Auto air bleeders

Hello all..

Just wondered which brand of automatic float type air bleeders you prefer for hot water systems…? Whether it's installed directly on a radiator (fin tube) or a main line somewhere.

Which ones do you all prefer for reliability and functionality ?

Comments

-

I'm not a heating pro, just a homeowner/engineer, but I like the Caleffi Minical 5020 series. I just put two on our boilers. They're very well made and work reliably.

0 -

-

Caleffi

0 -

I've never used the Caleffi ones. But I am certainly not opposed in any way. I know Caleffi makes good products…

And yes, I'm aware that float type bleeders tend to leak over time.. Which is why I asked the question as to what you all prefer.

0 -

-

Caleffis have an optional hygroscopic cap for the Schrader bleed valve to prevent leaks. The caps have a cellulose washer that expands when it gets wet, making a seal that prevents water leakage out of the valve. Caleffi recommends using those in places where leaks could be problematic.

Our Caleffis on the boilers have those hygroscopics caps, even though a small leak on the boiler isn't going to hurt anything.

0 -

i feel like you just won't notice that it is leaking until the cellulose disc fails.

on upper floors you can sometimes get conditions where auto vents pull in air.

0 -

-

Used to put one at highest point. In elevator shack on top of roof. Was that back to future as open expansion tank? I'd recommend an overflow to boiler room so that one would know when something is amiss. Nobody listens to me.

0 -

Thanks for all the responses.

The reason I asked this to begin with is because a customer says they have to bleed radiators all the time and they were asking about automatic air vents.

But I've found out more info and I don't think it's an air problem at all. This home has a mono-flo system and it does not seem to be circulating thru all of the radiators. I do not believe there is an air lock anywhere. This is a ranch style home with a full basement. The system fill pressure is about 15 psi cold. It just does not seem as though the circulator is moving the water properly.

Which brings me to my next question…

How is a circulator pump sized for mono-flo ? I have not dealt with mono-flo systems much at all, so I'm not extremely familiar with them. I realize there has got to be some restriction created thru the mono-flo tees. But how much ?? There are some radiators fed with 1/2" and some fed with 3/4".

I still need to go back and figure out the total length of piping and count up all the radiators. I do know that this system is a single zone with 1 1/4" copper mains. The main supply from boiler is 1 1/4", then splits and makes two separate loops around the basement , and then back to the return. The main returns coming back to boiler are also 1 1/4" copper. There are also ball valves on each of the supply mains to adjust flow to each of loops. The circulator is currently installed on the return line near boiler, and it is also "pumping away" from the expansion tank. Again, I'm thinking that the current circulator is just not sized correctly.

So how do I determine what circulator is required for this type of mono-flo system ?

How do I calculate everything?

Thank you for any advice

0 -

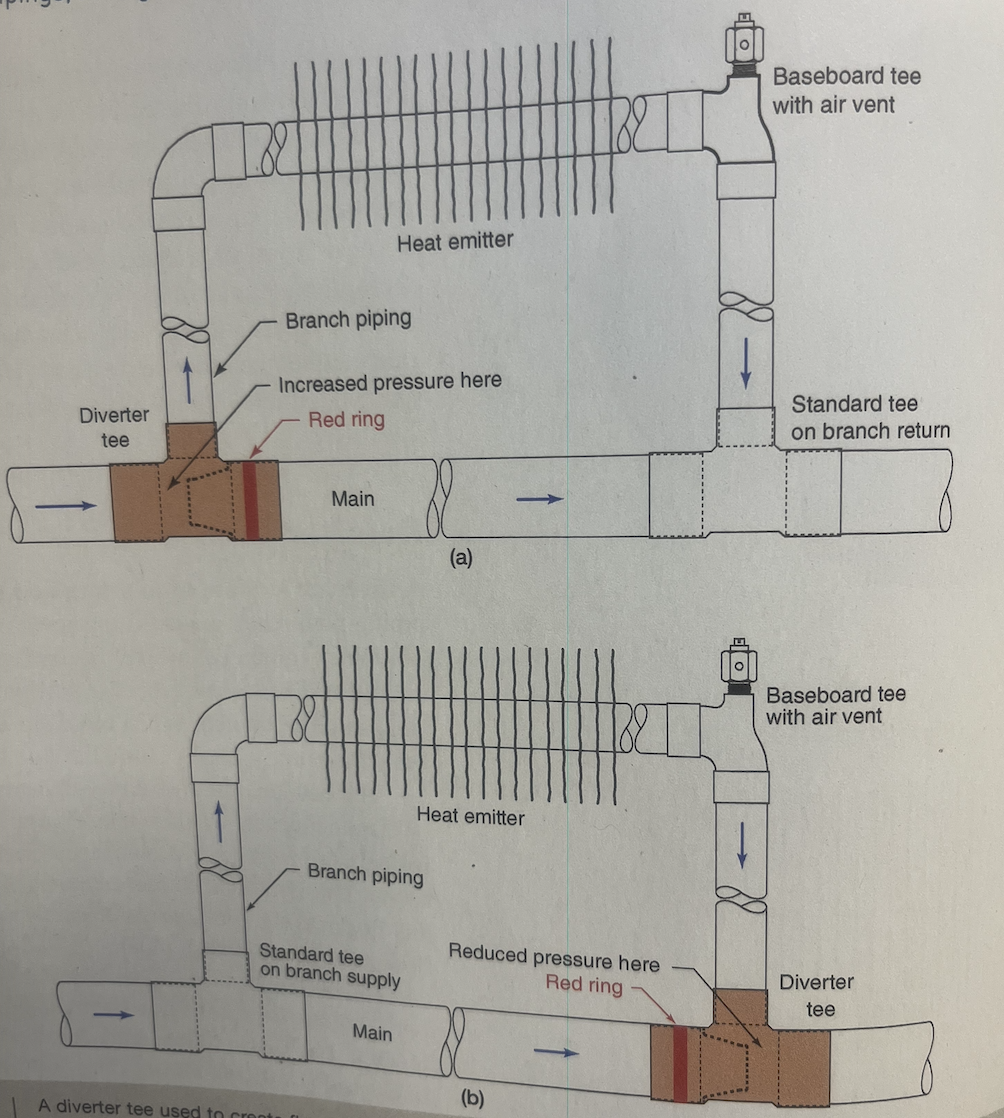

the tees aren't as much a restriction as they are a partition that separates the flow between the main and the emitter. the tees all have to be in the right direction and which direction is the right direction depends on if it is on the supply or the return of the emitter. if they are in the wrong direction that partition will restrict the flow in the entire loop.

the flow through the emitter is the harder path than straight through the main so you need to have enough flow and head to make it take both paths.

0 -

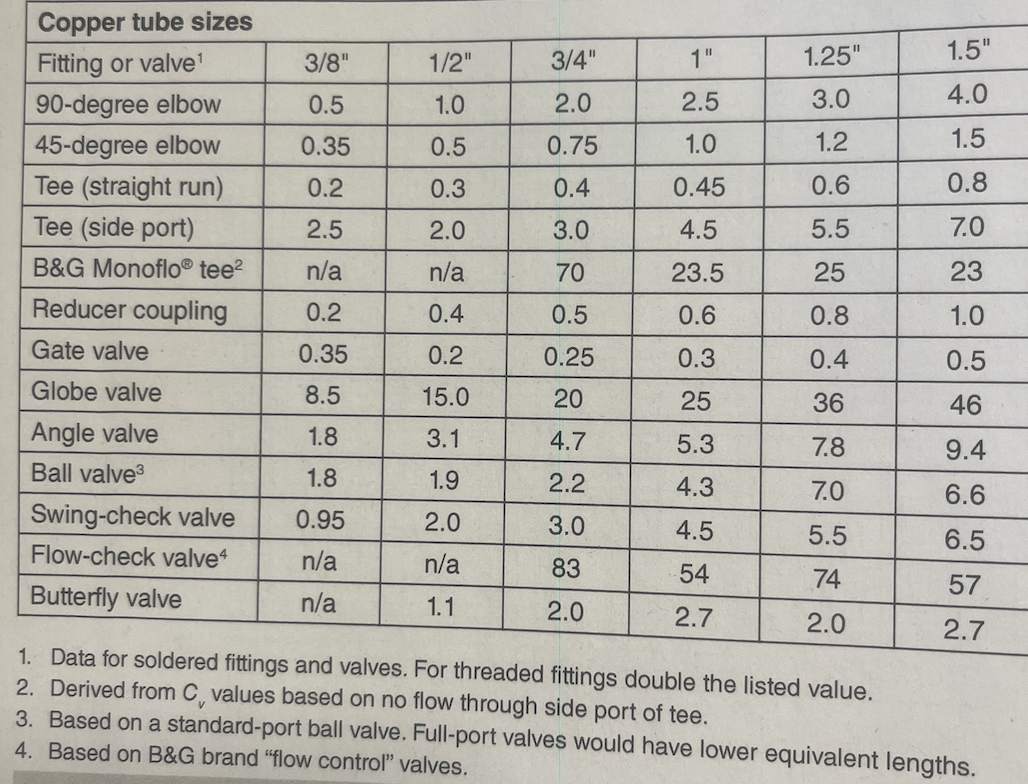

This chart shows the EL equivalent length. Notice the Monoflo® compared to other fittings, tees for example. So it does add some flow resistance, depend on the flow path, note the asterisk.

Adding TRVs changes or stops branch flow, so pressure drop is straight through in some cases.

Same with B&G FloChecks, compared to a common swing check.

So you would need to know gpm flowing to determine the pressure drop through fittings and complete circuit

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Have you told your customer to just turn the thermostat all the way up to purge the air in the system???????

0 -

-

Probably another Monoflow system with a Taco 007. We get these posts from time to time on here.

That combination does not seem to play well regardless of what the pump curve shows.

0 -

Exactly ! It has an 007 currently installed

0 -

how are you getting that much air in there?

I bleed all my radiators once in the fall one to two seconds of air out of each and that’s it

0 -

Mystery for the ages. Some systems don't consume water and don't ingest air. Others do.

0 -

pumping at an expansion tank especially in a circuit with high pressure drop could pull a negative pressure and sip air in through an auto vent

More likely is the air has never been purged adequately

If the system is in fact under pumped, flow under 2 fps, feet per second, small air bubbles will never get entrained in the water flow and pushed back to a central air purger at the boiler

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

What is the general layout? How many monoflow tees? Is all the radiation above the main" What size pipe is the main? BTUs of the boiler" Length of the main out and back to the boiler?

I had an 007 at my house. 11/4 "main 8 monoflow tees. 55,000 BTU boiler, 1" zone valve and the water wouldn't move

0 -

Not sure of all of that exactly just yet..

But there are a total of 13 emitters above the mains, and 6 emitters below the mains in basement. Not sure if each emitter has only one mono-flo or two mono-flo's. Most of the main piping is hidden in the ceiling cavity. But the ones I can physically see only have one mono-flo each

Mains are all 1 1/4".

Not sure total length of mains until I go back. Quick guess for now is about 310 feet total. Like i said, it's a ranch style home and it's fairly big.

And I'm not certain what btu the boiler is, but if my memory serves I think maybe 120,000 btu. It's an older Weil McLain.

And it currently has a Taco 007-F5 circulator

0 -

are the ones not heating below or above the main? emitters below the main are harder to get flow in

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements