Copper to Pex in hydronic heating for DIY

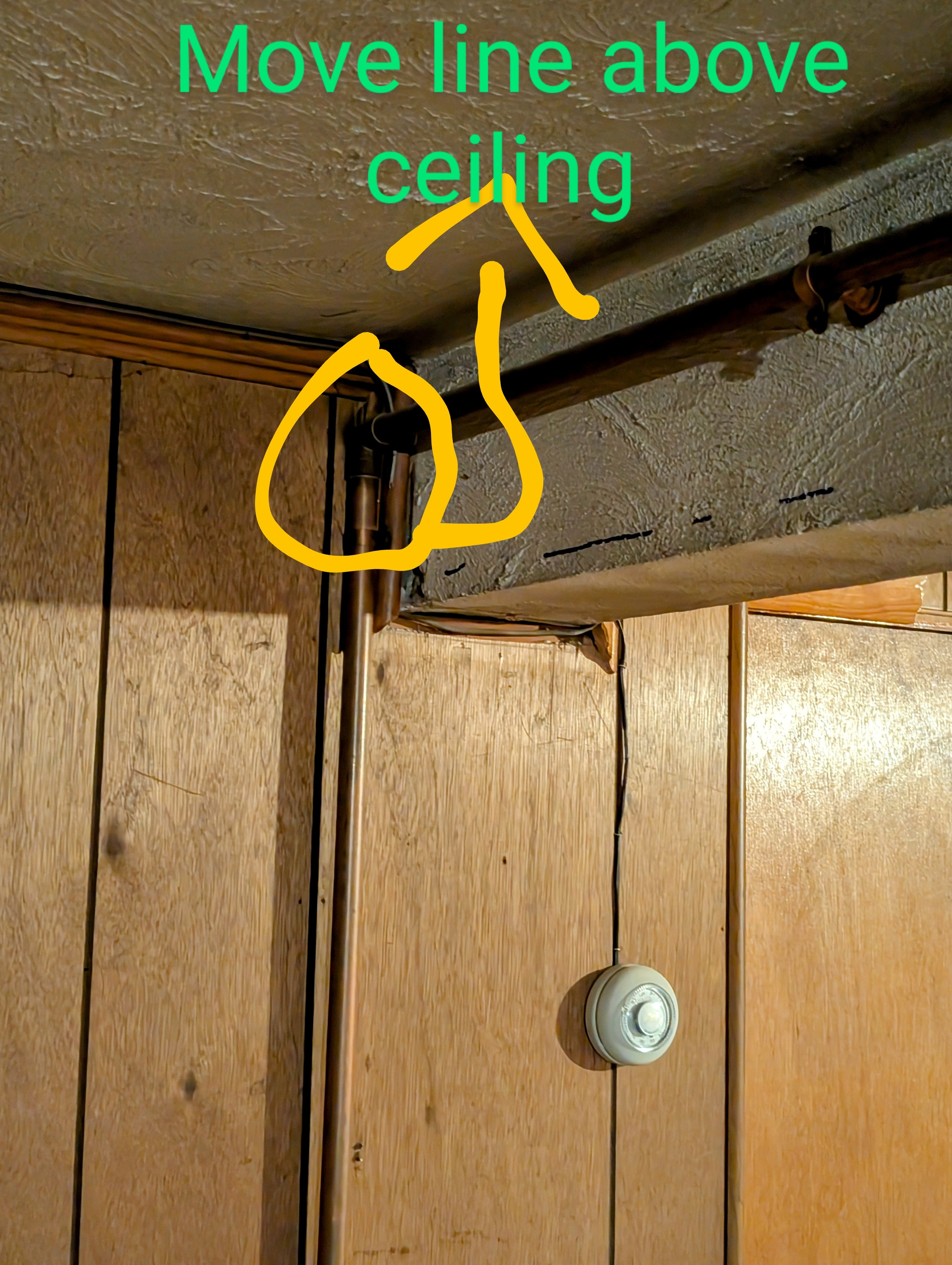

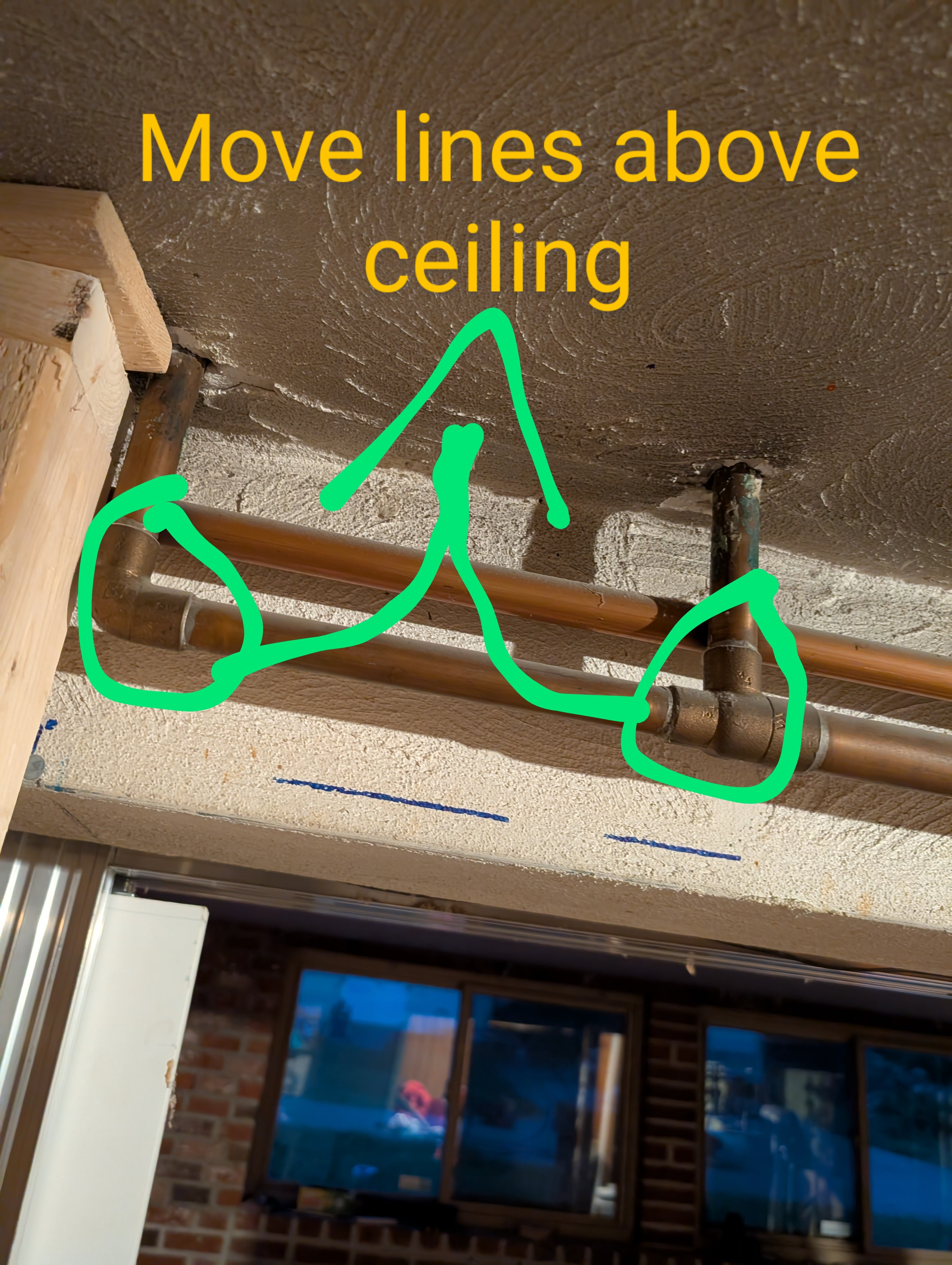

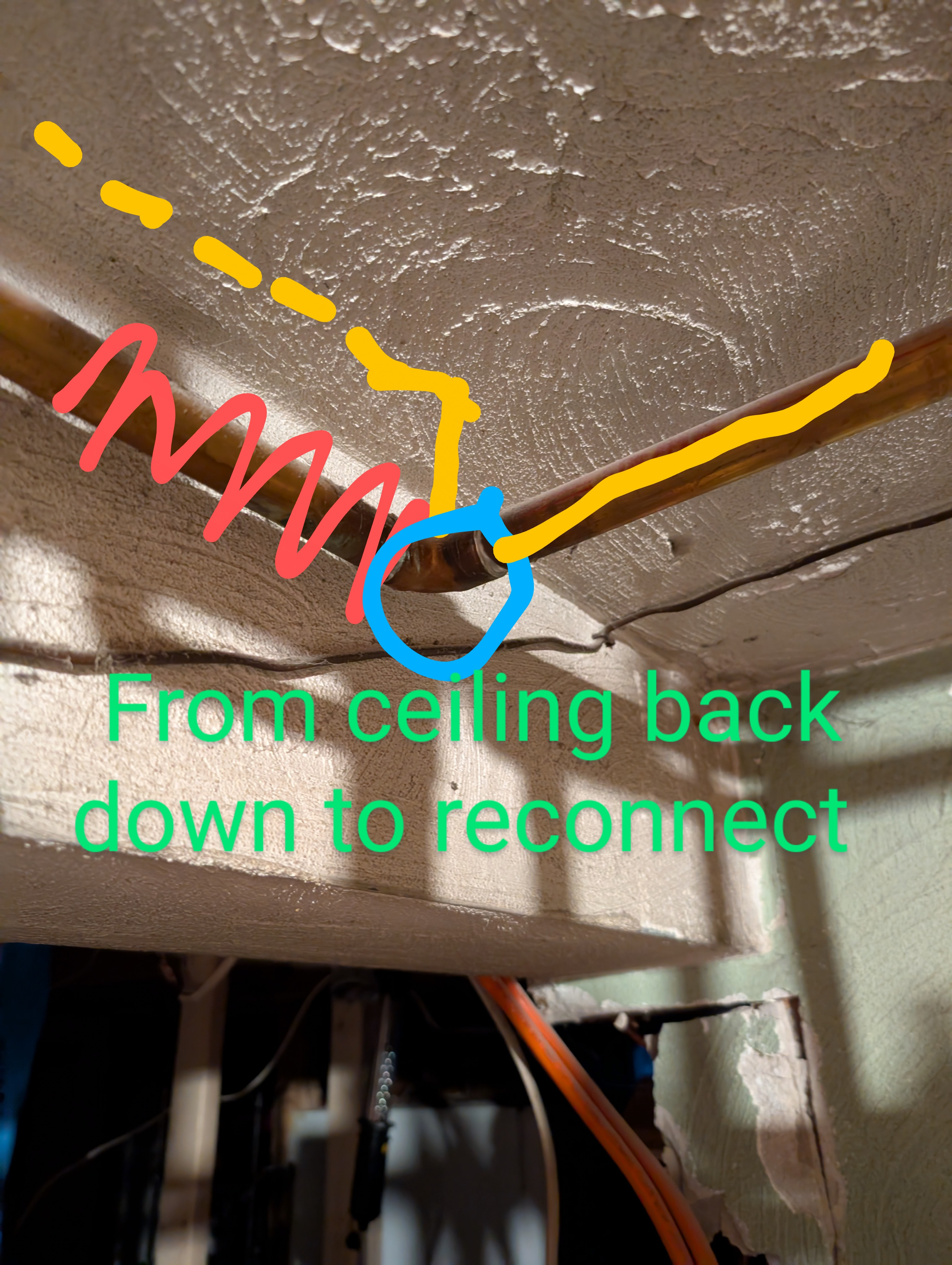

Hi, I'm doing a remodel and need to move a couple of pipes connecting my baseboard heating to the boiler.

It's copper. I don't know how to sweat copper so I was thinking of using PEX and shark bite connections.

So for those of you who know; is this a bad plan?

I need to do this as inexpensively as possible but also, and just as importantly, safely.

Does anyone have a different suggestion? Know of a plumber who could do the job on the cheap? (Woburn, MA 01801 area)

I NEED to move one line (3/4” copper), which means 2 new connections. But I'd LIKE to move a total of 2 lines (the 2nd being 1" copper) which would be a total of 5 new connections.

Thanks for the input!

Comments

-

Moving heating pipes, without knowing what you're doing, can make your life miserable

0 -

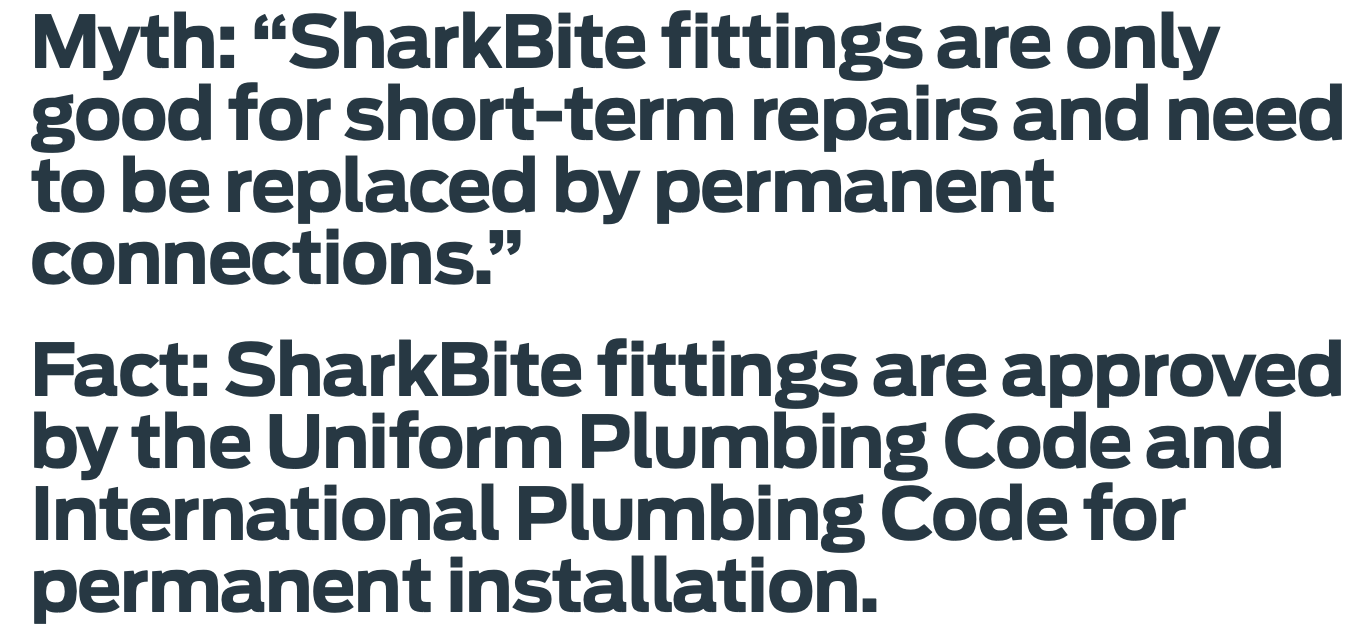

Sharkbites are OK — for a temporary or intermittent use (and yes, I have used them!). They really shouldn't be used for a permanent installation… and I think you have more than two connections there…

PEX is OK. But use proper crimp type fittings everywhere you can.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Nothing will be cheap in Woburn.

0 -

SharkBite is listed for that use, temperature and pressure. Large size reducing fittings are not always available.

Copper press to pex would be another good option. You can rent or borrow the press and crimp tool.

Compression fittings are also available. Use a pex fitting adapter to fit inside a coupling.Compression fittings are common in Euro hydronic systems.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Hi, I'll just throw out there that learning to "sweat" copper really is not that difficult. Here's a video from the CDA showing how: I'll add that much of what they give applies more to bigger pipe and fittings. Smaller sizes are quicker and easier. Every plumber has their preferences, but I like C flux as it turns dark when it's time to apply the solder. I only use mapp gas also. You can back the torch away from the pipe to quickly control the amount of heating. It's important to thoroughly clean flux off the joint when finished. I keep a spray bottle with water in it to both wet nearby surfaces and to help with rinsing off the flux. Practice on a few joints first, and you might be surprised by how easy the process is.

Yours, Larry

0 -

Thank you everyone, I appreciate all the input! I'm leaning towards giving a go at sweating the fittings myself.

My newest concern is wondering how to know if my practice joints are up to snuff or not.

0 -

after you solder them and they cool down heat them back up and take them apart you will see where the solder flowed .

- clean the fittings good with sand cloth, scotchbrite and or cleaning brushes. For the fittings I buy a cleaning brush and cut the handle off. Chuck the brush in a drill. It makes very quick work of cleaning the fittings

- Controlling the heat is the key. Its better to start with to little heat you don't want to overheat the fittings.

- clean the tubing with sand cloth or scotchbrite

- apply flux to the end of the tube. just a thin film

Practice makes perfect. Most say for 1/2" tubing use 1/2" of solder, 1" tubing 1" of solder etc. a little more is ok. You want the solder to flow so pull the heat away when the solder starts to flow, you can reheat if needed.

The solder follows the heat and you want the solder to pull in so with a coupling you would aplpy the heat to the center of the coupling with an elbow you apply the heat to where the end of the tube is inside the fitting.

Doing the bottom of a fitting on a vertical pipe is a little more difficult. Kepp the heat higher on the fitting to pull the solder up. Use minimal heat. Don't heat the pipe below the fitting or the solder will fall out of the joint and flow down.

After soldering have a dry rag to wipe the excess solder off. Do this gently to not disturb the joint.

It sound more difficult than it is. With a little practice you will be fine. Water in the pipe is your enemy.

2 -

My first concern is if you have the room above the pipes to move them there. I wonder why if there are two pipes going up into the ceiling that are close together, why they didn't run both of them up together and then split off. You might want to cut open the ceiling first and make sure there is not any structural issues in the way, and the pipes can go up in that space.

Also, if you do decide to move them yourself, keep a spray bottle of water and a fire extinguisher handy. You will probably be soldering next to some very dry wood, and you don't want to start a fire.

Rick

1 -

@EBEBRATT-Ed you can buy fitting brushes with a hex shaft that fits in an impact driver or drill now, don't have to cut apart one with a handle.

1 -

Thank you everyone, you've been great. To answer the question of ceiling space, there is plenty. You can't see it in these photos but most of the ceiling is actually already down. I left the parts that have the pipes sunk through for the time being. The ceiling was basically the only part of our basement that wasn't destroyed by the flood but it was a poorly done job in the first place so replacing it all is a bit of a relief anyway.

0 -

In my opinion, you, as a first time pipe-sweater, have a far far greater chance of permanent success with sharkbites than you do with a torch.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

-

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

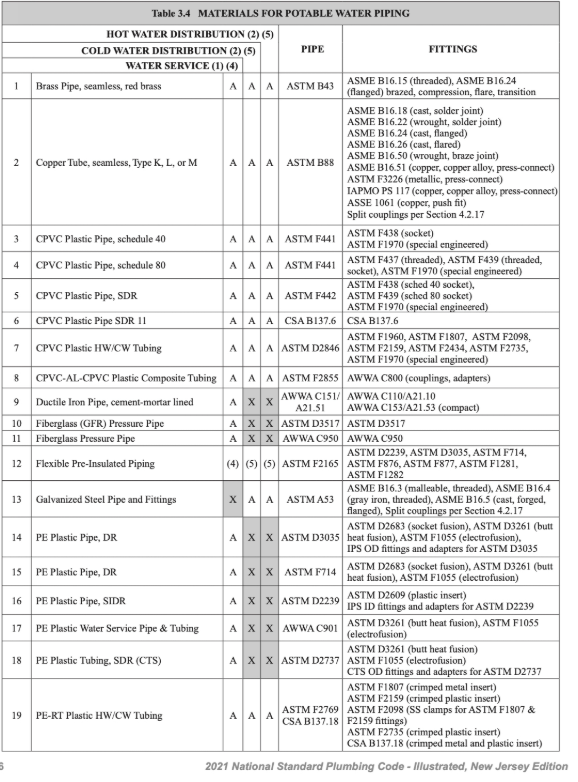

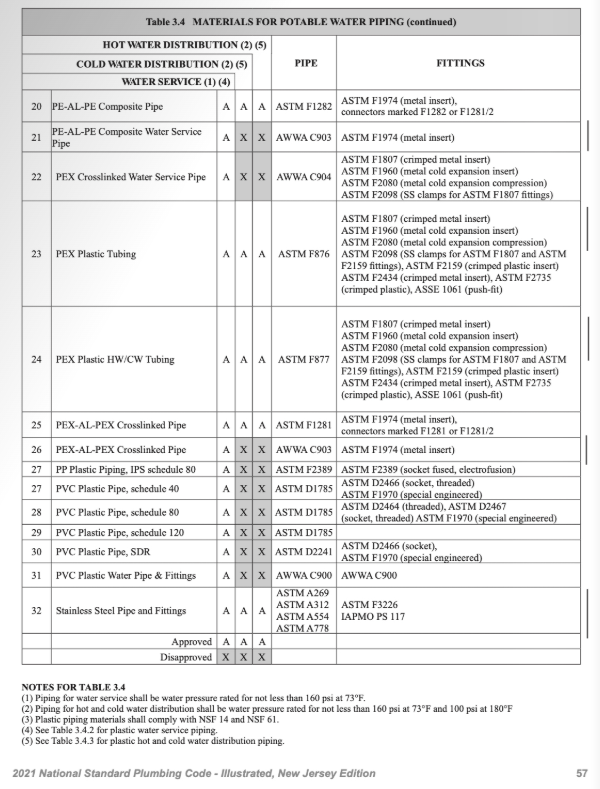

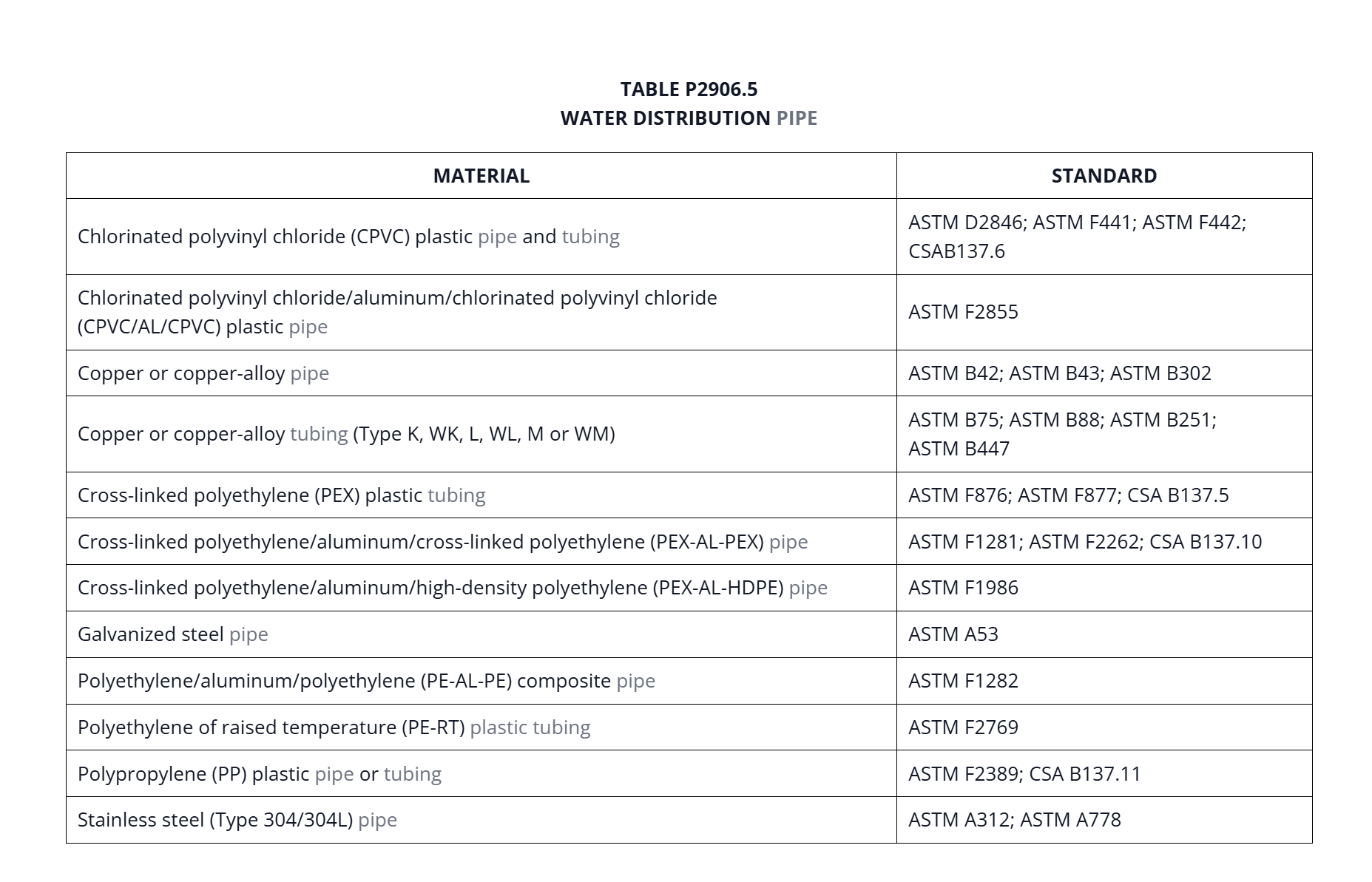

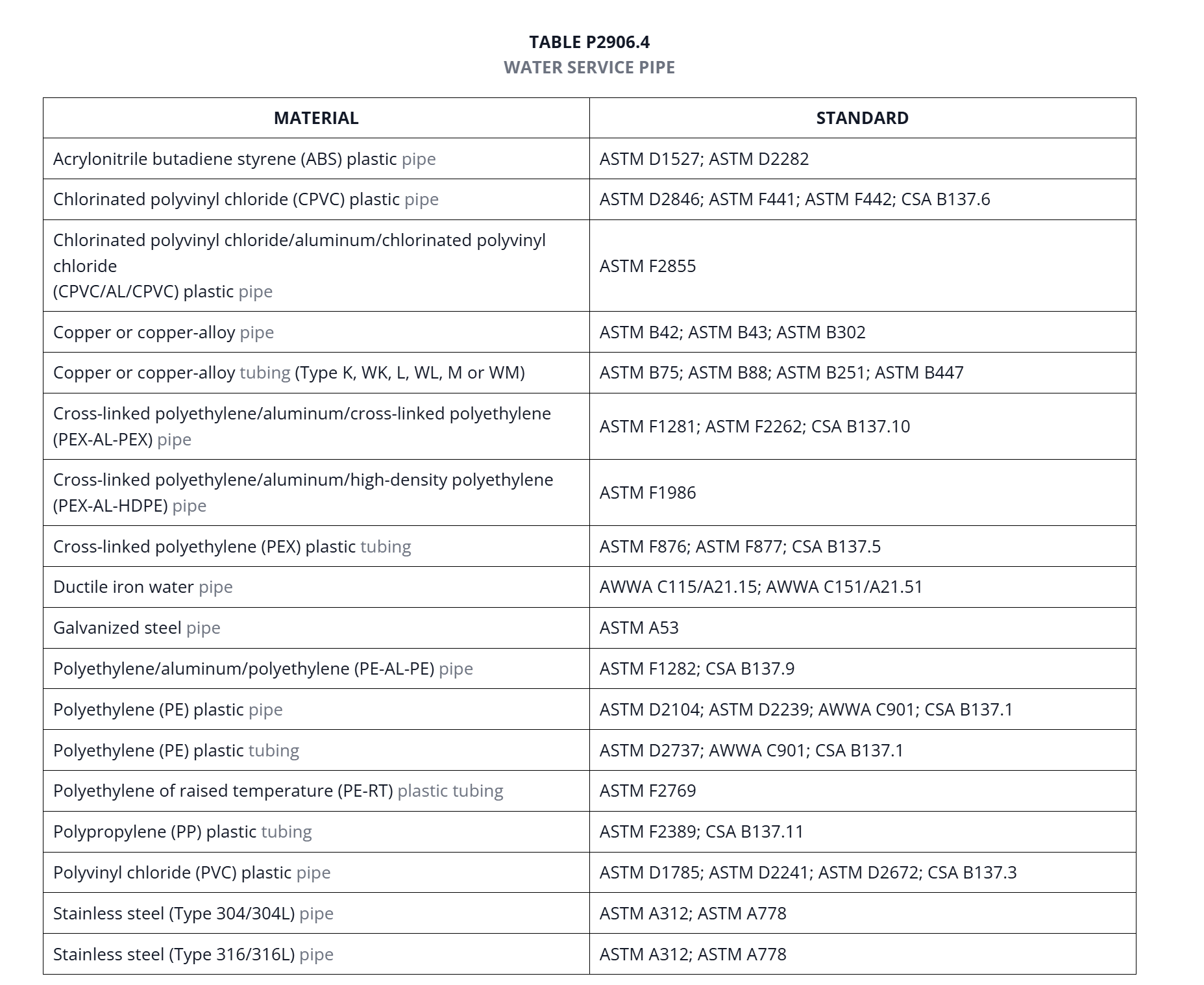

that is ai. it is allowed in the code.

0 -

I didn't check other areas, but in New Jersey galvanized pipe is allowed within the home, but not for a water service. I'm not sure why anyone would use it, but, you can. Even in a brand new house. At least in NJ.

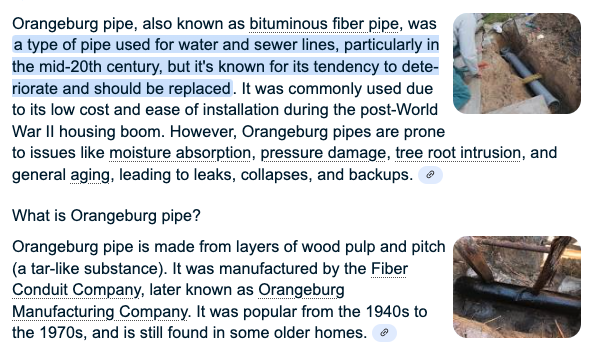

I tried to look for Orangeburg for soil pipe, but I don't know it's real name. Best I can tell, there's absolutely no mention of Orangeburg, fiber tube, or anything remotely similar in NJ's code. Probably because the stuff disappeared 50 years ago because of how wonderful it was.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

From the 2015 michigan residential code

It looks like they removed orangeburg. it was in the 2002 code.

0 -

Orangeburg for water distribution or service? Under pressure?

Wasn't that strictly for drains etc?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

waste. i believe outside of the building only but i'd have to dig out the 2002 code and look. the 2002 code book is about 1/4 the thickness of the 2015 code book.

0 -

Isn't orangeburg just clay tile used for drainage?

0 -

no. thick tarpaper. like 1/2" or so thick wall.

0 -

Ok I have seen that as well tough to cut

0 -

i have a couple very gooey sawzall blades with no teeth on them.

0 -

You posted charts for water distribution and water service, not waste.

Or, did you check the waste / soil pipe section for that and just not share it because it wasn't there anyway?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

only posted the part for galvanized in supply piping. the orangeburg looks like it isn't in the current version but I'm pretty sure it was there 20 years ago. still never really got a clear answer about if the galvanizing sometimes had some lead in it. it would need to be lead free for potable water.

0 -

I worked with Orangeburg pipe when I was young, cut it with a hatchet! Basically cardboard and tar.

Started in Orangeburg, NY!

I don't recall it being used form potable water use? Or any pressure? It didn't have much of a coupling feature.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I don't have access or ability to understand the codes, I admit.

So galvanized pipe is allowed for new homes in 2025?

And if so, how many years does it last? I imagine quite a few. Just like sharkbite. Even Orangeburg reportedly lasted 50 years. Anyway all this is distraction. Sharkbite is accepted by the standards bodies for permanent installations, today.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

All piping materials have a weakness. With galvanized, softened water, for one, can be too aggressive., attack starts at the threads, fittings and pipe, where the galvanizing has been removed.

Water + bare steel= rust and corrosion.

Both press fittings and grip fittings depend on an o-ring for the permanent seal. If that frightens anyone then sweat, braze, thread, copper glue :), compression, flare are other options.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

the galvanizing is still at the joint on the water side but the wall is thinner where it is threaded. they frequently leak at the valley of the threads

0 -

MAPP Pro is not the original MAPP gas….and doesn't burn as hot….

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements