Warren Webster air vent

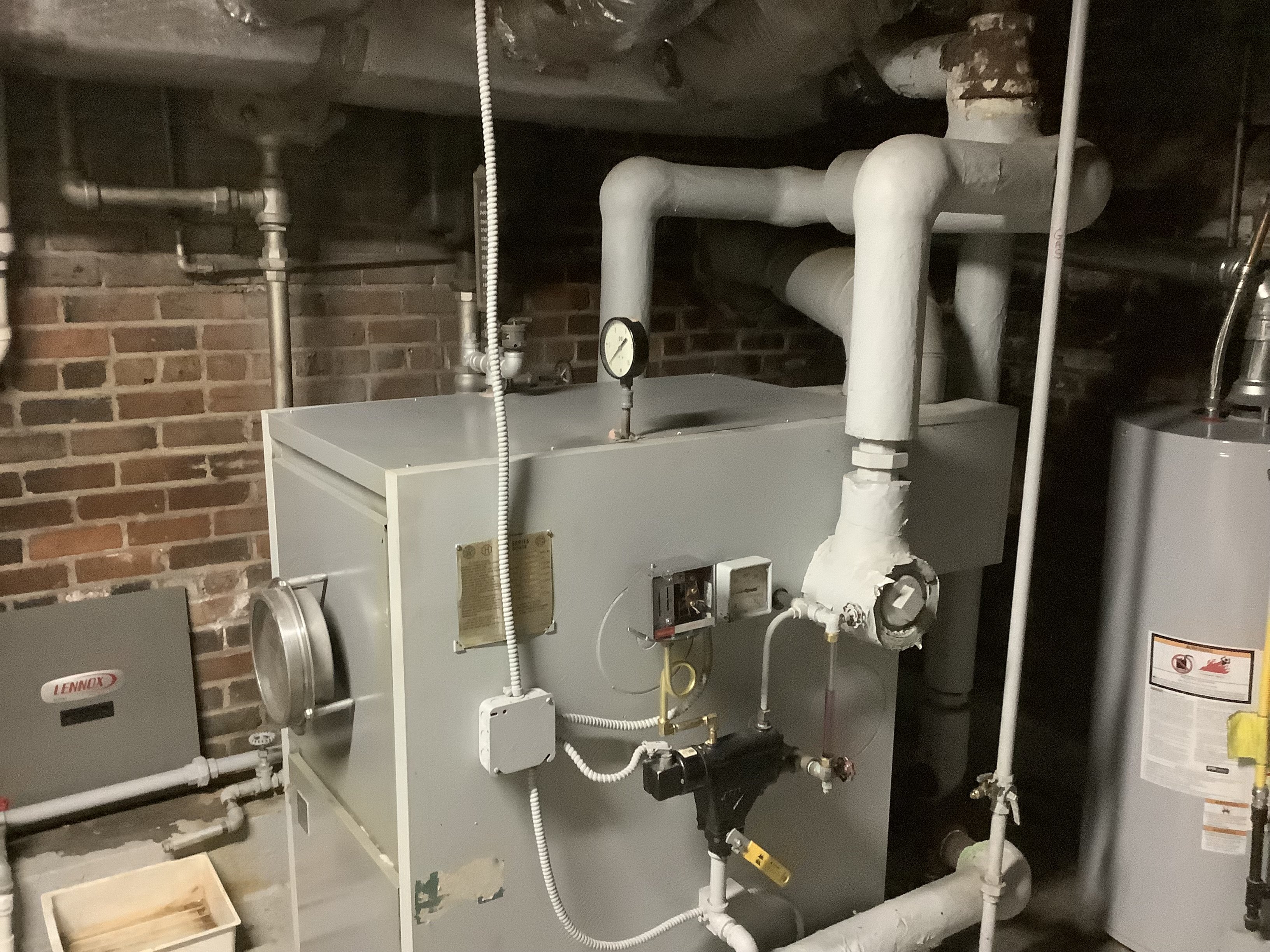

I have a Warren Webster type R two pipe steam system. The air vents in the basement are gurgling and the boiler water seems to be discharging out of them. We have 13 radiators and about six are now not getting hot. I have replaced the steam traps in the radiators with the Tunstal steam traps. Definitely helped. Now the air vents on the returns are being problematic. What is the best fix for these things? The system is 95 years old. The boiler was replaced in the sixties but works great at creating steam and pressure. The system runs between 1.5 and 2.5 psi.

Comments

-

keep the pressure much lower. does it have crossover traps? are they good?

the vents on the returns can be replaced with modern vents but if there is steam in the returns you need to figure out why.

Not sure about a webster system but some systems can only have vents on the returns and have to vent the mains through crossover traps in to the return, they can't have vents on the mains.

1 -

The vents are probably toast. Just replace them with Gorton #2s.

Then before anything else gets ruined, get a vapourstat to control the system pressure. Your system should run at between 4 OUNCES per square inch and 8 OUNCES. Half a pound. 1.5 to 2.5 psig is way too high and will cause the system to work poorly if at all (may be why some of your radiators aren't heating).

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

Thanks for the information

I ordered two Gorton air vents. The pressure gauge on top of the boiler has no markings for what scale it measures. The pressutrol on the side is dialed down as low as it can go for cut in and cutout pressure. The boiler seems to get the pressure up in about twenty minutes from a cold start then cycles on and off in two minute intervals to maintain pressure.

0 -

I replaced the dry return air vents with the Gordon #2. No more gurgling and spitting.

I replaced the Pressurtrol with the Vaporstat. I am now running between 4oz and 8oz of pressure.

I also removed the air vent on top of the steam trap by the boiler. My understanding is that was to take care of any vacuum in the system from the coal days.

All of the radiators are now getting hot. The boiler is now short cycling, on for 30 seconds off for 30 seconds. I guess that is due to the pressure being so low on the Vaporstat. The water level is also all over the sight glass. In the previous picture it is down to the cutoff level but will shortly rise again. Not sure why is happening with the low system pressure. Also I am not sure if I should replace the air vent on top of steam trap with a Gordon #2, a Hoffman main air vent or a plug with a a couple of holes in it?

The vent in the middle of the lower picture is what I took off the steam trap by the boiler.0 -

are you sure the boiler is going off on the vaporstat and not the lwco?

might need to be skimmed if the water level is all over the place. does the water level bounce around and change quickly or does it just slowly fall over a cycle?

0 -

Sounds like a steam trap has blown or it is the LWCO shutting down bc the wet return is jammed up.

0 -

The water level is all over the place. Starts off about 2/3 from the top of the sight glass. Once the steam is produced, the water level starts to drop as if it is being pushed out of the boiler. The boiler pressure is between 4.0oz and 8.0oz of pressure. The vaporstat appears to be maintaining the correct pressure. Turning on and turning off the gas valve appropriately. About half time the water level will reach the low level cutoff and shutoff the gas valve. Other times the vaporstat will shutoff the gas and the water level will be about an inch above the low level cutoff. The short cycling of the gas valve is about 20 seconds on 20 seconds off. Not sure why the water level is dropping. Comes back to normal level when the boiler is not producing steam. I removed the main air vent on the steam trap and now all the radiators through the house are working nicely. The air is definitely getting out of the system. Now I am trying to figure out my water level issue.

Thanks for your help.0 -

Im sorry, I should have been more specific, I meant a blown steam trap on a rad. If steam blows past a rad steam trap and back to the return main, it closes the Gordon #2's and the system. Stops breathing, immediately increasing system pressure.

0 -

More pics are always helpful, of the boiler, near boiler pipework, end of mains farther back, etc.

0 -

The wet return pipes downstream of the Gorton air vents going back to the boiler are hot as s%#t. I have replaced the steam traps in most of the radiators with the Tunstall capsules. What is the check to see if the steam traps are working properly? How long should it take for a radiator to warm up fully. Seems like the tops get hot then eventually the heat transfers to the bottom of the radiator. I am also wondering about the integrity of the four check valves on the wet return.

0 -

Check your Hartford Loop and make sure the top of the close nipple is not installed too high. Most boiler ma nufacturers say 2 in. below normal water line. Peerless says 2 to 4 in. If it is too high it might be inhibiting return of condensate to the boiler and the whole thing just escalates from there.

0 -

it is a vapor system

0 -

it will just raise the water line in the returns which is beneficial in a vapor system

0 -

it could be the amount of condensate that has to stack up behind the check valves to open them and return the condensate to the boiler. if the valves are right the steam should never get to the outlet of the radiator. in the original configuration the devices at the boiler would equalize pressure so that the condensate could return to the boiler.

there shouldn't be steam in the returns, you need to figure out where that is happening, if there is a water seal that is above the water line of the new boiler like from a drip of a main that is likely where it is coming from.

also see if the return vent you removed the vent from now has steam coming out of it.

0 -

I don't know a lot about two pipe steam because I haven't had to study it but why is this happening?:

"The water level is also all over the sight glass. In the previous picture it is down to the cutoff level but will shortly rise again. Not sure why is happening with the low system pressure."

0 -

it will do it in a 2 pipe too, but the water has to get above the ell in the hartford loop to get ot of the retyurns so the returns will fill to that level. it will happen in a 1 pipe system too.

the water ling fluctuating might be the return trap doing what it is supposed to.

you might be able to remove the check valves but i will leave that to someone that understands webster systems better than i do.

0 -

Isn't the return main ending with that webster f&t trap? Is there a vent on it?

0 -

There is no steam coming out of the hole where the I removed the vent on top of the dry return steam trap, just air. I think I am going to adjust the Venturi on the burners underneath so the smaller will build heat a little more slowly. Like a simmer on a stove instead of a raging boil.

What is the best way to check to see if the steam traps on the radiators upstairs are doing their Job? I have replaced most of them.

The wet return getting super hot between the Gorton air vents and the boiler seems to be the boiler water in the return being hot. I really don’t want to open the check valves0 -

0

-

don't change the firing rate of the boiler, it is likely to cause problems like sooting of the heat exchanger and it will reduce the efficiency of the boiler. your problems are elsewhere. how much additive do you have in the water? too much can cause priming and the hot foamy water being pushed up in to the mains and returning through the returns will make the returns hot.

if the radiator valves are set up right the radiators should heat almost to but not all the way to the return on the radiator. the valves should meter the steam so it never reaches the trap.

if the valves are not right and the traps are bad, the return will be hot beyond the trap. the return will also be hot beyond the trap if steam is getting in to the radiator from the return because there is steam in the returns from some other source, probably a different radiator that steam is blowing through in to the return or a water seal that is too far above the water line or some piping that has been knuchleheaded or a bad crossover trap. a trap that is steam hot on both sides would be suspicious of being bad.

1 -

Thanks for all the great information. I have a lot to check. At least the house is warm.

What type of air vents should I replace on top of the steam trap by the boiler. The one I took off did something with negative pressure. Air is just blowing out of the hole now. Sounds like a quiet whistle. Is a Gorton #2 or a Hoffman air vent appropriate?

0 -

-

Hoffman 67 buts its over $300 last time I checked.

0 -

I dont think the webster needs a vacuum vent though. Gordon #2 should be fine.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 168 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements