Fixing this manufacturing defect in an electric water heater

Hi everyone,

I installed a new electric water heater. The upper thermostat was improperly seated at the factory (and/or wires were improperly run) and it does not make much/any contact with the steel tank. The heater is not working properly. There is no play in the wiring; the insulation jacket has a gorilla-grip on the wires.

If I properly re-seat the thermostat, the two black wires will not reach the terminals on the stat and a third wire, if properly secured to its terminal, will pull the back of the stat off of the tank.

The manufacturer, who has no authorized service contractors in my area, wants me to hire a plumber to fix this and will reimburse parts & labor to a maximum amount.

I'm concerned that the only fix is using wirenuts and that doesn't sit well with me, though it is difficult for me to articulate my concern with wirenuts in this scenario. Let's just say that I can imagine a world in which someone posts a picture of wirenuts in a water heater thermostat bay and y'all shake your heads and say, "you can't fix stupid." So…..

- Do you see a solution to this problem that doesn't involve wirenuts?

- If not, are wirenuts a safe choice? (I hope they are)

I'd appreciate any insight you have to share. Thanks.

Comments

-

Hi, A few thoughts. There are waterproof wirenuts available. Also one can just fill a wirenut with silicon before making the connection. I always point the wirenut up so water cannot pool inside of it. I suppose you could use waterproof crimp connectors (or add heatshrink) to extend the wire. I prefer the serviceablilty of wirenuts though.

I think it's not polite of the manufacturer to ship product like this. Maybe if they had to replace it and pay for a new installation, they might add an inch or two of wire in future. 🙄

Yours, Larry

3 -

Well, this is one I have never come across in my fourty plus years.

My first thought would be wire nuts but not the best connection in such a tight area.

If you want a bettr connection, I would use a heat shrink connector. They are used in water proof situations and might be a good choice here. ie…submersible pump installations.

When you spoke to the manufacturer, did they suggest what type of connection? Probably give them another call and ask what they would suggest. If you get no where with them, maybe ask for a new water heater if it is, as you say, "improperly seated t-stat/improperly run wires"? This could be seen as a manufacterers defect and can treated as such.

1 -

-

-

I thought the same thing @Intplm. but he says the thermostat isn't making good contact with the heater so I assume it's mis-reading the temperature in there? But I'm curious too, what is the failure you are seeing?

The top part is just a terminal strip, right? The thermostat is the bottom part?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Yeah,

While it's not great I do not see anything there that would make the heater not work.

That thermostat screws into the header, no? With a probe that sticks into the tank?

What brand of heater is this?

Who would wire terminals like that with the wire under half of the screw? I do it if there's a pressure plate contact setup, but not under just the screw head. Then the red and blue under a single screw, again, no pressure plate. Seems terrible in my opinion.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

Agreed. The insulation looks like the blown in type and has hardened as it should. There is a little extra wire up there in the insulation that if needed can be accessed, but why go to the effort if the thing is truly not working properly.

How, I wonder is it not working?

Maybe scrape away a little of the insulation to straten out the t-stat. It should move.

0 -

-

No. It just sits on the surface of the tank and attempts to read the temp that way, there is no bulb like on an aquastat.

I'd probably use solder or a crip splce with proper tooling. If you use wire nuts make sure you get a good bite on it, you might not have enough wire to work with to do that.

I suspect that t-stat has plates the wires should go under that they weren't placed under.

0 -

Crimp-style (AKA Sta-Kon™) connectors are unreliable on solid wire. They'll often hold while you're installing them, but it's only a matter of (a short) time before they fail. Wire nuts work well, but you don't have much room to work with. I might try li'l baby split bolts like the Big Box stores carry. (They're uninsulated, BTW…) A mechanical butt splice will work as well, some of them (Polaris™ connectors come to mind) are insulated, but I'm unsure if they go down that small. There are also insulated set screw style terminal strips that might work.

0 -

Keep in mind that the manufacturer uses #12 wire with XHHW insulation on it. The conductor is allowed to get much hotter than we do. So a suitable connection would be a crimp and a short amount of #12 XHHW. Standard THHN wire may melt, and would certainly melt a wire nut in time.

XHHW and other appliance wire insulations are rated for 105+C.

Serving Northern Maine HVAC & Controls. I burn wood, it smells good!1 -

-

I'm really surprised it doesn't have a probe that goes into the tank.

Isn't this how all gas water heaters work? The regulator / control threads into the tank?

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Gas water heaters have a tappign for the vavle. They found it was cheaper to not have one on electric water heaters.

Actually I had a power vent water heater that was all run off an electric water heater type themostat just jammed up against the tank.

0 -

Hi @ChrisJ , Nearly all tanks use a surface mount thermostat these days. A problem is when it doesn't make good contact or when the insulation that should cover it is missing. Then it doesn't really read tank temp. It's common to find the covers off and insulation missing.

A leaky element can cause the spring clip that holds the thermostat/limit in place to rust through and create potential problems.

Yours, Larry

0 -

Thanks for the thoughts everyone…

@Intplm. When you spoke to the manufacturer, did they suggest what type of connection.

The manufacturer declined to suggest a specific fix saying, "It would be up to the service tech." When I mentioned concern over that response, they said, "the service tech can call us with questions."

@ethicalpaul … thermostat isn't making good contact with the heater

Correct. I can push on the thermostat and then it will make contact with the tank, and when I remove my finger the stat springs backwards away from the tank. Even when I put pressure on the stat, it isn't sitting flush with the tank - I think the wires are asserting more influence on its position than is the bracket.

@Intplm. Is the water heater not working properly? … leave well enough alone

It is not, which is why I ended up looking further and finding the crooked stat.

I get 140-142° water after I turn on the breaker, but subsequent heating cycles will not produce hot water above about 118°, which is more consistent with the lower stat setting.

I would expect subsequent heating cycles to reach either the upper stat setpoint or the "mystery" 140-142° but I don't get either of those temps. @Larry Weingarten does heat cycle this make sense to you? Every time I turn off the breaker I also hit the reset button, which doesn't feel like it needed to be reset, on the upper stat. This last time I didn't hit the reset button and the temp is not hitting the 140° and no voltage to the elements. I bet if I hit that reset button I'll get the 140° water again.

@ChrisJ thermostat screws into the header, no? …. What brand of heater is this?

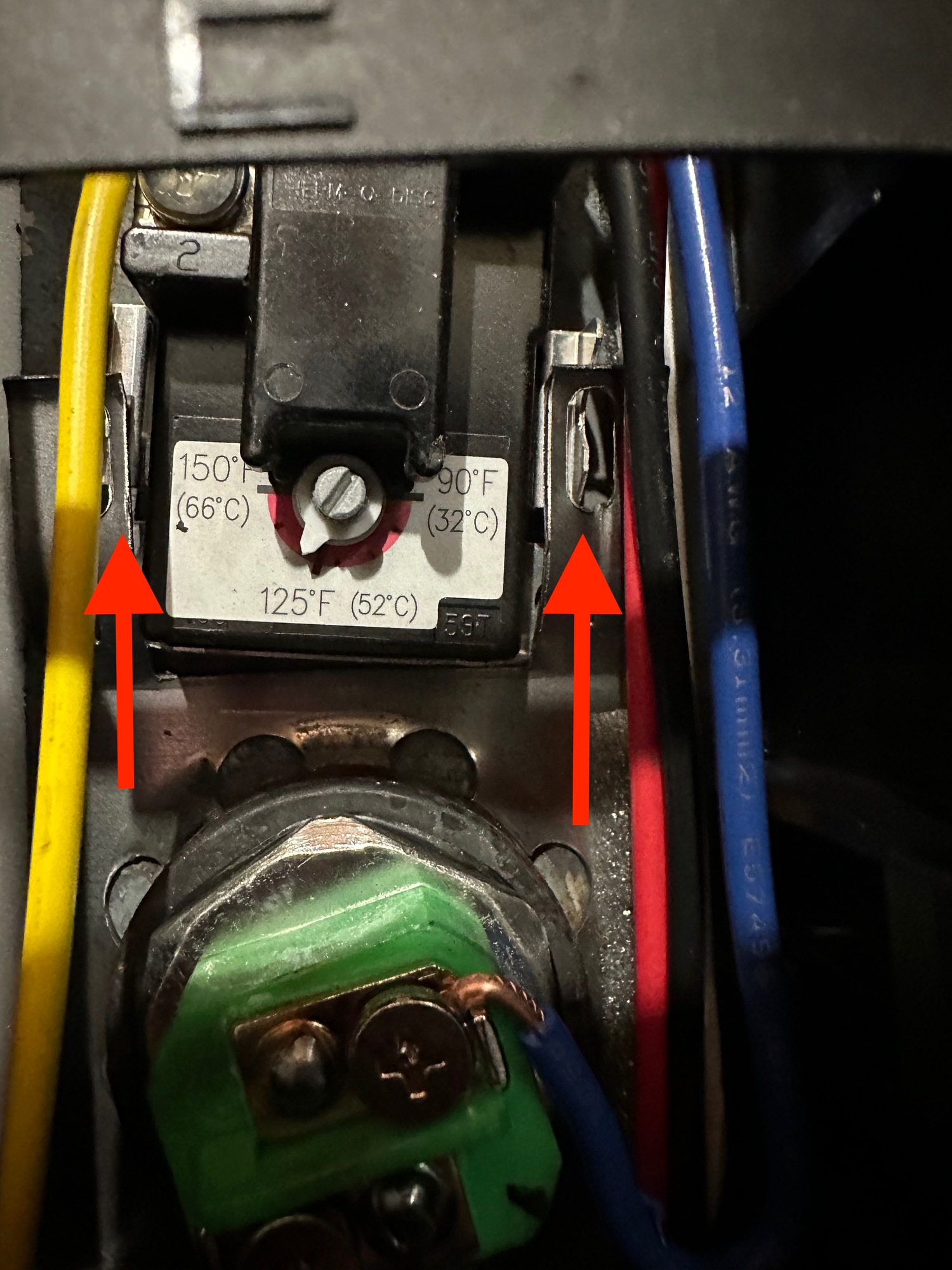

The stat snaps into a bracket [red arrows in pic below] that appears to be secured by friction along the edge of the heating element port. I didn't think naming the brand would be productive. FWIW, they are responsive and didn't hesitate to send a claim form. It's Rheem.

>>>@ChrisJ Who would wire terminals like that with the wire under half of the screw?

It crossed my mind but seeing it written out, oof, that is wild. Then, I looked at the 1990 AO Smith I just replaced and it is wired the same! No pressure plates under the screws, wires slipped halfway under.

@pecmsg

Do you know the heating element is good? Has it been ohmed out?Did not test the element. Pretty sure I wouldn't get the 140° in a reasonable amount of time with a bad upper element. Hmm… on that top black wire I barely have room to "hat" a wirenut.

My last interation with the Rheem was to send them pictures. I'll call them back shortly and see if they have changed their minds about the path they laid out yesterday.

Thanks again for all your thoughts.

DIY'er ... ripped out a perfectly good forced-air furnace and replaced it with hot water & radiators.1 -

Hi @Boon , About the function of the thermostat… A question. Do you have insulation over the thermostat and the cover in place when it does this strange, not getting up to temp stuff? Some years ago I talked with a thermostat manufacturer, and they were building stats with a 30F dead band/differential. That could make it difficult to control temps with any precision. Also, if the high limit has tripped, you will hear and feel a click when you reset it. Are you sensing that?

Yours, Larry

0 -

Hi Larry, The foam insulation has been in place with the exception of the last 24 hours, but I've been chasing this for a week+ now.

I don't feel any positive motion/snap/feedback when I hit the reset button so I'm not sure it's doing anything. I'll go flip the breaker, hit the reset button, and watch hit with my voltmeter and see if anything changes….

I'd put up with as-is if it weren't for the 140-142° showing up unexpectedly. I don't like that.

DIY'er ... ripped out a perfectly good forced-air furnace and replaced it with hot water & radiators.0 -

At the very top, is that that foamed in place foam or is that a piece of softer foam shoved in there that you could pull out to get more clearence to the wire?

0 -

Thanks for all the clarification, Boon. It is a little strange—I would expect the temp of the water to run hot (not cool like you are seeing) if the problem were that the thermostat wasn't making good contact with the tank.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Hi, Just to rule out the possibility of an element defect, here are some tests to do. Turn off power and disconnect one wire from the element to be tested. Now put your meter in ohms X 1 setting and test between the two element screws. You should have very good continuity. Next put your meter in something like ohms X 100 setting and test between each screw and the flange of the element. You should get no continuity at all. If you do find continuity, there is a leak to ground and that element is slowly heating, even when off… Just trying to eliminate possibilities.

Yours, Larry

0 -

Hard to believe the manufacturer would assume responsibility of an unknow splice done in the field? What would a replacement tank cost the manufacturer? Compared to a failure or lawsuit if things really go south?

Are there Rheem certified, licened electricians that you need to contact?

Do electric tanks have a UL listing? Field modification would void that listing. Will UL relist the tank with a field splice? In the event of a meltdown or fire, and insurance inspector would note a wiring modification.

Where did the tank come from? Box stores take back most any product without an augument.

Take a close up of the control not touching the tank. Just in case.

Those snap disc type controls are very reliable and accurate. When installed properly.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream3 -

I’d try wiggling, pulling the wires to see if you can get more slack. It may take some patients but they should eventually loosen from the foam.

If that doesn’t work, try making a pathway where you can get new ones down. There’s not enough length there now for a wire but.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

My first choice would be return it and make them pay if possible. They take the liability etc.

If it was my house I would splice it and be done with it

What do you do when you come across a burnt wire? Do you toss the whole tank or make a repair? Crimped and heat shrunk I don't see how anyone could have an issue with it.1 -

-

What about using Wago connectors? The bottom element appears to have two metal brackets holding it against the tank. Upper element appears to have one black plastic band-clamp for holding it against the tank. And the main problem to us (viewers) appears to be that the upper element is askew. The back of that upper tstat element MUST be completely parallel with the tank and fully in contact with the same. The "skewed" aspect is maybe a "red herring'?0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements