Is there such a thing as too much?

Can you have too much flow or too high a GPM for baseboard radiant heat to become less effective? The only downside I can think of is noise.

Comments

-

yes

Flowing to Quito allow heat transfer

0 -

Flow should be kept under 5 fps.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

The downside is noise and head loss.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

assuming the same supply temperature is maintained, then increasing the flow will give you more heat output

The math is 488 x flow rate x delta T (488 is the factor for water at 180 degrees)

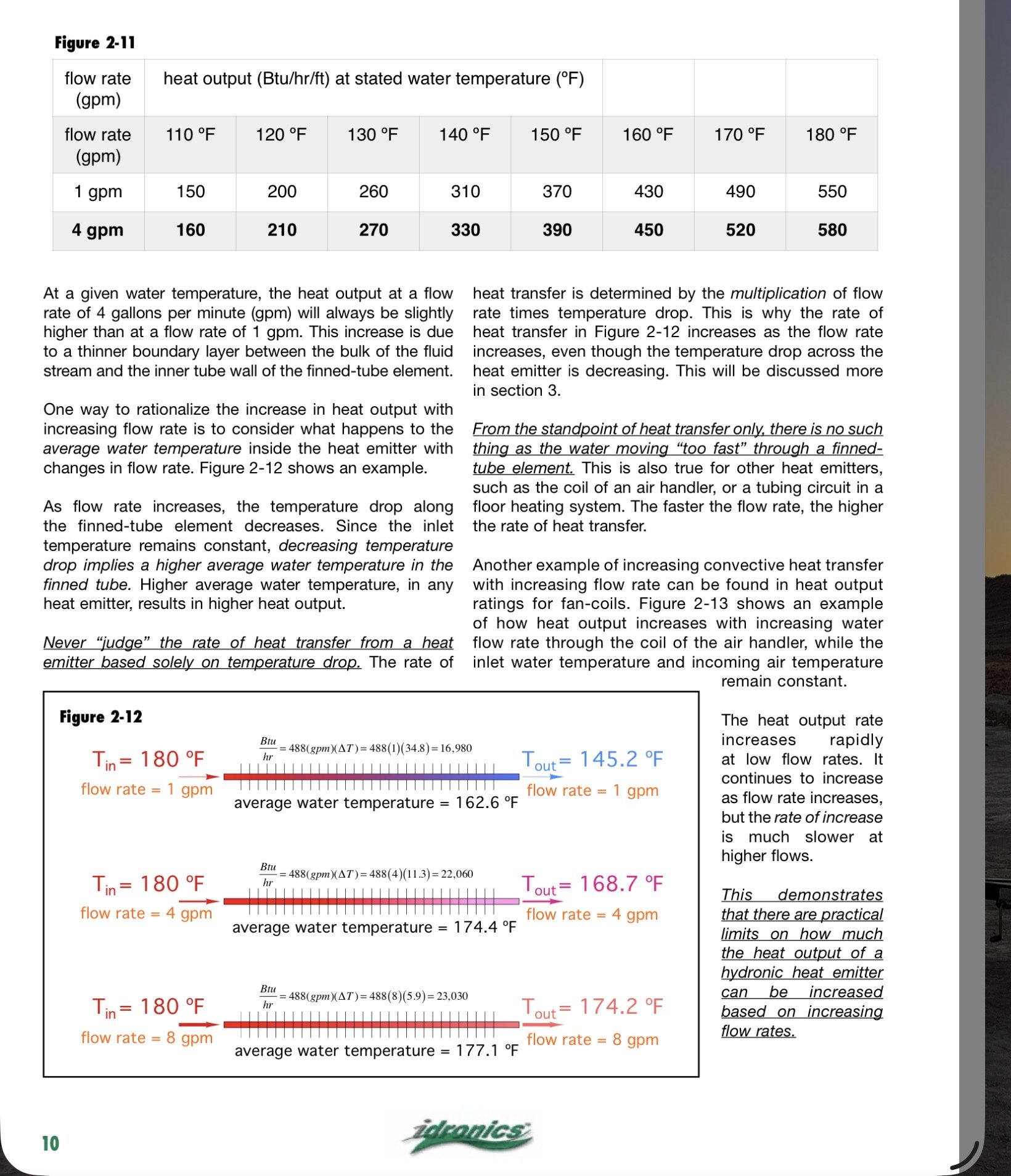

At the top of this page is a fin tube output chart. You notice the output / ft. goes up at 4 gpm vs 1 gpm

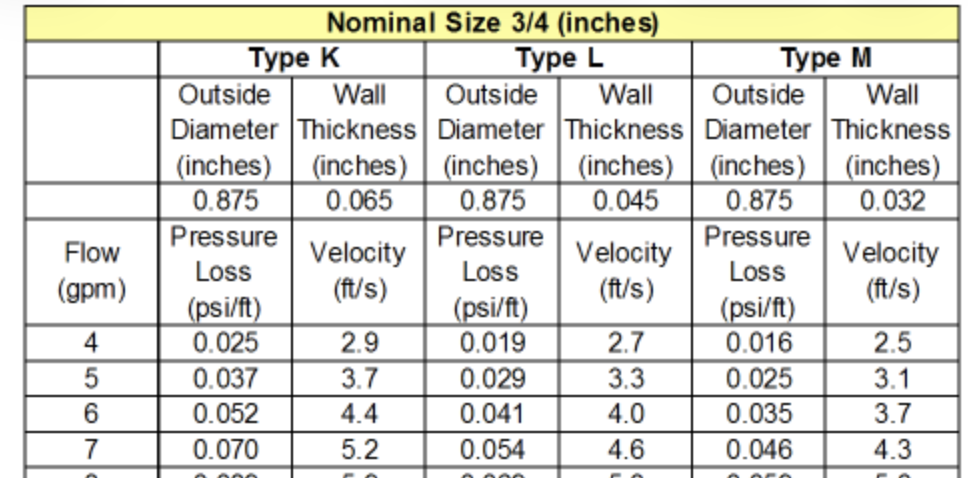

The limitation is the tube size and acceptable flow. 4 gpm in 3/4 tube is about as much as you want to flow. Excessive flow leads to noise and tube and fitting erosion.

Which is probably why the manufacturer used 4 gpm

The lower graph shows output increase as flow increases also. It goes from 16,980 btu/ hr to 23,030 on the lowest example.

It takes flow out to 8 gpm, that would be excessive for 3/4 fin tube, but doable if you had 1” fin tube

At some point the extra pumping power required may not be worth the small % increase in heat output

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Yes, but the odds are pretty slim that you'd ever hit that mark unless somebody ran 1/2" element and/or a way oversized circulator. The typical 3/4" loop with an 007/15-58 variety circulator will almost always be well below 4 FPS

0 -

I believe although this seems natural (give the water time to transfer its heat), in fact this isn't a valid reason—faster flow always gives more heat transfer

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Is there ever a point at which the flow would be too fast that the heat in th fluid (water) would not have time to transfer out of the fluid into the air around the heating sections of the radiator/convector/aluminum fins/etc.?

The reason I asked is because of a lesson I learned about a 1.5 Ton condensing unit added to an oil fired furnace. In the early days before I was properly schooled, I installed a 1.5 Ton condensing unit and evap coil with a oil fired furnace. As a rule you always put cooling on the highest blower speed and heating on the medium blower speed, so that is what I did. The AC didn't cool. I called the tech support people and the factory tech rep arrived on the job site and explained that the air was moving too fas across the coil for only 1.5 ton of cooling. He instructed me to place the low blower speed on the cooling fan terminal. That made everything work.

The furnace was the smallest size available and still way oversized for the job. but that was way before I took night classes offered by RSES on how HVAC was supposed to work. That is way back in time, when I realized that I needed to learn more about air conditioning and all that goes with it.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

I'm not sure what might have gone into that decision—there could certainly be some other aspect I'm not familiar with.

But I will say I never felt a winter wind that was so strong that it kept me warm because the cold air didn't have time to transfer the heat away from my face

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

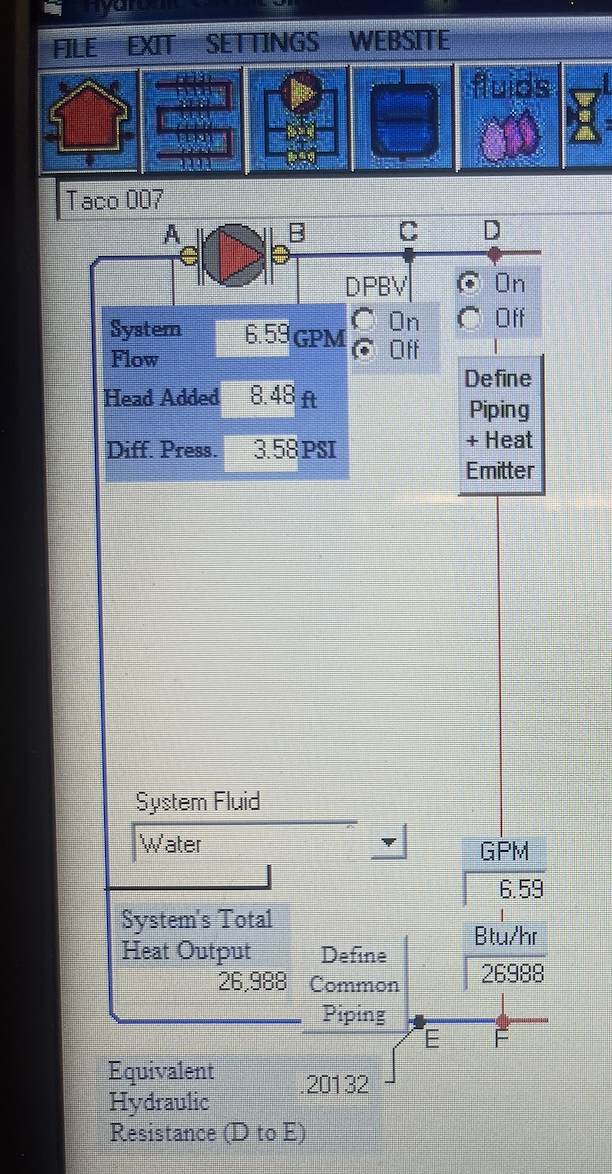

If someone want to push a 3/4 fin tube circuit to the limit, here is what it could look like.

I put 60' of fin tube, 40' of 3/4 tube for a total of a 100' loop. Plain water at 170°, about 450 btu/ ft at 170AWT

With a 007 it looks like this.

6.5 gpm keeps you right at the 4 fps velocity in type M copper

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

And possible pipe / fitting erosion, if someone hasn't mentioned it.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

the issue with higher AC air flow is your trading sensible and latent, so as dehumidification with higher air flow across the coil drops the comfort level goes down, but generally faster air flow = more cooling

Assuming ducting is sized for the higher air flow and knowing higher fan speed = more power consumption

Just as higher gpm requires more pump power in hydronics

The key is finding the correct balance with AC as it needs to cool and pull moisture so what works in arid Utah would be different from a humid climate balance.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

the higher airflow doesn't allow the air to cool as much, you are removing the same amount of energy from a greater volume of air so the air temp in the space drops the same amount but the air temp at the coil is much higher so it doesn't fall below the dewpoint so you aren't condensing moisture out of the air.

1 -

Just throwing it out there, we are dealing with sensible heat with radiators and water flow. so the GPM and the FPS will offer greater heat transfer as the numbers increase, but they are not linear and therefore there is a point where the gain is not worth the effort. Makes sense.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements