Steam Boiler Comparison help

Comments

-

I like small boilers, as steamhead said, it's probably not best for you as it takes a lot of effort and time to make it work and could be very frustrating.mynameisphunk said:@KC_Jones - why would you personally use the 120 (I don't know the reasons why/why not)? The 340sqft actually includes a radiator in the attic that hasn't been used since at least 1988 (previous homeowners never used it), but may eventually be used. What is the risk of using a slightly undersized boiler?

@ChrisJ - why the IN4 for you?

I would however, recommend not going any larger than necessary. I usually recommend guys use a 20-33% pickup, but not over 33%.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

In my opinion they should be taking that tee out no matter what. The mains are supposed to connect to the header individually. With the old coal boilers it didn't matter as much because they were low and slow and basically just ran continuously.mynameisphunk said:Additional question so I can understand the piping:

If we went with the Burnham IN5 and used both supply mains to the header as indicated in the manual, would the installer need to eliminate the current T from our two steam mains and have those individually come down and connect to the new header? Or can the T remain, and just have the vertical pipe connect to the new header?

With new boilers the system needs to be looked at not just plug it in and go.

I would want some specifics on the piping in the contract you have about what they intend to do. Also the Burnham manual lists the second connection as optional, I wouldn't assume they will use it. It would be better if they did, but I doubt they automatically will.

As Steamhead said it's about pick up factor and your system. We all have our opinions that have been discussed at great length. I don't want to derail this thread and distract from your needs by rehashing it.

Other than the IN4 proposal I would go with the smallest boiler suggested. The slant fin is a quality boiler, but if they suggested the 160 I would have a hard time going the route.

The 120 would have a 19.6% pick up factor and the 160 would have a 59.6% pick up factor. The generally accepted standard is 33%.

So you would either be 13.4 under or 26.6 over. With the Slant Fin offerings.

0 -

I'd take 19% over 60% any day.

You may need to insulate all of your piping well, and vent your radiators slow, but the system will work beautifully.

60% is way too much unless you want to come with up some cycling scheme to try and cope with it. I wouldn't do it.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

Well, as you expected, the Slant/Fin quote came in and they quoted the 160. Additionally, at least for the foreseeable future, we won't have 340sqft of radiation, as the attic radiator is not planned to be used (but we'd like to eventually).0

-

So given the quoted units so far, the Burnham IN5 is the closest match for our home at 358 rating, correct? Does that matter more than brand preference, etc... (for those recommending Slant/Fin)?0

-

It's been said on here many times, the contractor matters the most. Guys have their boiler preference I can tell you I see Weil Mclain, Burnham and Slant Fin all posted by some top notch Steam men on this site.

If you feel the contractor will do a proper job and install the boiler at least to minimum specs in threaded steel pipe with iron fittings then I say go for it. If they start talking about copper (for steam carrying pipes) and how they don't need the manual, things along those lines I would dismiss them.

Ask them for pictures of their installs and post them here, we can review them and let you know if they are any good.

Again make sure it is very clear what kind of job they will be doing before signing anything.0 -

Yours and ChrisJ's boiler install pictures (as well as your commentary) is very helpful in assisting with the final decision. At this point, I'm leaning towards the Burnham IN5 from the most responsive of the companies we'd worked with. I will use some of your pictures to help aid with what I'm asking for in the conversation.

Unfortunately, they quoted the Burnham IN5 at a very significant amount more than the Bryant BS2, and I'm not sure why - I'll get more detail on that. I expected a difference, but not this much.0 -

Additionally - I noticed you and ChrisJ both have king valves on your steam mains, presumably for blowing down the boiler. How important do you feel it is to request those in the install?0

-

I haven't used my king valves at this point, though I plan to this year to see what I get out of the bottom of the boiler. I am running water treatment and I changed to copper wet returns, those 2 changes seem to keep things much cleaner than the old boiler.

From my perspective I would rate the king valves as a cool extra, but not a necessity.

We don't discuss price as you know, but with the boiler installs you get what you pay for. I did mine on my own, but ended up spending more than the quotes I got. When I realized this it really made me wonder what the contractors would have done.

If they do a quality job with quality materials, it's money well spent.1 -

Yeah........

If I had to do mine over I'd leave the valves off. I never use them as I use a Gerry Gill style wand to wash the boiler out, and I've had the valves leak several times. This brand apparently tends to loosen up over time from heating and cooling. A while back it soaked my header insulation and I ended up replacing all of it. Maybe I should've just let it dry, I don't know.

But yeah, for me, useless and another leak point. Mine are Matco Norca brand gate valves. Oddly enough, the same brand radiator valve hasn't given me a single problem yet.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Thank you both, that is very helpful.0

-

As a BS2 owner, don't get a side exit boiler if you can help it. It's a very basic boiler, no dedicated skim port (they have you put a 2-1/2" tee on the steam exit to use the tee for skimming, economical but not the most practical since you have to tighten and loosen a 2-1/2" plug!)mynameisphunk said:

Unfortunately, they quoted the Burnham IN5 at a very significant amount more than the Bryant BS2, and I'm not sure why - I'll get more detail on that. I expected a difference, but not this much.0 -

I know some of us use steamaster tablets in our boilers to keep the water in good shape. I've used them since the boiler was installed 5 years ago and last week when did a little work to make sure I was all set for heating season the boiler water was as clean as it was 5 years ago.

If you keep the water in a steam boiler clean the need for king valves will go away.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

One other thing. Make sure they install a skim port this is very important to be able to get the new boiler cleaned. Don't do chemicals or anything, just the skim port and hours of time skimming.1

-

New boiler coming in a week! We went with an appropriately sized Burnham from a local company who will then be able to service it as well, should the need arise.0

-

I hope they are going to remove that tee and bring the mains down independently to the header like it should be.0

-

Make sure you tell them you want it piped per the manual, using a drop header is well worth the extra pipe it costs.

BobSmith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

I specifically asked for a revised quote (in writing/email) including the following:

1. Would like the Burnham IN5 w/ no extended warranty

2. Drop header using both steam taps on the boiler - steam mains separated from the existing T and brought directly into the new header

3. Skim port installed

Revised quote at least mentions the skim port and drop header, and I will make absolutely sure they use both steam taps and split the existing T. I ordered an Ecobee3 thermostat (rather than the standard Honeywell basic model they included in the quote) with extra sensors as I'm looking forward to having independent temperature information from each bedroom to fine-tune the radiator vents.

Quote verbiage: To install a Bunrham PIN5SNIMERE2, natural gas fired steam boiler, connecting to existing supply/return lines, gas, electric and chimney; will install hand feed; Honeywell thermostat; will install a drop header into the Hartford loop; will install a skimmer port; will cover all floors in working areas with drop cloths; will clean up and dispose of all existing units; 1 year warranty on Burnham parts and a 10 year limited warranty on section assembly; 1yr warranty on workmanship; all work to be performed in a professional manner; materials and labor

0

0 -

-

Just emailed to clarify.0

-

They were struggling mightily with the T on the steam mains when I left for work (sledgehammer + saw etc...) - but the boiler is here, and it's downstairs. Heading home to check in shortly to see how things are going now.0

-

While I wouldn't have minded them going a little higher with the header due to having the extra space to work with, this is still about 27-28" above the midpoint on the sight glass (installation manual calls for minimum 24" above the normal water level). Any reason to ask them to undo a portion of this and go higher, or should this be just fine?

All I have to compare to are images of other people's drop headers, which all (edit: most) seem to go much higher than this - but it may not make that much of a difference beyond a certain point (more of a "why not").

Edit: I re-measured, and it's a good 27" from 2/3 of the way up the sight glass to the midpoint of the top pipe. I'm happy with that (well, kind of, I'm still sort of agonizing over it as I would have gone higher and used the available space, but I understand that I probably shouldn't be) and glad to see things appear to be coming along nicely. It technically meets my requests (use drop header, use both steam supply taps on the boiler, separate steam mains) and meets the installation manual's near-boiler piping, so if I wanted it to be higher vertically I should have been more specific - and it really should be fine.

2 -

I wouldn't worry about the height, the drop header will make all the difference there. It's really looking good so far.0

-

It's in, surging and triggering the LWCO but it's in and looks good. They skimmed it some before heading out - I'm going to skim more tonight after hooking up the new thermostat. Will post pics shortly.0

-

It's going to take a long long time to get all of the oil out, as in months.

I think I skimmed mine 6 times before finally washing it with the wand. Each of those 6 times I removed something like 10 gallons of water slowly.

If you had a Cycle guard LWCO I'd change it out for a normal probe that doesn't cycle the boiler every 10 minutes.

All of that said, the piping looks fine to me. Better than most and certainly not minimum.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I don't believe it's a cycle guard type - it will flash the low water light for a minute or so, then kick back on. It's making steam and all radiators are hot. Going to spend some time down there tonight skimming.

The new Ecobee3 thermostat is awesome! This is going to be amazing for really setting the system optimally for the rooms we care about during specific times.0 -

All the Burnhams I’ve seen come with the Hydro Level cycle guard. Chris is saying replace it with a Hydro Level Safe Guard at some point. There is no reason to turn the burner on and off for a water check.mynameisphunk said:I don't believe it's a cycle guard type - it will flash the low water light for a minute or so, then kick back on. It's making steam and all radiators are hot. Going to spend some time down there tonight skimming.

The new Ecobee3 thermostat is awesome! This is going to be amazing for really setting the system optimally for the rooms we care about during specific times.

DL Mechanical LLC Heating, Cooling and Plumbing 732-266-5386

NJ Master HVACR Lic# 4630

Specializing in Steam Heating, Serving the residents of New Jersey

https://heatinghelp.com/find-a-contractor/detail/dl-mechanical-llc

https://m.facebook.com/DL-Mechanical-LLC-315309995326627/?ref=content_filter

I cannot force people to spend money, I can only suggest how to spend it wisely.......0 -

Pictures of the final?!0

-

0 -

Any detail pics that would be helpful? About to go downstairs for a good skim session.0

-

@mynameisphunk ok is appears you have a McDonnell Miller LWCO, not familiar with that one on a Burnham, but if it don’t cycle your good to go.DL Mechanical LLC Heating, Cooling and Plumbing 732-266-5386

NJ Master HVACR Lic# 4630

Specializing in Steam Heating, Serving the residents of New Jersey

https://heatinghelp.com/find-a-contractor/detail/dl-mechanical-llc

https://m.facebook.com/DL-Mechanical-LLC-315309995326627/?ref=content_filter

I cannot force people to spend money, I can only suggest how to spend it wisely.......0 -

Correct, model PSE-802-24.0

-

Skimmed another 5-6 buckets for an hour, roughly. Just cycled it for a good 15+ minutes without it cutting off, and water level is fluctuating in the (very dirty) sight glass only slightly, within an inch or so. It's getting a little too toasty (73-75 in all rooms right now, and that's bound to go up since the rads are now all nice and hot) in the house at this point to keep testing, so I backed the schedule down to 70 and I'm confident enough that I won't blow anything up leaving it on overnight

Thank you to everyone for the knowledge you've helped me gain over the past years I've been browsing the forums. Due to the information I've been able to pick up through members here, I'm confident that the system we have now is at least a reasonable foundation for a long-lived, properly functioning steam system.

Now to order insulation for the mains!1 -

Would you bother mentioning to the owner (who quoted the job originally) the pressuretrol setting of 4psi w/ 1.5 (subtractive) differential? I set it to 1.5 main, 1 differential as soon as they left, but not sure if it's something I should bring up.0

-

I would wonder why they set it that high, just out of curiosity. It could have been an honest mistake or maybe they don't know.0

-

The boiler fill is piped into the wet return side of the hartford loop rather than the boiler side. Is that an issue, and if so, why?0

-

No issue with that. If the feed is done while hot it helps temper the incoming cold water.0

-

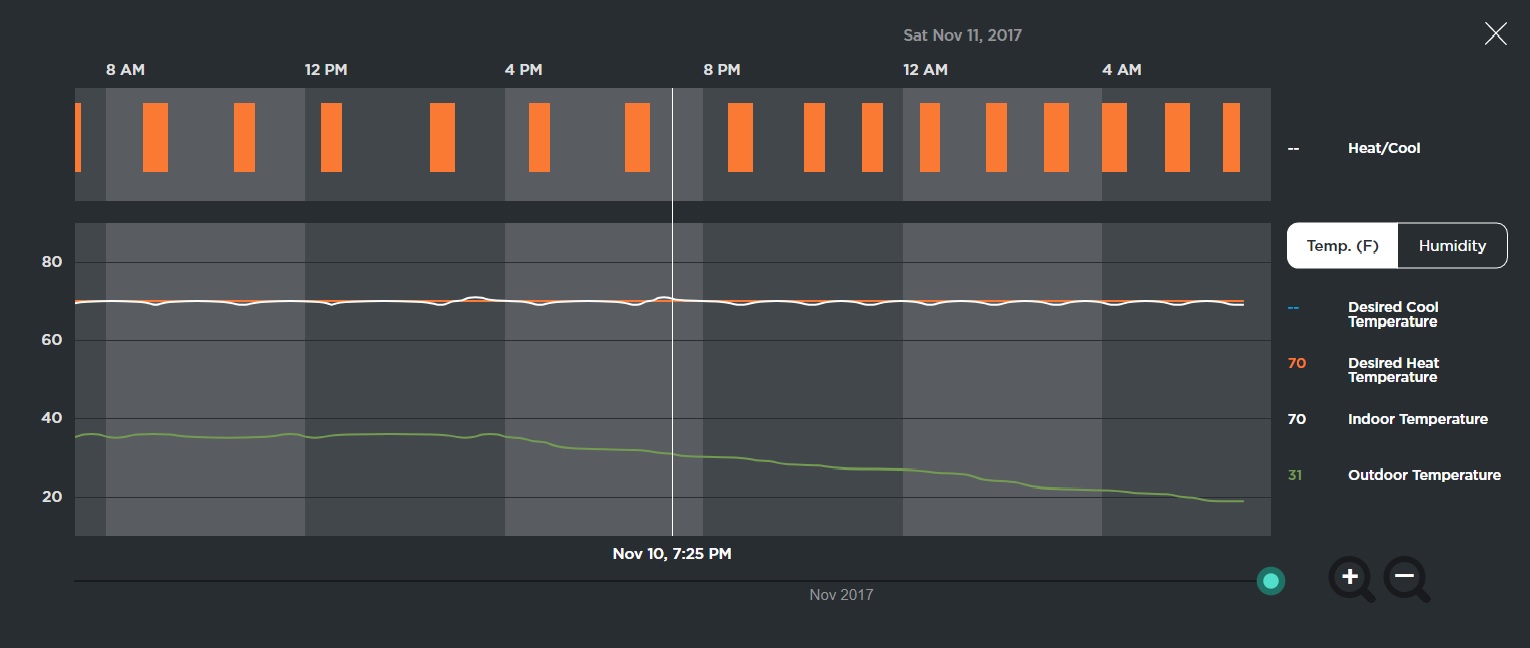

Got pretty cold in the past 24 hours. I still haven't insulated the mains except for the sections that had easy 3ft sections that didn't require any cuts (not many).

We still have one small radiator removed from the bathroom that's torn out for remodeling, with the door closed to that room.

I love having the visibility into the heating cycles that the modern thermostat (Ecobee3) provides, as well as being able to have temperature based on an average of multiple sensors around the house.

How does this look for cycle time based on the outside temperature?

0 -

If you are doing it yourself, use 1-1/2". You'll thank me.mynameisphunk said:

Now to order insulation for the mains!

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com0 -

Issue moot now. But if you pipe it into the boiler side, and take the trouble to valve the return side, then upon start up you can close the valve and drain away all the dirty condensate , but keep things running with the fill on trickle.mynameisphunk said:The boiler fill is piped into the wet return side of the hartford loop rather than the boiler side. Is that an issue, and if so, why?

New England SteamWorks

Service, Installation, & Restoration of Steam Heating Systems

newenglandsteamworks.com1

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 427 Carbon Monoxide Awareness

- 119 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 165 Indoor-Air Quality

- 3.7K Oil Heating

- 76 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.6K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements