Replacing wet return on 1-pipe steam system

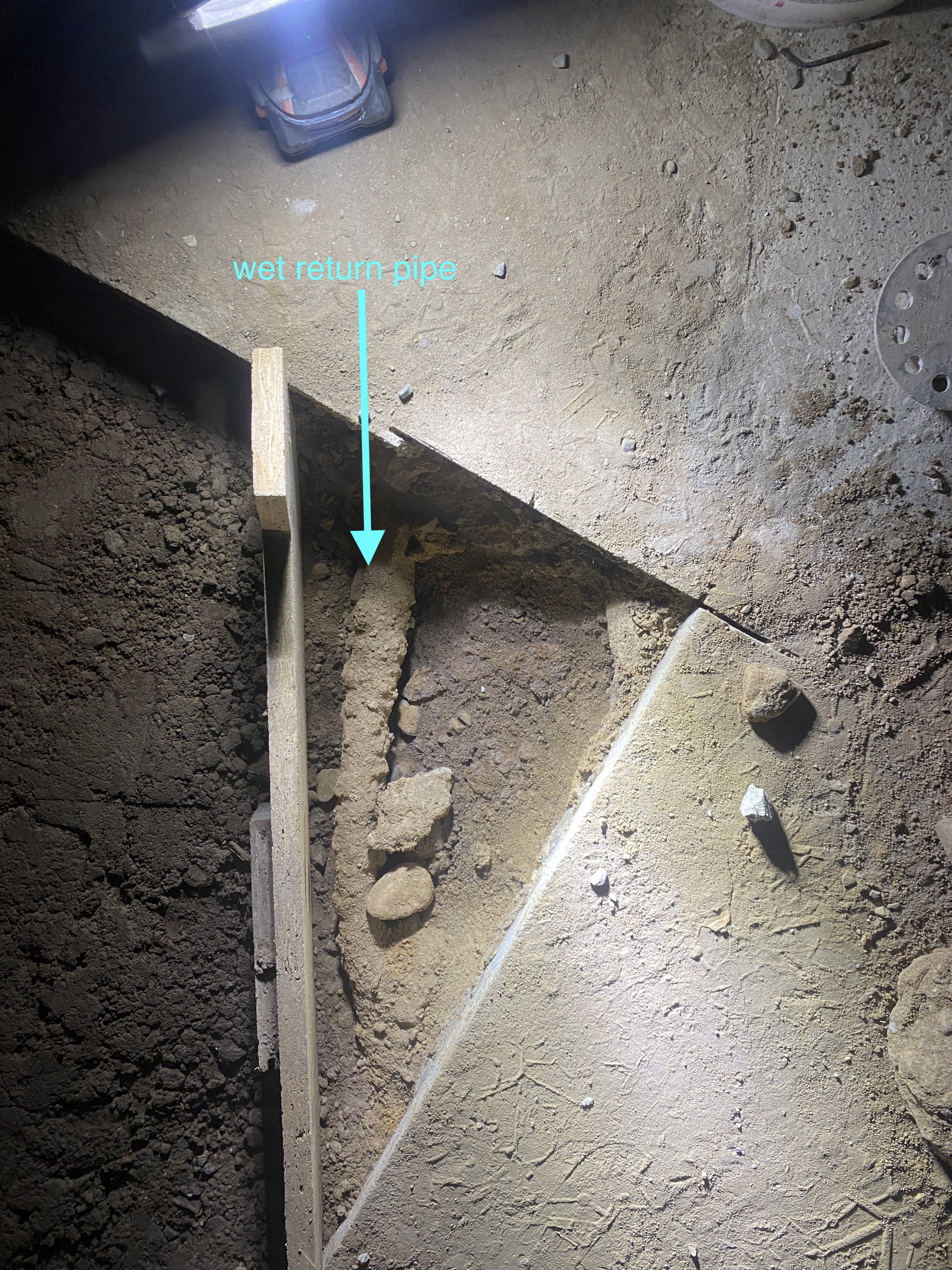

I’m doing some demolition in the basement and with the walls open I’m considering replacing the 100+ year old wet return pipe.

IT runs about 60’ from the front of the building to the back and then over 15’ and then under the slab for 8’ to the boiler.

The pipe looks pretty rough. The pipe is sitting on the slab and someone framed double stack 2x3 right on top of the pipe. All that framing is coming out. I’m going to replace it with metal studs.

- If replacing, should I replace with copper type L or use black pipe. Copper is going to be MUCH more expensive. Black pipe will corrode faster. But who knows how long/often the steam system will be used. I’m going to use it as a backup system for heat, when it’s too cold for mini splits to function. (It’s a well insulated building) When the pipe goes under the slab I plan to use copper.

- Does it have to pitch 1/8” foot toward the back of the building? There’s no way my slab is 60/8” lower in the back.

- I’m going to install a ball valve and hose connection in the front of the building so I can flush the system. There is a similar setup at the boiler.

- Return pipe sizing - I think the return pipe is 1 1/4” (will measure with calipers). Is that size adequate.

Boiler Burnham IN6. 15 radiators. 3 family building.

Any advice or tips greatly appreciated.

Comments

-

Is copper really that much more expensive? (I honestly don't know) Is that including labor?

Honestly either one is going to outlive most of us, do whatever you prefer.

I ran steel pipes because it was short and easy but one of these days I'm going to try Pex.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

No slope is required on a wet return. So long as it never goes above the water level in the boiler, it can go up and down or sideways — doesn't matter. Keeping it below the water level in the boiler does matter, though!

That said,, provide at least a few places (plugged Ts) where you can get at it to flush it out from time to time.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

-

-

Thanks for the feedback guys.

I'm going to use black iron in the walls and copper underground.

Here's my plan, let me know what you guys think.

- In the front of the building, remove the pipe on the 1st tee and replace with a nipple—> 45 —> close nipple —> 45 to get if off the ground. Abandon the rest of the pipe on the ground.

- Add a ball valve —> tee —> boiler drain. Install an access panel after drywall is installed.

- run black pipe all the way to the back

- Right before it goes underground in the boiler room, install a tee w/ boiler drain and a ball valve. There is another boiler drain right before the wet returns goes into the boiler, but no ball valve to isolate. So sludge could get pumped right back into the boiler.

- 1 1/4 Copper underground and tie back into existing copper.

Questions

- I see 2 types of boiler drains that could work. Is one preferred over the other? See pics.

- Supporting the pipe. How far should I space my supports? I have an old stone wall, which will be difficult to drill into I'm guessing. Here are some support ideas

- Install 2x3 on the walls with tapcons and then use split ring hangers to support horizontally.

- use split ring hangers and attach to joists overhead. I'll need a lot of threaded rod but will be MUCH easier.

0 -

How high off the floor do you want that pipe? If it were mine, first I'd do it in copper — mortar is kind of tough on black iron, but copper doesn't mind — and second I'd set it a brick or two off the floor and support it every 10 feet or so. On bricks. Slope isn't relevant for wet returns.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

-

-

I could put a couple bricks under it. But that floor isn't exactly flat b/c I'm going to abandon the old wet return on the ground. You guys don't like the threaded rod/split ring hanger idea?

In terms of height off the ground I am a bit limited on how high I an raise it, b/c I have to tie into another pipe in the back of the building. Picture #4 from my original post. But my two 45s plan would get me enough room to work a wrench underneath.

Well if its copper, I'd sweat it. I don't have a propress. So brass nipple into the black tee on the ground and copper from there?

I've got to think thru copper vs black iron. I guess I'm not getting that supplyhouse order by 5pm. 😅

0 -

The floor doesn't have to be flat. Surely there are a couple of places more or less ten feet apart which are more or less on the same level? Or if not, which are an even number of bricks different? And keep in mind that the wet return doesn't have to be level.

And if two bricks is too high, how about 1 brick? Or a paver from the Big Box?

It's not that I don't like your threaded rod and hanger idea, or the tapcons into rock (but good luck with that…) — it's just that it's wildly more work and complexity than is needed.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England3 -

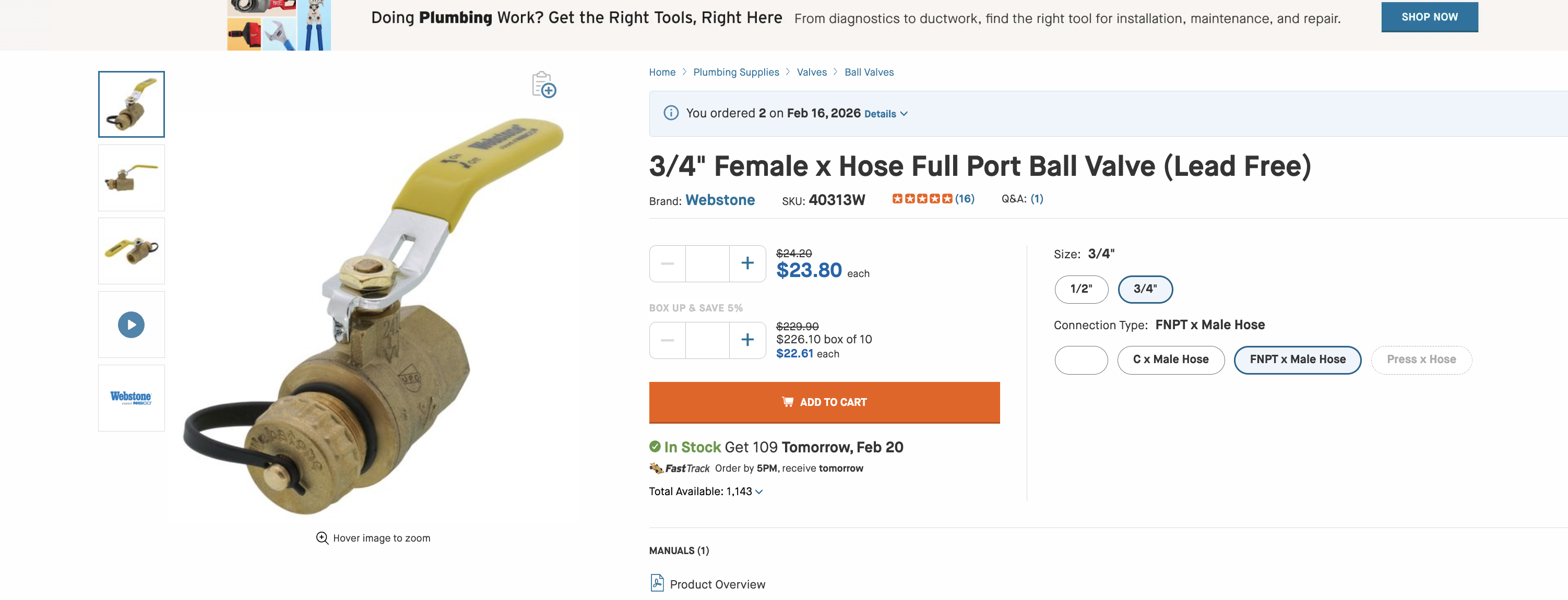

I like to use this type of boiler drain because it is full port and built a bit better than most:

https://www.supplyhouse.com/Webstone-40313W-3-4-Female-x-Hose-Full-Port-Ball-Valve-Lead-Free

I would use a threaded version so if the valve fails it is easy to replace it.

1 -

-

I'm going to do copper as guys here suggested.

I dug up the underground section near the boiler. Looks like they went copper to a black 90 back to copper and back to black pipe underground. It is what it is.

I've read the copper pipe doesn't need to be sleeved underground, but should be sleeved when it comes up thru the slab.

0 -

I would have probably just abandoned in the ground and run the new pipe above the floor and eliminate all the underground hassles and digging up the slab.

3 -

Do you absolutely need to bury the new pipe underground? It will cause a problem eventually and someone will be here asking where all the missing water from their boiler is. Might be our grand-kids or great grand-kids but it will happen.

Keep it above ground if you can. Maybe route it behind the water header and along the foundation?

1 -

i thought there was a doorway involved here somewhere.

when I buried some pipe in concrete I got some of the collapsible discharge hose and sleeved the pipe in that. If I were burying pipe in the ground like that I would probably sleeve the whole thing, not just where it goes through the slab. If the soil attacks it or not depends on the chemistry of the soil.

1 -

Theres a door to the backyard in the back there.

I'm going to bed it in sand to protect the pipe.

0 -

-

-

-

I just want to verify this is the valve to drain the wet return so as to minimize the amount of water leaking once I cut the line. I'm going to drain it until almost empty on the sight glass.

I got the full port drain valves mattmia suggested. I'd like to sweat the 1 1/4 x 1 1/4 x 3/4 tee with the 3/4 leg facing up so I minimize the space lost once I frame a new wall w/ access panel around wet return. I don't want to face it down, b/c that's where my baseboard will be. Am I going to regret that later when I drain the wet return with a hose. + bucket? It's going to be a finished basement.

0 -

-

-

First mishap right at the starting gate. 😥 I nicked the threads right thrue on the old black tee on the ground. Usually when I've done this on steam fittings in the past, I use Blue Block on it and I've never had a leak. Will the block be adequate or do i need a better solution.

0 -

-

Clean it with alcohol, spray the nipple that is going in there with dry lube, let it dry, put a noodle of JB Weld Epoxy putty in there, screw in the nipple about 1 or 2 turns past the finger tight point (premarked on both pipes), let it cure and disassemble. That's what I'd do because that is a pretty deep cut.

2 -

It's in his picture lol. I did not say your method wouldn't work but everyone has easy access to jB Weld epoxy putty and dry lube. He could use "hardening sealer".

I'm not saying for sure it won't work but I have had RTV rubber end up in my boiler when using that to repair my steam main, for example. Not real keen on that where air can't get to it or allow it to cure through escape of acetic acid, which is corrosive to steel.

1 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements