Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

Steam Main Valve Issues

Options

prm510

Member Posts: 13

Hi All! New to the site and had a question. I live in my late grandparent's house and it has a steam system powered by an old boiler. My grandfather was an oil man (commercial and residential) and owned his own business- he also built the house. Before he passed he didn't pass on any of the pertinent information on the system he set up- and my dad is not oil savvy. So here I am in the house and I noticed two radiators weren't working- one in my living room and the other in the garage (Grandad liked a little heat when working on the car in the winter and helps keep the pipes warm).

Long story short- I call my oil company- burner guy # 1 comes out and replaced one old Dole #5 with a VentRite #35 and said - I know it's too small we will come back with the correct part! Burner guy # 2 comes back and replaces two more old Dole #5s with VentRite 75s- doesn't replace the #35. The issue is still the same. I go down the basement and look- there are 9 radiators in the house- and 9 vents. One zone is on a group of 4 on the return, another on a group of 3 on the return and there are two on the send.

Group of four in order from left to right- VR #77, VR#75, #75, #35. Group of three- Dole #5, VR #77, Dole #5. The two on the main supply are VR #77. I'm thinking I should replace the 75s, the 35 and the Doles with 77s. All of these used to be Dole #5's. Is that what could be causing this heating nightmare? Mind you I am no plumber or heating guy- just a homeowner who is trying not to have the oil company come back out and screw something else up...

EDIT: All the valves replace radiator valves on the physical radiators themselves.

EDIT: Steam Valve Pictures:

Photo 1: Four return valves- for Bathroom, Dining Room, Kitchen, and One Living room radiator

Photo 2: 3 Return Valves- for Master Bedroom, Middle Bedroom, Front Bedroom

Photo 3: The problem valves- Left- Living room radiator 2. Right- Garage radiator.

EDIT: Boiler pictures Added

Long story short- I call my oil company- burner guy # 1 comes out and replaced one old Dole #5 with a VentRite #35 and said - I know it's too small we will come back with the correct part! Burner guy # 2 comes back and replaces two more old Dole #5s with VentRite 75s- doesn't replace the #35. The issue is still the same. I go down the basement and look- there are 9 radiators in the house- and 9 vents. One zone is on a group of 4 on the return, another on a group of 3 on the return and there are two on the send.

Group of four in order from left to right- VR #77, VR#75, #75, #35. Group of three- Dole #5, VR #77, Dole #5. The two on the main supply are VR #77. I'm thinking I should replace the 75s, the 35 and the Doles with 77s. All of these used to be Dole #5's. Is that what could be causing this heating nightmare? Mind you I am no plumber or heating guy- just a homeowner who is trying not to have the oil company come back out and screw something else up...

EDIT: All the valves replace radiator valves on the physical radiators themselves.

EDIT: Steam Valve Pictures:

Photo 1: Four return valves- for Bathroom, Dining Room, Kitchen, and One Living room radiator

Photo 2: 3 Return Valves- for Master Bedroom, Middle Bedroom, Front Bedroom

Photo 3: The problem valves- Left- Living room radiator 2. Right- Garage radiator.

EDIT: Boiler pictures Added

0

Comments

-

You should start with larger main steam pipe air vents in the basement.

How long is each main and what size of pipe is it?

Pictures of existing main vent install would help.0 -

I have a horrible feeling those are the main vents, @JUGHNE ! And I don't see a whole lot of overhead clearance... however, if the steam is dry enough, one could probably swap out a couple of those vents for a couple of Big Mouths on each antler, and do a world of good.

That said, it would help to know -- is this a two pipe system? Or one pipe? (the radiator piping will tell you).

And we always like to see pictures of the boiler and the piping in that vicinity!Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Notice the split ring hangers holding up the pipe....those are old style they used 1/4" pipe instead of threaded rod. They are old0

-

As you suspect everything is wrong. What diameter mains do you have and how long are they?0

-

To all- the house was finished in 1952- system is a two pipe system- one for supply and one for return. The system according to the oil company is a commercial style system for residential- doesn’t surprise me as my grandfather did this for a living.

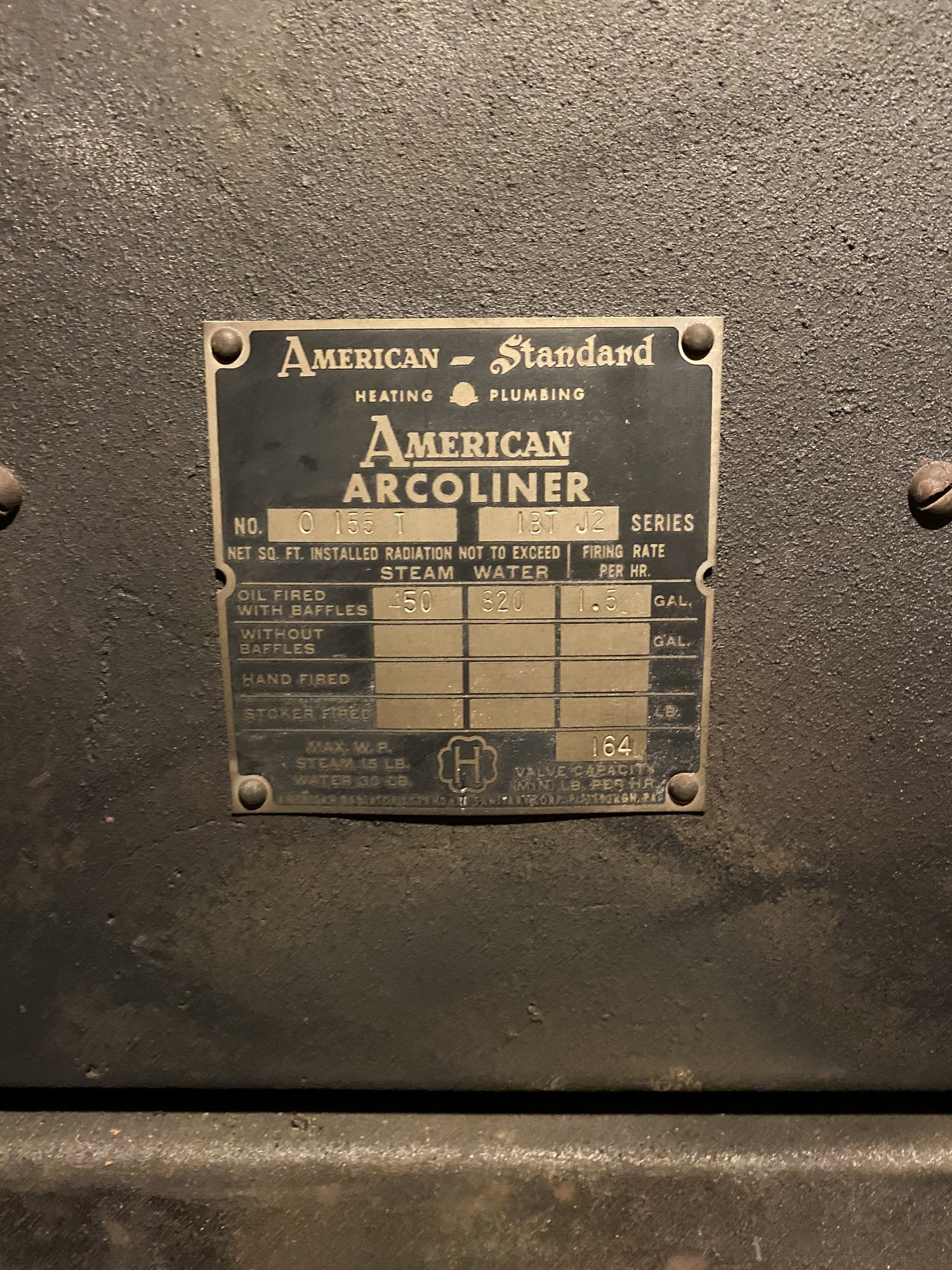

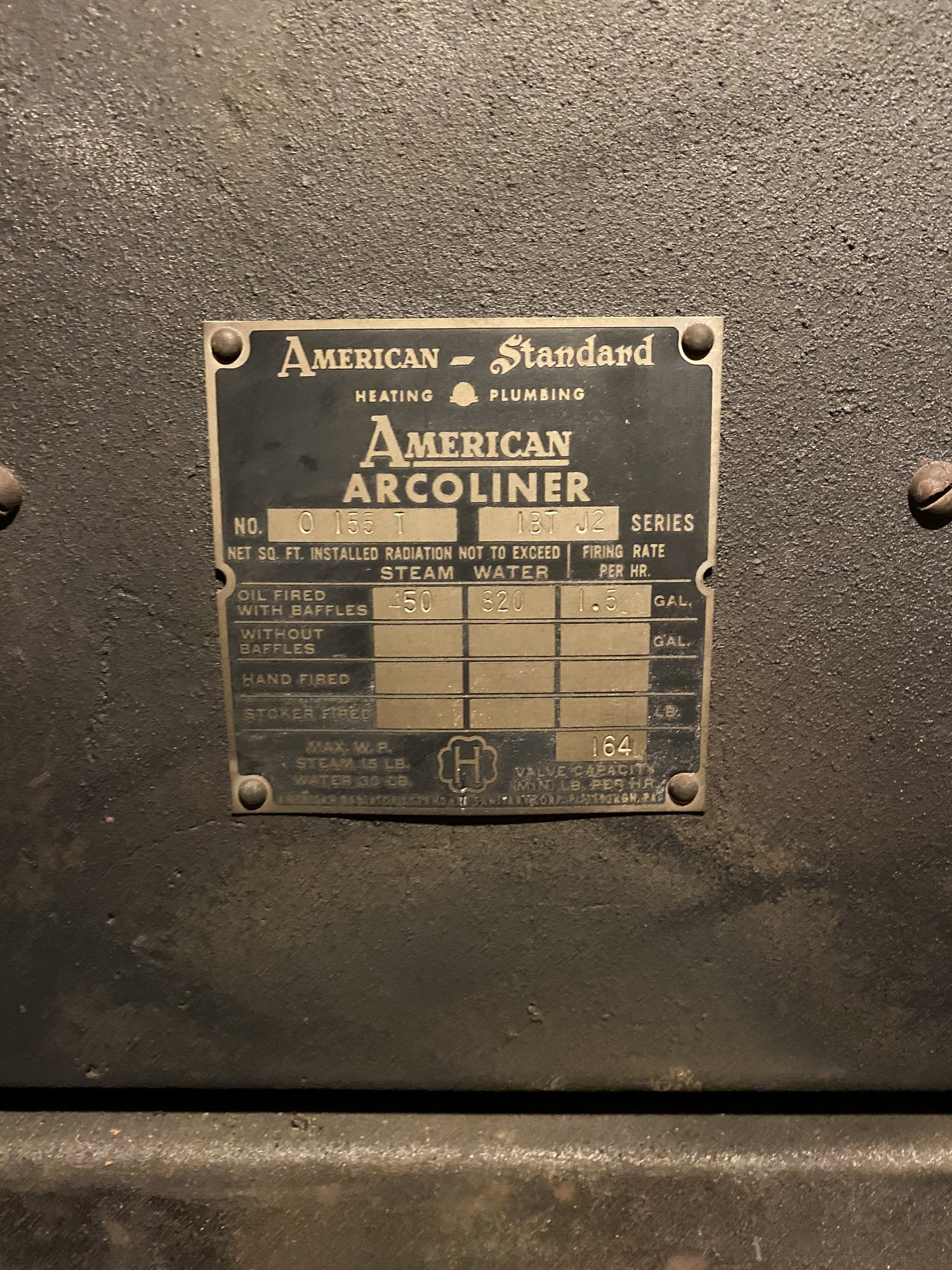

More pictures to come of the boiler- it’s an original American Standard Arcoliner from ‘51 and runs at 78% efficiency. I don’t have the $ to replace it otherwise I would!

The mains are really long they run the length of the house which is 1,300 sq ft. More pics to come. I’m not a happy camper right now as I’m running through way too much oil.0 -

> @Jamie Hall said:

> I have a horrible feeling those are the main vents, @JUGHNE ! And I don't see a whole lot of overhead clearance... however, if the steam is dry enough, one could probably swap out a couple of those vents for a couple of Big Mouths on each antler, and do a world of good.

>

> That said, it would help to know -- is this a two pipe system? Or one pipe? (the radiator piping will tell you).

>

> And we always like to see pictures of the boiler and the piping in that vicinity!

Yes those are the main vents. Sigh. Lol0 -

> @gfrbrookline said:

> As you suspect everything is wrong. What diameter mains do you have and how long are they?

I don’t know- my grandfather was extremely proud of the systems he installed and was meticulous about it- probably a reason he set it up that way- but I can’t ask him. Personally- is love to redo it haha0 -

I posted before I saw it was 2 pipe steam. There is a strong possibility that your grandfather set up a perfectly working system and who ever installed the newer venting screwed it up.

From what I can see on the first picture the vents on the left side are not pitched correctly and will just fill with condensate.

I don't have experience with two pipe but that is wrong with either system.0 -

> @gfrbrookline said:

> I posted before I saw it was 2 pipe steam. There is a strong possibility that your grandfather set up a perfectly working system and who ever installed the newer venting screwed it up.

>

> From what I can see on the first picture the vents on the left side are not pitched correctly and will just fill with condensate.

>

> I don't have experience with two pipe but that is wrong with either system.

I suspect the clowns from the oil company did that. I’ll have to take a little PB Blaster to loosen the rust up and straighten them out.0 -

Don't use chemicals, two wrenches should work. I also notices they didn't use any tape or dope on any of the fittings, that should also be corrected so you don't have leaks.

If you use chemicals you will need to skim the boiler to remove them.0 -

> @gfrbrookline said:

> Don't use chemicals, two wrenches should work. I also notices they didn't use any tape or dope on any of the fittings, that should also be corrected so you don't have leaks.

>

> If you use chemicals you will need to skim the boiler to remove them.

Chemicals are a no in my book :-) I’ll use wrenches and I have tape in my tool box. I will let you know how it turns out!0 -

I would plug pictures 1 an 2, add Gorton 2's to replace the original vents and see if that corrects your problems. The new vent's are not helping your situation.

0 -

> @gfrbrookline said:

> I would plug pictures 1 an 2, add Gorton 2's to replace the original vents and see if that corrects your problems. The new vent's are not helping your situation.

Interesting thought- took a look at the Groton 2 and the connection is too small for the entrance of the main pipe. In addition- these vents are to replace radiation vents on the radiators themselves. None of my radiators have steam vents- picture attached of the very 1950s colored blue one in the bathroom :-)0 -

The majority of two pipe steam systems don't have radiator air vents and if it's worked for decades without them it does not need them. This system worked well for a long time and something has happened to make it stop working correctly.

Look at the steam mains and feeders that feed the problem radiators to be sure they are sloped so water can find it's way to the boiler; the house may have settled over the years and some slopes gone wrong.

The multiple mains vents you have are rated for about 0.11cfm, a Gorton #1 is 0.33cfm, the Gorton #2 is 1.1 cfm and the bigmouth is 2cfm. If you can just replace one or two of those small vents on each steam main with a #2 or bigmouth your venting will be vastly better. If $$ are a concern you can replace the undersized vents with Maid O Mist #1's, they vent just as fast as a Gorton #1 and are a lot cheaper (maid o mist #1 is about 1/3 the cost of a Gorton #1). The #1 vents are small enough to fit most spaces whime the #2's and Big Mouths are huge. The Gortons are a better vent but the MOM's have worked fine for me for years now.

If there are any steam traps on the radiator outflow pipes, make sure they are working. He may have put orifice plates in to meter the amount of steam and if so there won't be any traps.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge1 -

You can always use a bushing to correct the thread size of the Gorton #2s, and I would do that in this system.

On the radiators which aren't working. Two pipe steam depends on the steam being able to get to the radiators -- that's where the main vents come in. But it also depends very much on the condensate and air being able to get out of the radiators at the other end and go somewhere. So if you have two radiators which aren't working, I'd take a good look at the traps on the radiators. They have been known to fail closed, at which point the air can't get out -- no heat. Then I would look at the return lines, to be sure that they are pitched correctly so that any condensate in them can get out. Then... what vents do you have on the return lines? It's not immediately clear from all of the above whether those interesting antlers are on the mains -- or on the returns. The dry returns on your two pipe system must be vented at least as well, if not better, than the steam mains themselves.

Are there vents on the returns? Where? And what size? And how do the dry returns get their condensate back to the wet returns and the boiler.

Don't sweat that old Arcoliner. Yes, you might be able to save some oil with a newer boiler. But it your heat loss from the building is excessive, that's the place to put your money. Insulation, good storm windows, sill and perimeter sealing, doors, that sort of thing.Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Before you get crazy, i noticed all the steam pipe shown is uninsulated. as the steam flows thru the steam piping the pipe heats the basement and condensate forms. the waters of condensate is spent steam and that steam is no longer available for the upstairs radiators.

I do not see the the overhead dry returns, the vent valves belong on the over head dry returns not the steam main as the vent valves on the dry returns vent the entire system and radiators.

The steam main should connect to the dry returns via a radiator type steam trap. The steam trap vents the air to the dry return and closes when steam pressure is established.

This type of system usually operated at about 1.5 psi with a .5 psi differential.

Jake

Steam: The Perfect Fluid for Heating and Some of the Problems

by Jacob (Jake) Myron0 -

> @Jamie Hall said:

> You can always use a bushing to correct the thread size of the Gorton #2s, and I would do that in this system.

>

> On the radiators which aren't working. Two pipe steam depends on the steam being able to get to the radiators -- that's where the main vents come in. But it also depends very much on the condensate and air being able to get out of the radiators at the other end and go somewhere. So if you have two radiators which aren't working, I'd take a good look at the traps on the radiators. They have been known to fail closed, at which point the air can't get out -- no heat. Then I would look at the return lines, to be sure that they are pitched correctly so that any condensate in them can get out. Then... what vents do you have on the return lines? It's not immediately clear from all of the above whether those interesting antlers are on the mains -- or on the returns. The dry returns on your two pipe system must be vented at least as well, if not better, than the steam mains themselves.

>

> Are there vents on the returns? Where? And what size? And how do the dry returns get their condensate back to the wet returns and the boiler.

>

> Don't sweat that old Arcoliner. Yes, you might be able to save some oil with a newer boiler. But it your heat loss from the building is excessive, that's the place to put your money. Insulation, good storm windows, sill and perimeter sealing, doors, that sort of thing.

The antlers are on the return.0 -

Ok- updated the pictures with some text and did some spelunking in the basement- the valves are all on the returns. Antler with 4 valves (don't know what order) Bathroom, Living room radiator 1, kitchen and dining room. Antler with three controls (again order unknown) Master Bedroom, Middle Bedroom and Front of house bedroom. The other two see the picture for the descriptions.

Pipes are sloped and the house hasn't settled much in the 65 years it's been here. Grandpa used plates and not traps for the radiators. This is a commercial system from 1950 in this house. It took some digging and picking my dad's brain to figure it out.

Looking at it now, Grandpa set it up beautifully and it's no wonder he was so proud of it. House is drafty and we're looking at insulation now and for a quick fix, using plastic over the single pane windows.0 -

Air vents in the basement do not know your radiators exist.

There is not any dedicated basement vent for any particular upstairs radiator. If your service people believe that they are really lost.

Those vents only vent air out of the pipes, be it supply or return.

They all look too small for the job.

Do you know if he used "plates" in the supply valves to avoid the use of traps. If so they were sized based on rad size and steam pressure. Most likely low pressure.0 -

They might not 'know' what rooms they are for (the vents that isJUGHNE said:Air vents in the basement do not know your radiators exist.

There is not any dedicated basement vent for any particular upstairs radiator. If your service people believe that they are really lost.

Those vents only vent air out of the pipes, be it supply or return.

They all look too small for the job.

Do you know if he used "plates" in the supply valves to avoid the use of traps. If so they were sized based on rad size and steam pressure. Most likely low pressure. ) but I did trace the return pipes from each room to the antlers. In terms of the valves these vents were all Dole #5's - so I did my research and found this link that states the VentRite 77 replaces the old Dole 5:

) but I did trace the return pipes from each room to the antlers. In terms of the valves these vents were all Dole #5's - so I did my research and found this link that states the VentRite 77 replaces the old Dole 5:

https://ventritevalve.com/products/77-main-vent/

There are no traps on the radiators- just a valve to open the supply and a return pipe. I popped open the access panel on each one to take a peek. I'm guessing the supply uses those plates you mentioned but I wasn't alive in 1950 to see what Grandpa did (Kinda wish I had a time machine!).

(Kinda wish I had a time machine!).

I am calling an old friend who I remembered this evening is a licensed MA oil burner tech to see what he thinks.0 -

I'll bet the "plates" your grandpa used had orifices in them. These he would have sized to deliver -- at a certain maximum pressure -- just the amount of steam the radiator can handle, and no more. A beautiful, elegant system with no moving parts.

But. Note the comment "at a certain maximum pressure". It's really important with an orifice system to keep the pressure down. He may have sized it for what might thought of as a higher than normal pressure for an orifice system, however -- perhaps as much as a pound and a half. Fortunately, there is a very very easy way to tell if the pressure is right: the outlet pipes from the radiator can (and on a long run should) be nice and hot -- perhaps as much as 205 to 210 -- but they should not be steam hot (212). Use a good IR thermometer on bare metal or a black surface (electrician's tape?), and the comparison (dropping 5 to 10 degrees from the inlet to the outlet) is more reliable than the actual number.

I hope the "plates" are still in all the radiators?Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

As everyone else has mentioned the main venting needs to be upgraded to larger vents and the piping needs to insulated which will make a huge improvement.0

-

Note: I don’t own the house - my dad does. He’s not upgrading anything on the heating vents if it’s been working fine for all these years. I spoke to my friend who is licensed and coming over on Friday to take a look.0

-

“If” being the operative word.

If it’s fine to burn a lot of extra fuel unnecessarily in order to get steam to fill the mains every time there’s a call for heat, then you’re all set.NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

True0

-

Mods please close this discussion. Issue has been solved this morning. Valves needed to be replaced- all 75s, 5s and the 35 were replaced with VentRite 77s. Magic- heat is working the way it should now- thanks for all the help folks!0

Categories

- All Categories

- 87K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 57 Biomass

- 425 Carbon Monoxide Awareness

- 112 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.7K Gas Heating

- 106 Geothermal

- 160 Indoor-Air Quality

- 3.6K Oil Heating

- 70 Pipe Deterioration

- 980 Plumbing

- 6.3K Radiant Heating

- 388 Solar

- 15.4K Strictly Steam

- 3.4K Thermostats and Controls

- 54 Water Quality

- 44 Industry Classes

- 48 Job Opportunities

- 18 Recall Announcements