, which I would have to shut down separately, each time I shut down the boiler. The other circulators aren't wired separately. They are part of the system. When I cut power to the boiler, that's supposed to shut it all down, except for the water heater, which I paid to have put on a separate switch. I have shut down the boiler dozens of times over the years. I never had to shut down that circulator before. It never acted up when the boiler was off at other times. Since it never caused a problem before I barely noticed it until yesterday, so I don't know why it's wired the way it is. I thought I had shut down the entire heating system months ago, and then the water feeding that system several weeks ago. But now I discover that no, I have to remember to shut this circulator down as well, during times when the boiler is going to be off for an extended period, because it's apparently trying to work anyway. I wish I knew more about my heating system, but can't seem to gain a deeper understanding of it at a pace I need to - there's just too many layers.

3. Is it correct to say that I inadvertently deadheaded the circulator by cutting water to the (shut-off) boiler? And that I was supposed to allow water to continue flowing through the boiler, to that circulator, even with the boiler shut off?

If yes, that means the circulator is probably ok, and I just need to restore water flow to it before I flip the switch back on, right?

4. The control strategy for the building is - leave everything in place, don't cut any pipes or wires or disconnect anything, wait for the fuel company to come and install a gas boiler and take the oil boiler/furnace and tank away. Once they connect the gas, and flip the switch, everything is supposed to work like it did on oil. I'm hoping the new gas boiler won't make the relief valve leak constantly, because it'll be brand new.1 -

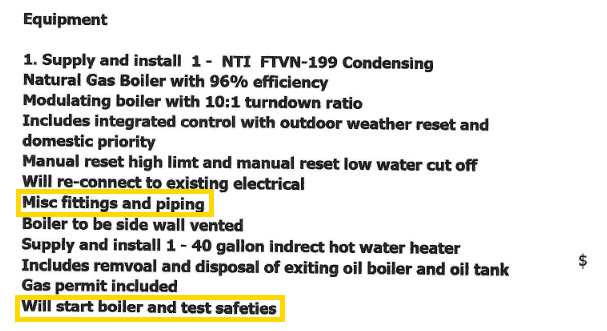

Sounds like it could be low on water? What is the boiler pressure? 10- 12 psi is common.

That is a water lubricated circulator, so it needs to be filled and air free.

You can dead-head those circs for a short period, eventually they can boil the water out of the volute then you are running dry.

A leaking relief valve is often traced to a failed or water logged expansion tank, or a fill valve that is leaking past.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

My first guess , you blow the cap in the circulator …

There was an error rendering this rich post.

0 -

So I take it that I first need to drain the expansion tanks, and then remove and replace the relief valve? And then I'll be able to restore water flow to the (defunct) boiler, which will flow through to that circulator in the panel room?

0 -

-

Just shut the circulator off using the white toggle switch (lower left of panel 1) when servicing the boiler. It is being controlled by a thermostat or an aquastat. It NEEDS to have WATER in it and NO AIR and most preferably water moving THROUGH it while running. It is lubricated with water. It looks to be "brand, spanking, new".

0 -

I'll do that from now on. This time, to deal with the leaking relief valve, should I drain the expansion tanks and then replace the relief valve?

0 -

I have some idea that @sjh does not have a full and complete understanding of the heating system and just wants to stop the noise that the B&G circulator was generating as a result of some other influences regarding either a leaking relief valves, shutting off the burner, closing a valve, and/or running out of oil or some combination of them. or perhaps another unrelated cause.

I also understand that there will be, in the near future, someone that understands boiler systems, on location, to install a new gas fired boiler.

I also understand that turning off the switch to the B&G circulator resolved the immediate noise issue.

I might suggest that @sjh leave the B&G Circulator switched off until such time that the new gas boiler installation commences and to make mention of that noise to the installer(s) of the new gas boiler, as they will be able to resolve the noise issue as a part of the new boiler installation project.

Any attempt to get that pump to operate at this time, without a more complete understanding of the purpose of that circulator, would be unhelpful as the information provided to date does not actually tell the whole story.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

It's true that I don't have a full understanding of the heating system or what I'm supposed to do whenever something goes wrong with it. There are times when I've been able to figure out the problem and solve it, and other times I had to call the fuel company.

Often, when they came out on a service call, they'd drain the expansion tanks. Then they'd fix whatever the problem was. They wouldn't drain them every time, but often.

I need to understand my heating system. There's nobody helping me with it right now. I'm not currently on a plan. Even on a plan, service calls can get into the thousands of dollars.

I don't just want to stop the noise the circulator was making before I turned it off, I want to understand the system and how to maintain it so that I don't inadvertently cause more problems by for example leaving that circulator on when there's no water flow reaching it because I turned the water off to solve a separate problem. I never knew that circulator wasn't controlled by the same switch as the rest of the system. But now I know that, so it won't happen again. Now I need to know what I should do next besides waiting for them to come and install a new boiler. When they do, they're not going to solve all the issues with the system, they're just going to install the boiler, and then they're going to leave, and the rest of it remains my problem. I'm asking if for this specific case, should I drain the expansion tanks, and then replace the relief valve. Would that a) stop water from constantly running out of it onto the floor, and b) allow me to restore water flow to the boiler, which is still in place even though I've shut it down, and then would water resume flowing to that circulator, which would mean I could turn it back on?0 -

I see your point @sjh. I have a question for you. What is your role at this location? Are you the homeowner or a building superintendent. In other words, do you control the contract for the new heater installation? If you have a sya in the what the replacement boiler is installed, then I would make sure that the contractor installs the replacement boiler in such a way that many of your problems (like waterlogged expansion tanks) are eliminated. Here is a book you may want to read before the boiler installers arrive.

You can also look as some of @DanHolohan's videos on the subject

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

A competent contractor would evaluate the system and include what is needed to make it work in their quote. No one competent "just replaces a boiler" because people are going to tend to not pay them when they replaced a boiler and they still don't have heat that works properly.

Are you sure you need a new boiler? A leaking relief valve is usually a water logged expansion tank or leaking fill valve, nothing to do with the boiler. The only way it could be part of the boiler is if there is a leaking tankless coil for the and there are much less expensive ways to fix that than a new boiler.

0 -

I'm the homeowner. There's an oil boiler here that has been heating the house since before I bought it. It's dead now. It's being replaced with gas, I don't know the exact date. The heating oil company was responsible for maintaining the boiler, because I paid them every year for a maintenance plan. But that only covered the boiler and the rental water heater. I'm responsible for the actual heating system - the pipes, the circulators, the motors, the radiators, etc. It won't be a better arrangement than that when the boiler gets replaced with a gas boiler. So I need to understand the system so I can do routine maintenance myself. I can do things like that. One time I dismantled the boiler to save it from flooding, and then put it back together. I've replaced a coupling in one of the circulators and the relief valve, once. I'll be happy to replace the relief valve this time, again, if it is in fact broken and in need of replacement.

Why would they care if the expansion tanks need to be drained seemingly all the time? If that's not normal, it's not their problem, it's mine. They get paid anyway. If that issue isn't solved by replacing the boiler and the source of energy, I can't imagine them redesiging that part of my system, and reconfiguring the system, unless I pay them thousands of dollars. This is the system that's in place. I'll ask them when they come to install the new boiler, but I don't quite share your optimism. If I ask them about that extra circulator, they'll look at it and tell me what they think, and give me a yes or no answer regarding turning it off when cutting water supply to it for an extended period of time. But they're not going to take it out and connect it somewhere else so it doesn't require a separate switch, unless I pay them. It was probably wired that way for a legitmate reason.

I'll see if I can find a copy of that book. I'd like to gain a fuller understanding of this - not just to make my life easier, but because I also appreciate the beauty and performance of hydronics. That's partly why I agreed to switch to gas when the oil boiler started dying, instead of switching to mini splits like so many other buildings around here have done.

In the meantime, do you think I should drain the tanks and replace the relief valve?0 -

Do nothing at this time.

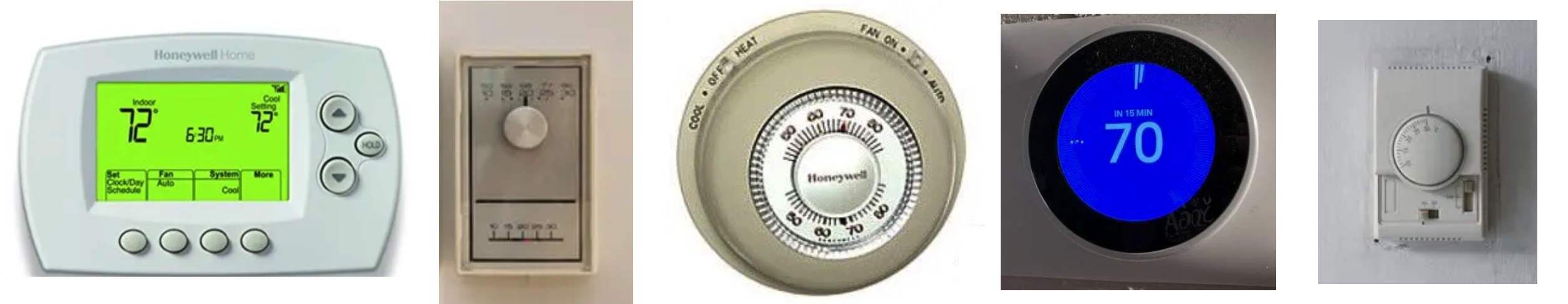

The expansion tank is part of the heating system and when I was in business, I included a replacement expansion tank in the price of the new boiler job. Do you have the contract for the replacement gas boiler? look closely at the terms of what is included in the job. Your contract should include a new expansion tank (but not necessarily) and a new relief valve (because that comes with the boiler already installed at the factory). You should also get a new circulator pump because that is included at the boiler factory. that is why I am suggesting that you do nothing.

Depending on the contract for your replacement boiler, things like gas piping, electrical connection to the existing power switch (that operated the oil boiler) and several other things should be part of the job.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Note that a properly installed cast iron boiler should last 30+ years and it isn't unusual to see ones that are 50 or 60 years old.

0 -

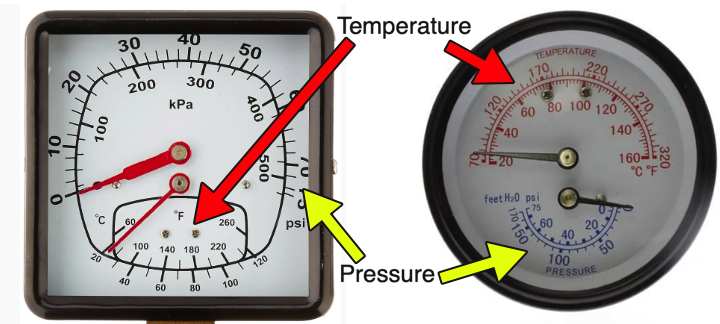

I also included a new thermostat with the job. That did not come with the boiler from the factory but I just didn't want to hear a year after the job was done "You just charged me $$,$$$.00 for a new boiler and now that your boiler doesne't work you want to charge me $$$.00 for a new thermostat because it was not included in the price of the job?" If your professional boiler installer is half way decent, there will be a thermoatat included in the job too. Unless you have more than one thermostat… How many zone thermostats do you have?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

There are 6 zone thermostats for the hydronic system. The boiler itself has a gauge or maybe that's also called a thermostat. I'm pretty sure the new boiler will come with a new gauge or thermostat.

The contract doesn't say anything specifically about any expansion tanks. There's a line about 'Misc fittings and piping' which I could bring up, but they might say that's not what it's referring to.0 -

By cast iron, are you referring to the part inside the metal housing, or the whole unit?

0 -

the heat exchanger which i guess would be "the part inside the metal housing"

0 -

@sjh said: "The boiler itself has a gauge or maybe that's also called a thermostat."

This is a gauge with a thermometer to tell you the temperature of the boiler water.

This is a thermostat that you might find in the room being heated

Based on the fact that you have 6 zones, you may have had the option to have all the zone controls controls replaced but that would add a large expense to the job. I have a feeling that you are using all the existing zone thermostats and zone controls and zone circulator pumps.

Not an ideal situation because you may have some newer and some older zone related parts that may fail as a result of age, use and also the interruption of operation by swapping the boiler.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Looking at the NTI boiler you selected to purchase, there is a relief valve included and there is a circulator pump included within the boiler.

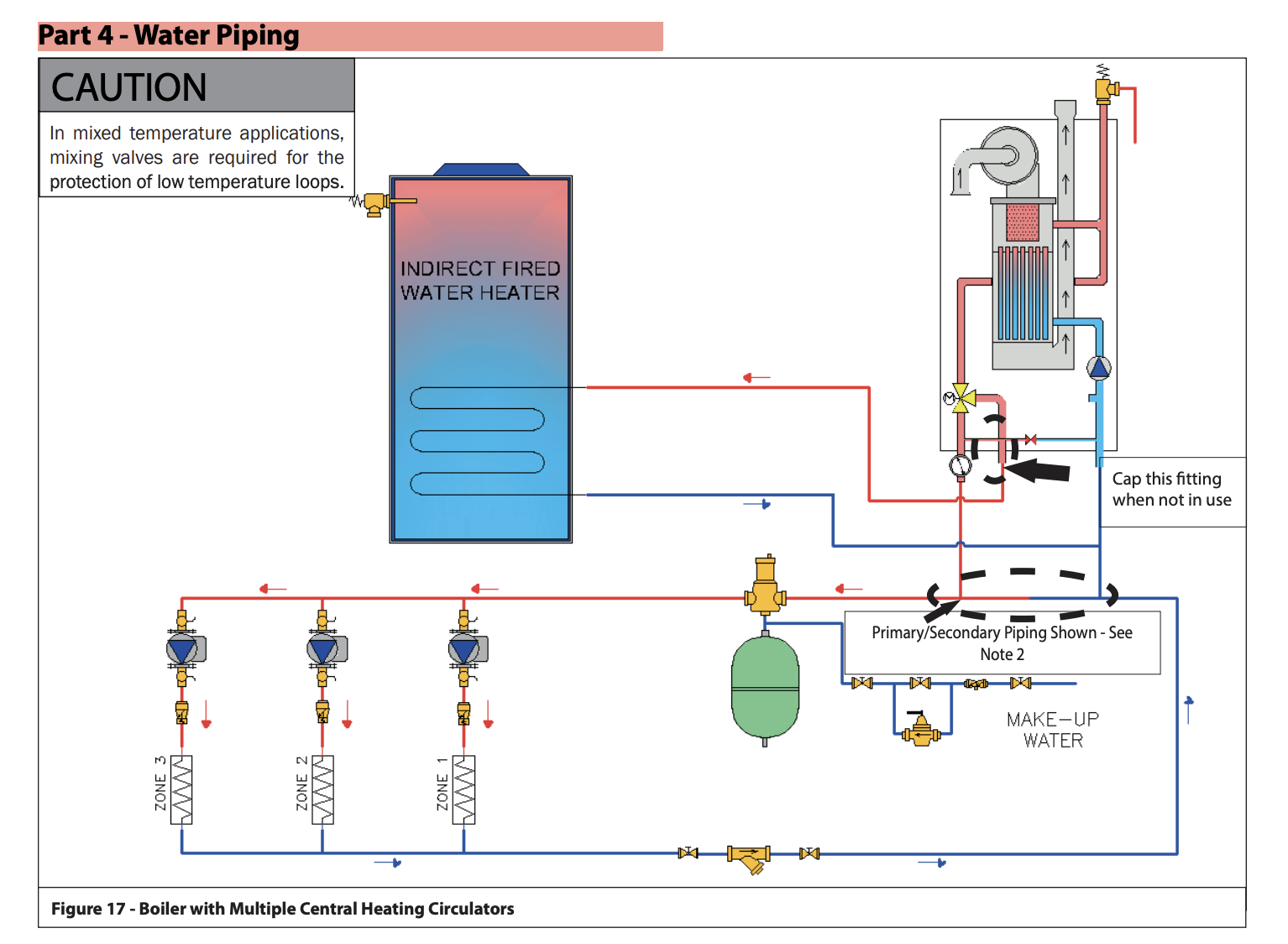

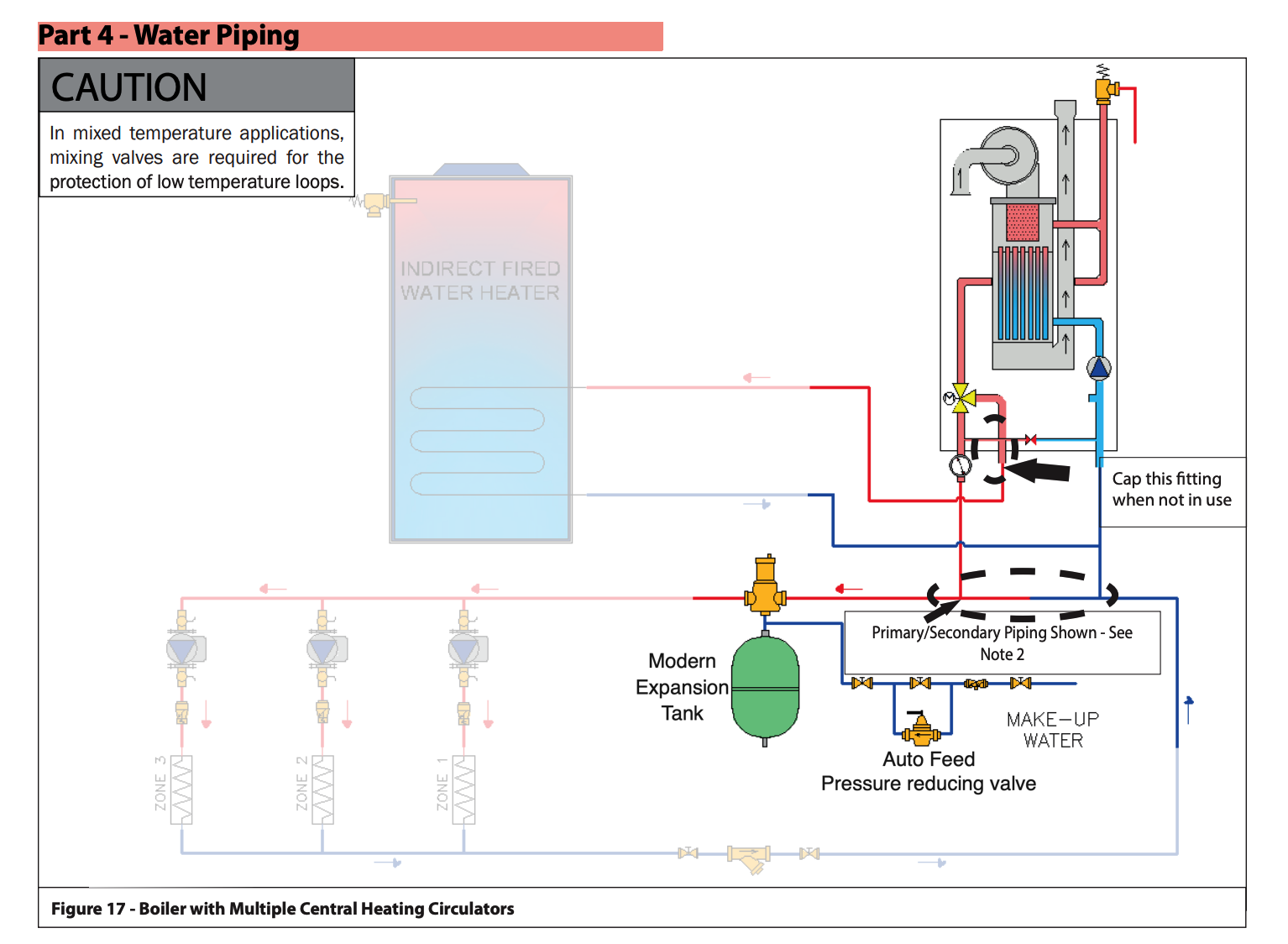

Now if you could look at the Installation manual, and the fact that you indicated that you have more than one circulator pump (6 pumps for 6 zones) and perhaps a water heater that is another zone that is heated by the new NTI boiler this is the piping arrangement that you would want the installer to follow.

Since you have an indirect water heater (indicated by the DHW priority in the contract specifications) I am guessing that since the oil tank is empty, you have no hot water in the building. If you still have hot water, then there are some contrary information herein.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I would like to suggest that you hold final payment on the project until the final inspection is completed by the authority having jurisdiction. This is a common practice when the contractor applies for a permit for a job like this. Often the contractor will request final payment when the boiler is operational before the final inspection is even called in.

In many locations this yellow card is to be posted at the jobsite. On the back of this card it often states: "Do not make final payment until final inspection is completed"

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

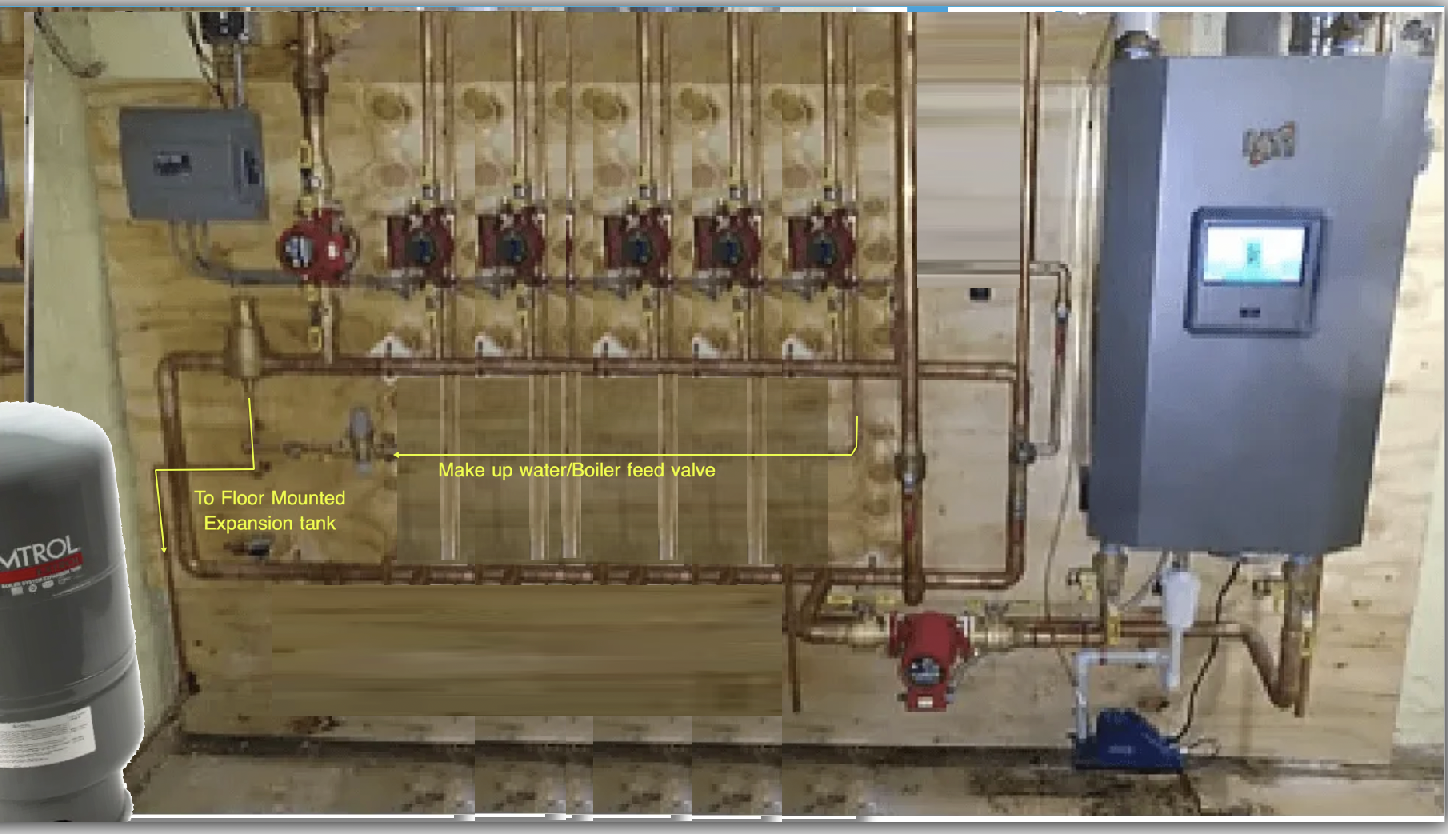

If your contractor is any good. The expansion tank and the auto feed valve with some type of air separator should be included. I think the shaded area is what is not included in your job. The near boiler piping with "Primary/Secondary" design should include the expansion tank on the system portion (not the boiler side) of the design. This piping design will reduce your air problems and eliminate water logged expansion tank problems.

You will want to take several pictures of the near boiler piping of the oil burner boiler before it is removed. This will insure the system piping when the oil heater worked just fine will not be a problem when the new boiler is installed and perhaps the new system near boiler piping is installed as NTI recommends.

Can you post some of the boiler piping and circulator locations for us to review?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Sorry man, I don't mean to be the furnace or boiler bonehead :)

I see that Jamie already clarified Deadheading so I'm not going clog up the thread.

0 -

@sjh You should probably look at the installation manual and get fammiliar with the different ways the system can be connected. I believe this is your installation manual FTVN I/O manual. Page 28 has the piping design that will most fit your system using zone circulators.

Ask the contractor if their specifications include "Installation according to the manufacturers installation manual and accepted industry standards". Since that is understood in contracts of this nature, would they add an addendum to the contract to that effect?

Or you may end up like this guy with the inability to use all the features of a proper design:

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

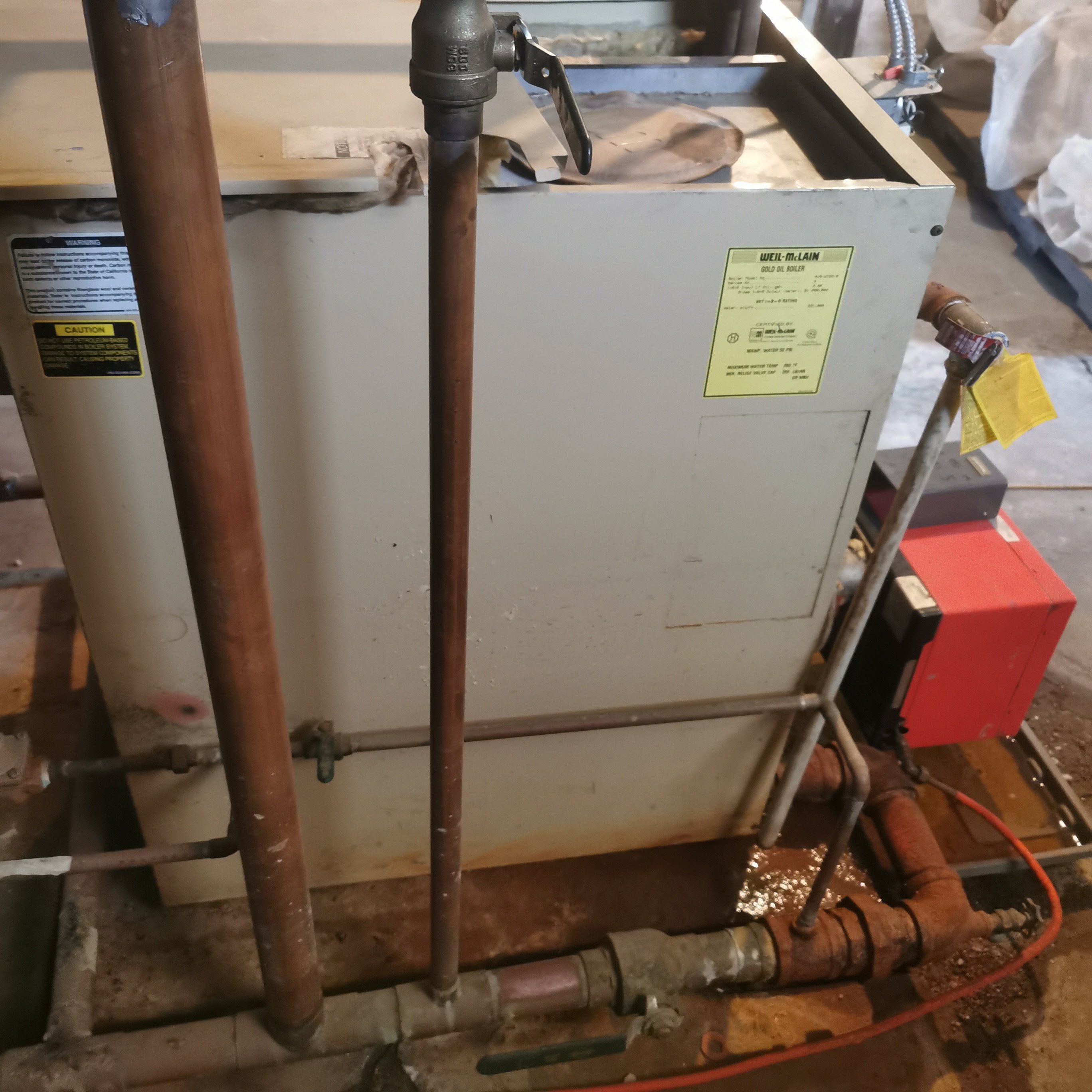

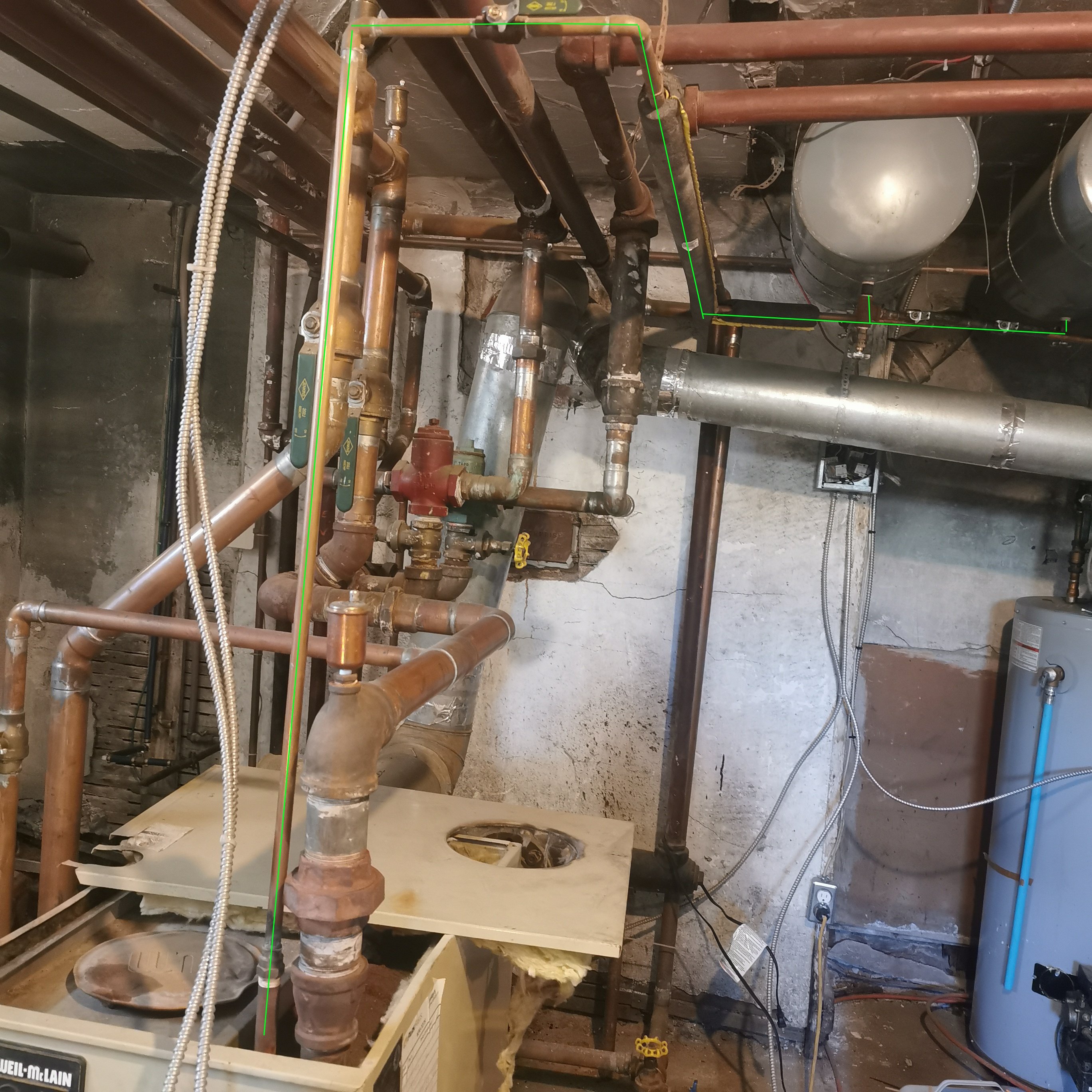

Here's some photos, if you need more photos, just let me know.

Front view of boiler. You can see a circulator behind it on the right side, near the floor. That one is Armstrong and it didn't seem to be working when I ran the system a few months ago to check if everything was working. You can see there's an older part connected to the newer Armstrong part - that circulator died a few years ago, and I had to pay hundreds of dollars to get it replaced. They replaced that part and left the rest of it. Now it might have to be replaced again, if it's not something that can be fixed.

The boiler was leaking constantly, and I don't think it was just from the relief valve, because the relief valve points straight down, not towards the tray under the controller. But that tray was overflowing, even though I had cut power to to the boiler, until I also shut off the water to it a few weeks ago. The tray is still full of water. If I were to restore water to that line, it would just overflow the tray again and there'd be water all over the floor again.

Rental oil water heater in back right of shot.

Plumbing on left side of boiler. Relief valve and ingoing & outgoing pipes

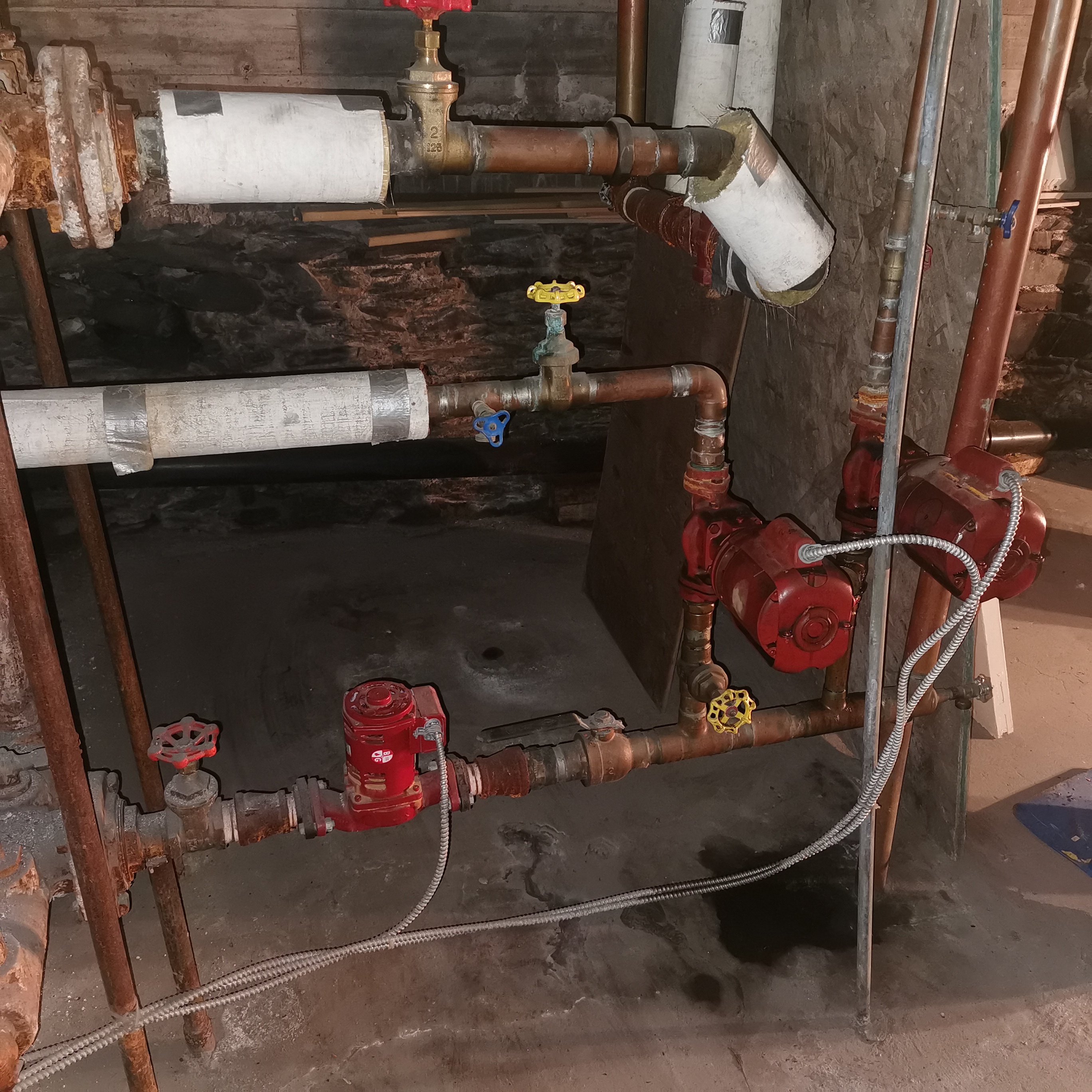

Plumbing on left side and back of boiler. The Armstrong circulator is near the top of this photo now, partially obscured. The other circulator seen is a Grundfos.

Plumbing on the right side and back of boiler, with the Armstrong circulator in lower front of photo and the Grundfos circulator in the upper centre, blending in with the background

Plumbing above boiler

Three more circulators are located in the middle of the basement (the boiler is in the front of the basement). These are all B&G, as is the one shown in the first photo I posted at the beginning of this thread. At least one of these is not working. May be the coupling has broken off the one furthest to the right and I'll have to replace it again. That's already happened 3 times since I've lived here. Or maybe it's something else. When I have time I'll open it up and look.

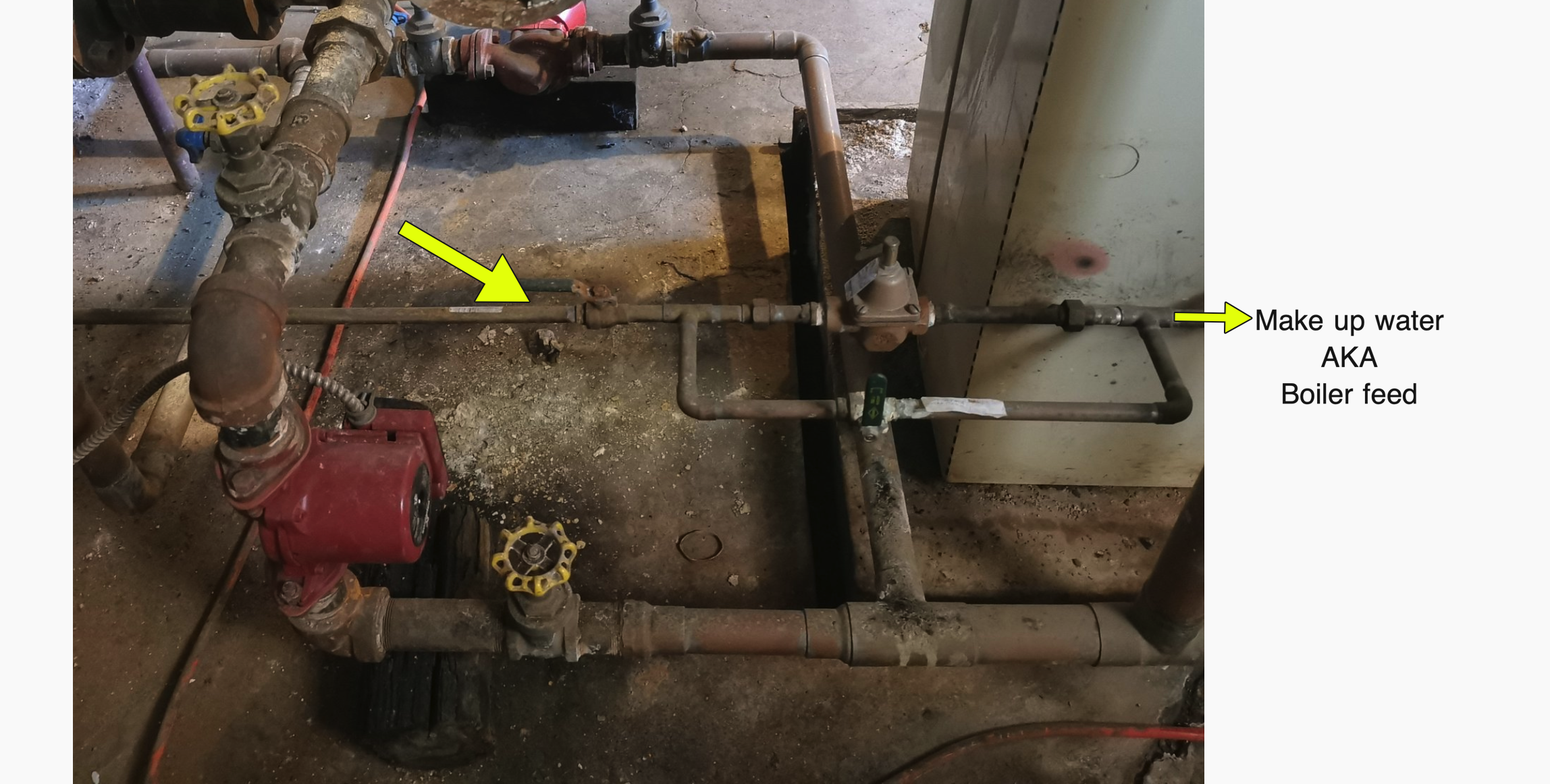

Question: What's 'Make-Up Water'? I see Figure 17 in the NTI manual shows an expansion tank after the Make-Up Water, while Figure 16 has the expansion tank before the Make-Up Water.0 -

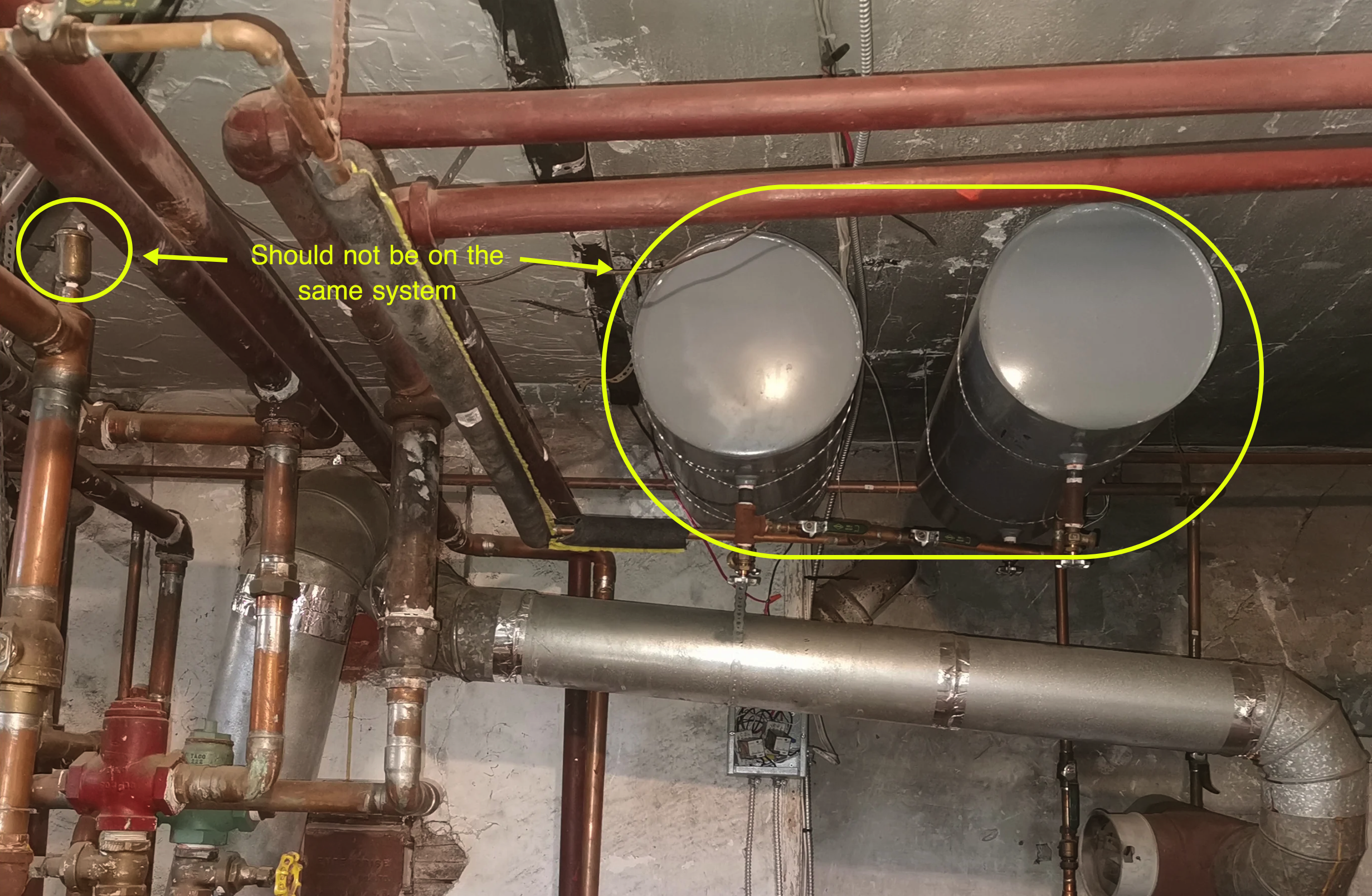

Whoops, I forgot to include a photo of the expansion tanks. They're about 1:00 from the boiler, a bit to the left of the water heater. Here:

0 -

WOW! I can see that the zones were added over time and were not built into the system at one time. Perhaps as different sections were added to the home, or as different sections were changed form unheated spaces to heated spaces.

Make up water is how you add water to the boiler. it is the pipe that connects the house's water you use at the kitchen sink and shower and all the other places there is a water connection to the boiler so it can be filled without using buckets and a funnel in the attic.

This is your make up water line

Here is the reason why I do not like to do only. part of the job. The oil boiler appears to be about 2 feet from the wall. the new boiler will hang on the wall. so the new boiler will be 2 feet away from the pipes that it needs to connect to. A hack will just remove the old boiler and leave all the pipes that are hanging in mid air and run the supply and the return from the boiler to the pipes that are way out 2 feet away from the boiler and that will look like CRAP.

This is what you do not want the installing contractor to do, (See the old pipes in front of the boiler and the new pipes in light copper color) however you end up getting what you pay for. This will be difficult to work on in the future, and may have operational problems also because all your circulators are in the incorrect position for eliminating air problems. If they decide to use the existing expansion tanks in lieu of a new modern expansion tank, then there will be air problems similar to the ones you are experiencing with your old system design. Also, when you use the type of expansion tanks you currently have, you should not have any automatic air vents which you also have at least one. This is how waterlogged expansion tanks happen.

I might suggest that you talk to the contractor and ask about making the system conform to the manufacturer's recommended diagram. You may as well get it all done right at the start of the job, in stead of having them cvome back trying to fix stuff because of a poor initial design.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

So that means my expansion tanks are after the Make-Up Water, or in other words, on the system side.

Below, I've drawn a green line on the pipe coming out of the boiler, feeding the expansion tanks. At least I think that's the directional flow. That's what it looks like to me.So they're installed in the right place, at least.

Where's the automatic air vent for the expansion tanks? What are you looking at?

You're right, I don't want pipes doing a 180 back to the wall from where they are now, and taking up that floor space and creating air problems. There's a lot of that in this house, and it makes it very difficult to sort out which pipe is going where and doing what. I will definitely bring these issues up with the contractor.0 -

You might want to pay extra for doing this.

You could let them use the existing pumps because they are working just fine. You just want something easy to work on where you wont bang your head on pipes that are way out in front of the new boiler.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

One more comment about the system: The service personnel that have been maintaining your boiler are in need of some training. (or they have offered you the necessary upgrades and you have decided not to pay for them). You are having air problems and water logged expansion tank problems as a result of two items that are not compatible are included in the same system.

The air vent on the left side of the photo is letting out all the air that is supposed to be inside the tanks on the right side of the photo. The process in which this happens is called gas dissolution. There is a long and interesting explanation of this process as related to a boiler in a heating system like yours, but it is safe to say that if the expansion tanks are not replaced with the modern style expansion tank you will continue to have the same problem

The other way to fix the waterlogged expansion tank problem is to add two AirTrol® ATF -12 Tank Fittings to the existing tanks and connect them to an air separator located in the system at a strategic location on the hottest portion of the system piping and where the lowest pressure is in the system. In order to make the lowest pressure and the highest temperature happen in the same location you will need the circulator pumps moved.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@sjh, The plastic flue access cap on the jacket looks like it saw some pretty high temperatures. Even if the insulation is gone, it shouldn't warp. There's also scorch marks around the burner door. What's the stuff around the inspection window and the air tube?

You mentioned a gas fired boiler is replacing the oil fired. But all the zones need to work first? So they're sliding out the old boiler, and sliding the new in, only to reconnect to that existing mess of piping? Please tell me I'm crazy.

1 -

Actually your expansion tanks are connected to the built in air scoop on your Weil McLain boiler. The 3/4" pipe tappint is actually a built in air scoop at the top of the boiler.

Your new boiler does not have a built in air scoop so you need to provide one as shown in the piping illustration.

The air separator is the yellow part just abpve the light green expansion tank. Since the contractor is removing the built in air scoop that Weil McLain has provided, the contractor will need to provide one to comply with NTI's instruction manual.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I was not offered any upgrades or changes to the system. The gas company is paying for the installation, and the fuel company that used to deliver oil here and maintain the boiler is going to install it. I suppose they'll then offer me an annual service plan that only covers parts, and only for the boiler itself. Other than that, I don't pay anything. I'm under the impression it's a standard contract. I didn't choose the boiler or the water heater, they did - it's what they install for all their customers. No one has said anything about rearranging components like the expansion tanks or the circulators. Instead they use as a selling point, "nothing will change with your plumbing and radiators, you don't have to do anything." Now I'm wondering if I can get them to rearrange components that are apparently installed wrong after already having signed the paperwork. I'll talk to them about following the manufacturer specifications.

What are the modern expansion tanks? How are they better?

I would definitely like the tanks upgraded if the ones I have are the source of a problem. The ATF tank fittings option seems like an extra complication.

Why is there that copper vent, if it's not supposed to be there? Why did somebody build the system that way if it's wrong?

I actually installed that vent myself, when the previous one stopped working. I had no idea I was replacing something that shouldn't even be there. I just told myself "this thing was here when I got here, then it died, so I'll find out what it is and replace it with a new one."0 -

I don't know why those things happened. I assumed it was normal. I haven't seen a lot of oil boilers and don't know enough about them. I've been trying to figure the system out for years, but where do you start? It's a mess and I have no training in this area and never had an opportunity to get training in this area. The boiler was cleaned annually by the oil company, and they never said anything like "this is dangerous" or "****, what are those scorch marks from?" I would usually ask them questions whenever they came here to clean it or do a service call, and they answered me, and sometimes I learned something. But that hasn't been enough for me to be able to say "oh, this was installed wrong, and here's what I have to do to fix it." or even "here's why this radiator isn't working." Sometimes I know why, sometimes I don't. Sometimes they don't know why either. I have 2 rads that never work, and they can't tell me why - I've asked them.

The corrosion looks to me like sulfur. It's quite rusted inside. The unit is being taken away soon, it's no longer in use.0 -

-

I'm getting the impression that this system in this house is poorly designed and installed haphazardly, which I didn't know before. If you can tell me what else should be done, I'll see if I can convince them to do it. I've had nothing to compare it to and haven't really had the time to figure this system out, and usually I could just call in and have somebody come out and fix whatever was not working. But improving the design of the system never came up. It was always 'this is an emergency, there's no heat because this object is not functioning, replace it with the same thing or the modern version of the same thing.' or call in, they show up and drain the tanks and maybe they replace a part. I should have discovered this forum sooner.

0 -

@sjh asked: "What are the modern expansion tanks? How are they better?"

Let's first understand why you need an expansion tank. When water is heated it expands, 100 gallons of 60° water will become 103 gallons of 190° water. Now when you fill the boiler and all the pipes and all the radiators with water and there is no air left in the system, you need a place for that extra 3 gallons of water to go. If the system is completely closed and there is no air in the system at all, then that expanding water can become explosive. See this video about an overheating water in a closed tank with no relief valve:

So HOW you do you make room for this extra 3 gallons per 100 gallons of water in a heating system? The expansion tank has an air cushion that can compress as the water temperature increases Tha compressed air will make way for the extra water.

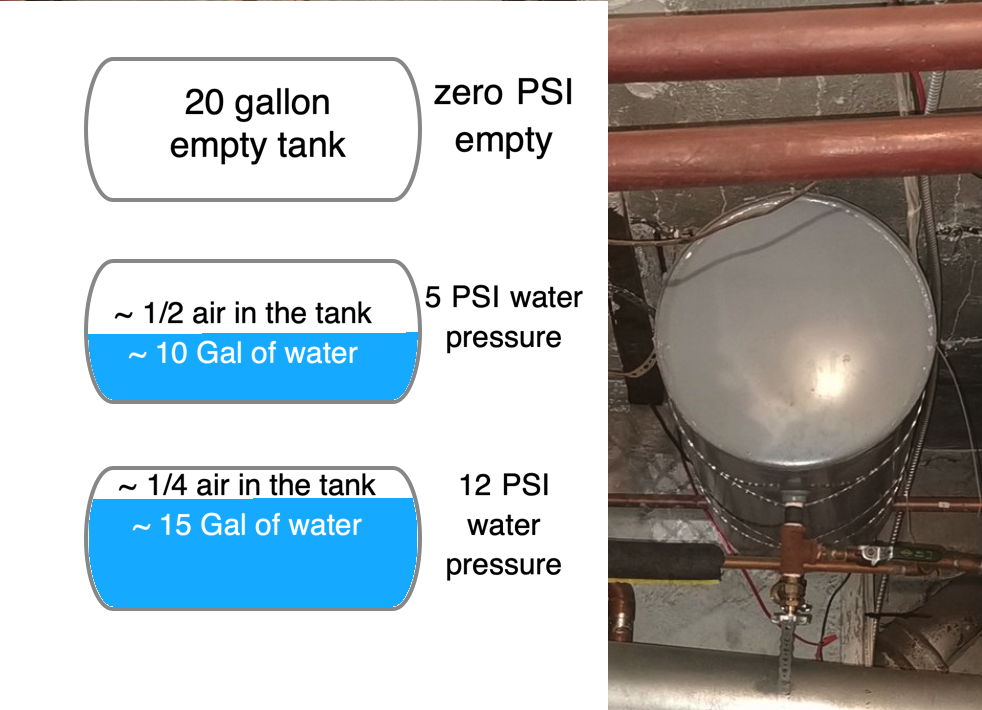

In the tanks that you have, you start out with an empty tank of air with the only opening at the bottom. then as you fill the system with cold water until you have enough pressure in it to fill all the radiators on the top floor. That might be about 15 Pounds per Square Inch (PSI). it would look something like this inside your expansion tank. (Note: the following pressures and gallons are not exact measurements and are provided for illustration only)

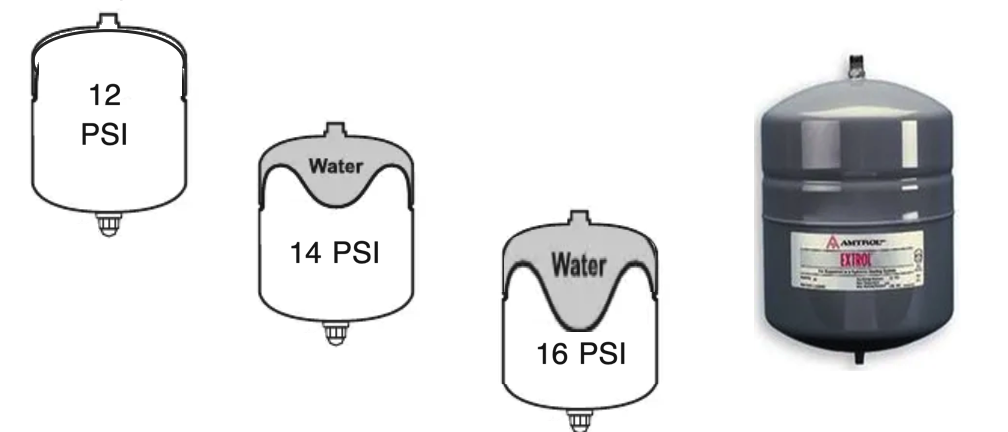

in the late 1950s a company called Amtrol invented a smaller tank that came with 12 PSI air pressure already installed inside it and placed a flexible membrane between the air side of the tank and the water side of the tank. This was the first Modern Precharged expansion tank. Since the 12 PSI was already in there, you only needed a 5 gallon tank to do the same job as a 20 gallon tank old style tank.

As the water temperature in the heating system increases the additional water volume moves into the tank and compresses the air in the tank the same way it does in a old style tank. more water expanding the pressure increases a little. as long as there is enough air in the expansion tank, the system water and air pressure will stay at a reasonable level well below 30 PSI of the safety pressure relief valve

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements