Gorton vents is there a way to test them?

Comments

-

Thanks for the info. I have both TSP and washing soda. Yes, that initial water was black as coal, hadn't seen water ever look like that. I suspect it's not clean yet, despite 4 skimmings. The manual mentions using a "recommended boil-out compound" to clean the boiler, but nowhere do they tell you what that mythical stuff is. I even called them, pretending to be a contractor, and they can't or won't provide that information. So why put that in the manual?

Perhaps not surprisingly these days, this Installation, Operating and Service manual doesn't tell you the fill capacity either. It only tells you the dimension of the normal fill line from the base of the unit. That's it. I just went through all the manuals, page by page, and there's no mention of water capacity! Maybe it is online, but I haven't tried that. I'll go do that now. Not available, that I can find. Weird. Make everyone reinvent the wheel when the factory obviously knows this…

0 -

-

-

Fair question. It's boringly the same as before. All the plumbing was reused. At the moment I don't have any new pictures. It will be a week before I can take some pictures. Thank you for your continued interest and help. I will post the pic in a week.

0 -

Sorry about the pictures. Reused all the old piping, but I will be able to take pics in a week.

Thank you for the answer regarding the water capacity. What year manual are you quoting? I see it in the 2024 manual available online. Didn't see it in the 2021 manual that came with the boiler. Or I missed it! Those kinds of things can happen when you are frantic about your heating.

0 -

Finally bit the bullet and bought some (6) "new" Gorton vents. Except they don't really look all that new. My 15 year old Gortons look newer. The male thread looks poorly plated, it's slightly corroded, and inside the hole, it's got loose green corrosion. Everything else on the exterior looks ok. I'm concerned that the lifetime of these "new" vents may not be as good. 3 out of 6 have full green interior pipe surface, the other 3 have maybe 15% green.

The float seems to move. I can blow air through one if right side up, but not if upside down.

Is this how they come these days? Or should I contact the online vendor? At $40 a pop, I was expecting they wouldn't look corroded.

A month ago, I broke down and had to buy some terrible vents from a big box store. Some leak. All used some terrible chemicals in their manufacturing process, and stunk up my house. Not worth it. The Gortons don't stink. I will replace all the horrid vents with the Gortons.

I also bought a #1 vent. It looks gorgeous and brand spanking new. Hope it works well. The vent location is not in a good spot for me, as it is near my milling machine. Spitting water on it is not allowed!

0 -

You have testing 1/2 of their functionality—their ability to pass air.

You will have to heat them to test their ability to block steam (although it seems likely they will since you did the "upside down blow" test), or just put them into service and keep an eye on them.

I think Gorton and Maid O Mist are functionally equivalent, and MoM are $14 on supplyhouse.com right now so that's what I buy for my radiators. Sometimes they fail. All vents fail, but all vents don't cost $14.

MoM also have the extremely convenient swappable orifices (without tools) which is amazing for balancing.

Regarding the corrosion, Gorton are soldered as part of their manufacturing process, I assume in an oven, and so flux seems to get inside them and it has some corrosive effect on the brass (or whatever the material is). The bimetallic strip can also come rusted from the factory, again possibly from the flux getting in there. I know this because I opened up a brand new one that arrived stuck in the open position due to physical trauma during shipping or something).

Maid O Mist are crimped, not soldered, which some people see as a flaw, but in regard to this flux issue, it could be a benefit.

You can see inside my Gorton vent here:

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

The MoM counterfeit vents, sold by the big box stores also have replaceable orifices, which is why I bought them. Unfortunately they stink to high heaven. They were giving me headaches from the fumes. I had made my own custom orifices to balance out my system, which worked ok. The venting I needed was in between a #4 and a #5. I used a #55 drill to vent at 1.7x a #4 vent. That almost filled my radiator, which was close enough.

@ethicalpaul are your (hopefully authentic) MoM's scent free? The no name one's have the stench of some chlorinated solvent, which they freely pass into the rooms.

0 -

I moved a few gortons around that I had installed a year or two ago, the paint on all of them was flaking off. I wouldn't be too concerned.

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

Yes, you can trust supplyhouse.com

They come in the very nice orange boxes from Chicago. Never buy a vent from a big box store (as you now know, but I repeat it here for others).NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I'm going to say, that the Gorton #1 works, and seals, but it is making the marginal plumbing stand out like a sore thumb. The heating in the back of the house got worse. The radiators fill later, not sooner.

Somehow there's a lot of water (condensate) at that end. I could hear water in the radiator and steam ?gurgling through it, bubbling. (The boiler was on and in mid cycle.) Without the main vent, the amount of water was tiny. The right way to fix it is the tear out my walls and totally replace the work of the "plumber from hell" who is torturing me from 20 years ago. I can't afford this, and honestly, I'm going to be selling this house to move closer to my kids, so I really don't want to sink a lot of funds into this.

The boiler cycled on LWCO. I don't know why it does that, maybe that's due to residual oil in the boiler. When the water returns, the boiler is 2/3 full in the sight glass. During the first cycle, the upstairs radiators fed by the vented main were cold, and I could hear water sloshing in the pipes. Then the water drained back. The second cycle, the radiators heated, but I also heard water, but I guess, not as much.

I think I will remove the #1, because the heating behaves better. Not optimal, but the heat arrives sooner without the main vent. I know there's a problem inside the walls, likely a badly pitched horizontal section, but I would have to pull a toilet and a radiator to get any access. That denies me use of my bathroom for an extended period of time. And I'm not sure I can fix the problem easily. The access is poor, there's a chimney coming up, which takes up room that could have used to fix the problem.

Kind of perplexed really.

Don't know if I should return these Gortons and get MoM's. That would let me reuse the orifices I made which work in my house. I would have to drill out (modify) my Gortons to balance my home. Obviously, I'd check them first to see if they even work before modifying them. If I use the MoM's I could return the #1.

Confused as to whether I should return the #1. Dogma says use the vent. Empirical evidence is to the contrary. No matter what the reason was, I got less fill in the radiators using the #1, and the heat onset was late. That's like having undersized radiators, and the rooms are colder. Not good.

Color me confused. What would you do?

0 -

The only thing I can add here is that the surging from your boiler has sent all sorts of oil and debris up through the system and some of that has probably found its way into your nice Gorton vents.

I wouldn't pronounce the Gorton vents dead just yet. They probably didn't fail from being rusted shut or something, they probably just got gunked up and clogged.

Tap them hard on countertop or something to see how much junk comes out. Boil them in vinegar for 10 minutes. Drain them and rinse under the faucet and tap again. Boiler again with regular water, drain and tap. Let them fully dry and tap again.

Happened to me once. A lot of junk came out. All but one vent went back into service.

100% recommend using TSP or Washing Soda to clean out that boiler! If you can fix the surging and fix/replace your vents I'm certain the system will return to its former glory!

0 -

The boiler cycled on LWCO. I don't know why it does that, maybe that's due to residual oil in the boiler.

This carryover is not caused by your vent in my opinion. Your water has oil in it or a combination of rust and treatment. Skim and/or drain until the water stops exiting your boiler with your steam.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Ok. Since I don't have many good choices and there's a consensus that things point to crud in the boiler, I can do that. I found a package of TSP. I don't have a real drain in the basement. There's no sinks. So I'd like to limit the amount of water I have to drain, since I need to carry the 77 lbs per boiler fill upstairs to a drain. Don't have any young plumber's apprentices, have to do it myself.

I'm looking for sort of a check list. Please correct what I have written.

- Drain the water completely now. Dispose of water

- Fill boiler with water and TSP (~3 oz, dissolved in warm or hot water). Use safety vent port.

- Bring to boil

- Turn off heat

- Open skim port. Turn on a trickle of water to create a thin stream of water out the skim port? For how long? Or do I drain this, then fill with clean water then skim?

0 -

@ethicalpaul I asked this earlier, but are your MoM vents from Supply House, free from strong chemical smells? You didn't directly answer me. And sorry for this personal question, do you have a reasonable sense of smell? Some folks don't.

0 -

they are free from all chemical smells because my wife who has an overactive sense of smell has never complained!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

-

-

Sure, I'd make these modifications:

4.5 let boiler set quiet for an hour or so to allow any oils to rise to the surface

4.6 Open skim port.

4.7 Open makeup water valve slightly to slowly allow water to rise to skim port

5.0 Adjust makeup water valve to allow a thin stream of water out the skim port (doesn't have to be TOO thin). Observe output to see if oils are being floated out. Fill 2-3 5-gallon buckets or so.

6. When finished, drain water from drain tapping to lower water level to normal water line

7. Close or cap the skim port!

8. Put boiler back into service and watch the waterline to see if it is quietI add detergent or water treatment into the skim port rather than the PRV since you have it open anyway

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

It's a good idea. A quick search doesn't reveal a pump that can handle boiling water for reasonable cost. Can you offer a suggestion? A lot of pumps that I have seen are made of cheap plastic and not rated for hot water use, or even water with particulates.

0 -

Thanks, that makes things clearer. I'll see if I can scare up a transfer pump, that would make things a lot easier for me.

0 -

The water isn't going to be boiling. It will be hot(ish)

It don't have to be fancy!NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

-

-

-

Referring to the title of the thread. I knew I had seen one of Gordon's videos and bookmarked it. Here it is, and it is a bit of a contraption to build. Testing them in a bad install could subject them to unfair water hammer or other conditions which they are not expected to be able to endure.

0 -

I had to delay this a few days with the cold snap that arrived. Didn't want to let the house temp drop that fast. Tomorrow ought to be better temperature wise. Had to get another hose along with a pump. Shouldn't be too hard to do, he hopes.

The Gorton #1 is behaving itself, much better than the Hoffman vent's I had previously tried. At least it is sealing! The Hoffman's never did seal. If I can finally fix this oily boiler, maybe things can get back to normal again. Strangely, the first couple of heating cycles with the #1 were troubling. Some spitting and lots of water being pushed to the second floor But after a day or two, even though there's still a little water in the pipes, from a cold start, it's much better. The Gorton is venting like crazy when it needs to, and seals when it has to. Big win for the Gorton main vent.

Ok, today was warmer, and I drained the green water out until the drain was dripping. Dissolved 3 oz of TSP in about 1/2 gallon of hot water and poured it in the skim port. Then slowly refilled the boiler water. Finally fired it up. It's not good yet, but the water does move less, about 1/2 as much . I "lost" about 3" during the firing, at first it wasn't moving hardly at all. Bounce was plus minus 1/4", but would occasionally drop. Didn't hear much evidence of water in the lines, which is good. No banging or clanking. I need to do the actual skimming now.

Have to really watch it with near boiling water and plastic buckets. These buckets really aren't made for it. The bucket got a wee bit distorted. I'm only carrying a few gallons at a time, because I think the bucket will fail with more weight.

0 -

Went back to your old posts and seems you had a boiler installed very recently, another in 2013 and another before that all with rather short lives. Your picture shows a single riser from the boiler going into a drop header with a single riser from that that which goes to a bull head T into 2 mains. Your radiator EDR calculated to 404sqft. 454sqft boiler so not great but not terrible. (This is all for my own reference because it gets confusing for me with the multiple posts on one homeowner project).

I can't stress enough that when problem solving something that as you say was working fine prior to the installation of a new boiler focus on what has changed or could possibly change with the new boiler. Unless they changed hangers and pitch on the mains from your description there seems like very little could have changed other than pressuretrol function and the oils introduced from the new boiler. I would 100% focus on skimming and nothing but skimming for hours and hours and hours. When I had my new boiler installed initial cycles were also quite "volatile". I never completely drained the boiler. Over the course of about 1 week I would heat it up and skim for about an hour or so (would only fill a couple buckets with the slow trickle). After letting it cool I would open the drain spigots one at a time for 5 or 10 seconds each to drain off some of the really black stuff. Next day I would repeat. After a week or so things really calmed down. I never added any additives to the boiler.

Seems like a single Gorton #1 is not much main venting for a system utilizing a 454sqft boiler but that could be looked at after. I'm not sure I found out from the earlier threads either how you work just a single main vent when you have two mains?

0 -

How to test it?

When off from pipe, you can blow inside. In the right side up position you should be able to easily pass air, but as you blow and flip it, the air passage should stop.

When on the the pipe, when it should be open, when you lightly tap it, you should hear movement of the float suspended by bi-metal spring. When you tap it when it should be closed, you should hear nothing as the bi-metal spring pushed the float against the opening).

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog0 -

-

Thanks for your reply. I went out of my way to make sure nothing changed but the boiler, including all the near boiler stuff. What did change was the boiler and it's sensors, including the pressure trol. Not the header, nor the Hartford loop, or even the indirect HW heater loop.

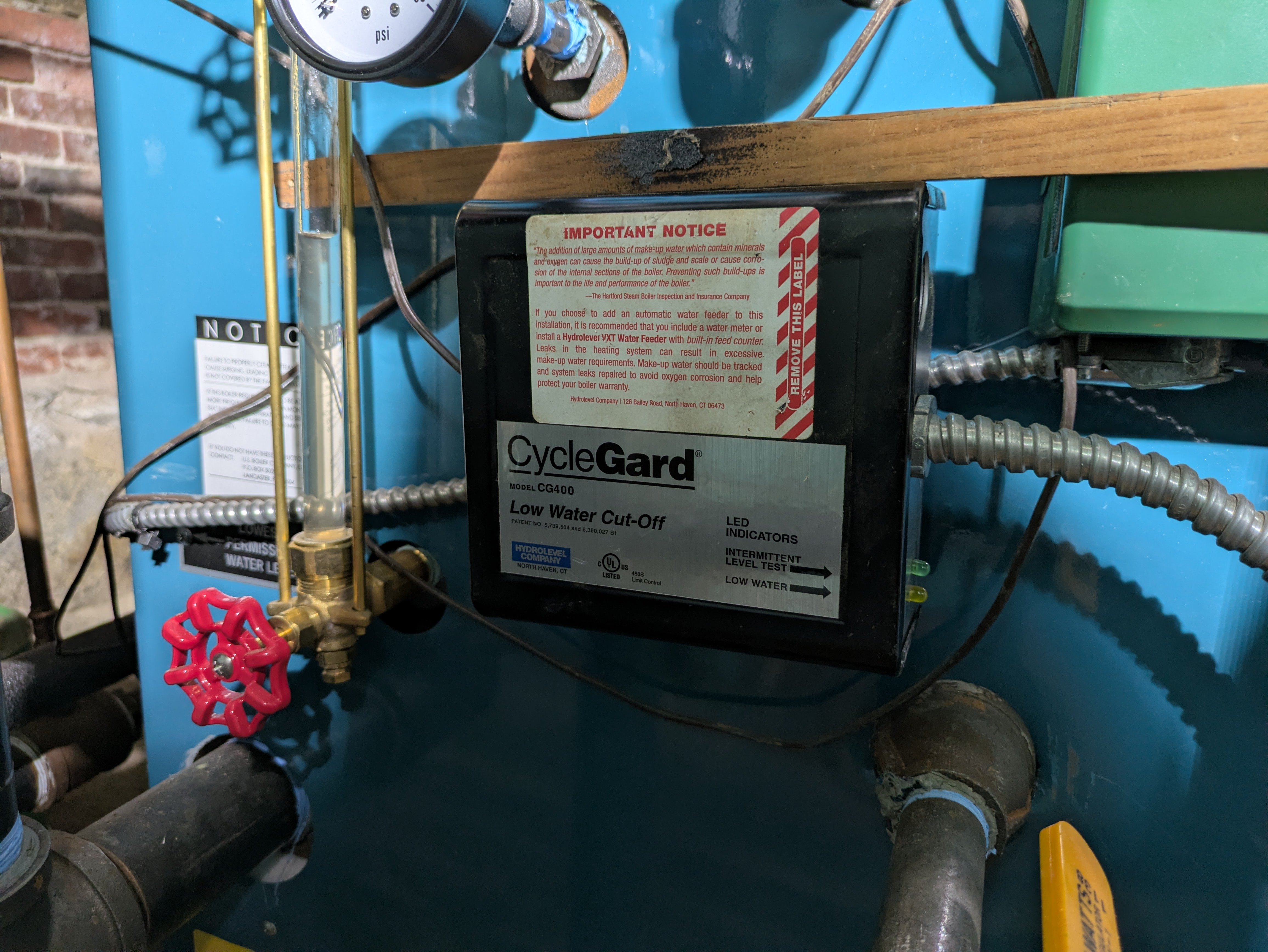

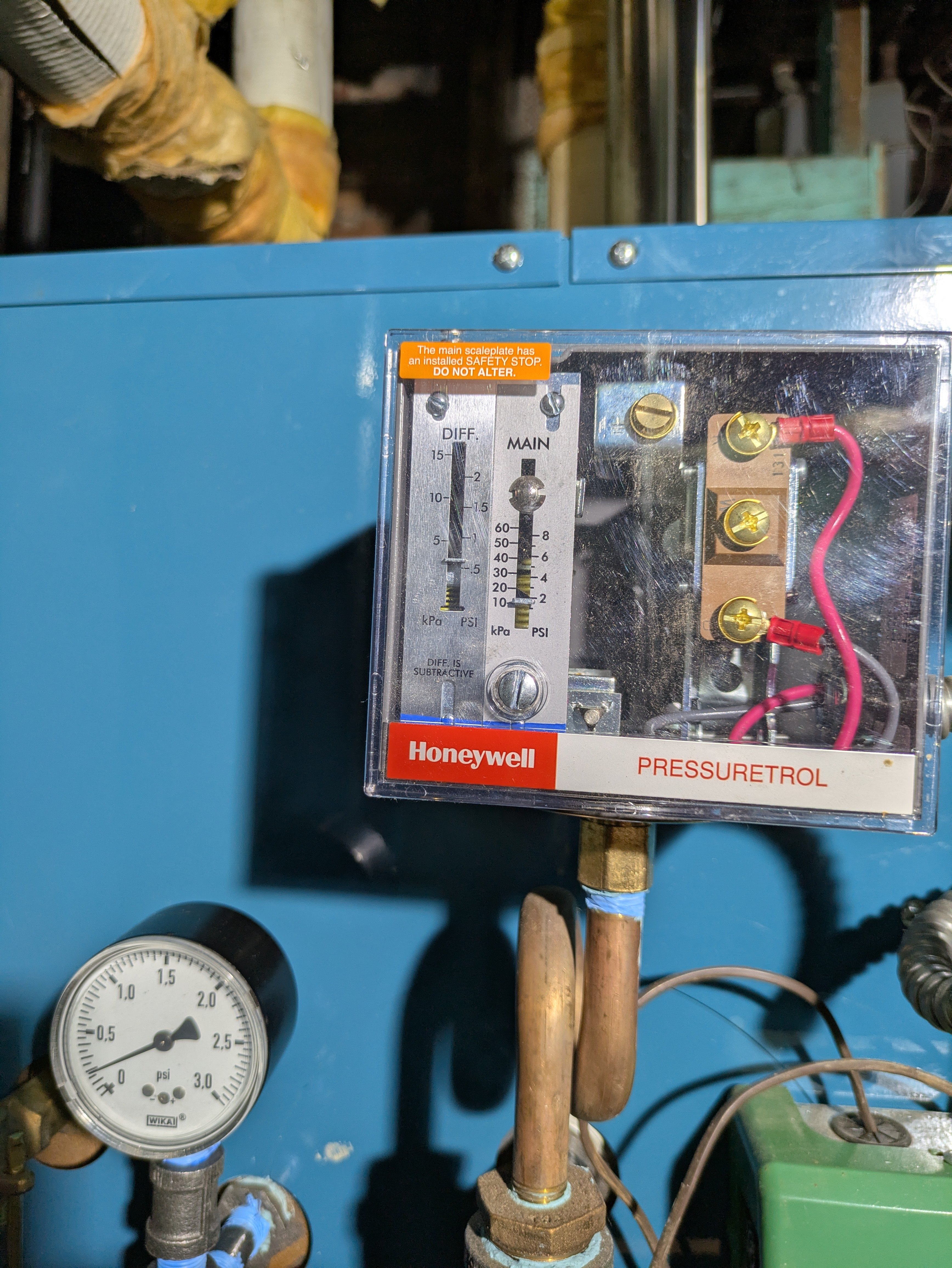

I just finished skimming the boiler, for the 4th time (in it's existence at my residence). This time I followed @ethicalpaul 's suggestions, using 3 oz of TSP. The water is cleaner. The water surges less, and the water drops less on a full heat cycle. But it does drop some. Apparently enough to trip the CG400 LWCO intermediate sensor. I saw that, because I watched the whole cycle watching the boiler. I don't know how it does that, because the sight glass did not seem to be that low.

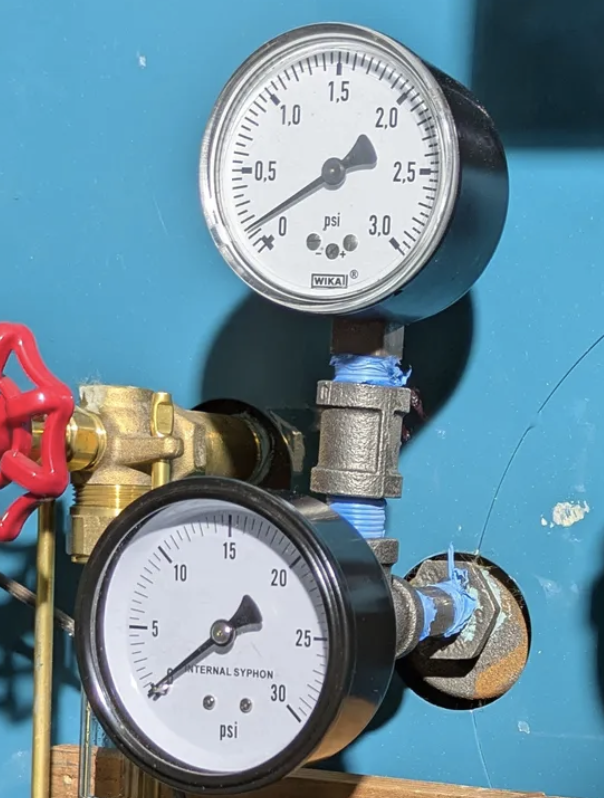

While I was finishing up the skimming, I added my old 0-3psi pressure gauge to the boiler, on a tee fitting. I don't know if I have a small leak or not, but the pressure during the full cycle never exceeded 0.2 psi. It heated the house fine, although it took a while due to the fact I had turned off the heat for 3 hours while doing the skimming. It was quiet, there was no hissing, no noise, save for pipes occasionally expanding. So the pressuretrol didn't seem to be involved at all. Before you ask, no it's not been calibrated by me. I did see it cycle (I think) but since there was no decent pressure gauge installed at that time, I don't know what it really cycled on. Now that I have a good gauge on it, it's quite instructive. You can even see the boiler go into vacuum when it shuts off and the vents are closed. It stays in vacuum a while, so I guess my handiwork isn't leaking that bad.

Oh, here's some pictures of the boiler and stuff near by.

While I was firing this boiler, the sight glass started leaking at the bottom gasket. The brass fitting that compresses the gasket was loose. So I tightened it. Then I noticed the bottom brass fitting was installed crooked (not vertical). I'll have to fix that since that will annoy me forever. It also makes for an asymmetrical seal on the glass tube. There's really no excuse for that, in my opinion. If you look at the first picture, you will see it needs a few more degrees of tightening.

0 -

Looks pretty good, but your low pressure gauge is going to be exposed to steam which could damage it so you might consider relocating it above the pigtail with the pressuretrol.

And on your skim piping I would remove that vertical long nipple and the elbow and just let the water drop out of the horizontal nipple into a bucket. You can see the water and flow rate better that way. Have the horizontal part going slightly uphill so the water flows over the edge.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Thanks for the critique. I probably have another pigtail in my stash of plumbing junk, I'll check and install it.

When skimming, I rotate the vertical pipe to about 15 degrees, so it comes out in a well defined pencil like stream. When vertical it was all over the place. With the angle it makes a stream, and more importantly, it clears the bucket!🙂

1 -

Found and Installed the second pigtail. That's a little better, the gauge is now a lot cooler.

As for a main vent on the other side, I haven't been able to find it. It sure isn't obvious, at least peering down the pipe run, even with a really bright light shining down there. Could be at the very end, but I'd need to crawl on my hands and knees in dirt to get there. At least that's a space that would be pretty easy to extract myself from. If something is there, it's not working. If nothing is there, installing one would be beyond my abilities or tooling. I'll try to take a look.

Still a mystery to me, I'm not cycling on pressure at all. I'm cycling on the intermediate low water cut off. There's tons of water when it turns off. Is there a slight adjustment I can make to the CG400?

In the interim, I have simply added more water, to run at a higher level. The boiler stopped this time, when the thermostat was satisfied. Pressure was about 0.15 psi.

0 -

No, you can't adjust the LWCO to fix this. It sounds like your boiler water is carrying over into your system. Is there oil in your water, or tons of rust, etc?

If it's oil you should skim your boiler. If it's just junk in your water you may have to drain and refill.

If you see your water level drop more than a couple inches when the boiler is steaming, especially if it happens real fast, it is likely carryover.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I don't see any evidence of oil in the water. The final bucket of water was clear. I don't see tons of rust either. It's rather clear. That doesn't mean there isn't junk in there, but it's not obvious to me. I let each bucket of 2-3 gallons settle for a while before disposing. No oil sheen, or film, nothing.

The water dropping is slow, but there is some bounce on top of it. Considering how bad it was earlier, this is so much better.

Pity on the LWCO. The old bellows units you could access the mechanism and make minor adjustments. I understand why one shouldn't change or defeat it, but this LWCO appears to be actuating when the sight glass water is 3/4" above the LWCO sensor location port.

For the record, the CG400 LWCO has two outputs. The real low water cut off, and a second "Intermediate water cut off". The boiler is cycling on the intermediate water cut off, not the true LWCO, nor the pressure trol. Since everything else is behaving well, I raised the water level a little. It is below the steam pressure sensors, about 2" below the top of the sight glass. We'll see how that does. I don't like the idea of cycling on a LWCO at all. That's supposed to be a safety device, not to regulate the normal operation of the boiler.

0 -

The real low water cut off, and a second "Intermediate water cut off". The boiler is cycling on the intermediate water cut off, not the true LWCO

Hmm, I'm not sure what this means. There is a single probe, correct? What is the difference between cycling on this "intermediate water cut off" vs "true LWCO"? I don't understand what you mean so maybe I'm ignorant about some aspect of this LWCO

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

You shouldn't be seeing your water level go down more than 1/2 in. or so, and even that seems like a lot, considering steam occupies 1,700x the volume of the water that it was created from. I'd don't blame you for not liking what is happening and there is no way it should be tripping the LWCO, or cycling on the LWCO. You must still have oils coming back from your piping from previous carryover, still to be dealt with.

Another possible issue is some problem with partially blocked returns that are slow to return the water to the boiler.

0 -

The LWCO has two LEDs on the side. One is labeled LWCO, the other is "Intermediate level cut off". I presume the LWCO is like bone dry low water sensor. That used to turn on before I did today's skimming. That's when the water disappeared from the sight glass. After flushing out the green stuff, and doing the TSP skim, the water goes to midway in the sight glass, and not to the bottom.

The intermediate level cut off is triggering when the water line is below 3/4" above the center of sensor port hole in the boiler. When that LED turns on, the boiler gas is cut and the boiler is disabled. A minute later, the LED goes off, and maybe 15 seconds later, the boiler fires again.

I suppose all this is still indicating that more skimming is needed. Still don't see any oil or anything like that, but it's behaving as if there's still something in there that's affecting the boil quality.

0 -

How to get rid of the oily carry over? It's not so easy disconnecting these radiators and flushing water down those pipes. I can't even move some of them, or for that matter, even disconnect the pipes.

There's still crud in the system, apparently. However, ignoring the boiler, the radiators are behaving rather well now. Probably need to review the balance, but they are minding their manners.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements