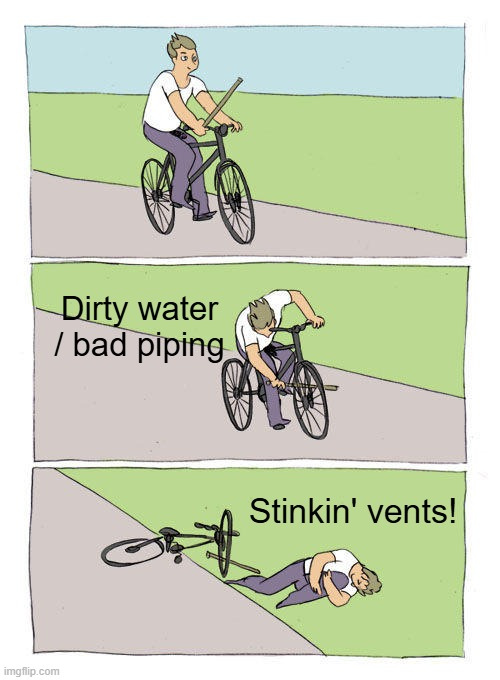

Gorton vents is there a way to test them?

Is there a way to test them easily? I have 3 that seem to be leaking. What is their expected service life?

What's strange is they seemed to have failed just after a new boiler install. I lost a #4, #5 & #6. To make things harder to diagnose, I have wet steam right now. (New boiler, exact replacement to the old. The valves all appeared to be working before the replacement.) Now the house heating is totally imbalanced.

So is the failure due to hammer/wet steam, or do they sort of stop working after a decade of normal use? Or something else?

Comments

-

Wet steam can affect the vents ability to close properly. See this all the time. Not much of a chemist. Maybe the wet steam is cooler. Maybe the moisture affects the vents ability to close properly. You should really take care of the wet steam regardless. Try to remedy that, and then see what happens with the vents

0 -

When you say "leaking", what exactly do you mean? Actually releasing steam — in good quantity — into the room? Or spitting water droplets? Or?

Reason I ask. Radiator vents have two elements in them. One is a float which is supposed to close if there is liquid water (not droplets, water) present. The other is a thermostatic element which is supposed to close when it is at or very close to steam temperature (it should close at about 210F). One not uncommon problem is that the thermostatic element may not close if there is "wet steam" — steam with significant water droplets — as that "steam" may not be hot enough to close the element. Under those conditions the vent may spit water droplets.

Some some vents are more sensitive to this sort of problem than others…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

How is the boiler water level while steaming. Normal is steady or gently bouncing an inch or so. If it is jmping violently the boiler need skimming. Can you post a few pictures of the boiler and the piping around it? and the boiler model #?

Lets see if they piped it right.

Did the installers measure the radiation or just replace like for like?

0 -

"wet steam" isn't a good term. All our steam is wet by definition because it's not super-heated. In my observation, water droplets are not carried in steam in any significant way. They fall out of the steam as it goes through the pipes (even without a header)

What I think you mean, since you mention a new boiler install, is that water (not droplets, but buckets) is being sent up into your mains and possibly to your radiators (because the installer didn't clean the new boiler properly). This water carries gunk from the boiler which goes into the vents and prevents them from sealing.

Also, vents just plain fail all the time even without carryover, so the above conjecture might not even apply in your case.

Does your water level in the gauge glass drop more than 1" when you are making steam?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

I'm trying to. The boiler has been skimmed a couple times, although I'm not positive it was done correctly. The boiler install manual says to "pour the recommended boil-out compound into" it, but fails to say what that compound might be. I sent the manufacturer an email, but they'll probably never answer it.

I'm trying to figure out if these Gorton's are still good or not. At roughly $40 each, I don't want to toss them if I don't have to.

0 -

I've seen vents work after taking them off and dumping out the water and maybe boiling in vinegar, but not always. You need to find out how water is getting to the vents first. With a new boiler installed there are lots of possibilities although insufficient skimming is the most common. Don't worry about adding an additive (8-way) until skimming brings satisfactory performance. I look at additives as just optizing pH to minimize corrosion more than anything else.

1 -

Flooding my kitchen and bathroom floor with black hot water. Dripping water out of the others. 8 foot by 3 foot black puddle in the kitchen, twice. Always at cold start. Upstairs bathroom small flood out the vent. Don't know if either were hot or cold water, I wasn't going to put my finger in a potentially hot water stream. The vents never leaked or spat during pressure cycling of boiler, since the pipes were hot.

It's weird. Had a well dialed in system for more than a decade. Then replaced the boiler with exact same one. Reused the existing piping. Sure there's a couple of minor things wrong (according to the book) but it was quiet, well for about 30 years now.

My fourth Gorton seems to be passing steam. It seems crazy and statistically astronomically unlikely for four Gorton vents to drop dead on me within 2 days. I don't think any manufacturing company can engineer MBTF that well! I had switched to Gorton vents after reading the venting guide on this website. Worked great for a long time.

0 -

I just reviewed the other thread about your boiler. You mention that with the old boiler you had a main vent spitting so you plugged it and left it like that.

To be very, very clear. You should not have water in the vicinity of any vent with volume adequate to come out of said vent, it just shouldn't happen. If it does you have issues with the system somewhere. This entire thing sounds like pitch or sag issues, maybe even poor piping and now the new boiler which is most likely surging is amplifying those issues.

I'd speculate the vents are working just fine. Water hitting the vent cools it down and opens it back up.

I'm of the opinion you need to have the boiler skimmed again, and probably need to do it a few more times. After that, review the entire system and see what's going on. I agree with your contractor, you need main vents, it dramatically alters system performance in a good way.

1 -

The water level drops a lot, sometimes below the sight glass, but the LWCO is not activated. If there's more water (starting at 2/3 the sight glass) the water just bounces some, like an inch. The LWCO does work, as does the pressure trol. I witnessed all the testing. Set to about 1.5psi, with a 1psi differential. It has the horrible 30psi gauge on it, but that's apparently mandated by law. So the pressure just lifts the gauge off the pin when running. Don't know if I still have my 3psi gauge around. Had that on an old boiler.

The boiler is your non-recommended IN6-PV. It has a drop header. It reused all the old plumbing, that I showed in my earlier threads this year. (Last month and December.). Hartford loop looks ok. I don't want to use up this forum's storage, by reposting that. They didn't quite reinsulate the main boiler pipes the way I had it originally, but it's close. I probably need to redo that.

It bugs me a lot that the hard work I put into balancing the vents has disappeared. I now have an 11F difference between rooms, it used to be around 4F.

0 -

There's a ton of water being ejected along with the steam. There have been times when I've heard air bubbling through water in a radiator.

The contractor did not do anything besides a simple skimming. Actually, a simple skimming was done twice. The IN6-PV Installation Instructions say to use a "recommended boil-out compound". This was not done. My friends at Burnham don't mention what that compound is, at least not in the manual that was provided to the contractor (and me).

0 -

you have a sag in your supply to that radiator, holding water, OR the boiler is carrying over all that water you are hearing (or both)

The washing compound would be TSP substitute (also called TSP) typically.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

I didn't do skimming per Should I?

Or should I do a variation of Dan's TSP or MEX and sodium carbonate. Sodium carbonate is mildly basic. I don't want to deal with hot lye. Washing soda does clean things, and is mentioned in Ch 16, Cleaning Up under Weil McLane cleaning instructions. I have both TSP and washing soda.

0 -

Yike. Don't kill the messenger… wait. Let me rephrase that. You already have. However, the problems you are describing aren't the fault of the vents. Something — or somethings — about your new boiler install is really truly horribly messed up, and you are getting slugs of water attacking the vents. Which has ruined them.

OK. They're toast. But before you replace them, you need to find out — and fix — the rest of the problems. Violent surging is one; the new boiler probably needs to be drained and wanded, and then flushed a couple of times, then refilled with pure water (no additives) then properly skimmed (which latter does NOT involve putting anything other than water in the boiler). Then all the piping needs to be rechecked for level; I'd bet that some of it was moved during the boiler instal.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I just can't believe it, a fifth and sixth vent have failed. the parlor Gorton is leaking water onto the hardwood floor. The front bedroom vent won't seal, there's steam coming out. The whole radiator is hot. It's 76 now, other rooms are cold. How miserable.

0 -

My system behaves very different than most, but, occasionally I'll get a drop of water that forms in the orifice of the vent, and it stops the radiator from heating. Sometimes tapping on the vent will drive the water out and it'll heat again. Other times I give it a shot of "air" from a can of air, and that'll fix it.

Perhaps this is what's happening to you, but for different reasons. If that's the case, the vent isn't bad, it's just clogged it a drop of water.

No idea if that's the case, but worth a shot.Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

1 -

-

"Gorton is leaking water onto the hardwood floor"

As stated in my previous post the water being there is the problem, not necessarily the vent. The vent could be bad, but until you get the system to the point that water isn't getting to the vents, you really cannot determine which thing it is. Water will open the vent as it's not steam hot.

You already stated in another post that years ago you had water pouring out of a main vent. That is a problem and agrees with what I'm saying, you have had an issue for years that has gone unresolved. Removing and plugging that main vent didn't fix the problem, it ignored it.

Water, in large quantity, should not exist at the vents to come out of the vents. That indicates an issue with the piping and/or more skimming on the boiler. When I installed mine with all the new piping it took me about 6-8 hours of total skimming over several different days, separated by a few weeks each to get things in order.

1 -

-

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

I also have a Burnham Independence PV boiler. I found it's VERY sensitive to boiler water quality—specifically the build-up of suspended solids, either from long term corrosion if using untreated water or just the junk that comes with a new install that wasn't removed. Then the surging starts and gets progressively worse.

Start with another skim/cleaning to calm it back down. I recommend using water at first without any additives. As others have stated, it can take a few cleaning seasons throughout the season to get the all the junk out from a new install.

Burnham IN5PVNI Boiler, Single Pipe with 290 EDR

18 Ounce per Square Inch Gauge

Time Delay Relay in Series with Thermostat

Operating Pressure 0.3-0.5 Ounce per Square Inch0 -

Pipes are properly installed at boiler. There's pitch where it needs to be. First skimmings were the blackest water I've ever seen. Second wasn't so great either. I was getting a lot of water getting slugged down both ends of the main. One radiator sounded like is was full of water with gurgling of air or steam in it. There is pitch to the main, running downhill to the boiler. Been checked with a level.

Now this is not to say that everything is good. A long time ago, before I knew of this place, I had a plumber, who was hired by my general contractor to do some plumbing. And all the suspect plumbing was done by my plumber from hell. A lot of it, I had to replace. He didn't know how to solder. None of his sweated joints were any good. They leaked. I wouldn't be surprised in the slightest that some of this hidden, inside the wall work is deficient.

Now as a home owner, I see what was a quiet, well balanced heating steam system turn into a clanking surging flooding mess. And I have lost a lot of sleep in the past week, especially the last couple of days due to the clanging in the middle of the night. And I have mopped up black water off my kitchen floor my bedroom, and watched my hardwood floors get ruined by it. So please gentlemen, show some understanding. It's easy to be glib from afar, when it's not your house. Not so easy when it IS your house.

Thanks for everyone's help so far. Dunno, thought I kind of had some of this steam stuff figured out after living with it for 38 years. Apparently not.

0 -

Might be right, but mean spirited nonetheless. Not called for.

0 -

-

Thanks for understanding. The problem area may have been identified, I will find out tonight. Have basically plugged the two radiators that my PFH did more than 20 years ago. Not happy about this, but for fault isolation it could be a good exercise.

0 -

I'll try to be gentler, as I know this sort of thing can be stressful.

First, I would plan to replace the vents in question — they are probably sufficiently damaged at this point that the cost will worth it.

But. Don't bother until you get the surging and other possible problems straightened out. Besides flushing and skimming the boiler — without chemical additives, which can cause problems of their own — double check the piping. From your description, it appears that you have counterflow mains. Is there provision near the boiler for condensate (or carryover) to return to the boiler before it gets to the boiler header? A drip to a connection on the return below the water line? If not, the system will be very sensitive to carryover, so that is one thing to consider. I know you have checked levels and pitch on the pipes — but it won't hurt to do it again, section by section (not end to end) to be sure that there are no sags. It's absurdly easy to get a section of pipe pitched wrong when attaching other pipes or redoing hangars. You wouldn't think iron pipe could flex enough, but it can!

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I'm not mad at anyone, especially my contractor. He did come to my house at 5pm tonight on Friday night. He and I worked at it until 7:30pm. I even shared some pizza and beer with him. I'm astonished that 20 year old bad work that sort of got by, all of a sudden, COINCIDENT with an identical boiler replacement started acting up. Might be sagging in a wall or some shifting. But it was a quiet system for well over a dozen years. It's puzzling in someways.

New boilers often have junk in them. We spent time cleaning the boiler and attempting to isolate which end of the main was causing issues. Problem appears to be multiple issues, oily water/dirty boiler, and some hidden plumbing defects. None of the visible plumbing has an issue, we checked that.

0 -

No problem. It did touch a nerve, I'll admit.

It's been a bunch of long days for me with little sleep and a lot of anxiety trying to work through this. It would be one thing if this was always the case. But this system was balanced thermally and quiet for so long and then bam, everything seemed to come undone. Unfortunately that time stamp was immediately after an exact boiler replacement, reusing the same pipes. So not much changed, yet everything changed.

0 -

Take a deep breath and forget about trying to solve the mystery how "simple" boiler replacement causes the racket. The aim is not to discover the mystery of the universe but to give you heat. It's a typical scenario of working on vintage stuff. The best you can expect is 2 steps forwards/1 step back. Sometimes you get 2 steps forward/2 back and, on occasions, 1 step forwards/2 back (as seems to be the case with your install). It happens.

There is lots of knowledgeable people on this site. You won't get far with just words. You gotta take lots of pictures so people can start pointing out what might be the issues.»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog1 -

FWIW, high pressure kills vents, too. Do you have a low pressure gauge? Is the pressuretrol new? Was it calibrated?

0 -

It's been hard. My wife left to see the kids 8 days ago. I was supposed to join her as soon as the boiler was done. Everyday has been a new surprise, with few of them being good. Honestly wasn't expecting this much messing around for an identical boiler swap. The only thing that changed was the serial number of the boiler. Same part number. Used the old pipes, no changes. This particular boiler seems to be quite sensitive to some things, but we have yet to isolate them.

Honestly it seems to be related to all of the "new work", by that I mean anything that has been done since the original steam system install some hundred years ago(?). So that's what we have been concentrating on.

There's an upstairs radiator on a two floor riser. The pipe from the basement to boiler may have a pitch issue, but it's in a nearly inaccessible crawl space. 38 years ago I was able to get in there, but I've put on some weight since then, and lost 38 years of mobility. I attempted to mitigate this somewhat, by raising the height of this radiator on the wall. Yeah, it's a wall hanger radiator, and the knucklehead who installed it 7 years ago made it effectively impossible to service. No union there. Fool installed a bathroom vanity one foot from the radiator. Also they installed the vent in the wrong location, so it gets half hot. I can barely get access to the wall hanger, I'm going by feel on to to access the hanger screws. Very restricted access.

My other known problem area was done 20 years ago by a plumber that was hired by my general contractor for a bathroom upgrade. I'll call him the plumber from hell. (PFH). He reeked of marijuana, and didn't have any attention to details. The PFH had problems with copper sweating. I discovered this because of the enormous amount of leaks. I had to remove and replace a lot of his work. It's possible I screwed something up there, but I was attempting to route them the same way. I did try to have everything pitched correctly, but hey stuff can move over time, or I may have screwed it up. The piping is in a horrible place to work. Inside wall work. I had to cut the wallboard behind one radiator and behind a toilet. To work in the area, you have to pull the toilet, because there's just no access. Even with those trapdoors, it's tough to tell what you are looking at. Eventually I, or my plumber need to go in there.

I have a pressure gauge, it's a Wika 0-3psi, but it's bottom fed and the existing 30psi gauge is back fed. I can see if I have some 1/8 NPT piping and an elbow in my stash of parts. The pressure on the 30psi max gauge is indicating 1.5psi max, but that's really not far off the peg. But it seems to correspond well to the pressuretrol settings.

I can repost pictures, or even take new ones. At this point I can't travel, because this system can't be trusted yet not to cause damage to my home by leaking crud on my floors. My grandson called me today, and that made me feel a little better, I've been very sad that I have been unable to visit.

For me, at this time, I'm trying to get the house ready to sell. Obviously the heating system needs to work. But I think I won't get any noticeable payback for this work. This stinks, because I'm moving to a more expensive area, to be nearer my children, further south. So I want to fix this, but not overspend, if that makes any sense. I'm perfectly willing to improve my new home, but don't want to go overboard here, because I won't be able to afford my new home if I make it world class here. That's my financial reality. I'm retired, there's no money tree in my backyard.

0 -

Thank you Jamie. Some of the vents might be ok, some might be toast. If they seal steam, and the system isn't surging water, some of them could be reused. I'm really ok with replacement, at least not under an emergency basis. Then I can order them from a decent supplier and not get price gouged. There seems to be a very wide price range for the same unit. (Nearly two to one difference.). I didn't order any, because I thought, any day now, I will go see my kids. So I didn't want the parts to sit out in the weather, or get stolen. Since it seems I'm not going to see them this year, maybe I can order replacement vents. I had Gortons, are they still good? Home Depot seems to have terrible vents, and some counterfeit ones of Maid O Mist's. And they don't have a good assortment of sizes, especially in small vent rates.

Yes, 8 radiators are counter flow steam. I have two 2 pipe radiators. As currently plumbed, the counter flow steam return flows back into the header, there's no drip or connection to below the water line. Correctly or not, it didn't used to matter for the 38 years that I've been here. But maybe it matters now.

Since I'm currently "home alone" and pushing 70, I don't want to overexert myself in a crawl space. I can do some things, (a lot really) but it would be much better to do this with someone else around. I understand the need to check this. But that nearly inaccessible crawl space would be tough. And that is exactly where the (likely) poorly pitched pipe for my wife's bathroom is. I can't see the pipe elbow going up from the boiler, it is blocked by a granite wall. The pipe passes through a hole in the wall (top of the granite) and goes into the el in the foundation. The horizontal run continues for another 8-10 feet before an elbow and then goes up two floors. If a pipe hanger fell off, or something like that, it just isn't visible, unless you shimmy on your stomach to an access way 5 feet to the left of the pipe. The height of the access is maybe 24 inches at best. When you get there you can at least see the pipe, but you will be pretty far away. One could crawl there, (I could 38 years ago, but I am fatter and less limber now), but I'm not doing that alone.

0 -

Pretty sure we are not running high pressure. I have a low pressure gauge, but it's not plumbed in right now. Bought it for a previous boiler. But the gauge on the boiler is measuring very similar to the pressuretrol settings. If I get a chance, I will install it. The boiler manufacturers are required to install the 30psi gauges by law, even though no one in their right mind would run a home boiler that high. It's a throwback to the old days in the 1880's when boilers were blowing up. I'll check to see if I have some 1/8 NPT stuff to attach it. It's a bottom feed, where as the boiler is using a back feed connection.

I've always run low pressure, 1.5psi max. It works great.

0 -

I know what you mean about not doing things that you used to do…

On that one possibly problem pipe in the crawl space. Can you get your hands on a good laser level — the kind which shoots out a nice red beam — and project that along that pipe from your access point? Be a start anyway…I

A counterflow system with no drops at the boiler is absurdly sensitive to carryover If the boiler is running smoothly, it won't be a problem — but if the boiler is still surging and burping, that may be a major part of the problem. I know it's a bore, but make sure you are starting with clean boiler water — no chemicals or additives — and skim. And skim some more. And then some more. Collect some of the skimmed water in a bucket and let it stand — if there is even a trace of a sheen, it's not done.

One other thing. Or two. When you are working alone in the house, make sure you have your cell phone charged and on your person, or have a life alert button around your neck. I'm a couple of decades older than you are so perhaps I'm a bit paranoid about that, but…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

My phone is usually on me, but there are times, I've found that you simply can't get to it, especially if in a restricted area. Not yet at the stage of a lifeline, but someday, I will have to do just that.

I'll do some more skimming. The plumber put in a variation of Squick, and it's freaking green. Now if there's a leak, or more accurately water driven out of the vent, there's green junk on the floor. I'd like to get rid of it, but that's a lot of me going up and down stairs with buckets of hot water. So it will take me a while. The good thing about this green stuff, is the waterline is easy to identify. The bad thing is it's green, and the only listed ingredient is washing soda and whatever proprietary junk they put in there. They claim it doesn't require it to be flushed or removed from the boiler. Personally, I don't like it there, mostly because I have no idea everything that is in it.

Don't currently own anything like a laser level, never needed one before. I'll look into it. From the access point one would be looking at the pipe at roughly a 30 degree angle from it's axis. It's definitely a weird view.

0 -

aargh.. Well, Squick will emulsify the junk. That's all it will do. that's good. It will also cause surging and can really make things worse. I'd suggest that you drain it all out, fill the boiler, drain it again, then fill with good clean water and start skimming from there.

Surely there is a water supply and a drain somewhere down in the basement?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

There's water supply in the basement. But no real drain. Where the pipes (water and sewer) come in it's dirt. But it's not an easy access to that point. And there's signs of erosion there, due to water dumping. So it's better not to dump there. I don't need to undermine the foundation walls of my house. That part of the house was built circa 1875. The original house (where the boiler is sited) was built in 1853. Better for me to haul out, than to cause another problem here. Stinks, but I think I've already used up my luck for this year.

0 -

My experience with real Squick was favorable. It calmed things down, a lot. Needed to remember to do some draining, but it wasn't onerous. Remember using it at least three times in the past decades and it always helped. I only used it if skimming didn't seem to solve things.

0 -

I'm hoping that using the squick like stuff wasn't heresy. It helped a little, but no miracles. I'll start draining.

Made a little progress on isolating problems. Basically have found there's two major problem radiators. Got to turn on a radiator in my back bathroom and there was a little midcycle noise, but not at start up at all. It's much better than before. But the back of the house was plumbed by the PFH, so I'm not surprised. Still will need to open up the wall to investigate. At least it's not in an isolated hard to get to confined space.

0 -

Squick is OK. I don't have any evidence that it can cause surging, I wonder where Jamie got that information. It's basically just that Diatomaceous earth stuff.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

You asked about skimming and what chemicals. Look in the manual and on line to see how much water your boiler holds at the normal water level.

You can use TSP or washing soda.

The ratio is 1 pound of tsp or washing soda to each 50 gallons of water. So if your boiler holds 10 gallons you would need .2 pounds or 3.2 ounces.

Mix the TSP with water in a pail and pour it in the boiler . Remove the safety valve if no other tapping. Reinstall the safety valve. Run the boiler until the steam outlet burns your hand and shut the burner off. Start skimming a water stream the size of a lead pencil. Control the skim rate by adding water. Just a trickle the slower the better.

You had black water which to me means oil. Oil will float on top of the water in the boiler and the steam will make huge bubbles trying to brake through the oil.

2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements