Snowmelt

Comments

-

The slab insulation helps to limit downward loss. Remind the engineer that heat does not rise, heat moves to cold. The heat from the tubing will move to cold in any direction, up, down, doesn't matter. Without the slab insulation substantially more of the heat energy will move down into the ground, instead of melting snow on the surface, because there is no thermal break between the earth and the slab you are trying to heat. Every unit of heat energy that is not melting snow, is wasted dollars, while the slab insulation does not stop this entirely, it reduces it greatly. It is not even that it necessarily won't work, if it does work it will cost them (the taxpayers?) substantially more money

3 -

Here is a visual aid, 2 examples. 1 of your slabs with no insulation, and 1 with 2" foamboard. Loads are based on Uponor load method, the default location St. Paul, location doesn't really matter for this purpose is to show the difference for design. 35 F slab temp Everything about these two slabs is identical except for the insulation. Look at how the pump spec changes, and note that the supply temp isn't valid for the un-insulated slab. In this example you will pay approximately 2x the cost to run the system as the insulated slab

0 -

The engineer is a dope. Considering he/they are going against all best practices and conventional wisdom, ask him/them for proof it's not needed, and ask him to sign off on this with language that he/they accept all liability and agree to pay all costs to repair/fix the project when it doesn't work as expected.

Note: the dual pronouns is simply because it could be one engineer or their firm. It's not to comply with any ridiculous notion of insulting someone by using the wrong pronoun.

There was an error rendering this rich post.

3 -

Richie English of All Island Radiant @Allislandradiant and snowmelt has tons of experience. Hopefully he'll chime in here...Oh Richard...where art thou??? Mad Dog

0 -

A 9" slab?! Yikes what is the application an airport runway?GGross said:Here is a visual aid, 2 examples. 1 of your slabs with no insulation, and 1 with 2" foamboard. Loads are based on Uponor load method, the default location St. Paul, location doesn't really matter for this purpose is to show the difference for design. 35 F slab temp Everything about these two slabs is identical except for the insulation. Look at how the pump spec changes, and note that the supply temp isn't valid for the un-insulated slab. In this example you will pay approximately 2x the cost to run the system as the insulated slab

That is a huge mass to warm up.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

haha not my choice. 9" slab is what the OP cited for their application. Sounds like a fire hall so big truckshot_rod said:

A 9" slab?! Yikes what is the application an airport runway?GGross said:Here is a visual aid, 2 examples. 1 of your slabs with no insulation, and 1 with 2" foamboard. Loads are based on Uponor load method, the default location St. Paul, location doesn't really matter for this purpose is to show the difference for design. 35 F slab temp Everything about these two slabs is identical except for the insulation. Look at how the pump spec changes, and note that the supply temp isn't valid for the un-insulated slab. In this example you will pay approximately 2x the cost to run the system as the insulated slab

That is a huge mass to warm up.1 -

Unless the engineer signs off on it and takes full responsibility I wouldn't do the job. You are going to be going back all the time making adjustments.5

-

Yep..or a Flat installation price and T & M for tweaking...Otherwise as The guys say...you're gonna lose your shirt...Mad Dog

2 -

The edge loss is a big number also as it is exposed to ambient air temperature all the time.

At some point the earth under a non insulated slab warms and reduces the downward losses.

Not to say ignore underslab insulation, some of the early radiant design guides did not always show snowmelt slab insulation insulation.

A slab with that much mass, about 30 yard per slab at 9" = 120,000 lbs! and no insulation in a critical application like a fire station may need to be idled as the start up response will be very slow.

Hopefully the design is a high BTU/ sq ft? Appropiate for the class of melt as per ASHRAE

You would want a certified compaction test for that much slab and equipment weight also. Slabs fail due to improper site work often times.

It may require high load foam. Most foam board is 15- 25 psi.

Dow makes high load foam board up to 60 or 80 psi $$.

The insulation may cost as much as the slab

I doubt any engineer will sign off on operating costs, and that is where you will take the hit without insulation.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream4 -

I wouldn't have thought about high load foam board. I see some by the pallet online, it's pretty pricey but considering how much this system will cost to run, and how much the install will cost anyway, I imagine it is a drop in the bucket for this job. Looks like about 2 pallets will cover the area0

-

-

-

Thanks for all the comments and suggestions everyone. The 9” slab is at the entrance and exit of the drive through fire hall. I want to show this blog to the fire Cheif for several reasons. I know the correct way to do it but sometimes Engineers seem to carry more weight than 40+ years of experience. Also, I won’t install something I know won’t work. Too much reputation to preserve. This project was a public bid so we did not have a say in the design. Even the GC had a puzzled look on his face and questioned it. Just getting into submittal phase so we still have time to save it. Will let you know how it turns out.2

-

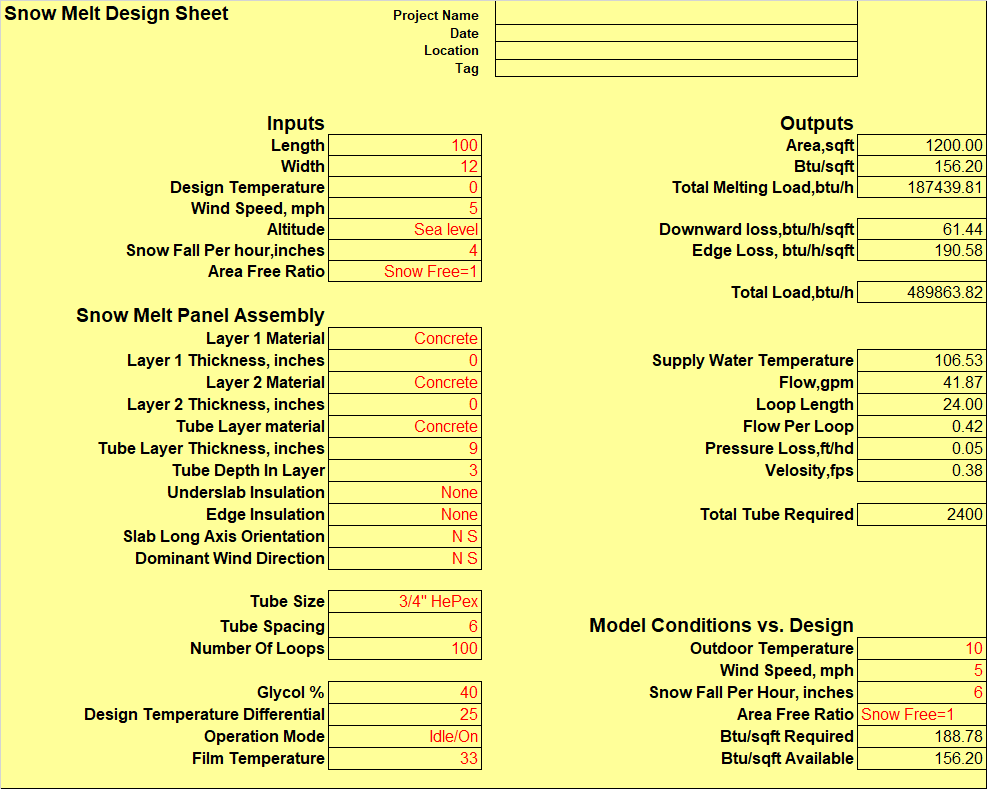

Here is the design info using the ASHRAE design methodology. It calculates about 61 btu/sqft of downward loss with no insulation.

Snow Melt Design Sheet Project Name

Date

Location

Tag

Inputs Outputs

Length 100 Area,sqft 1200.00

Width 12 Btu/sqft 156.20

Design Temperature 0 Total Melting Load,btu/h 187439.81

Wind Speed, mph 5

Altitude Sea level Downward loss,btu/h/sqft 61.44

Snow Fall Per hour,inches 4 Edge Loss, btu/h/sqft 190.58

Area Free Ratio Snow Free=1

Total Load,btu/h 489863.82

Snow Melt Panel Assembly

Layer 1 Material Concrete

Layer 1 Thickness, inches 0 Supply Water Temperature 106.53

Layer 2 Material Concrete Flow,gpm 41.87

Layer 2 Thickness, inches 0 Loop Length 24.00

Tube Layer material Concrete Flow Per Loop 0.42

Tube Layer Thickness, inches 9 Pressure Loss,ft/hd 0.05

Tube Depth In Layer 3 Velosity,fps 0.38

Underslab Insulation None

Edge Insulation None Total Tube Required 2400

Slab Long Axis Orientation N S

Dominant Wind Direction N S

Tube Size 3/4" HePex

Tube Spacing 6 Model Conditions vs. Design

Number Of Loops 100 Outdoor Temperature 10

Wind Speed, mph 5

Glycol % 40 Snow Fall Per Hour, inches 6

Design Temperature Differential 25 Area Free Ratio Snow Free=1

Operation Mode Idle/On Btu/sqft Required 188.78

Film Temperature 33 Btu/sqft Available 156.20

1 -

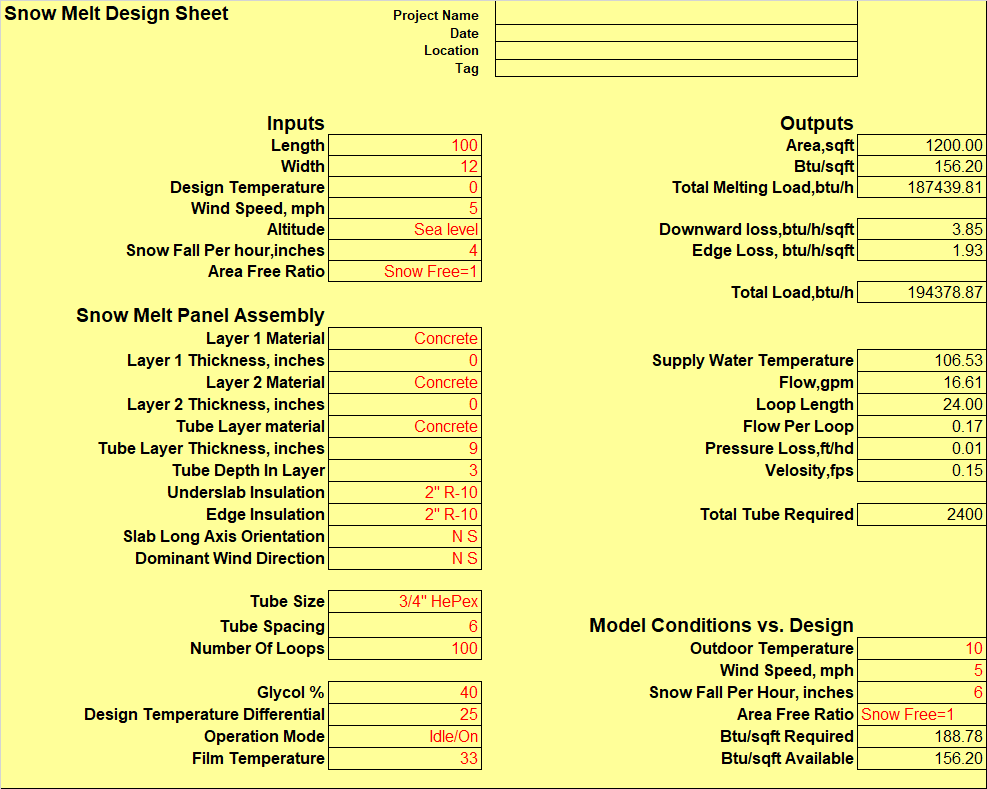

Same design but with R-10 edge and underslab and the downward loss drops to 4 btu/sqft.

Snow Melt Design Sheet Project Name

Date

Location

Tag

Inputs Outputs

Length 100 Area,sqft 1200.00

Width 12 Btu/sqft 156.20

Design Temperature 0 Total Melting Load,btu/h 187439.81

Wind Speed, mph 5

Altitude Sea level Downward loss,btu/h/sqft 3.85

Snow Fall Per hour,inches 4 Edge Loss, btu/h/sqft 1.93

Area Free Ratio Snow Free=1

Total Load,btu/h 194378.87

Snow Melt Panel Assembly

Layer 1 Material Concrete

Layer 1 Thickness, inches 0 Supply Water Temperature 106.53

Layer 2 Material Concrete Flow,gpm 16.61

Layer 2 Thickness, inches 0 Loop Length 24.00

Tube Layer material Concrete Flow Per Loop 0.17

Tube Layer Thickness, inches 9 Pressure Loss,ft/hd 0.01

Tube Depth In Layer 3 Velosity,fps 0.15

Underslab Insulation 2" R-10

Edge Insulation 2" R-10 Total Tube Required 2400

Slab Long Axis Orientation N S

Dominant Wind Direction N S

Tube Size 3/4" HePex

Tube Spacing 6 Model Conditions vs. Design

Number Of Loops 100 Outdoor Temperature 10

Wind Speed, mph 5

Glycol % 40 Snow Fall Per Hour, inches 6

Design Temperature Differential 25 Area Free Ratio Snow Free=1

Operation Mode Idle/On Btu/sqft Required 188.78

Film Temperature 33 Btu/sqft Available 156.20

1 -

-

Specified boiler is only 600,000 input for both slabs. Will cost a ton to idle that all winter long!0

-

-

Hopefully it will have a snowmelt control for each pad. The control monitors slab and air temperature to run the system. It doesn’t idle all winter

In idle mode the boiler is not under full load it maintains a low temperature above freezing.

Does any of the slab face south? How much of the slab touches the building floor? Typical annual snowfall? All of these effect the operating cost.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I visit for the comments!

Tiny add. EPS foam is oft measure at 10% deflection. The thicker the foam the greater the potential deflection.

Assuming standard XPS at 20-25psi will be stressing the slab a bit. I have run across 100psi EPS in Alaska.

Even so, multiple 120psi tires will cause deflection especially where they park, ie, if a 2 inch foam slab, that would be about 1/4 of an inch with 100psi foam, so all the stresses are distribution via the concrete. I would guess a 20psi foam board would undergo permanent deformation after some time as the propagation of pressure under a dually set.

For stuff this heavy, i'd be googling for alternates under the load path. Even vapor protected CCA wood sleepers in the load path would be huge strength add compared to foam,(only R-value ~1), but use foam in low load locations. Maybe low thermal conductivity FRP I beams with foam in between. Some useful info maybe found in Permanent Wood Foundations prescriptions for underlayment gravel base and drainage.

Cheers.0 -

The good news is that it will probably “work”. I see mountain resorts in climate zone 8 do this all the time. Unfortunately that’s also the bad news. They will probably need to idle the slab to avoid having to thaw the ground underneath every time they fire it. In the end the operating costs will be 3 to 4 times (or more) than they should be."If you can't explain it simply, you don't understand it well enough"

Albert Einstein1 -

I've been told the load pattern spreads out as it transfers through a slab or footing.

So a tire patch of say 6X6" spreads that weight to the load across a wider foot print on the foam below.

Maybe @Jamie Hall has some engineering info on this?Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

What about using reflective bubble wrap insulation, maybe even multiple layers of it will give insulation protection and the advantage is no flex.0

-

-

Not great R value and I wonder about the longevity of the bubbles through or after the installation.

I suppose if you lose all the bubbles at some point the slab settles?Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

What about foamglas?

https://www.foamglas.com/en-us/advice-center/general-advice/compressive-strength-in-industrial-insulation

It seems foamglas is a TM

Otherwise, look for cellular glass.0 -

-

-

The manufacture will quote an “effective R value”. This is nonsense the R-value of bubble wrap is <1 and serves little or no insulation purpose.ambercontractors said:"If you can't explain it simply, you don't understand it well enough"

Albert Einstein1 -

Referring back to Hot Rods comments on load patterns-

A modern six axle diesel locomotive can weigh as much as 400 tons with fuel.

The contact area of each steel wheel is the surface area of a "dime" so the entire 400 tons is placing this downward pressure on a total square area of 12 * .705" = 8.46 square inches

The locomotive weight of 400 tons divided by 12(the number of wheels) divided by 12 equals 47.28 tons on each wheel.

I would want to know if they are using a high strength sand mix concrete before I went further with this for sure as every truck will have a different weight per axle load.

It is no fun dealing with municipalities as it all goes to the low bidder-that is unless they being the municipality have the proviso to reject any and all bids to start all over again. This engineering firm was probably the low bidder for the design job.

Every fire station of any size in a cold climate could make good use of overhead steam and heated aprons and foil backed closed cell foam insulation placed over a 30 mil+ vapor barrier.

Hire your own licensed mechanical engineer for an hour to prove to them it won't work and maybe they will change the design.0 -

Well I disagree. One has to do calculations and consider what happens in future years. Otherwise we're speculating. Perhaps that engineer did his work and has reasons for his recommendation.

I remember a project with A/C rejection heat going under a parking lot. Some years retained ground heat melted snow for entire winters. Some summers retained ground heat was so much that auxiliary air cooling had to be run.0 -

If they are not willing to listen to actual facts

there is no point in even bidding on the job.

Suing the engineer after the cows break out of

the pasture fence and get hit by the train comes

to mind here.

0 -

I think the FTC got involved with some of the bubble foil claims

https://www.ftc.gov/sites/default/files/documents/cases/2009/03/090305meyercmpt.pdfBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Document, Document and Document with RFI to engineer. Maintain a paper trail! No shame in withdrawing the bid for that portion of the work.

Our engines are 48K GVW (750) gallons of water. The weights going to go up if it's a ladder truck or a water tender with 1000 gallons. Now couple that with a busy department going on multiple runs a day, that slab is going to get beat up!

Owner of Grunaire Climate Solutions. Check us out under the locate a contractor section. Located in Detroit area.

0 -

I used to build up the Hale and Waterous water pumps on the saulsbury rescue trucks in Tully, NY.

I enjoyed the work, the pay was lousy, and the management hoovered. I asked for one day off to be with my wife for her hysterectomy surgery and they said absolutely NOT. I did not miss a day for 3 solid months before this and for $8.50 an hour working the night shift and commuting 110+ miles 5 days a week in 1999-2000 really wore on me.

=================================================================

That why I was thinking 8,000 PSI sand mix with expansion joints spaced every 6 feet and top fed steam heat speaking as a lay person. The top fed radiators are above the cabs of the equipment and would have full air flow and perhaps 2 very large dry steam to air garage heaters at each end.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements