would you replace these controls immediately or wait and see?

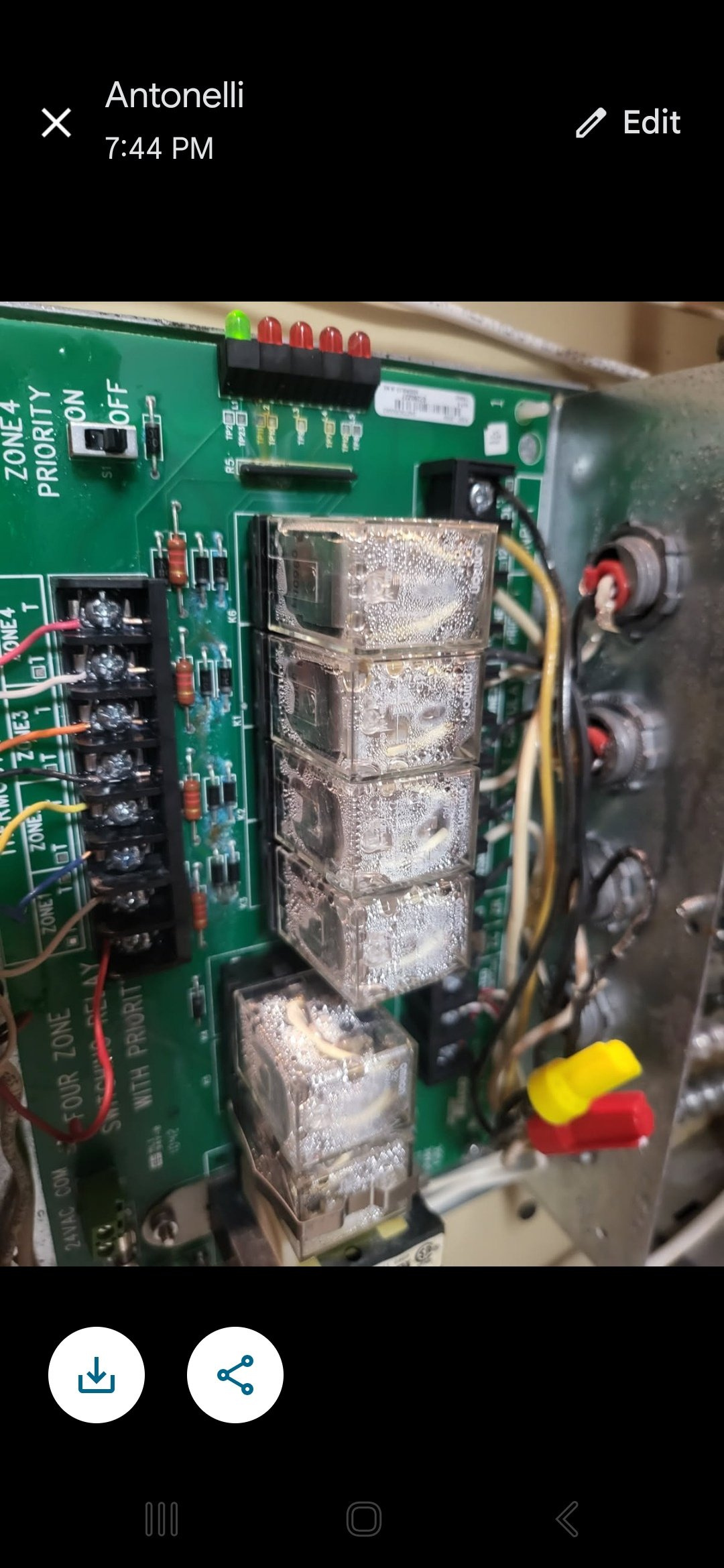

I have a customer who had water sprayed on his boiler. Two of his taco control boards had water condensation inside the "ice cube relays" as can be seen from the pictures taken about a month ago. he let it dry a month and asked me to inspect. There is no more condensation and completely dry.. I tried all the zones and all respond properly. one of the boards shows some physical water damage to the board, but all functions properly.

Would you make him replace it or see if eventually starts to malfunction. do you think its a fire hazard.

(ps. There is another board that fried from the water which im replacing because its clearly not functioning properly)

Thanks

Joe

Comments

-

Since the best practice to 'Save' the water contaminated / damaged equipment was not implemented at the time when the damage happened, I would recommend that it should be replaced.

Simply just letting it dry out is (was) not a good plan.

The present problem is where is the corrosion hiding and what issues will it cause in the future ?

It certainly could be cleaned up and the relays replaced (if needed), but it is probably not worth the cost (Vs. replacement) to have it professionally repaired. If the homeowner wants to assume the liability, get it in writing.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System2 -

-

-

-

-

Those relays will fail — the question is, when? If the equipment is properly fused and safetied, I doubt that there is a fire hazard, but check and make sure that the controlled equipment is properly safetied, as one of the failure modes is to lock something on which shouldn't be.

Me, I'd replace the stuff.

The rice trick is one what to handle electronics which have gotten wet. Another is freeze drying. Niether will help much if the water was salty or otherwise grundgy, not if the exposure was more than just a dunking.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

@Hvac Nut.. I appreciate the advice.. so Id have them sign a release with warnings on their accepting liabilty stating the possible risks. I told them i will send question here to help them decide for themselves based on what trade professionals across the country advise. They will read everyone's response to be better informed

Thanks

Joe

0 -

Look at the moisture in those relays and the corrosion around the resistors on the board! The control should have been replaced without any further testing.

The manufacturer of any control that’s been subjected to water like that will tell you to replace it.

You’re not doing yourself or the customer any favor by trying to re-use controls in that condition.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.6 -

How long ago was the water damage event?

It may be too late but Water Damage from a leak is covered by homeowners insurance policy. Usually not the actual leak, but all the damage caused by the leak. With the cost of labor and the prices of electronics that you are already replacing and the suspected electrical controls, along with perhaps some other controls that operate the burner, like ignition equipment, there will be a pretty substantial claim. Should be well over a $500 or $1000 deductable.

Replace all that you can in one large invoice and tell the customer to file a claim.

If you are the last one there and something overheats and starts a fire, you may be filing a claim with your insurance company in the future. For a lot more!!!

If you recommend replacing all the controls and wiring, and the customer declines the repair, then get a signature that the repairs are declined. Keep the signed paper on file for your protection. And Photographs are always good to keep on file.

There are several Taco support staff that are on this forum and if they looked at those pictures they would cringe. Perhaps we can get the official response from @SteveSan or @Dave H_2 from Taco Tech Support

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

-

Water damage to electrical controls can lead to corrosion, short circuits, and electrical failures, posing safety hazards and reducing functionality. Water is a conductor of electricity, and its presence in electronic devices can create unintended electrical connections and damage components, especially if the device is powered on during contact.

As others have suggested, I would replace any components with said water damage.

3 -

-

as mentioned above, i'd be more concerned with water that got in the 120v wiring than the board. the board itself is unlikely to be a hazard, the relays are likely to have problems. Since it isn't a safety control if it gets stuck you either get no heat or a heat call that won't end. If it were a primary control or gas ignition control or valve or part of the safety chain i would say you have to replace it.

I wouldn't be super concerned about the mineral stains around the diodes for the relays, you can wipe it off, it isn't going to conduct unless it gets wet again. I would probably replace the relays if I can find an inexpensive source, otherwise I'd replace the whole control. I think the relays with the line voltage are the only place something might burn up as it fails. Electronic components are designed to be washed as part of the assembly process but those relays clearly got more than that.

The way to try to salvage electronics that got wet is to rinse them out with fresh or ideally deionized or distilled water then let them dry completely, usually a few weeks, before energizing them. Even then it can sometimes go wrong.

3 -

-

-

can you cite that code?

0 -

Here is one manufacturer's take on boilers and other components that got wet:

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

-

-

-

As tempting as it is to "wait and see," recommend replacement of them. Unless you are a Licensed Electrician or a P.E. Electrical Engineer, you're getting yourself caught up in the red tape of potential litigation IF there's ever a fire. Mad Dog

0 -

The liability risk extends to the engineer as well with expectation they can develop remediation plan in colaboration with OEM. Typical documentation includes details inspection / remediation steps taken to bring equipment back to OEM standard.

0 -

Of course, but they are actually qualified & licensed to take on that calculated risk...most of us, myself included, aren't. Mad Dog

0 -

I think the OEM instructions and written opinion trumps all others. I doubt legally an engineer not employed and under the manufacturer’s insurance umbrella can override the manufacturers recommendation or liability.

In this case the manufacturer is on record with the requirement.

Unless the control was housed in a NEMA enclosure intended for under water, or wet locations and approved by UL, NEMA, et al, Allowing or putting that control in service is an expensive, maybe risky liability decision for all involved.

Hopefully the licensed, insured pros on this list understand their due diligence🧐

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements