Bell & Gossett Circulator

Comments

-

I wonder if their system has so much volume that they need 2 compression tanks or if someone added the second one trying to fix the auto air vent problem.

I will say more explicitly if you install a mod con to that system that was installed by someone that didn't know what they're doing it will never work right, the cast iron boiler is much more forgiving of improper flow.

0 -

Thanks for explaining how expansion tanks work. I'm going to ask the contractor if they're replacing them with the modern kind. They're coming today. I'm going to ask them about the tanks, and which wall they're going to install the boiler on, and make sure they're not going to have pipes doing u-turns across the room, and if they could improve the drainage system instead of having it drain into a tray which fills up and overflows onto the floor, and demand they put the water heater on the separate switch I paid to have installed, and I'll ask about the air vent connected to the air scoop.

What else should I ask them?0 -

Sorry for late response: Was rushed to hospital this AM. All is well and I'm back home.

If it is not too late, ask about moving the existing circulators to be pumping away from the expansion tank (New or existing) for better air control. and what kind of air separator will they be installing? The newer microbubble type with the newer expansion tank or if they are keeping the old tanks can they install Airtrol® ATF-12 fittings on both tanks with a standard air scoop. Either way is fine. If they are using the existing expansion tanks, then all the automatic air vents must go.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Glad you're ok.

I showed them all the circulators. They said they were going to make sure everything's working, all the rads, including the circulators, before they leave, which sounds great to me. I didn't ask about moving them, but will ask if it makes sense to move any of them. But they also said they're going to be replacing the expansion tanks with the modern ones you recommend, so maybe it won't matter?

We also talked about where the new boiler will be vented, and which wall it's going on. It looks like it'll be going onto a wall conveniently located very near the stack pipe, so if there's a lot of drainage, it could be easily directed into the stack. They promised not to u-turn any pipes across the room, and how the new boiler comes with its own relief valve, so it's good I didn't replace the one that was there. Overall I feel like it was a good talk. All the equipment is on site for installation and they dismantled most of the old infrastructure today and took everything away that I didn't want to keep for myself.0 -

And HVACNUT, you were right, scorch marks are not normal. I asked the guy who is doing the installation, are these scorch marks on the boiler flue access cap normal, and he said no, it must have never been cleaned properly. It's the same company doing the cleaning and the installation though. They cleaned it every year and signed off on the sticker on the side. I just assumed they knew what they were doing. You never know unless you ask, I guess…

0 -

They changed their plan to install the boiler unit on a wall. They said it can't go on the wall because the wall isn't concrete, it's just a stud wall, and the unit is supposedly too heavy to attach to the studs. So instead, they've installed it on the same slab the oil boiler was on, on a stand, in the middle of the room. I tried to argue with them, but I didn't know how to convince them to put it on the wall anyway. If they say it's unsafe to attach it to studs, how can I prove it isn't? Some of the basement walls don't look like they're in the best shape and it's possible that the studs on that wall are not in the best condition, but I wouldn't know for sure without ripping off the plaster and probably also the lath to examine them. Behind that is going to be masonry which in some cases is deteriorated.

The indirect water heater is going beside it, rather than in the corner where the oil water heater was. They tell me the pipes aren't going to be a mess going all over the place. They are making an effort to clean up the plumbing runs. But having this all set up in the middle of the room is not ideal.

The fact that it's an indirect water heater means it won't be on its own switch that I paid to have installed a few years ago for the oil water heater. So that's frustrating… I need to ask them if that means I won't be able to regulate it separately.

I also tried arguing with them about venting it with plastic. I would prefer metal venting. Page 35 of the manual says stainless steel is an approved material for venting. But when I tell them that, they say you can't use steel, it rusts, it's not allowed, and they're only allowed to use plastic."Stainless Steel AL29-4C Certified for Category IV and Direct Vent Appliance Venting": Part 5: Venting - page 35 of manual https://ntiboilers.com/wp-content/uploads/2020/09/87030_IOM_FTVN_420011303800_022823.pdf

How do I convince them to install metal ventilation, or should I? Is using metal a bad idea like they're telling me? I did some research and It seems that the plastic manufacturers are not recommending the use of their products for this type of use, even when the boiler manufacturers claim they recommend it. The plastic manufacturers admit their product could melt if the temp goes above 65C or 149F, which is a temp this boiler is designed to be at consistently, and higher. https://www.phcppros.com/articles/1911-is-pvc-an-acceptable-vent-material-for-flue-gases

There's a lot to first become aware of, and then to remember, so when they just spring surprises on you after you thought it was all settled, you don't know what to say. By the time you research it, it's often too late because they've already done it.0 -

I also tried arguing with them about venting it with plastic. I would prefer metal venting. Page 35 of the manual says stainless steel is an approved material for venting. But when I tell them that, they say you can't use steel, it rusts, it's not allowed, and they're only allowed to use plastic.

This must be a company policy and is not a legal or code requirement. I would talk to the installation manager on this topic of you feel that strongly

I have used PVC for venting that type of boiler. As long as they use the proper schedule PVC pipe. Solid core schedule 40 is approved for higher temperature than drainage PVC. I sometimes found that some installers will use the drainage pipe for the air intake and the schedule 40 for the exhaust. In some cases the boiler manufacturer may specify Polypropylene for the first 6 feet of venting since that material is rated at 230°F.

There is some controversy as to using PVC for venting at all, since the manufacturers of the pipe have not listed "combustion byproducts" as an approved use for their product. They also, however, have not said that you can’t use it for venting combustion byproducts. That may be decided at a later date but for now, since PVC has been used this way for over 40 years, and there has been no recall on the use of PVC for venting in all that time, I believe you can let the PVC stay there.

The fact that it's an indirect water heater means it won't be on its own switch that I paid to have installed a few years ago for the oil water heater. So that's frustrating… I need to ask them if that means I won't be able to regulate it separately.There is always a way to regulate the operation of the water heater separately. What exactly you are regulating is the question. There is no separate burner for that water heater. There is a thermostat to control the water temperature and that can be adjusted to OFF. There is a circulator pump on one of the pipes that goes from the boiler to the water heater, that moves the heat from the boiler to the water heater. That pump is operated by the tank thermostat and as was previously stated, is controlled by the tank thermostat that can be turned OFF or set to a desired water temperature. So I would not worry about controlling the water heater, basically it is a tank full of water with no real mechanical device inside of it that needs electricity to operate it, as your oil fired water heater did.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

The owner said no, I can't have AL29-4C Stainless Steel because it's obsolete, it's too expensive (the gas company is paying them, not me), and they don't have any in stock and would have to order it which means they wouldn't be able to complete it for an unknown period of time. If I had known in advance any of this, that they only use plastic, ever, that they were going to refuse to use steel despite my requesting it, I would have had time to get it put into the contract and they would have had plenty of time to order the pipe. But I had no idea. I never think of these things until it's too late.

The new expansion tank is the modern type, but I don't get why it's directly attached to incoming city cold water instead of acting as an expansion tank for the hot water produced by the boiler or to relieve pressure somewhere else in the system. The installer says he's going off Figure 17 in the manual, on page 28.

Is this the best way it should be installed:

The copper coming from the left is the incoming city water. It branches off up, over, and down into to the boiler as well as directly down to the expansion tank.More photos:

0 -

If you hire a competent professional instead of whoever was the lowest bidder for the gas company, the professional automatically accounts for and includes these things, you are hiring an expert instead of doing it yourself for a reason but these people don't seem to be experts.

0 -

-

-

They wanted to drain the condensate directly into a large pit in the floor. Every time they come here to do maintenance, they ask me "hey, can we drain your tanks into the floor pit?" I say "No, let's drain it into the actual stack pipe because I don't want even more water undermining the foundation than is already happening." And then I have to climb down into the pit, unscrew the cleanout lid of the stack pipe, and place the hose into it. They never do it themselves, and if I'm not there to do that, they just drain it into the pit. Even when I explain, "no, I want you to drain it into the stack pipe", and they say ok, I come back, and they've drained it into the pit anyway. I have to repeat myself every single time.

If I went to somebody's house to do plumbing, and I just drained everything onto the floor, I doubt most customers would find that acceptable.

So when they said "we're going to have the condensate drained into that pit. You don't mind, right?" I said no way. Absolutely not. So then they said "well then we'll have to install a pump and run a plastic pipe along the ceiling, over to these other drains halfway across the basement." That seemed like really going out of the way, when the stack pipe drain is right there, maybe 6 feet away from the new boiler. And it wouldn't require a pump to drain it directly into the stack pipe, nor any ceiling plumbing.

I had a couple hours to think about it, so I did that, then went back down and told them "I don't agree to that plan either. I want it drained into the stack pipe. What is the reason why you won't do that? Is it because it's not possible? Or is it because you don't want to?" He said "It's because I don't work with sewage pipes. I won't do that." He has an issue with the smell. "And I don't have to. The company won't force me to. They'll approve a pump and running the condensate across the basement to those other drains (that then eventually end up draining into the stack pipe I'm talking about)

I still refused to agree to that. I said "is there a lid for these cleanouts that has a hole in it for a hose? Could you just replace the lid with one of those lids, and then we stick the hose into that? He said "Not really, but I could do something with a trap, into that. But then you gotta unscrew it whenever you want to remove the lid." So we agreed on that as a compromise.

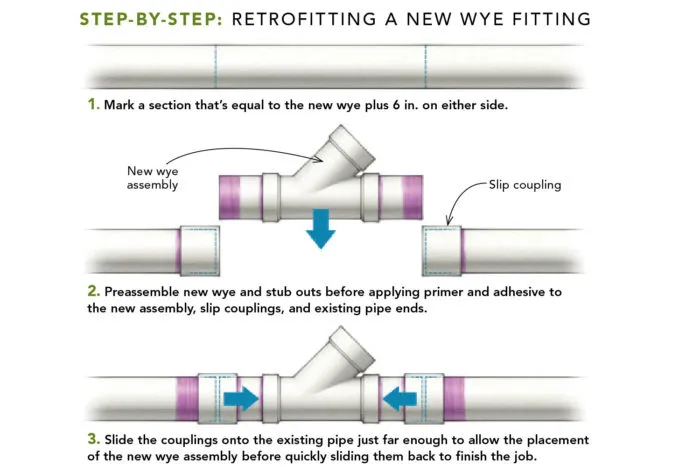

But then I thought about it overnight and I would prefer this condensate gets drained in what I believe is the correct and best way, which is to cut into the stack pipe, place a fitting into the cut-out section of it, and run whatever is the correct pipe over to the boiler to collect the condensate, so the condensate runs directly into the stack pipe, and there's no problem.

I would do that myself, except I'm no plumber. I kind of know what to do on the stack pipe end - cutting out a section of it with a sawzall and gluing in a fitting something like this:but I wouldn't know what to do after that, what diameter pipe to buy, which fittings to get, how to connect it to the boiler, etc. Whenever I have to do something I haven't done before, it takes days, or even longer, for me to plan it out, with multiple trips back and forth to different stores, because I often end up purchasing the wrong materials or tools for the job and have to exchange them. So if I have to do this myself, I'm pretty sure that would happen, and I would waste a lot of time that I don't have on this.

I don't want the basement in worse shape than it was before the gas conversion. I've been trying to improve the house, including the basement. That pit is unacceptable, and I intend to do something about it eventually. Having water running into it constantly would make that more difficult, IMO. I also don't want even more pipes running across the ceiling, making the system even more confusing, especially with a pump thrown into the mix which could fail and probably will fail at some point.

I'm thinking of calling the heating company and saying send somebody else who does work with sewage pipes, because I don't agree to the other plans.

Am I off base here? Should I just agree to the compromise? Or agree to their plan of pumping the condensate across the ceiling half way and upstream across the basement? Or should I care if they add a constant stream of water into the pit?0 -

you'd have to cut a standpipe with a trap in to the waste stack, assuming that is a location where you can wet vent the trap for that standpipe.

I hope they are putting a condensate neutralizer in the condensate line.

0 -

I don't know the answers for any of that because I barely understand the concept. I've never heard of a condensate neutralizer and don't know what qualifies as an appropriate location to wet vent the standpipe, or what even is a standpipe. Based on your reply, I will not be attempting to do this myself. I shouldn't have to be considering doing it myself anyway. How do I convince them to do it the way you suggested? They don't seem to care if they're pissing me off - all they care about is fulfilling their contract with the gas company, and if that creates a worse mess in my basement, too bad for me.

0 -

You'd have to get a plumber to install a standpipe, pretty much with any heating contractor. the might subcontract a plumber, but installing a standpipe isn't heating. most contractors would just run it to an existing drain somewhere in the basement.

The deal with the devil that you've made for the utility to install the equipment is that the contractor works for the utility, not you.

1 -

They put in a condensate neutralizer because I brought it up. If I hadn't said "are you going to put in a condensate neutralizer?" they weren't going to. The installers literally dropped what they were doing and went back to the store to buy one. So thanks for the heads up. They attached it to a new stack pipe cleanout lid with a hole for the IPEX pipe which the condensate flows through, and it has a trap. I guess I can live with that as long as I don't have to shut the boiler down to unscrew the lid to drain anything into that stack opening. Usually it's only used when they come to do maintenance and they're draining the tanks, but occasionally I want to use it to drain something else.

There's other issues but not related to my initial question about that one circulator, or the gas install, but that's finished now, so I guess I'll start a new thread for those.0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements