Washing machine drain solution

Comments

-

no. the drain is too small for a washing machine, at least without adding a laundry tub to buffer it

you'd have to add the washing machine to the stack that ties in to, assuming that has the capacity for it

0 -

I can upsize the PVC tube to 2" but the connection to the stack is fixed size

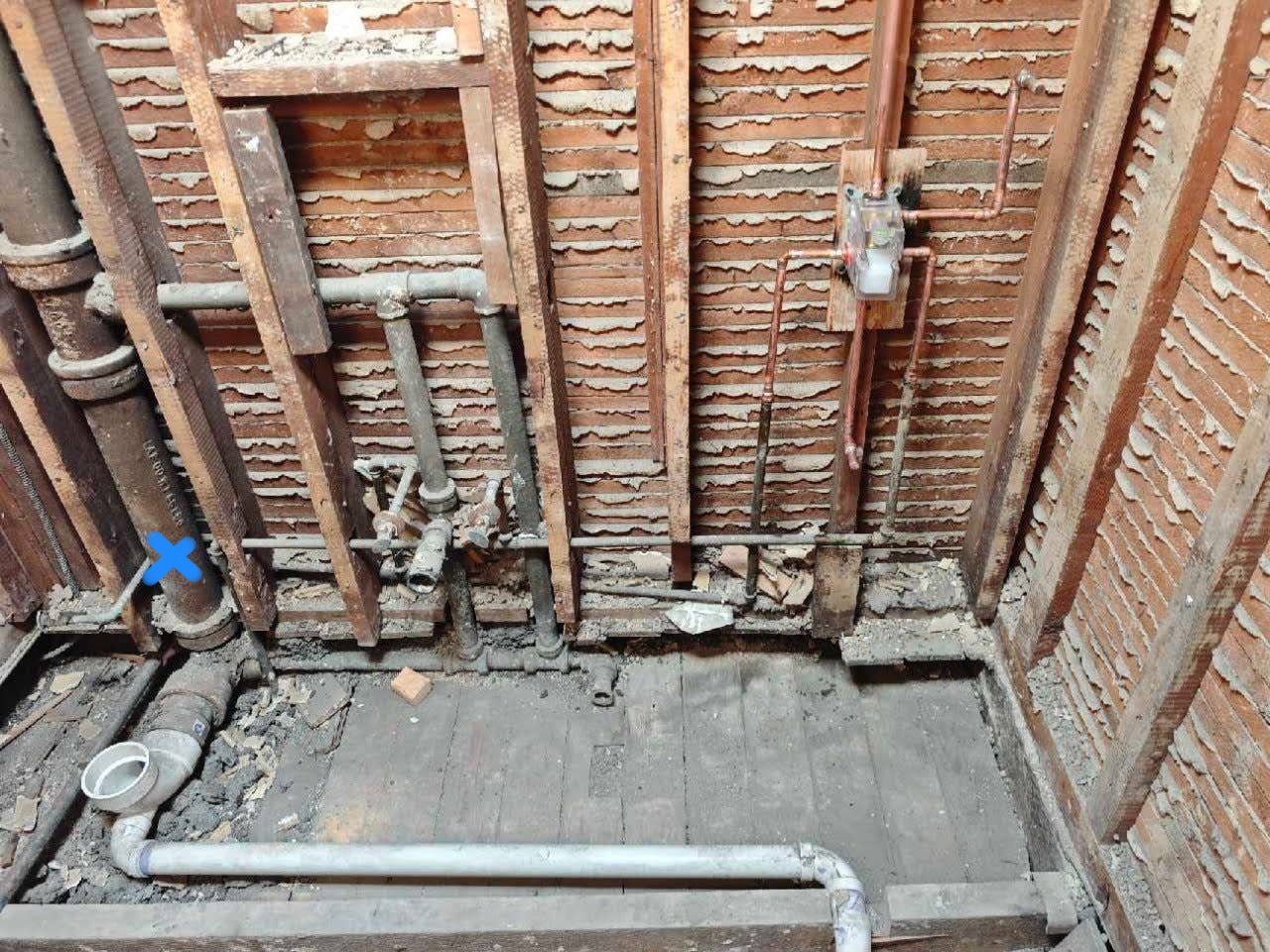

This is the ci stack behind the drywall. ~2" piping. How do you cut the pipe and insert a T?

0 -

-

-

-

Which pipe is galvanized?

0 -

Could you push to YouTube and share the link?

0 -

-

Cut a section off, or cut the entire galvanized grid away, then plug in assembled PVC piping, join to the existing stubs using Fernco no hub couplings, correct?

If not using PVC. Does such practice exist: cut off a small section and plug in a threaded T (black steel)?

0 -

i would remove the threaded pipe from the ci and screw a threaded pvc adapter in to to ci. it might unscrew but if it doesn't it is easy enough to cut the pipe close to the ci stack fitting then make 2 cuts almost to the threads inside the fitting, break out a little piece of the pipe between the cuts with a small chisel then unscrew the remaining piece of pipe. once you cut the piece it it will release the tension on the pipe and it will unscrew easily.

0 -

-

Thanks for all your posts.

Back to the initial question.. now I see the code requires minimum 2" pipe for a washer, connecting to the existing PVC pipe as is will cause water back up.

If I change the PVC pipe to 2", does that make it sufficient to accept the washer drain by providing enough buffer?

0 -

-

Heard you.

The wall is already closed. See my first post and this

The washer is planned behind the wall. It will be a front loading 2.4 cu ft washer dryer combo that features water saving.

0 -

My understanding is you need 2" all the way to the main drain stack in the wall. If you are proposing adding a 2" stub outside the wall, that's not going to cut it.

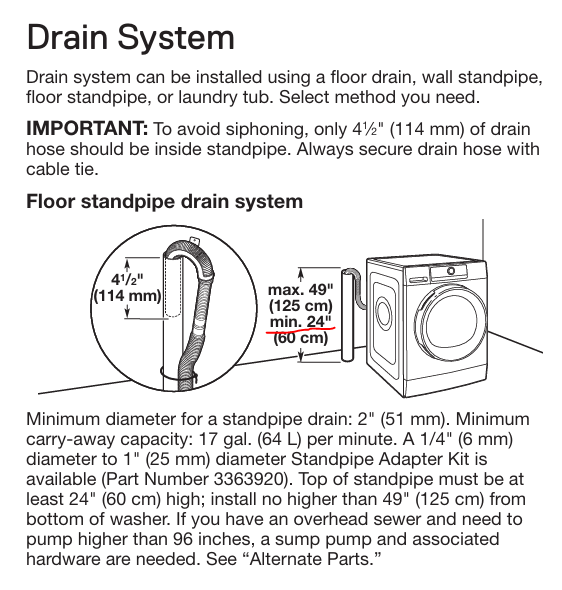

In addition to that, will you be able to have the proper height requirements for the drain hose? I grabbed this from a whirlpool manual, but as far as I know they all have these requirements. 4" inserted into the pipe, Minimum 24" tall and straight down into a trap. I really don't see how you would accomplish any of this under a bathroom sink.

1 -

Everything is finished!? To your first post then. The answer is no, you cannot install it where you ask.

If you can access the wall from the other side of the finished bathroom, exposing the cast iron stack there, then you should be able to add a washing machine.

0 -

-

It seems that's the way someone did it.

0 -

Shower drain

I was told the toilet flush might cause the shower drain p trap to lose seal, or it might work out ok. I have yet tested it out.

0 -

Hi, Two thoughts. It would be working with physics more than code, but you could add a valve to the washer drain outlet to slow it down. It would work, but's a bit of a hack…😈 The other thing is at the shower, copper pipe is attached directly to steel pipe. This will fail as the copper forces the steel to rust. It's another reason to redo the water lines… possibly in PEX.

Yours, Larry

3 -

-

Thanks. your post just reminded one more time of the gal corrosion.

but the work has been completed that way. I'd wait for leakage to happen to give me a strong reason to redo everything.

does the connection b/t the copper and steel pipe look like propress?

0 -

Hi, The connections look like copper female adaptors screwed onto steel pipe and soldered to the copper… I'm not seeing press. How fast they fail will depend on water qualities like conductivity and acidity. In agressive water, those connections could leak in months. With nice water they could go for years. I do not think of connections like those as "workmanlike manner", which contractors are supposed to deliver.

Yours, Larry

0 -

No. It was like this

0 -

-

Ok. I used to think there does not exist a copper pipe with threaded connection.

He might have used Teflon or dielectric sealant b/t the steel and adapter, that may help as a buffer to slow down the rusting

0 -

-

5' in two inches? Do you mean the pitch of that PVC pipe?

0 -

your joists are also essentially nonexistent, those should have been fixed before it was closed up unless there is another support system under the 1x wood.

0 -

@EBEBRATT-Ed I worked as maintenance for a company that had a bunch of group homes and except for a couple that were newer, there was nary a 2" wash machine standpipe in any of them. We went thru many different brands of machines and I never had to deal with a standpipe drainage issues. I really don't understand the code requirement of 2" drain line as the pumps on most household machines are 3/4" to 1" and really not that high volume, even our commercial grade equipment never gave us problems on 1-1/2" standpipes. We also had some machines that would pump almost 8' up without any special pumps. Funny how things can work fine when parts of the systems are not up to code.

1 -

Do you mean he opened a notch on the joist to channel the PVC pipe?

It's probably ok. You see the steam pipe also goes through notches on all the joists. These joists are secondary structural. The major beams are along their perpendicular direction. I would not do such compromise. Next time it opens, I would repair it with fiberglass and reinforcement.

0 -

the notches in the joists especially for the steam pipe means the span of the floor between the beams is essentially being held up by a couple pieces of strapping. the fix is to figure out how to route the plumbing and box out the joists to get the plumbing through or make it so the plumbing can run through a hole drilled in the middle of the joist preserving the top and bottom.

0 -

-

So, all agree that the pictured drain is a code violation.? That PVC drain would have to enter the stack behind the toilet and not as shown , but it seems to have worked out for the OP. But then this is off point.

In order for a washing machine to have proper drainage it should be drained using a 2" drain with a 2" p-trap .

To do this properly, the cast iron would need to be exposed and have the washing machine drain plumbed there. This would accommodate the newer high pressure pumps that are in pretty much all of todays washing machines.

If the easy route were to be taken, drain water discharged from the washing machine would overflow into the room. Years ago the code changed from 11/2" to 2" . This code change was made because of the new high discharge / pressure pumps supplied in washing machines.

The way to get this job done would be to access the wall from the other side of the new finished bathroom and cut into the cast iron vertical stack there.

1 -

the steam pipe is as old as this prewar townhome. so ppl at that time didn't mind notching the joists for plumbing. you mean replacing those joists and reroute the steel pipe? the project is too large to justify for a prewar row house. This requires reducing the bathroom to its raw state, jack support the walls on both sides.

0 -

how does the 2" pvc connect to the 2 1/2" hole on the stack?

i found this mechanical boss, but it supports up to 1 1/2" pipe

pictures would help greatly

0 -

That "mechanical boss" is what's called a saddle tap or saddle fitting and are not plumbing code accepted in most areas.

Here are some pictures as requested.

One of these.

Two of these. With the properly sized PVC, DWV Schedule #40 drain pipe.

I suggest you hire a professional for this if you plan on following through.

Where are you from?

1 -

Location is near Jersey City.

The stack weight above the cut would be over 300lbs, is this within the weight capacity of that PVC T?

0 -

-

Now I see the point.

It looks like some temporary support needs to be in place before the PVC pipe is substituted in.

I was looking for a draining solution that avoids demolition though.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements