hour meter to estimate fuel usage with hi/lo fire

I see that there have been previous discussions recommending installation of an hour meter to estimate fuel oil use. I'm wonder how this works on a boiler with hi/lo fire. Is there a way to clock the two rates separately? Do you recommend a different solution? We are currently just looking at our oil deliveries, which doesn't tell us much.

https://forum.heatinghelp.com/discussion/164631/boiler-hour-meter

https://forum.heatinghelp.com/discussion/103092/fuel-oil-flow-meter

https://forum.heatinghelp.com/discussion/100483/easy-way-to-monitor-burner-run-times

Thanks,

Eric

Comments

-

Someday i may rig this up and see how it work. For two stage it would need two

It's a simple device. I don't know if it will pick up 24v though. But it's cheap.

https://www.motosport.com/moose-hour-meter?variant[MOA003S]=MOA003S-X001-Y0010 -

Probably not cheaply.

What kind of boiler do you have? What kind of controls?

It's possible maybe to use a data logger for overall time, and depending how your burner switches from low to hi, another logger just on one mode, then subtract the 2 numbers to figure out the other.

But the main question, why?

If your steamer is properly sized, properly vented, pipes insulated, that's the best it's going to do.There was an error rendering this rich post.

0 -

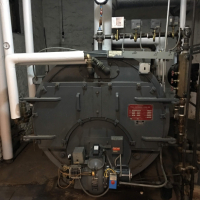

The boiler is a Federal FST Scotch Marine boiler. Carlin 801 burner, I believe. It has a Heat Timer EPU-CH for control. I'm sure it's oversized. The mains in the basement are properly vented, probably not in the top of the risers. That's my next project. And we have new, very nicely done insulation in the basement.

There are a few reason I'm interested. I'm not sure I trust our oil company and want a way to verify that what we're burning is what we're paying for. I also want to see if the efficiency work we're doing is having any effect. As we add venting to risers and replace air vents on radiators, etc.

We just had a feed water meter added. This just seemed like another basic number to watch. I guess it's not as common as I was guessing.Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

I logged an oversized commercial boiler by disabling high fire and then sticking one of these on the side of the burner motor. https://www.onsetcomp.com/products/data-loggers/ux90-004

"If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

My burner had a fixed burn rate, every night I read the hour meter and ACCURATELY measured tank oil gauge with a machinist ruler , to 1/64 inch. Ran the tank from "full" to flame out empty. This way I calibrated the gauge.

Did it several time to check for repeatability, mine was good....60 year old Sulley type gauge

Also note that "fill" varies between drivers. Oil foams up and they have to stop filling. Some are done and walk off, others wait 1/2 minute to let it settle then top it off.

Also sometimes gauges get friction and hang up.....wack the tank to loosen it out.0 -

very simple. 2 timers one wired to low fire valve other wtred to hi fire valve ed n.y.c.0

-

-

I'm still baffled by the need for all of this measuring, in this case, to try to ascertain information that will most likely be incorrect. If an oil company wants to cheat you, and there are a few, they are going to cheat you. So find a company you trust.

-A heat loss will tell you if your boiler is oversized.

-A reputable oil company

-Check gauge after fill.

You won't get the exact amount filled every time. Nor are you running your tank out (I hope not) every time. Like measuring a car's mpg, unless you are filling it up every time, the math will not be accurate.

I don't recommend what @Leonard did and open a bung on the oil tank to measure. You're risking a spill catastrophe where the liability is on you for removing the cap. I'll leave out snarky comments about a ruler measuring 1/64's of an inch, which I find ridiculous ( ok I tried...).

Also, data logging won't help you figure out if you're being cheated unless you first verify exactly how many gallons you are burner per hour. A calculation coming from the following method may get you close:

Considering your boiler is most likely oversized, do like @Zman said and lock it into low fire.

Take a measured amount of oil in a container, say exactly 5 gallons. Run burner and time until you are completely out of oil.

Then with that data, you can do absolutely nothing with it. But then you'll get a fairly accurate gph burn.

Then fill your tank. Log amount of time burner is on. After next refill, do the math.

Then what?

What's your margin of error?

You calculate you should've burned 150 gallons, but you got a delivery for 155 gallons. What do you do next? Call? Complain? Take to court?

Seems like a giant time waster...again, in this case.

With all my customers who fill their tanks (and the will-calls who run out), I track their Degree Days-which is another arbitrary way to do math that's pretty close, but not an exact science.

---------------------------

Oh here's another way...will definitely work.

Buy and have calibrated a 200 gallon Weights and Measures proving tank. Have an exact 200 gallon delivery made so you can check. Then dump that into your heating oil tank.

Ok enough rambling...There was an error rendering this rich post.

0 -

I agree with your points, but how do you find out if an oil company is reputable?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

How do you find out if any business is reputable?ethicalpaul said:I agree with your points, but how do you find out if an oil company is reputable?

There was an error rendering this rich post.

0 -

I wasn't checking on honesty of oil guys, I just wanted to calibate my tank.

I marked my gauge after ~ 4 different oil companies "filled" the tank. I measured gauge ~ 10 minutes later. Height of gauge after "full up" varied by 6/32" = 18 gallons.

I attribute this to oil foaming (gasoline does this too). Some hurried oil truck drivers would leave after 1-st whistle gurgling. Others would shut off, wait 1/2 minute for foam to dissipate, then continue to slowly fill tank till whistle gurgled again.

I wanted an accurate tank gauge calibration, so I measured to 1/64" because if your sloppy with measurements then you don't know if errors come from gauge or sloppy measurements. Easy enough if use forehead lamp, reading glasses., and machinist's ruler. In retrospect 1/32" would have been fine, gauge travel is only ~ 2". But I'm a mechanical engineer and routinely measure to even better accuracy at work. ( < 0.001inch)

Don't have to remove tank plug to calibrate gauge. Although I did to stick the tank to calibrate how much oil was left when gauge stopped falling ( zero) , mine was ~ 15 gallons to flame out, 275 gal tank. IF you remove the plug MUST put it back in tight EVERY time, other wise tank whistle won't gurgle to tell driver to STOP filling tank. Oil will spill out of tank hole onto your floor. $$$$$$$$$$ damages1 -

I'm asking you haha you said find a reputable oil companySTEVEusaPA said:

How do you find out if any business is reputable?ethicalpaul said:I agree with your points, but how do you find out if an oil company is reputable?

The OP was wanting to measure his oil to find out if his company is cheating him which seemed a reasonable way to verify at least that much reputabilityNJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Reputation and references.

I agree it's fine that he want's to know, I'm just saying there are too many variables to truly know. And he really didn't say why he suspected he was being cheated. Colder winter means more oil used. Especially for people who keep their thermostats lower, and poorly insulated houses. They may run less in the shoulder seasons and sunny weather, but a deep freeze means they burn more. I see these variations in Degree Day Intervals and K Factors.

Same with usually older people who keep their thermostats @ 75°. Degree days aren't being counted technically with a mean temperature above 65° but they are running their heaters.

I analyze this a lot so I can maximize my delivery volume, and delivery more efficiently.

Consider getting gas at a gas station. You couldn't prove accuracy there at all without the proper test instruments.

One way could be to measure the oil tank immediately before fill, measure tank immediately after fill and use a tank chart. But even the charts are made by math formulas and are for reference only.

Then you have to see if you are in a state which allows temperature compensation (must be clearly marked on the ticket). So a delivery of 200 gallons at 30° could be an actual volume of 196 gallons (don't have my chart in front of me), because it will be 200 gallons when it warms up to 60°. For reference I do know 3000 gallons at 30° will roughly equal 3035 gallons @ 60°.

And you have to verify the meter is accurate at the time of delivery (which is why I mentioned the calibrated and verified prover tank).

Truck meters get checked once a year by the state. And like everything else that's checked, only proven accurate at the time it's checked. Electronic meters can bounce in and out of calibration over the course of the year.

And after all of that, what if the person has an underground fuel tank or a buried oil line? Either of those could be leaking.

And all of that variation applies to a reputable dealer.

As far as foaming, I don't know a whole lot of drivers who are going to stop when the whistle stops, then wait a minute to see if they can squirt another half gallon. Too many deliveries to hang around. However, foaming has it variables too. Not all trucks deliver at the same pressure or speed. Some tanks will foam on high speed, so stopping and trickling in more fuel can give the customer and extra few gallons. Some foam at low speed. Some don't foam at all. Has a lot to do with the turbulence created in the design of the fill piping.There was an error rendering this rich post.

1 -

Fuel usage is based on how many btus are you transferring to the water or air per gallon or cubic foot of fuel used. Size of equipment determines how long it is going to run. If the combustion numbers in low fire are the same as high fire they will use the same amount of fuel. High fire will do it faster. If the combustion numbers in low fire are bad, then it will use more fuel.

Btus transferred is determined by how many btus were actually produced and available for transfer versus how many went up the flue. We always produce 99.9% of the btus in the fuel but the O2 or CO2 reading determine how many are available for transfer,

After 41 years of using combustion analyzers in the field, one thing has not changed for the better, That is the fictitious, fabricated false efficiency calculations analyzers make. But these have been wrong since the beginning.2 -

Think driver only waited 15-20 seconds to de-foam, but he was younger. I give him my interesting old engineering magazines, so I guess he liked me and took time to top it off. Difference between his fill and other company's was ~ 18 gal top off.

I knew my nossel GPH size so I filled tank and took measurements of tank gauge and hour meter EVERY night at same time. Gauge reads 0 when tank is below ~15 gal, so over summer I let tank run out (flame out) so I could know how many gallons tank had left for any gauge reading.

Then entered data in EXcell and made a plot of gauge height VS gallons burned.

With that plot know how many gallons are in tank for any gauge reading, within an error of ~ 5-6 gal (depends on how accurately you read the gauge 1/64" or 1/32", and gauge linkage friction ----whack the tank. )

I only did all this to make sure tank could take on > 150 gal to get the price break. And if I forgot to call and gauge read REALLY low I could stick the tank and know if I could make it thru the night/weekend.1 -

> Consider getting gas at a gas station. You couldn't prove accuracy there at all without the proper test instruments.

True but a state inspector comes to check those. Thanks for the writeup!NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Yes, state inspector checks my trucks too (actually the county), as well as anything that is measured for commerce. Go look at the giant measuring stick at Home Depot by the cash register (as well as the cash register). Weights and Measures stickers on them.ethicalpaul said:> Consider getting gas at a gas station. You couldn't prove accuracy there at all without the proper test instruments.

True but a state inspector comes to check those. Thanks for the writeup!There was an error rendering this rich post.

1 -

Bought stick is likely good enough, but I made my own.

To measure bottom of tank after gauge stopped falling ( ~ zero left) I took a broom stick, cut it into a D shaped cross section, and marked every 1/2 inch within ink. Then took nightly tank depth readings and hour meter readings. ( flat of D shape made seeing oil MUCH easier)

Knowing nossel size GPH I converted hour readings to gallons/day burned. Plotted it up in Excell, now the stick was calibrated to curves of MY tank. I suspect tank bottom curves might be SLIGHTLY different between tanks. Being an engineer I like being accurate,0 -

Right on Captain!

If I start a new thread on combustion, can you comment?

If you don’t, I may get a goose egg 😂0 -

You all are amazing. It appears that I asked a really naive question. Thank you so much for all the incredible information. I think my answer for now is that I am not up to the task of trying to determine precisely how much fuel we burn, and maybe it isn't that important since there isn't that much I can do about it, other than continue to work towards the best practices that have been so well-established here. I'm not an engineer

or an electrician, and would have to rely on others to do the technical work, so I'm thinking it's not worth it at this time, but I'll keep following the comments. Thank you. Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0

or an electrician, and would have to rely on others to do the technical work, so I'm thinking it's not worth it at this time, but I'll keep following the comments. Thank you. Single-pipe steam | 24 apartment, self-managed coop | Federal FST-40 Scotch Marine boiler | Carlin 701CRD burner | Heat Timer EPU-CH | Honeywell pressuretrols | Heating oil #2 (20% bio)0 -

I tymed my oil gun run time for 4 years after my tank gauge went south. I found the deliveries i got were always within a few gallons of my calculations.

If you oil gun has pre and post burn run periods (oil off) this method will not work unless you can measure the solenoid wires.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

I will be waiting Gary!!0

-

Same here, with hour hour meter I can tell the delivery guy what the bill will be within a few gallons , before he hands me the bill.

And once you have tank gauge calibrated you can compare it's reading to hour meters over a tank load to determine if your buried oil line has a significant leak.0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements