What's the professional way to raise this vent?

Want to raise this vent above the main into the ceiling. Easy peasy. Maybe one day I'll put a #2 up there. Aside from just putting a 3/4" nipple into the main, what's the way a future person wanting to replace the vent would be like "now this was done right"

Comments

-

-

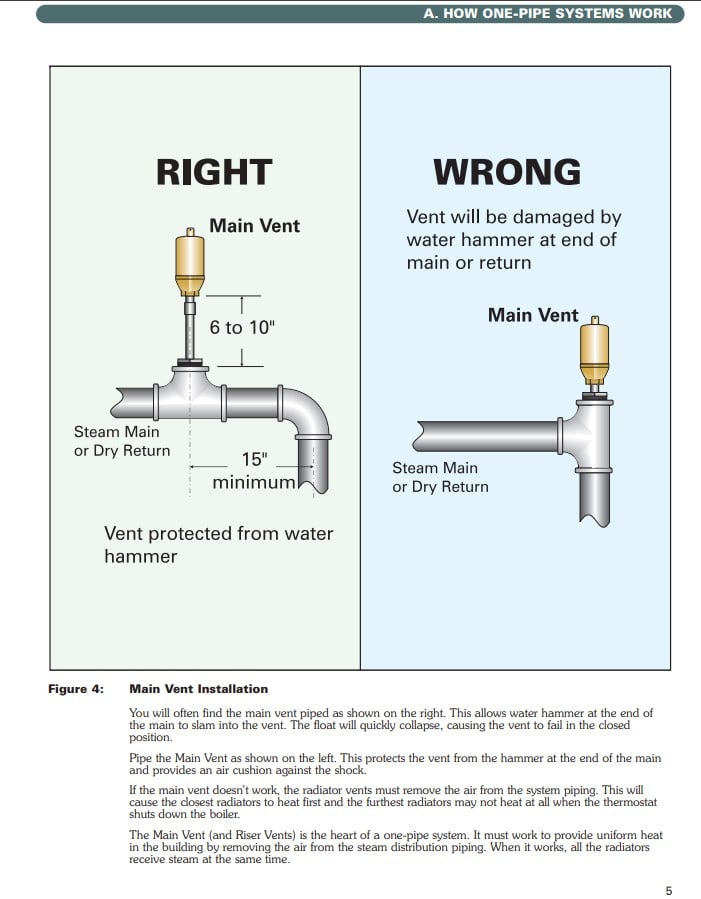

If you want to cushion the blow of water hammer, you don't have to raise it, although that is preferred. You could tree it off to the side with a 45 and an Ell and a couple nipples and the extra volume in those will give the vent an air cushion. Ideally it should be located further away from the elbow to the return but try that.

1 -

like @EBEBRATT-Ed said, i'd put a union in there right off the main so you can pull the whole thing down by just breaking the union but other than that nipples and couplers are the way to go. I think there is even a male-female union that could thread directly in to the main and eliminate the nipple there.

1 -

So like this

Gorton #1

|

3/4" Coupling ← service joint

|

3/4" Riser Nipple (6")

|

3/4" Union ← removable assembly

|

3/4" Close Nipple (1–2")

|

Steam Main Tapping

I'm guessing the close nipple will become permanent basically.

Yes agree , the vent should be further from return but not gonna fix that

0 -

you can remove the close nipple with an inside pipe wrench or sometimes you can grab it between the sets of threads with channelocks without damaging it. you certainly can remove it with a pipe wrench but that is likely to damage the threads.

0 -

-

Just make sure that you don't have water hammer, and you'll be okay. If you have enough water hammer to damage that valve, then you have bigger issues than valve replacements.

0 -

Well, the way to do this right is to build in a finished recessed box on the ceiling between the floor joists. Then you can use a union and a regular nipple to get the right height. This way the vent is always accessible.

Instead of a recessed lighting cavity, its a "recessed venting" cavity.

0 -

I know you all must get sick of me asking questions, but why would there be water hammer in the main?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

You can use any length nipples you want. I mentioned a close nipple because I don't know how much room you have. Use any length that works for you.

0 -

@ethicalpaul I enjoyed your previous post on comparing the #1 and #2. Enjoy seeing empirically derived data.

@EBEBRATT-Ed thanks for comments.

0 -

-

-

Ya. The other, long main, (not topic of this discussion per se) has iron routed into copper mains that aren't insulated but put inside a closed decorative box running along the ceiling. This main hammers like crazy at the 90 degree turns. Sigh. This was installed probably 20 years before i purchased the house. At least I'm fixing what I can

0 -

If it is doing it at the start of a call for heat, it could be as simple as needing to hoist up that part of the main due to a sag that is holding water.

That's the only thing I can think of, in fact, that would cause water hammer in a main, and that was the reason for my question, which was not yet an argument (haha)—I was honestly curious if anyone had any other causes for water hammer in a main because I haven't experienced or seen it yet.

Even crazy carryover in my old boiler never caused hammer—it just caused gallons of boiler water to flow through my main and to the wet return—that is something that could potentially foul a vent, but as @STEAM DOCTOR said, that's a problem that should be addressed regardless of how high your main vents are.

My question was really about how I keep hearing about "water hammer hurting vents" but I don't know what that means. Do people have water hammer at the end of their mains?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

i think a sag and steam from the boiler hitting a puddle could cause it, especially in an oversized boiler or poorly balances system.

in large especially 1 pipe systems where the building is tall there are a few risers with a lot of load on them and if the condensate coming out of them isn't managed properly i think that can cause hammer in the mains.

1 -

It's a shock wave, due to the fact that there is approx. a 1,700x volume change in going from liquid water to steam and vice versa. If it is severe enough it is audible. If it is severe enough it can do damage to vents, especially the float.

I heard it in this system 21 years ago when I first moved in. My varivalves weren't damaged by it afaik probably since they are only at the radiators, but it was quite disconcerting. My longest main had a large puddle at the last 6 ft or so of it, due to incorrect pitch. I also didn't have enough downward pitch in my dry returns. My main vents aren't at the 180 deg turns into my dry returns but are at the end of the dry returns by the boiler.

0 -

Thanks @Captain Who I can see it if there is a pool of cool water due to sagging. I'm familiar with what causes steam/water hammer generally and have experienced it with a sag in a radiator runout, but lots and lots of people say "raise the main vent to avoid water hammer" but there is not water hammer in a properly pitched main that I can picture.

If you have water hammer in your main, that is the problem… not the height of the main vent, and I, like you, would work hard to fix it. Thanks again.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

People word things wrong sometimes. The reality is that raising the vent helps prevent damage to the vent in the case of water hammer.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements