Steam pressure question

Hi all, looking for some additional guidance………..I had checked in a month or so ago. The good news is warmer weather is coming, and my single pipe steam system works great. My main concern is water loss……..when it’s really cold here in northern NJ (5 degrees overnight, teens during the day) I find myself having to add about a pint of water every 2 to 3 days. I’ve been able to locate an angle shut off valve below one radiator that has a pretty decent leak, so that’s a start once the heating system is over.

Peerless boiler that’s about 8 years old. Late last summer I had to replace my boiler sediment drain valve (at the bottom of the boiler) It had a slow leak and I had to really tighten it way too tight to get it to stop. At the same time, since I had the drain the boiler, I flushed the boiler and return line. I did not clear the pressure tool pigtail, as I knew nothing about that at that time. In my original note someone noticed that my 0-30 psi pressure gauge was stuck at 9 psi. I’ve been continuously tapping on it, hoping that I could get the gauge to register something. Eventually I got it to drop to 2psi, but not any lower. I plan to fit a 0-3 psi gauge in conjunction with a new pigtail after the heating season is over. Now when the boiler is running, the gauge goes up to 5 psi. So I’m not really sure what the actual pressure is (if the gauge is reading correctly) but it does appear that the system is running too much pressure.

I also know that I need to skim my boiler. My sight glass is clear at the water line and below, but above the water line it’s got what appears to be oily residue. I had forgotten that when I had an additional bedroom built, I had a radiator line extended approximately 12 feet. I’m fairly confident that the residue in that additional piping has finally made its way down to the boiler.

So besides my leaking angle valve, I appear to have a pressure issue. Am I at the point that I need to focus on the pressuretrol to correct this issue.

I get no noise whatsoever from my system. It heats, it’s quiet, I get no water spitting out of any vents, but I know it needs some attention related to the pressure. Any recommendations at this point would be appreciated.

Comments

-

you have the plan already.

clean the pigtail and install a low pressure gauge. Then you’ll know how things are performing.

No need to wait until summer, might as well have a look during spring.

You live in NJ so if you want, I can teach you how. See my link below.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

And yes I see you are concerned about oil. Skimming never hurts, but if your water line is pretty stable during steaming you can put it off until it's convenient.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Water line barely fluctuates as the system is running, it’s just that the water below the water line is clear yet the air space above the water line has a lot of contaminants stuck to the glass.

0 -

Yes I agree that is a sign that there is oil on your water, but it's not enough to cause surging, otherwise your water level would drop by a very noticeable amount.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

@geemalar Use a brass pigtail …not steel and all brass fittings. Put the low-pressure gauge on. Also replace your 0-30 gauge as well.

If it was me I would put a 1/4" ball valve or petcock under the new lo pressure gauge and keep it shut off unless your checking the pressure….it will last longer.

And don't worry about the lack of pressure. The lower it is the better. As long as the house heats and is quiet that is 90% of the battle.

3 -

Regarding the residue:

"Yes I agree that is a sign that there is oil on your water"

It's more that it's a sign there WAS oil on your water at some time.I have the same issue, but the last time I skimmed, I couldn't really see anything swimming on top of the water. Certainly not the way it looked the first few times I skimmed after installing the boiler.

The sight glass is installed in such a way that it can be removed and cleaned without draining the boiler. Yes you can do it now, but like you, I"m superstitious about touching a system I need to run every day, so I'm putting it off until April.See my DIY thread, last couple of pages, for the installation of a low-pressure gauge above a shutoff valve that protects the gauge.. You find it after clicking on my username. My Peerless runs at a fraction of 1 PSI even if I try to provoke a higher pressure, so I find 5 PSI hard to believe. My 30 PSI gauge has never once budged off zero.

cheers -matt0 -

My concern isnt lack of pressure……..its having too much pressure. My 0-30 psi gauge was stuck at 9 earlier this season, Ive been tapping it lightly trying to get it to break free. Not thinking that would actually work, eventually it did break free. I finally got it to drop back down to zero when the boiler stopped running for a while. I now get a reading of 6 psi during full heat. My understanding is that is too much pressure for my single pipe system.

I’m going to try and clean the pigtail today, as I notice the end connected to the boiler is hot and the opposite end at the pressuretrol is significantly cooler.

0 -

There is no 'flow' through the pigtail, since it's a dead end. It exists so the gauge does not come into contact with steam.

And yes, you should have NO measurable pressure on your 30 PSI gauge. The fact that it sticks is a sign it's not working right, but the fact that you can tap it, get it down, and it rises when the boiler is running is a sign of problems. Do you know the size of your boiler and the size of your installed radiation (EDR)? Domestic single pipe steam should run at less than 1 PSI… it'd be good to figure out what's going on.

Your Pressuretroll should be cutting out and back in to regulate pressure; never heard of one regulating up to 9 PSI. Something doesn't add up. Pictures of the boiler, the piping, and the Pressuretroll might help the pros here to help.0 -

The reading on the pressure gauge in this picture

is from when I took these pictures about 2 months ago. Now it goes up to 6psi.

AFA the pigtail, is it common that the output end is hot enough so I can barely hold my finger on it, yet the end at the pressure troll is lukewarm.

0 -

Here’s some of the return lines…..

0 -

And to clarify…….the pressure gauge drops down to zero on its own now, I no longer have to tap it to make it work. I also understand that the pigtail is a dead end and technically has no flow through it, but if it was NOT clogged shouldn’t both ends be relatively close in temperature. They are significantly different to the touch.

Thanks again to everyone who’s offered their assistance.

0 -

If your gauge is anywhere near accurate, I guarantee your pigtail is plugged. Your Pressuretroll should cut out long before you get to 5 PSI. Your cut-in appears properly set to about 1 PSI.

That boiler is a 63-04L or 63-04, depending on how many burner tubes are underneath; 5 or 6, respectively.

Given the single tapping used vs. the installation manuals requrirements , you should have the lower-fired 63-04L with 5 burner tubes.

The gas input is 147.5 or 177 per the maunufacturer; the net steam ratings are 383 or 458.

It'd be good to know roughly how many square feed of radiation this serves.0 -

I just counted, it’s got 5 burners underneath. Let me start by removing and cleaning or replacing the pigtail with a new brass one and take it from there.

After that I’ll start into investigating getting the EDR of what we have.

Like I said in my OP…….my heat works great, not a peep of clanging or hissing anywhere……..so I have that going well for me. I just know, from reading on this site, that it can be better.

0 -

I also understand that the pigtail is a dead end and technically has no flow through it, but if it was NOT clogged shouldn’t both ends be relatively close in temperature. They are significantly different to the touch.

This is expected and is the whole point of having it. Regardless of whether it's clogged, there is a water trap in there that will prevent steam from going past it.

The heat that conducts from the boiler itself dissipates rapidly into the air leaving the pressuretrol end of the pigtail cool to warm.

It's more that it's a sign there WAS oil on your water at some time.

Maybe. I'm not sure how you can tell from looking at oil in a gauge glass if there is still oil on the water in the boiler. I can say that when I have skimmed, it tends to clean the inside of the gauge glass and so I stand by my observation that an oil slick in the gauge glass is reason to consider skimming.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

tapping the gage that make the needle move is a 100% sign that the gauge is bad or the pigtail is plugged. probably the gauge.

0 -

Bad gauge. If you had 5 psig steam pressure you would know it. Spitting vents, banging, etc.

0 -

5 psi does not cause banging in a one pipe system but I agree you can never trust a factory 0-30psi gauge

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

-

Now you've done it! I know Paul has warmed up to this subject before.

I will say that "5PSI" to first order means "5PSI everywhere in the system," in which case nuthin' stacks anywhere.If you assume that it's 5 PSI inside the boiler, then you have to explain while it's just atmospheric pressure in the returns… what's keeping the steam for pressurizing the mains?

2 -

I don't recall whether this is a one pipe or a two pipe system. If it is a one pipe system, the @mattmich is correct, since in a one pipe system there are no returns at atmospheric pressure. All that will happen is that valves and vents will be overpressured, and leak or spit or hiss or otherwise misbehave.

If this were a two pipe system, in which the returns are at atmospheric pressure, then yes you would get water stacked up into the dry returns — and things would be very unhappy.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

It's a one pipe system and no pressure will cause water to stack up. Here's my video that proves it if you are interested. The reason is because the same pressure that is pushing water out of the boiler is also existing at the far end of the main and is pushing the exact same amount in the other direction.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Pressure creates altitude of water column. We also have to consider application. We know that many jobs are not set up optimally. As the water leaves the boiler, the auto feeder, if so equipped, may not be a VXT. Imagine that! As the pressure builds, make up water is added to satisfy the water line until it stacks up in the return. I have seen this so many times I can't tell you.

1 -

Very interesting video, but it is not any different that I would have expected it to be. If you read information about Dimension A, it will discuss that factors that you are measuring. Most of the dimension A is a safety allowance. The pressure at the inlet of course is going to be the same as the steam outlet in the boiler. Any difference that may exist causing the water to back up (dimension A) will be small and it is caused by the steam that is being consumed in the radiators. You have to remember that steam is traveling fast down the main and a portion is going into each radiator and coming back out as condensate. As you get to the end of the main, it will produce a slightly lower pressure causing a slight backup of condensate. But back at the boiler, the equalizer pipe will do nothing to effect this. I'm not sure anyone ever said it did. It is obvious to me that the equalizer pipe has nothing to do with pressure out at the end of the system.

What the Equalizer Pipe does do is return boiler water that flows with the steam into the header. The header is a steam and water separator, and the equalizer pipe allows that to flow into the boiler at a point that is assured to be equal pressure with the outlet. The equalizer, perhaps a misnomer, assures that the pressure at those two points connecting to the boiler is the same. Seems like it would be anyway. Maybe it would. But it is agreed that the equalizer has little to do with the conditions way out at the end of the system. You still have to worry about Dimension A.

Dave in Quad Cities, America

Weil-McLain 680 with Riello 2-stage burner, December 2012. Firing rate=375MBH Low, 690MBH Hi.

System = Early Dunham 2-pipe Vacuo-Vapor (inlet and outlet both at bottom of radiators) Traps are Dunham #2 rebuilt w. Barnes-Jones Cage Units, Dunham-Bush 1E, Mepco 1E, and Armstrong TS-2. All valves haveTunstall orifices sized at 8 oz.

Current connected load EDR= 1,259 sq ft, Original system EDR = 2,100 sq ft Vaporstat, 13 oz cutout, 4 oz cutin - Temp. control Tekmar 279.

http://grandviewdavenport.com0 -

Dimension A is the dimension at the end of the main down to the waterline, right? You don't have to worry about that.

Thanks for your reply though, you are in a very small club of people who saw in my video what happened and noted it.

And no water goes up to the header unless the water quality is real bad. I've got other videos that show that too.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

So I’m kind of on hold right now AFA removing the pigtail. I tried to unscrew it and it would not budge without using excessive force. I also could not get the pressuretrol to unscrew from the top of the pigtail. I guess that’s what I get for not unscrewing it and checking it regularly every season. Now I know……

We’re in a short cold spell right now, so I’m holding off until it gets warmer this coming week.

FWIW my pressuretrol dial shows the number 1 ………but not knowing if the pigtail is clear kind of makes the setting irrelevant right now.0 -

So with the warmer weather and some time earlier this week, I finally got around to taking on my stubborn pressuretrol and pigtail fittings apart. I first removed the pressuretrol, and noted that it was actually pretty clean at its inlet port. Likely due to……..my pigtail being completely clogged.

I wanted to use the original pigtail as it was brass and had a slightly longer stub pipe than any others I could find, which allows unscrewing of the pressuretrol without removing the pigtail. I was able to clean it out completely using a stranded cable run through it with my drill. Upon reassembly, at the same time fitted a 0-5 psi gauge with a shut off ball valve just before the gauge.

Before I fire up the boiler I plan to skim the water, as I have oily residue above my water line in my sight glass.

Interested to see how the system operates once I get all these previously unknown (to me) maintenance issues resolved. So glad I found this site to gain a wealth of knowledge and guidance in my quest to making my system work at its peak level. Thanks to everyone who’s guided me in the correct steps and direction with the questions I previously had.

3 -

Consider running the boiler for a brief time then letting it settle for a hour or so before you begin skimming. You want the oil/gunk to be warm and soft so it frees up during skimming. You could put some TSP substitute or washing powder in the boiler for this short steam production step too if that's convenient. It will help to break up the oil/gunk. Feel free to show your skimming pipes setup to us. I do see your installer gave you a nipple on the skim port, that's more than some of them do!

I like to run an elbow off that nipple to another horizontal nipple, that lets you slightly lift the pitch of the skim pipe in order to try to get the water level at the skim port to be about 1/2 way up the pipe, if you follow my meaning.

You can use the skim port to add the washing powder then seal it back up and make steam for some minutes. Watch the water level, if it drops suddenly shut it down and then start your skimming a little after that.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

So this is what I have set up to skim the surface……..will this be acceptable, or should I repipe it so it comes up at a slight angle.

0 -

I get what you mean about piping it so when it drains out the skim port the water level is halfway up the drain pipe……..is that setup substantially better. I would have to run out and get some more adapters.

0 -

I was meaning to run the second nipple horizontally, not downward. And don't put a reducer in the skim pipes.

You might be kind of tight on clearance there, but on mine I ran it to the right as seen facing the gauge glass. It doesn't have to be a long pipe. You could hang the bucket off the pipe or kind of set it on that return pipe.

It's good to be able to see the water as it exits the pipe so you can have a better idea of the flow rate and perhaps see if any gunk is exiting. I don't like it when there's a downward pipe to the bucket.

But if all that is too much trouble, what you have there is a lot better than nothing

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

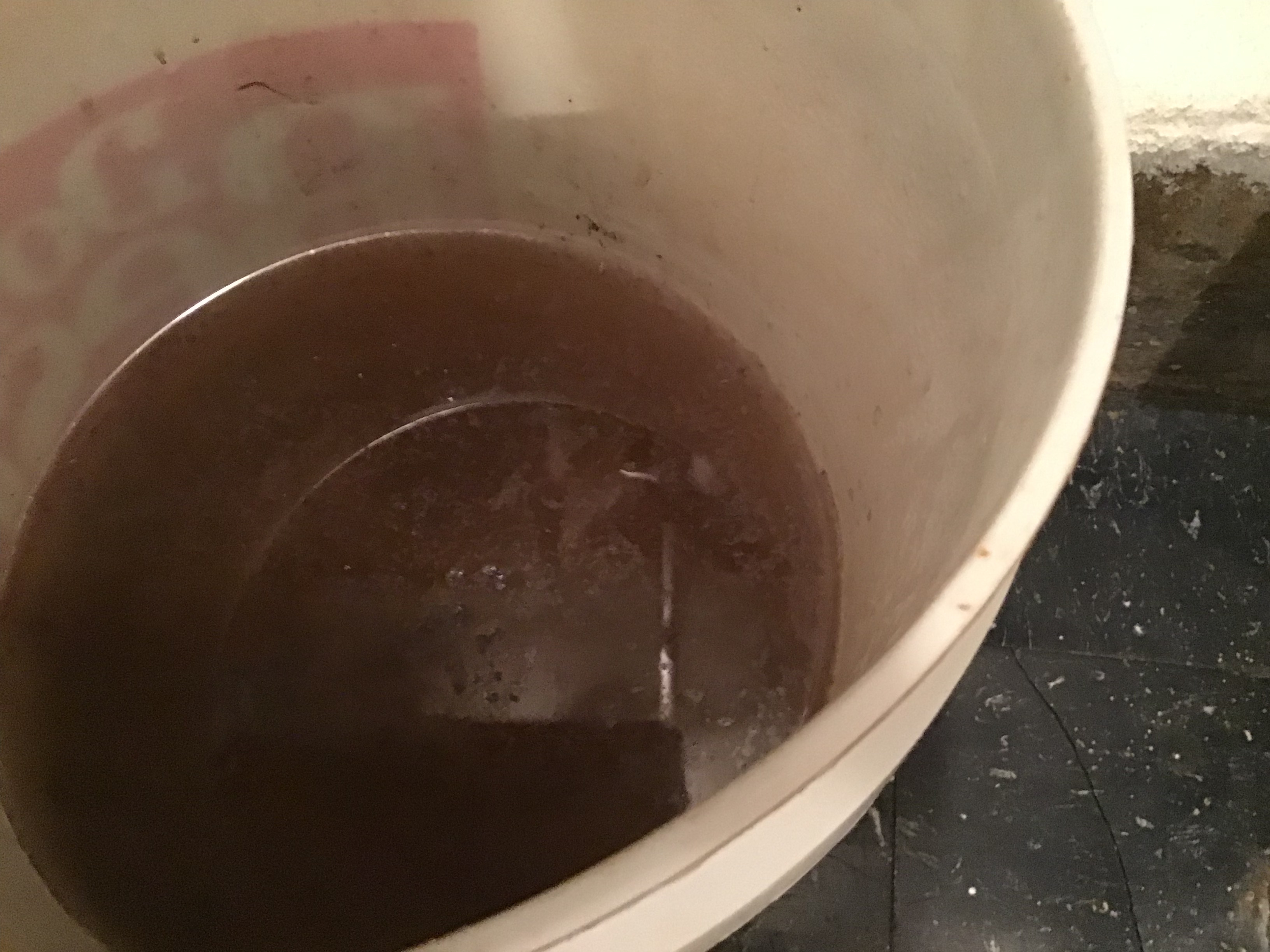

Ok, I understand now…….let me go out and get a few fittings. Here’s the first bucket of residue…..I can see a decent amount of oily substance on top, the water in the picture looks dirtier than it is. The bottom of the pail has some sediment which makes the water look really dirty.

0 -

-

Last few questions……..

How long do you skim for, until the water coming out no longer has residue?And should I just cap the stub pipe again, or put in a ball valve with appropriate fittings so it’s always set up to skim when required.

0 -

-

Yeah I agree with @pecmsg, I really like the ball valve on mine so I can add distilled water manually and any additives I feel like such as "8-way" to increase the pH to dramatically reduce the corrosion and the need to drain off "mud". Once your water is really clean, the need to skim is gone, but I still keep my skim hardware attached for those reasons.

Your setup there looks great, you did perfect, and good job getting some gunk out. Even though your boiler is 8 years old, in my mind, if there is oily residue in the gauge glass, then skimming is called for.

I tend to just skim until it's running out clean or like say 5-10 gallons or so. Then you can try it again after some days of operation like pecmsg said, because more stuff can break loose over time.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I saw a lot of what appeared to be oily residue when I first started skimming, now the water draining out just has an ever so slight brown tint to it. That appears just to be light sediment. I’ll do a gallon or two more, and then set the water to the correct level.

Probably best I just put the ball valve in for future convenience.

1 -

So my next questions……

1) Is this setup acceptable? I only ask as I ran the boiler to where heat was coming out of my radiators, and I could not get the 0-5 psi gauge to read anything. My 0-30 gauge was reading 6 psi, but that gauge had been stuck at 6 psi for the longest time and I’m fairly confident it needs to be replaced. I kept tapping on it this winter and it finally dropped to zero, and it always goes up to 6 psi when I run the boiler. Pigtail is completely clean, and I cleaned the boiler port as I ran a 8 inch long pipe cleaning wire brush into it to make sure the port is clear. Pigtail gets hot fun until it starts to curve up, then it is only warm from that point onward.I know I have to change the 0-30 gauge, but I’m waiting until the middle of summer in case I run into any issues.

I know the 0-5 psi gauge works, as I blew into it lightly to see if it would read before I installed it, and it did. Also, when I screwed it onto the stub pipe, it read about 1/2 psi as the ball valve was closed when I screwed it on. Once I opened the ball valve, it dropped to zero.

No water level bounce in the sight glass, no spitting at any radiator valves……..everything seems to be working as intended.One other question……so when I screwed in the pigtail, I was able to get it to the point where it sits now. Trying to screw it one more turn was not possible unless I really forced it, which I was hesitant. So I left it where it is, which is somewhat tight, but not bottomed out as I would like. Doesn’t appear to leak anything from the base, so I left it where it is. Easy enough for me to tackle later on if there is any signs of a leak, but that does not appear to be an issue on the first run of the boiler.

0 -

I should have just stopped, but the rainy day here said why stop now…….remnants of the 0-30 psi gauge removal process.

I’ve heated the adapter and stuck the proper size 1/2 inch drive socket on it with a 2 1/2 foot Snap On breaker bar and a pipe extension for leverage…………I’m on the verge of breaking the end of the bar off.

Should I try drilling out the remnants of the gauge and using a broken bolt remover, or work on trying to unscrew the adapter? Or can I just leave it in there, and tie in a 0-30 psi gauge opposite of my 0-5 psi gauge on the other side of the pressuretrol?Trying to look at the positive, it’s May and I have a few months to get this accomplished.

0 -

First, on the low pressure — you don't need much to get heat to everything, and in fact you don't want much. A few ounces at most is quite sufficient for most residential systems. So the fact that you don't see much on the low pressure gauge isn't a problem.

Your pigtail is fine. That NPT thread, which is tapered, so you don't have to screw it all the way in. At the pressures you are likely to run, hand tight is going to be ample.

You can replace the 0 to 30 gauge if you like. It's probably busted — most of them are — and it's there as much to keep the insurance people and building inspectors happy as anything else. Not to worry about it.

Sounds to me as though everything is good…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements