Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

Steam pipe foam spray insulation in recessed area

Options

MountainSteam

Member Posts: 20

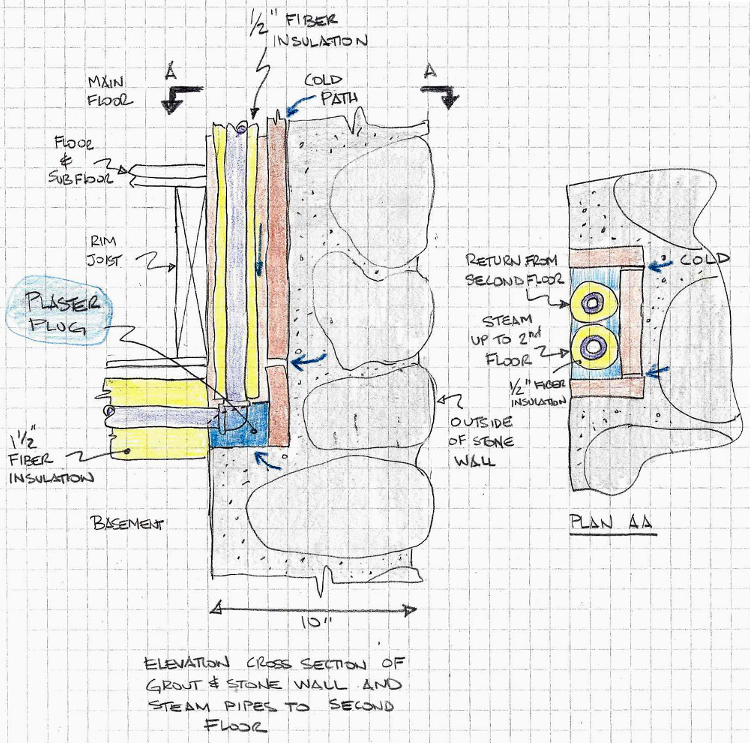

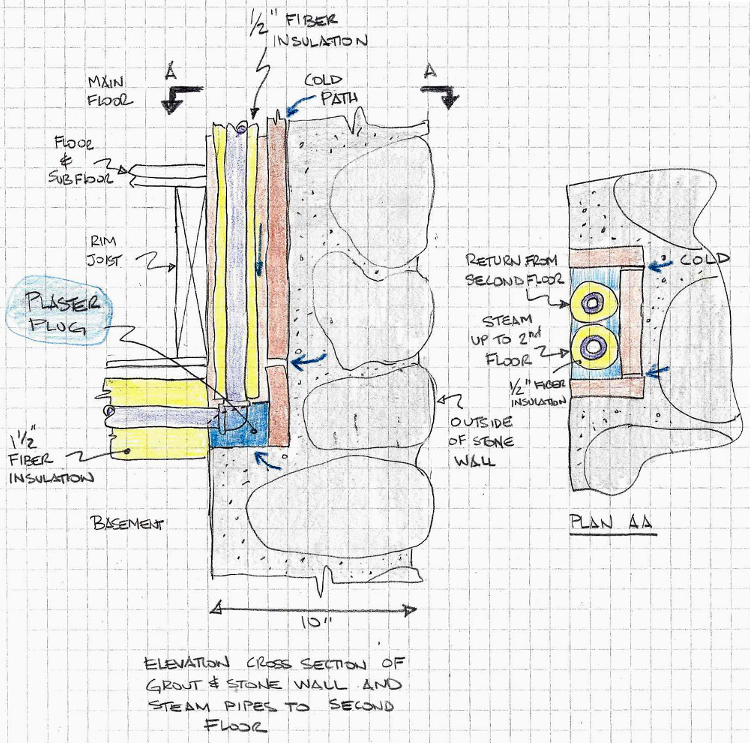

My ninety year old stone home is heated by a two pipe steam system. The 3/4 inch iron pipes from the basement to the second floor run up a vertical channel block-out in the stone wall. At the bottom of the channel, there is a plug of plaster and debris. I can chip out most of the plaster plug to expose the elbow (see sketch)

I am able to wrap the pipes with fiber insulation (shown in yellow on the sketch), but not the elbow. Because cold seeps from the stone wall through the cracks in the 1x blockout around the vertical channel (blue arrows on the sketch), the air around the elbow fluctuates from 60F (when the steam is on) to 35F (between steam cycles), when the outside temperature is 10F, so both the steam and return pipes get very cold from the elbow. On the coldest days of winter the elbows must get below freezing.

Once I chip out the plaster plug, I could insulate the elbows by stuffing some fiber insulation in the notch, but that will not stop the cold from seeping in the cracks along the channel, so I plan to spray some foam insulation behind the vertical fiber insulated pipes and around the elbow (see second sketch)

So the elbow of the pipe carrying the steam upstairs would be in contact with the foam spray insulation. I would spray the foam while the system is off and keep it off until the foam cures. I am at high altitude, where water boils at about 195F. My system operates with a vaporstat at less than 12 ounces of pressure, so the steam should never be more than 200F, well under the 240F rating of the foam spray. I tested foam spray around other steam pipes in the house and it seems to be holding up well after a month of contact with the steam pipes.

Is there anything wrong with this plan?

I am able to wrap the pipes with fiber insulation (shown in yellow on the sketch), but not the elbow. Because cold seeps from the stone wall through the cracks in the 1x blockout around the vertical channel (blue arrows on the sketch), the air around the elbow fluctuates from 60F (when the steam is on) to 35F (between steam cycles), when the outside temperature is 10F, so both the steam and return pipes get very cold from the elbow. On the coldest days of winter the elbows must get below freezing.

Once I chip out the plaster plug, I could insulate the elbows by stuffing some fiber insulation in the notch, but that will not stop the cold from seeping in the cracks along the channel, so I plan to spray some foam insulation behind the vertical fiber insulated pipes and around the elbow (see second sketch)

So the elbow of the pipe carrying the steam upstairs would be in contact with the foam spray insulation. I would spray the foam while the system is off and keep it off until the foam cures. I am at high altitude, where water boils at about 195F. My system operates with a vaporstat at less than 12 ounces of pressure, so the steam should never be more than 200F, well under the 240F rating of the foam spray. I tested foam spray around other steam pipes in the house and it seems to be holding up well after a month of contact with the steam pipes.

Is there anything wrong with this plan?

0

Comments

-

No, not really... overkill in my opinion, but... should help some.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

At those low temperatures I see no issues.0

-

-

Just be aware spray foam is best installed when the area is at 70 degrees so wait till summer if your going to try this.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

Is the current pipe wrap (yellow) done with those rigid 3' sections of pipe insulation sleeve halfs? if so, the vertical insulation must have been installed from the top as it does not appear that you'd be able to make the angle to get it up through the opening around the elbow.

if you have access at the top, could you get a rod or dowel and just stuff loose fiberglass insulation down to fill that red void? I imagine regular unfaced wall insulation is cheap and effective if you can stuff pieces of it in, no? compressed fiberglass insulation looses insulation efficiency when compressed as there are fewer air pockets, but i would think it should do quite well to block the drafts.

I've thought about spray foaming a few spots, myself, but I'm always stopped by the idea that the stuff is pretty much permanent as it sticks to everything! I mean that's part its charm, but I get scared about making changes that can't be undone.New owner of a 1920s home with steam heat north of Boston.

Just trying to learn what I can do myself and what I just shouldn't touch1 -

Thank you all for your replies. As I work on this, I realize I'm overdoing this, but once I put the drywall up, I never want to remove it!

Thanks to your replies, I'll use a combination of rigid insulation and foam to insulate and seal this area.

@Zipper13 - The sleeve insulation around the vertical runs is new. When I removed the lath and plaster, there was some ancient sleeves around some of the pipes, which I removed (carefully).

0 -

The only issue I have with fiberglass is it ability to absorb moisture and loose its insulation value. Foam will not.MountainSteam said:Thank you all for your replies. As I work on this, I realize I'm overdoing this, but once I put the drywall up, I never want to remove it!

Thanks to your replies, I'll use a combination of rigid insulation and foam to insulate and seal this area.

@Zipper13 - The sleeve insulation around the vertical runs is new. When I removed the lath and plaster, there was some ancient sleeves around some of the pipes, which I removed (carefully).0 -

I would NOT try this. There may be a BENEFIT from some heat going into outside wall. Pushes the "frost" line toward the outside?0

-

I don't insulate a steam pipe going up an outside wall because there are water pipes going up that same cavity. This house is almost 100 years old so it's not particularly tight. On rare nights when we dip to -10 F that steam pipe keeps the water line going up to the bathroom nice and cozy.

I did wedge a piece of 1/4" plywood to shield the pipes from any air leak at the rim joist. The surface of that plywood feels cold but it stopped the cold knife of air when the Montreal Express visits us. The other upstairs radiator feeders are in interior walls.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0

Categories

- All Categories

- 85.2K THE MAIN WALL

- 3.1K A-C, Heat Pumps & Refrigeration

- 55 Biomass

- 424 Carbon Monoxide Awareness

- 73 Chimneys & Flues

- 1.9K Domestic Hot Water

- 5.2K Gas Heating

- 129 Geothermal

- 160 Indoor-Air Quality

- 3.3K Oil Heating

- 61 Pipe Deterioration

- 884 Plumbing

- 5.9K Radiant Heating

- 376 Solar

- 14.7K Strictly Steam

- 3.2K Thermostats and Controls

- 59 Water Quality

- 49 Industry Classes

- 89 Job Opportunities

- 28 Recall Announcements